Grain Elevator Inside . Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting. It’s big, modern, full service, and importantly — perfectly upright. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. Grain elevators are a crucial part of.

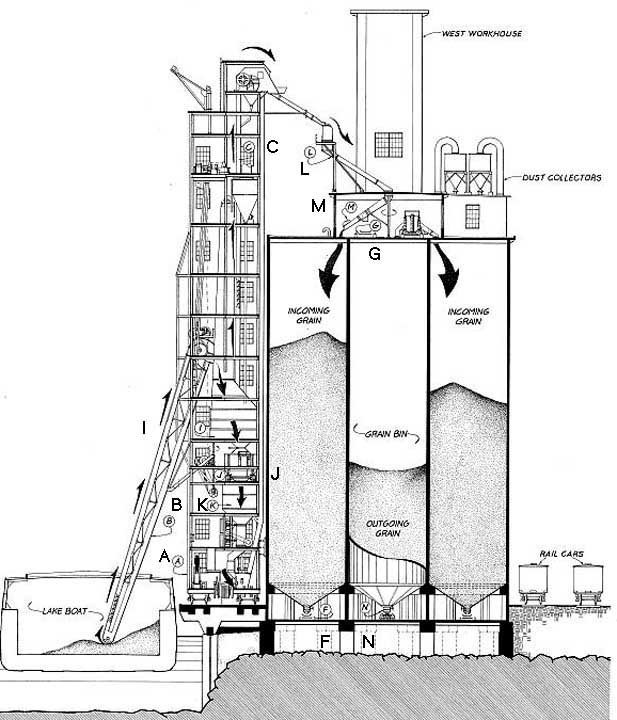

from buffaloah.com

It’s big, modern, full service, and importantly — perfectly upright. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. Grain elevators are a crucial part of. Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting.

Standard Grain Elevator

Grain Elevator Inside To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. Grain elevators are a crucial part of. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. It’s big, modern, full service, and importantly — perfectly upright. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting.

From mavink.com

Parts Of A Grain Elevator Grain Elevator Inside It’s big, modern, full service, and importantly — perfectly upright. Grain elevators are a crucial part of. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. The buckets travel up, depositing grain, and come back down to collect more, beginning their. Grain Elevator Inside.

From vanishingsentinels.blogspot.com

Vanishing Sentinels Grain Elevators to Vanishing Sentinels Grain Elevator Inside Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting. It’s big, modern, full service, and importantly — perfectly upright. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred. Grain Elevator Inside.

From montrealinpictures.com

Project 365 Day 147 Inside Montreal’s Silo 5 grain elevator Grain Elevator Inside The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. Grain elevators are a crucial part of. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. It’s big, modern, full service, and importantly — perfectly upright. Some of the responsibilities. Grain Elevator Inside.

From www.alamy.com

Grain elevator operator Bill Cummins inside a silo full of corn ready Grain Elevator Inside A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. It’s big, modern, full service, and importantly —. Grain Elevator Inside.

From www.destinationsdetoursdreams.com

Historic Grain Elevators In Manitoba Destinations Detours and Dreams Grain Elevator Inside Grain elevators are a crucial part of. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. A mechanism known as a grain leg transports the grain from the ground to. Grain Elevator Inside.

From www.alamy.com

Grain elevator operator Bill Cummins inside a silo full of corn ready Grain Elevator Inside The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. Grain elevators are a crucial part of. To dry grain, air and. Grain Elevator Inside.

From altoonamodelworks.net

O scale Grain Elevator KitPurina Nanton Elevator Grain Elevator Inside The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. A mechanism known as a grain leg transports the grain from the ground to the. Grain Elevator Inside.

From sah-archipedia.org

J.H. Hawes Grain Elevator SAH ARCHIPEDIA Grain Elevator Inside It’s big, modern, full service, and importantly — perfectly upright. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. Some of the responsibilities of a grain. Grain Elevator Inside.

From totalgrainsystems.org

Grain Elevators Total Grain Systems Grain Elevator Inside It’s big, modern, full service, and importantly — perfectly upright. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin.. Grain Elevator Inside.

From www.grainelevators.ca

Magrath Grain Elevators of Canada Grain Elevator Inside It’s big, modern, full service, and importantly — perfectly upright. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a. Grain Elevator Inside.

From albertashistoricplaces.wordpress.com

Ever Wonder How a Grain Elevator Worked? RETROactive Grain Elevator Inside The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. Grain elevators are a crucial part of. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. A mechanism known as a grain leg transports the grain. Grain Elevator Inside.

From shaunmerriganphoto.net

Wooden Grain Elevators on CN Drumheller Grain Elevator Inside A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. The buckets travel up, depositing grain, and come back down to collect. Grain Elevator Inside.

From www.youtube.com

Inside the Coop Inside a Grain Elevator YouTube Grain Elevator Inside The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. The buckets travel up, depositing grain, and come back down. Grain Elevator Inside.

From www.sasktoday.ca

History Corner Diagram of the major working components of a grain Grain Elevator Inside A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. Grain elevators are a crucial part. Grain Elevator Inside.

From www.alamy.com

Grain elevator operator Bill Cummins inside a silo full of corn ready Grain Elevator Inside The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. The components of a grain elevator may be a mystery,. Grain Elevator Inside.

From ourgrandfathersgrainelevators.com

September « 2012 « Our Grandfathers' Grain Elevators Grain Elevator Inside A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. Grain elevators are a crucial part of. It’s big, modern, full service, and importantly — perfectly upright. The components of a grain elevator may be a mystery, but this excerpt from the american grain. Grain Elevator Inside.

From apm.activecommunities.com

Grain Elevator Grain Elevator Inside The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. To dry grain, air and heat are pushed into the grain inside. Grain Elevator Inside.

From mavink.com

Parts Of A Grain Elevator Grain Elevator Inside Grain elevators are a crucial part of. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. The components of a grain elevator may be a mystery, but this excerpt from. Grain Elevator Inside.

From www.realagriculture.com

How an Elevator’s Made An UpClose Look at the Construction of a Grain Elevator Inside The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. To dry grain, air and heat are pushed into the grain inside the bin and the grain. Grain Elevator Inside.

From medium.com

How Grain Elevators Work. Grain elevators are a staple of the… by Grain Elevator Inside A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. Grain elevators are a crucial part of. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. To. Grain Elevator Inside.

From thisiscourtney.com

Inside the Bunge Grain Elevator, Part 2 Courtney Celley Grain Elevator Inside Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. Grain elevators are a crucial part of. To. Grain Elevator Inside.

From www.pinterest.com

How Grain Elevators Work Property GRIT Magazine Grains, Grain Grain Elevator Inside Grain elevators are a crucial part of. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. The components of a grain elevator may be a mystery,. Grain Elevator Inside.

From montrealinpictures.com

Montreal In Pictures Grain elevator Grain Elevator Inside The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. To dry grain, air and heat are pushed. Grain Elevator Inside.

From www.electrical-knowhow.com

Elevators Types and Classification Part Two Electrical Knowhow Grain Elevator Inside The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting. Grain elevators are a crucial part of. The. Grain Elevator Inside.

From www.youtube.com

Inside the Coop Grain Elevators YouTube Grain Elevator Inside Grain elevators are a crucial part of. It’s big, modern, full service, and importantly — perfectly upright. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. To dry grain, air and heat are pushed into the grain inside the bin and the grain. Grain Elevator Inside.

From sah-archipedia.org

J.H. Hawes Grain Elevator SAH ARCHIPEDIA Grain Elevator Inside The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. Grain elevators are a crucial part of. Some of the responsibilities of. Grain Elevator Inside.

From www.wecal.com

Grain Elevator Nampa, AB Woods Edward Engineering Ltd Grain Elevator Inside The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting. It’s big, modern, full service, and importantly — perfectly upright. A mechanism known. Grain Elevator Inside.

From www.flickr.com

Peeking into the Grain Elevator Grain elevator interior in… Flickr Grain Elevator Inside It’s big, modern, full service, and importantly — perfectly upright. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. Grain elevators are a crucial part of. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. Some of the responsibilities. Grain Elevator Inside.

From www.alamy.com

Grain elevator. Granary. Large metal structure grain elevator. Storage Grain Elevator Inside The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. To dry grain, air and heat are pushed into the grain inside the bin and the grain is constantly stirred or mixed to evenly dry out the bin. The video and photos below offer a closer look at how a concrete grain elevator. Grain Elevator Inside.

From www.britannica.com

Grain elevator Grain Storage, Harvesting & Processing Britannica Grain Elevator Inside A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. Grain elevators are a crucial part of. It’s big, modern, full service, and importantly — perfectly upright. The video and photos below offer a closer look at how a concrete grain elevator is built,. Grain Elevator Inside.

From buffaloah.com

Standard Grain Elevator Grain Elevator Inside Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is there, promoting. Grain elevators are a crucial part of. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides. Grain Elevator Inside.

From www.pinterest.com

Inside of an old grain elevator Model railroad, Elevation, Grains Grain Elevator Inside The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. It’s big, modern, full service, and importantly — perfectly upright. Some of the responsibilities of a grain elevator include checking the quality of the products, maintaining that quality throughout the entirety of the time that the grain is. Grain Elevator Inside.

From esask.uregina.ca

The Encyclopedia of Saskatchewan Details Grain Elevator Inside A mechanism known as a grain leg transports the grain from the ground to the top of the grain elevator through a series of rectangular buckets. Grain elevators are a crucial part of. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. The video and photos below offer a closer look at. Grain Elevator Inside.

From grainhandlingdirect.com

How Exactly Does a Feed Grain Elevator Work? Grain Handling Direct Grain Elevator Inside Grain elevators are a crucial part of. The video and photos below offer a closer look at how a concrete grain elevator is built, specifically cwb’s 34 thousand tonne. The buckets travel up, depositing grain, and come back down to collect more, beginning their journey again. To dry grain, air and heat are pushed into the grain inside the bin. Grain Elevator Inside.

From www.walthers.com

Walthers ADM(R) Concrete Grain Elevator Kit 131/2 x 9 x 131/2 Grain Elevator Inside It’s big, modern, full service, and importantly — perfectly upright. The components of a grain elevator may be a mystery, but this excerpt from the american grain elevator (grain elevator press, 2012) provides a simple explanation. Grain elevators are a crucial part of. To dry grain, air and heat are pushed into the grain inside the bin and the grain. Grain Elevator Inside.