Types Of Engine Block Casting . Common materials include cast iron, aluminum, and steel, each with distinct advantages. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Learn about composite materials aluminum alloy for casting engine parts. Engine block casting process explained: Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. This involves making the mould for the cast iron block with. What is engine block casting for automative? Sand casting has advantages over. Sand casting is the method widely used in the production of cast iron blocks. Is renowned for its exceptional strength. Impro uses sand casting to produce engine blocks for high horsepower and other applications.

from dsportmag.com

Sand casting has advantages over. Is renowned for its exceptional strength. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Sand casting is the method widely used in the production of cast iron blocks. Learn about composite materials aluminum alloy for casting engine parts. This involves making the mould for the cast iron block with. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Engine block casting process explained: The classification of cast engine blocks primarily revolves around the type of material used in their construction and the.

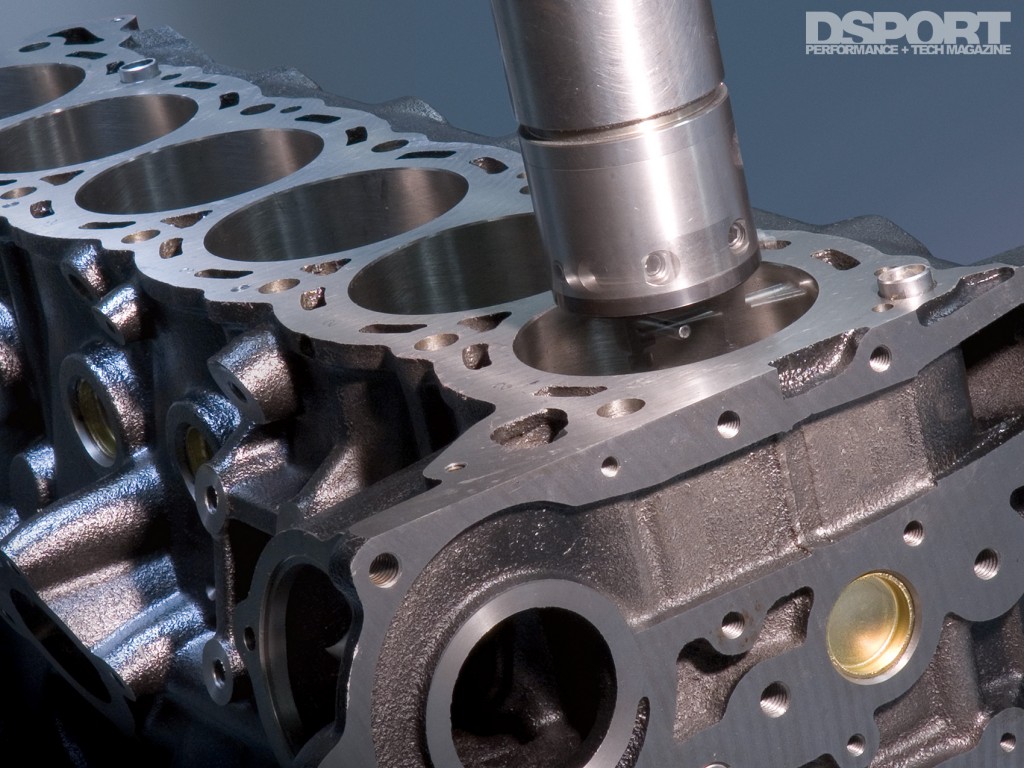

Engine Block Tech 101 Go Bigger or Go Stronger the Right Way

Types Of Engine Block Casting Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Engine block casting process explained: Sand casting is the method widely used in the production of cast iron blocks. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. What is engine block casting for automative? Impro uses sand casting to produce engine blocks for high horsepower and other applications. This involves making the mould for the cast iron block with. Learn about composite materials aluminum alloy for casting engine parts. Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Sand casting has advantages over. Is renowned for its exceptional strength.

From www.howacarworks.com

Engine blocks Everything you need to know How a Car Works Types Of Engine Block Casting Impro uses sand casting to produce engine blocks for high horsepower and other applications. Sand casting has advantages over. Learn about composite materials aluminum alloy for casting engine parts. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Common materials include cast iron, aluminum, and steel, each with distinct advantages.. Types Of Engine Block Casting.

From childhealthpolicy.vumc.org

💣 Engine block material. How Engine Block Is Made (All You Need To Know Types Of Engine Block Casting Sand casting is the method widely used in the production of cast iron blocks. What is engine block casting for automative? Sand casting has advantages over. This involves making the mould for the cast iron block with. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Engine block casting process. Types Of Engine Block Casting.

From www.investmentcastchina.com

Aluminum Die Casting for Engine Blocks CFS Foundry Types Of Engine Block Casting What is engine block casting for automative? Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Engine block casting process explained: Sand casting has advantages over. Learn about composite materials aluminum alloy for casting engine parts. The classification of cast engine blocks primarily revolves around the type of material used. Types Of Engine Block Casting.

From www.slideserve.com

PPT CHAPTER 30 ENGINE BLOCKS PowerPoint Presentation, free download Types Of Engine Block Casting Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. What is engine block casting for automative? Engine block casting process explained: Impro uses sand casting to produce engine blocks for high horsepower and other applications. The classification of cast engine blocks primarily revolves around the type of material used in. Types Of Engine Block Casting.

From themechanicalengineering.com

Cylinder Block Definition, Function, Construction, Types, Material Types Of Engine Block Casting Common materials include cast iron, aluminum, and steel, each with distinct advantages. Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Learn about composite materials aluminum alloy for casting engine parts. Is renowned for its exceptional strength. Sand casting has advantages over. This involves making the mould for the cast iron block with. What is engine. Types Of Engine Block Casting.

From www.zhycasting.com

3D printing process for Vtype gas engine cylinder block casting ZHY Types Of Engine Block Casting Common materials include cast iron, aluminum, and steel, each with distinct advantages. This involves making the mould for the cast iron block with. Sand casting has advantages over. Engine block casting process explained: Is renowned for its exceptional strength. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Learn about composite materials aluminum alloy for. Types Of Engine Block Casting.

From www.howacarworks.com

Engine blocks Everything you need to know How a Car Works Types Of Engine Block Casting What is engine block casting for automative? Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Sand casting is the method widely used in the production of cast iron blocks. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Involves. Types Of Engine Block Casting.

From engineeringlearn.com

Cylinder Block Types and Functions Details] Engineering Learn Types Of Engine Block Casting Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Common materials include cast iron, aluminum, and steel, each with distinct advantages. What is engine block casting for automative? Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Sand casting is the method widely used in the. Types Of Engine Block Casting.

From www.youtube.com

BMW Engine Block Casting HOW IT'S MADE YouTube Types Of Engine Block Casting Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Impro uses sand casting to produce engine blocks for high horsepower and other applications. This involves making the mould for the cast iron block with. Sand casting is the method widely used in the production of cast iron blocks. Engine block casting process explained: Learn about composite. Types Of Engine Block Casting.

From www.zhycasting.com

Casting technology of grey cast iron engine cylinder block ZHY Casting Types Of Engine Block Casting What is engine block casting for automative? Sand casting has advantages over. Engine block casting process explained: Learn about composite materials aluminum alloy for casting engine parts. This involves making the mould for the cast iron block with. Sand casting is the method widely used in the production of cast iron blocks. Common materials include cast iron, aluminum, and steel,. Types Of Engine Block Casting.

From www.enginelabs.com

Reference Chevy Engine Block Casting Numbers Types Of Engine Block Casting Is renowned for its exceptional strength. Learn about composite materials aluminum alloy for casting engine parts. This involves making the mould for the cast iron block with. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Engine block. Types Of Engine Block Casting.

From www.zhycasting.com

Casting technology of engine block ZHY Casting Types Of Engine Block Casting Engine block casting process explained: Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Sand casting is the method widely used in the production of cast iron blocks. This involves making the mould for the cast iron block with. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of. Types Of Engine Block Casting.

From www.zhycasting.com

Experimental process of sand sticking on the surface of engine cylinder Types Of Engine Block Casting What is engine block casting for automative? Is renowned for its exceptional strength. Learn about composite materials aluminum alloy for casting engine parts. Sand casting has advantages over. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and.. Types Of Engine Block Casting.

From www.researchgate.net

V8 engine block cast from an aluminium alloy Download Scientific Diagram Types Of Engine Block Casting Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Engine block casting process explained: Common materials include cast iron, aluminum, and steel, each with distinct advantages. Sand casting is the method widely used in the production of cast iron blocks. Involves steps like pattern creation, mold preparation, core installation, melting. Types Of Engine Block Casting.

From www.zhycasting.com

Present situation of casting technology and equipment for engine block Types Of Engine Block Casting The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Casting methods,. Types Of Engine Block Casting.

From www.romefamily2022.com

5 Types of Engine Blocks All You Need to Know Rome Family 2022 Types Of Engine Block Casting Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Sand casting is the method widely used in the production of cast iron blocks. Is renowned for its exceptional strength. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Sand casting. Types Of Engine Block Casting.

From www.enginebuildermag.com

Machining Aluminum Engine Blocks Engine Builder Magazine Types Of Engine Block Casting Common materials include cast iron, aluminum, and steel, each with distinct advantages. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. This involves. Types Of Engine Block Casting.

From www.performanceracing.com

Make The Case Iron vs. Aluminum Engine BlocksPerformance Racing Industry Types Of Engine Block Casting Learn about composite materials aluminum alloy for casting engine parts. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Impro uses sand casting to produce engine blocks for high horsepower and other applications. This involves making the mould for the cast iron block with. The classification of cast engine blocks primarily revolves around the type of material. Types Of Engine Block Casting.

From garagefixcarbonadph.z4.web.core.windows.net

Types Of Engine Blocks Types Of Engine Block Casting Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Common materials include cast iron, aluminum, and steel, each with distinct advantages. What is engine block casting for automative? Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. This involves making the mould for the cast iron. Types Of Engine Block Casting.

From www.slideserve.com

PPT CHAPTER 30 ENGINE BLOCKS PowerPoint Presentation, free download Types Of Engine Block Casting Sand casting has advantages over. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Sand casting is the method widely used in the production of cast iron blocks. Is renowned for its exceptional strength. Learn about composite materials aluminum alloy for casting engine parts. This involves making the mould for the cast iron block with.. Types Of Engine Block Casting.

From castmakers.com

cast iron engine block Cast Makers Types Of Engine Block Casting Sand casting has advantages over. Is renowned for its exceptional strength. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Engine block casting process explained: What is engine block casting for automative? The classification of cast. Types Of Engine Block Casting.

From www.chevyhardcore.com

Reference Chevy Engine Block Casting Numbers Types Of Engine Block Casting Is renowned for its exceptional strength. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Sand casting has advantages over. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Engine block casting process explained: This involves making the mould for the cast iron block with.. Types Of Engine Block Casting.

From www.motortrend.com

How It Works Edelbrock’s HIP Cylinder Head Casting Tech Types Of Engine Block Casting Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Common materials include cast iron, aluminum, and steel, each with distinct advantages. This involves making the mould for the cast iron block with. Sand casting has advantages over.. Types Of Engine Block Casting.

From www.howacarworks.com

Engine blocks Everything you need to know How a Car Works Types Of Engine Block Casting Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Is renowned for its exceptional strength. Sand casting has advantages over. What is engine block casting for automative? Impro uses sand casting to produce engine blocks for high. Types Of Engine Block Casting.

From www.zhycasting.com

Sand casting engine block ZHY Casting Types Of Engine Block Casting The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. What is engine block casting for automative? This involves making the mould for the cast iron block with. Engine block casting process explained: Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine. Types Of Engine Block Casting.

From www.my-cardictionary.com

Engine block Engine My car dictionary Types Of Engine Block Casting This involves making the mould for the cast iron block with. Sand casting is the method widely used in the production of cast iron blocks. Is renowned for its exceptional strength. What is engine block casting for automative? Impro uses sand casting to produce engine blocks for high horsepower and other applications. Engine block casting process explained: Common materials include. Types Of Engine Block Casting.

From www.zhycasting.com

Sand casting process design of engine cylinder block ZHY Casting Types Of Engine Block Casting Engine block casting process explained: Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Learn about composite materials aluminum alloy for casting engine parts. Sand casting has advantages over. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Involves steps. Types Of Engine Block Casting.

From kt-foundry.com

Premium Aluminium Engine Blocks Expert Casting Solutions Compare Types Of Engine Block Casting The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Is renowned for its exceptional strength. This involves making the mould for the cast iron block with. Sand casting has advantages over.. Types Of Engine Block Casting.

From www.youtube.com

Incredible Engine Block Casting Production Process in the factory Part Types Of Engine Block Casting Learn about composite materials aluminum alloy for casting engine parts. Sand casting has advantages over. Engine block casting process explained: Impro uses sand casting to produce engine blocks for high horsepower and other applications. This involves making the mould for the cast iron block with. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Is renowned for. Types Of Engine Block Casting.

From dsportmag.com

Engine Block Tech 101 Go Bigger or Go Stronger the Right Way Types Of Engine Block Casting Sand casting has advantages over. Is renowned for its exceptional strength. Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Sand casting is the method widely used in the production of cast iron blocks. This involves making the mould for the cast iron block with. What is engine block casting for automative? Common materials include cast. Types Of Engine Block Casting.

From www.youtube.com

ENGINE BLOCKS Aluminum vs. Iron YouTube Types Of Engine Block Casting Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Is renowned for its exceptional strength. This involves making the mould for the cast iron block. Types Of Engine Block Casting.

From www.youtube.com

Everything about Engine Blocks YouTube Types Of Engine Block Casting What is engine block casting for automative? Engine block casting process explained: Impro uses sand casting to produce engine blocks for high horsepower and other applications. Common materials include cast iron, aluminum, and steel, each with distinct advantages. Learn about composite materials aluminum alloy for casting engine parts. Sand casting has advantages over. Is renowned for its exceptional strength. Sand. Types Of Engine Block Casting.

From www.indiamart.com

Hot Rolled Cast Iron Engine Block casting, Capacity High Pressure at Types Of Engine Block Casting Sand casting has advantages over. Is renowned for its exceptional strength. The classification of cast engine blocks primarily revolves around the type of material used in their construction and the. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. Involves steps like pattern creation, mold preparation, core installation, melting and. Types Of Engine Block Casting.

From www.improprecision.com

Cylinder Block Impro Types Of Engine Block Casting Learn about composite materials aluminum alloy for casting engine parts. Casting methods, such as sand casting and die casting, are vital for shaping the initial form of engine blocks. What is engine block casting for automative? Sand casting is the method widely used in the production of cast iron blocks. Is renowned for its exceptional strength. This involves making the. Types Of Engine Block Casting.

From www.enginelabs.com

A Guide To Ford V8 Engine Block Casting Numbers, 19521996 Types Of Engine Block Casting Is renowned for its exceptional strength. Involves steps like pattern creation, mold preparation, core installation, melting and pouring, and. Sand casting has advantages over. Impro uses sand casting to produce engine blocks for high horsepower and other applications. Sand casting is the method widely used in the production of cast iron blocks. The classification of cast engine blocks primarily revolves. Types Of Engine Block Casting.