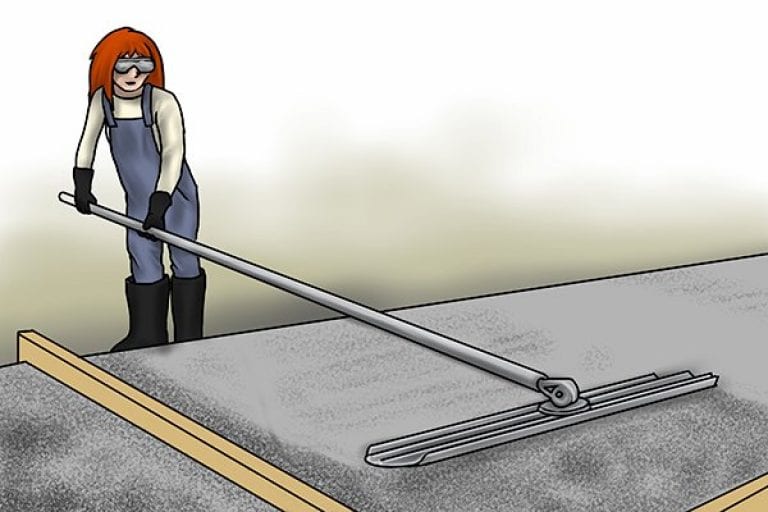

Concrete Float Process . Screeding helps compact and consolidate the concrete, and. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Hold the hand float at a. This section outlines the steps. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. For small projects, you can use a magnesium float instead. We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Use a large metal or wood board to screed the top of the concrete. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes.

from www.wonkeedonkeetools.co.uk

Use a large metal or wood board to screed the top of the concrete. For small projects, you can use a magnesium float instead. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Hold the hand float at a. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. Screeding helps compact and consolidate the concrete, and. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation.

How to float concrete? Wonkee Donkee Tools

Concrete Float Process The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Use a large metal or wood board to screed the top of the concrete. For small projects, you can use a magnesium float instead. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Hold the hand float at a. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Screeding helps compact and consolidate the concrete, and. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. This section outlines the steps. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes.

From www.concretenetwork.com

Over pouring Old Concrete The Concrete Network Concrete Float Process This section outlines the steps. For small projects, you can use a magnesium float instead. Use a large metal or wood board to screed the top of the concrete. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. Screeding helps compact and consolidate. Concrete Float Process.

From www.youtube.com

HOW TO FINISH CONCRETE BULL FLOAT DIY YouTube Concrete Float Process Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. Screeding helps compact and consolidate the concrete, and. The purpose of darbying or bull floating. Concrete Float Process.

From www.bigeasyconcrete.com

Types of Concrete Pouring Equipment Big Easy Concrete Concrete Float Process For small projects, you can use a magnesium float instead. Use a large metal or wood board to screed the top of the concrete. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. Screeding helps compact and consolidate the concrete, and. If you've already poured and leveled your concrete, begin. Concrete Float Process.

From www.concreteconstruction.net

Vibrating Concrete Float Concrete Construction Magazine Concrete Concrete Float Process The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. For small projects, you can use a magnesium float instead. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Hold the hand float at a. Only start hand floating concrete. Concrete Float Process.

From www.wonkeedonkeetools.co.uk

How to float concrete? Wonkee Donkee Tools Concrete Float Process If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. Floating concrete slabs distinguish themselves through a construction process that minimizes the. Concrete Float Process.

From www.youtube.com

Fiber Reinforced Concrete Finishing with a Power Float YouTube Concrete Float Process For small projects, you can use a magnesium float instead. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. The purpose of darbying or bull floating concrete is. Concrete Float Process.

From www.wonkeedonkeetools.co.uk

How to float concrete? Wonkee Donkee Tools Concrete Float Process Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. Use a large metal or wood board to screed the top of the concrete. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. The. Concrete Float Process.

From www.dreamstime.com

Polishing concrete stock photo. Image of float, process 50645630 Concrete Float Process Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. Hold the hand float at a. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. The purpose of darbying or bull floating concrete is to level ridges and. Concrete Float Process.

From www.wonkeedonkeetools.co.uk

How to float concrete? Wonkee Donkee Tools Concrete Float Process The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete.. Concrete Float Process.

From www.youtube.com

How to bull float and edge concrete YouTube Concrete Float Process For small projects, you can use a magnesium float instead. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Failure to bull float can lead to. Concrete Float Process.

From www.nationwideconcreting.co.uk

Power Floated Concrete Flooring Nationwide Concreting Ltd Concrete Float Process Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Screeding helps compact and consolidate the concrete, and. For small projects, you can use a magnesium float instead.. Concrete Float Process.

From www.coppardconcrete.co.uk

Power Floating Coppard Concrete and Screed Concrete Float Process Screeding helps compact and consolidate the concrete, and. We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Hold the hand float at a. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. Use a large metal or wood. Concrete Float Process.

From www.hirehere.ie

Bullfloat Concrete Float Process This section outlines the steps. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Use a large metal or wood board to screed the top of the concrete. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to. Concrete Float Process.

From pavdrive.com

Concrete finishes Pavdrive Concrete Float Process Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. We’ll show you the tools and techniques you need to get a smooth concrete finishing. Concrete Float Process.

From www.biordiconcretes.com

Float Finish Concrete Pathway12 (1) Biordi Concrete Concrete Float Process For small projects, you can use a magnesium float instead. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. Hold the hand float at a. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex. Concrete Float Process.

From www.amazon.ca

48" x 8" Bull Float Magnesium Concrete Float, Concrete Float Tool Concrete Float Process Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Screeding helps compact and consolidate the concrete, and. This section outlines the steps. Failure to bull float can lead to an. Concrete Float Process.

From www.vevor.com

VEVOR Bull Float Magnesium Concrete Float 48 x 8" Round End Concrete Concrete Float Process We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Use a large metal or wood board to screed the top of the concrete. Hold the hand float at a. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes.. Concrete Float Process.

From www.handyman.net.au

How to build and pour your own modern concrete patio Australian Concrete Float Process Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Use a large metal or wood board to screed the top of the concrete. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. The purpose of darbying or bull floating concrete. Concrete Float Process.

From www.finehomebuilding.com

Placing and Finishing a Heated Concrete Floor Fine Homebuilding Concrete Float Process Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. Use a large metal or wood board to screed the top of the concrete. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Hold the hand float at. Concrete Float Process.

From greenbuildingelements.com

Bull Floating Concrete (Everything You Need To Know) Concrete Float Process We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Use a large metal or wood board to screed the top of the concrete. This section outlines the steps. For small projects, you can use a magnesium float instead. Only start hand floating concrete when pressing the palm of. Concrete Float Process.

From www.drillingmanual.com

CASING CEMENTING OVERVIEW Drilling Operation Concrete Float Process Hold the hand float at a. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Use a large metal or wood board to screed the top of the concrete. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. This. Concrete Float Process.

From www.wonkeedonkeetools.co.uk

How to float concrete? Wonkee Donkee Tools Concrete Float Process The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. This section outlines the steps. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. Use a large metal or wood board to screed the top of the concrete. If you've. Concrete Float Process.

From www.familyhandyman.com

How to Finish Concrete Family Handyman Concrete Float Process Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. Screeding helps compact and consolidate the concrete, and. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. We’ll show you the tools and techniques you need to get a smooth. Concrete Float Process.

From www.vevor.com

VEVOR Bull Float Magnesium Concrete Float 48 x 8" Round End Concrete Concrete Float Process For small projects, you can use a magnesium float instead. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float over the concrete to smooth out the surface. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. This section outlines the steps.. Concrete Float Process.

From www.slideserve.com

PPT Tool Identification PowerPoint Presentation, free download ID Concrete Float Process Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. This section outlines the steps. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by. Concrete Float Process.

From www.dreamstime.com

Float Being Used To Smooth Wet Concrete Stock Photo Image of Concrete Float Process This section outlines the steps. Use a large metal or wood board to screed the top of the concrete. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. For small projects, you can use a magnesium float instead. Floating concrete slabs distinguish themselves through a construction process that minimizes. Concrete Float Process.

From www.familyhandyman.com

How to Pour a Concrete Slab Successfully — The Family Handyman Concrete Float Process For small projects, you can use a magnesium float instead. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Only start hand floating concrete when pressing the palm of your. Concrete Float Process.

From www.wonkeedonkeetools.co.uk

How to float concrete? Wonkee Donkee Tools Concrete Float Process Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. This section outlines the steps. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. We’ll show you the tools and techniques you need to get a smooth. Concrete Float Process.

From pavdrive.com

Concrete finishes Pavdrive Concrete Float Process Screeding helps compact and consolidate the concrete, and. Hold the hand float at a. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. This section outlines the steps. For small projects, you can use a magnesium float instead. Use a large metal or wood board to screed the top of. Concrete Float Process.

From www.bison-machinery.com

Concrete floatPower floating concreteFloating and finishing BISON Concrete Float Process For small projects, you can use a magnesium float instead. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. We’ll show you the tools and techniques you need to get a. Concrete Float Process.

From www.familyhandyman.com

How to Pour a Concrete Slab Successfully — The Family Handyman Concrete Float Process We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Use a large metal or wood board to screed the top of the concrete. This section outlines the steps.. Concrete Float Process.

From paragontools.com.au

Smooth It Out Your Essential Guide to Power Float Concrete Concrete Float Process We’ll show you the tools and techniques you need to get a smooth concrete finishing using a concrete float and concrete. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. Use a large metal or wood board to screed the top of the concrete. Screeding helps compact. Concrete Float Process.

From cinvex.us

How To Float A Concrete Floor Flooring Guide by Cinvex Concrete Float Process The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Only start hand floating concrete when pressing the palm of your hand into the surface leaves an indentation between ¼” to ⅜”. If you've already poured and leveled your concrete, begin the finishing process by moving a rounded bull float. Concrete Float Process.

From www.wonkeedonkeetools.co.uk

How to float concrete? Wonkee Donkee Tools Concrete Float Process The purpose of darbying or bull floating concrete is to level ridges and fill voids left by the screeding operation. Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Screeding helps compact and consolidate the concrete, and. Hold the hand float at a. We’ll show you the tools and techniques. Concrete Float Process.

From victoriaconcretesurfaces.ca

Power Trowel Concrete Floors • Victoria Concrete Surfaces Concrete Float Process Floating concrete slabs distinguish themselves through a construction process that minimizes the need for deep excavation and complex footings. Screeding helps compact and consolidate the concrete, and. Failure to bull float can lead to an uneven surface, a compromised curing process, and difficulties with later finishes. Hold the hand float at a. The purpose of darbying or bull floating concrete. Concrete Float Process.