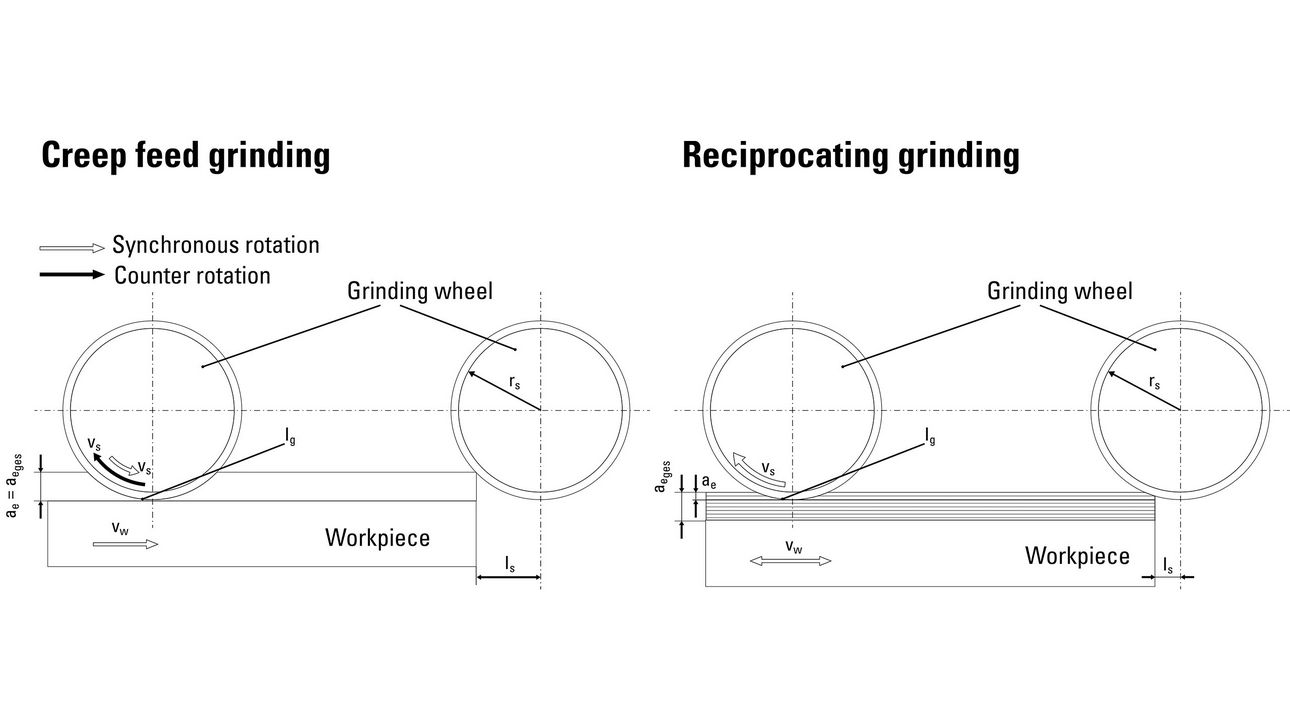

Creep Feed Grinding Vs Conventional Grinding . creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. True, the feed rate is low, but the increased depth of cut more than compensates for this. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. In contrast, conventional traverse grinding usually produces short, thick chips. The process involves grinding at. with creep feed grinding, the chips are relatively thin and long.

from www.grinding.ch

The process involves grinding at. creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. with creep feed grinding, the chips are relatively thin and long. In contrast, conventional traverse grinding usually produces short, thick chips. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. True, the feed rate is low, but the increased depth of cut more than compensates for this. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding.

Differences Between Creep Feed Grinding and Conventional Traverse

Creep Feed Grinding Vs Conventional Grinding The process involves grinding at. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. with creep feed grinding, the chips are relatively thin and long. True, the feed rate is low, but the increased depth of cut more than compensates for this. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. In contrast, conventional traverse grinding usually produces short, thick chips. creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. The process involves grinding at. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference.

From www.mmsonline.com

10 Things to Know About CreepFeed Grinding Modern Machine Shop Creep Feed Grinding Vs Conventional Grinding creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. The combination of abrasive grain/bond must be selected in such a way that the chips can be. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Schematic diagram of creepfeed grinding Download Scientific Diagram Creep Feed Grinding Vs Conventional Grinding with creep feed grinding, the chips are relatively thin and long. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single. Creep Feed Grinding Vs Conventional Grinding.

From www.grinding.ch

Differences Between Creep Feed Grinding and Conventional Traverse Creep Feed Grinding Vs Conventional Grinding creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. True, the feed rate is low, but the increased depth of cut more than compensates for this. with creep feed grinding, the chips are relatively thin and long. In contrast, conventional traverse grinding usually produces short, thick chips. if creep feed and conventional. Creep Feed Grinding Vs Conventional Grinding.

From www.machinery.co.uk

Creepfeed grinding wheels deliver productivity advantage Creep Feed Grinding Vs Conventional Grinding with creep feed grinding, the chips are relatively thin and long. True, the feed rate is low, but the increased depth of cut more than compensates for this. The process involves grinding at. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. commonly, surface grinding is. Creep Feed Grinding Vs Conventional Grinding.

From www.whitedoveabrasive.com

Creepfeed grinding wheelWhite Dove Abrasives Co., Ltd. Creep Feed Grinding Vs Conventional Grinding In contrast, conventional traverse grinding usually produces short, thick chips. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. with creep feed grinding, the chips are relatively thin and long. The. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Specific grinding force versus the cutting regime for creepfeed Creep Feed Grinding Vs Conventional Grinding with creep feed grinding, the chips are relatively thin and long. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed. Creep Feed Grinding Vs Conventional Grinding.

From eleat.co.uk

Creep Feed Grinding ELE Advanced Technologies Creep Feed Grinding Vs Conventional Grinding with creep feed grinding, the chips are relatively thin and long. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. if creep feed and conventional grinding. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Creepfeed grinding setup, a) Grinding wheel, b) Specimen, c) Coolant Creep Feed Grinding Vs Conventional Grinding creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during. Creep Feed Grinding Vs Conventional Grinding.

From lygoomai.en.made-in-china.com

Creep Feed Grinding Wheel China Grinding Wheel and Grinding Disc Wheel Creep Feed Grinding Vs Conventional Grinding True, the feed rate is low, but the increased depth of cut more than compensates for this. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. The process. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Thermal model of creepfeed grinding Download Scientific Diagram Creep Feed Grinding Vs Conventional Grinding creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. In contrast, conventional traverse grinding usually produces short, thick chips. True, the feed rate is low, but the increased depth of cut more than compensates for this. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Creepfeed grinding setup, a) Grinding wheel, b) Specimen, c) Coolant Creep Feed Grinding Vs Conventional Grinding creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. True, the feed rate is low, but the increased depth of cut more than compensates for this. The combination of abrasive grain/bond must. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

The parameters used in the creep feed grinding of the turbine blade Creep Feed Grinding Vs Conventional Grinding In contrast, conventional traverse grinding usually produces short, thick chips. The process involves grinding at. with creep feed grinding, the chips are relatively thin and long. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. creep feed grinding achieves significantly higher productivity in mass production. Creep Feed Grinding Vs Conventional Grinding.

From slideplayer.com

Chapter 26 Abrasive Machining Processes ppt video online download Creep Feed Grinding Vs Conventional Grinding if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. The process involves grinding at. creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. True, the feed rate is low, but the increased depth of cut more than compensates for this. creep. Creep Feed Grinding Vs Conventional Grinding.

From www.ctemag.com

Testing The ups and downs of wheel performance when creepfeed Creep Feed Grinding Vs Conventional Grinding commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. The combination of abrasive grain/bond must be selected in such a way that. Creep Feed Grinding Vs Conventional Grinding.

From slideplayer.com

Lesson 6 GRINDING AND OTHER ABRASIVE PROCESSES ppt download Creep Feed Grinding Vs Conventional Grinding In contrast, conventional traverse grinding usually produces short, thick chips. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. commonly, surface grinding is referred to. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

The creepfeed grinding process (a) The air barrier around the wheel Creep Feed Grinding Vs Conventional Grinding creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. with creep feed grinding, the chips are relatively thin and long. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. creep feed grinding is a specialized. Creep Feed Grinding Vs Conventional Grinding.

From wendtindia.com

Precision Creep Feed Grinding Machine WHS Series Creep Feed Grinding Vs Conventional Grinding The process involves grinding at. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. with creep feed grinding, the chips are relatively thin and long. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of. Creep Feed Grinding Vs Conventional Grinding.

From slideplayer.com

GRINDING AND OTHER ABRASIVE PROCESSES ppt download Creep Feed Grinding Vs Conventional Grinding creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. In contrast, conventional traverse grinding usually produces short, thick chips. with creep feed grinding, the chips. Creep Feed Grinding Vs Conventional Grinding.

From www.amazon.com

Creep Feed Grinding 9780831111670 Colin Andrew Books Creep Feed Grinding Vs Conventional Grinding True, the feed rate is low, but the increased depth of cut more than compensates for this. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of. Creep Feed Grinding Vs Conventional Grinding.

From www.grinding.ch

Differences Between Creep Feed Grinding and Conventional Traverse Creep Feed Grinding Vs Conventional Grinding with creep feed grinding, the chips are relatively thin and long. True, the feed rate is low, but the increased depth of cut more than compensates for this. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. The process involves grinding at. In contrast, conventional traverse grinding. Creep Feed Grinding Vs Conventional Grinding.

From www.linkedin.com

CREEPFEED GRINDING (PART 2 OF 3) Creep Feed Grinding Vs Conventional Grinding if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. In contrast, conventional traverse grinding usually produces short, thick chips. creep feed grinding achieves significantly higher. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Parameters of CreepFeed Grinding process Download Scientific Diagram Creep Feed Grinding Vs Conventional Grinding creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. if creep feed and conventional grinding are compared on the. Creep Feed Grinding Vs Conventional Grinding.

From www.canadianmetalworking.com

Tough materials continue to drive creepfeed grinding Creep Feed Grinding Vs Conventional Grinding commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. True, the feed rate is low, but. Creep Feed Grinding Vs Conventional Grinding.

From slideplayer.com

Lesson 6 GRINDING AND OTHER ABRASIVE PROCESSES ppt download Creep Feed Grinding Vs Conventional Grinding commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. The process involves grinding at. if. Creep Feed Grinding Vs Conventional Grinding.

From www.canadianmetalworking.com

Tough materials continue to drive creepfeed grinding Creep Feed Grinding Vs Conventional Grinding True, the feed rate is low, but the increased depth of cut more than compensates for this. The process involves grinding at. In contrast, conventional traverse grinding usually produces short, thick chips. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. . Creep Feed Grinding Vs Conventional Grinding.

From wendtindia.com

Precision Creep Feed Grinding Machine WHS Series Creep Feed Grinding Vs Conventional Grinding True, the feed rate is low, but the increased depth of cut more than compensates for this. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. with creep feed grinding, the chips are relatively thin and long. The process involves grinding at. commonly, surface grinding. Creep Feed Grinding Vs Conventional Grinding.

From www.slideserve.com

PPT Abrasive Machining and Finishing PowerPoint Presentation, free Creep Feed Grinding Vs Conventional Grinding creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. if creep feed and conventional grinding are compared on the basis. Creep Feed Grinding Vs Conventional Grinding.

From engineeringtechnology.org

Creep Feed Grinding Creep Feed Grinding Vs Conventional Grinding The process involves grinding at. with creep feed grinding, the chips are relatively thin and long. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. if creep feed and conventional grinding are compared on the basis of equal nominal removal. Creep Feed Grinding Vs Conventional Grinding.

From www.grinding.com

Creep Feed Grinding White Paper UNITED GRINDING North America Creep Feed Grinding Vs Conventional Grinding True, the feed rate is low, but the increased depth of cut more than compensates for this. with creep feed grinding, the chips are relatively thin and long. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. The process involves grinding at. The combination of abrasive grain/bond. Creep Feed Grinding Vs Conventional Grinding.

From www.hitekmfg.com

Creep Feed Grinding Creep Feed Grinding Vs Conventional Grinding In contrast, conventional traverse grinding usually produces short, thick chips. creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. The combination of abrasive grain/bond must be selected in such a way that. Creep Feed Grinding Vs Conventional Grinding.

From www.moresuperhard.com

How to creep feed grinding? Information More SuperHard Products Co Creep Feed Grinding Vs Conventional Grinding creep feed grinding achieves significantly higher productivity in mass production compared to reciprocating grinding. In contrast, conventional traverse grinding usually produces short, thick chips. if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. with creep feed grinding, the chips are relatively thin and long. creep. Creep Feed Grinding Vs Conventional Grinding.

From www.grinding.com

Creep Feed Grinding Might Be the Solution to Your Production Challenge Creep Feed Grinding Vs Conventional Grinding The process involves grinding at. The combination of abrasive grain/bond must be selected in such a way that the chips can be easily removed from the work zone during creep feed grinding. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. creep. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Creep feed grinding measurement system Download Scientific Diagram Creep Feed Grinding Vs Conventional Grinding if creep feed and conventional grinding are compared on the basis of equal nominal removal rate, then the main difference. creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. The process involves grinding at. True, the feed rate is low, but the increased depth of cut. Creep Feed Grinding Vs Conventional Grinding.

From www.researchgate.net

Performance and surface integrity of creepfeed grinding process Creep Feed Grinding Vs Conventional Grinding creep feed grinding is a specialized grinding technique used in manufacturing to remove large amounts of material in a single pass. The process involves grinding at. commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. In contrast, conventional traverse grinding usually produces. Creep Feed Grinding Vs Conventional Grinding.

From eleat.co.uk

Creep Feed Grinding ELE Advanced Technologies Creep Feed Grinding Vs Conventional Grinding commonly, surface grinding is referred to as creep feed grinding when depth of cut ae 0.1 mm and a feed rate vf 3,000 mm/min are. True, the feed rate is low, but the increased depth of cut more than compensates for this. The combination of abrasive grain/bond must be selected in such a way that the chips can be. Creep Feed Grinding Vs Conventional Grinding.