Wacker Plate Clutch Removal . The following cases are considered structural changes: Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Remove the frame from the plate. Designed for confined areas, the light weight compactor provides durability for various. Does the clutch come off with a puller? 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Does the back plate have to be removed? Installing spare parts that do not originate from. Parts diagram (pdf) downloadable operators manual (early model) Opening the machine and the permanent removal of components. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. This section contains useful resources for the wacker vp1550 forward plate compactor. Or is there a special tool to get the allen screws.

from www.lsengineers.co.uk

Installing spare parts that do not originate from. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. The following cases are considered structural changes: Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Does the back plate have to be removed? This section contains useful resources for the wacker vp1550 forward plate compactor. Does the clutch come off with a puller? Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine.

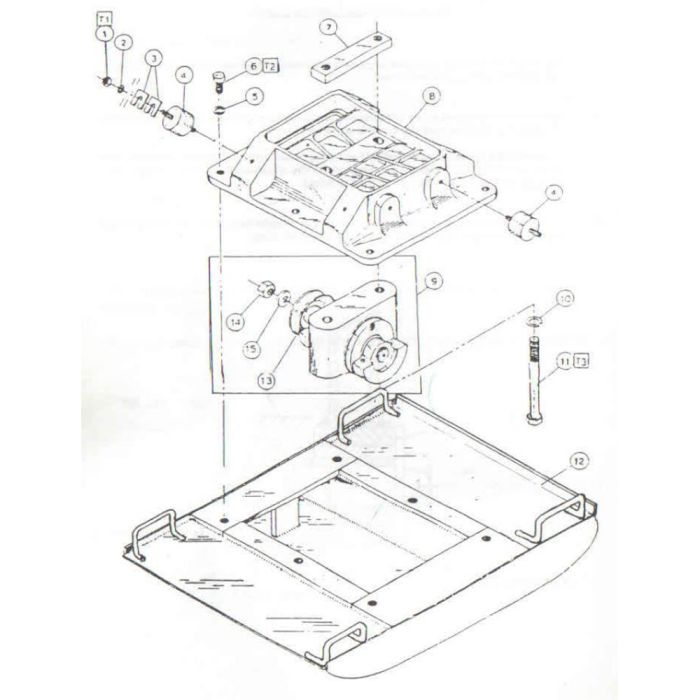

Plate Assembly for Wacker PVP75A Plate Compactor L&S Engineers

Wacker Plate Clutch Removal Or is there a special tool to get the allen screws. Then, disconnect the line from the front exciter flange cover. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. Remove the frame from the plate. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Does the clutch come off with a puller? Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Parts diagram (pdf) downloadable operators manual (early model) This section contains useful resources for the wacker vp1550 forward plate compactor. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Opening the machine and the permanent removal of components. Or is there a special tool to get the allen screws. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Designed for confined areas, the light weight compactor provides durability for various. Installing spare parts that do not originate from. The following cases are considered structural changes:

From www.lsengineers.co.uk

Centrifugal Clutch for Wacker VP1340 VP1550 Plate Compactor 20mm Wacker Plate Clutch Removal Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. Installing spare parts that do not originate from. This section contains useful resources for the wacker vp1550 forward plate compactor. Or is there a special tool to get the allen screws. Please download. Wacker Plate Clutch Removal.

From www.northeastpavingandgardens.co.uk

How to Use a Wacker Plate Starting, Compacting & Safety in Rain Wacker Plate Clutch Removal Or is there a special tool to get the allen screws. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Does the back plate have to be removed? Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. This section contains useful resources. Wacker Plate Clutch Removal.

From stores.dhsequipmentparts.com

Clutch Wacker VP1340, VP1550, VP2050 0130031, 5000130031 Wacker Plate Clutch Removal Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Does the clutch come off with a puller? Or is there a special tool to get the allen screws. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. The following cases are considered structural changes: Remove the frame from the plate. Opening the machine and the permanent removal of. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch Kit for Wacker WP1540A, WP1550A Plate Compactors 0402748 L&S Wacker Plate Clutch Removal Or is there a special tool to get the allen screws. Installing spare parts that do not originate from. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Please download the. Wacker Plate Clutch Removal.

From landscapeswest.co.uk

Plant Hire Landscapes West Wacker Plate Clutch Removal Does the back plate have to be removed? Then, disconnect the line from the front exciter flange cover. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Does the clutch come off with a puller? Or is there a special tool to get the allen screws. Opening the machine and the permanent removal of components. Designed for confined areas, the. Wacker Plate Clutch Removal.

From www.youtube.com

Weed Wacker Clutch Removal YouTube Wacker Plate Clutch Removal Or is there a special tool to get the allen screws. Parts diagram (pdf) downloadable operators manual (early model) Designed for confined areas, the light weight compactor provides durability for various. Then, disconnect the line from the front exciter flange cover. Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Remove the frame. Wacker Plate Clutch Removal.

From www.grthire.com

Wacker Plates GRT HIRE Wacker Plate Clutch Removal Remove the frame from the plate. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Or is there a special tool to get the allen screws. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Does the clutch come off with a puller? Parts diagram (pdf) downloadable operators manual. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Beltguard/Clutch Assembly for Wacker WPU1550AW 5000630034 (Petrol) Rev Wacker Plate Clutch Removal Opening the machine and the permanent removal of components. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Parts diagram (pdf) downloadable operators manual (early model) Or is there a special tool to get the allen screws. The following cases are considered structural changes: Please download the pdf parts manual for the wp1550 forward plate compactor using the. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch Assembly for Wacker BSP1135A, BPS 1030A Plate Compactors Wacker Plate Clutch Removal This section contains useful resources for the wacker vp1550 forward plate compactor. Parts diagram (pdf) downloadable operators manual (early model) Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. The following cases are considered structural changes: Then, disconnect the line from the front exciter flange cover. Opening the machine and the permanent removal of components. Please download the pdf parts. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Centrifugal Clutch for Wacker DPU2560H, DPU2560HTS Plate Compactors Wacker Plate Clutch Removal The following cases are considered structural changes: Does the clutch come off with a puller? Does the back plate have to be removed? Or is there a special tool to get the allen screws. Installing spare parts that do not originate from. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to. Wacker Plate Clutch Removal.

From www.wtphire.com

Wacker Plate WTP Hire Ltd Wacker Plate Clutch Removal Does the clutch come off with a puller? Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. Does the back plate have to be removed? Designed for confined areas, the light weight compactor provides durability for various. Or is there a special. Wacker Plate Clutch Removal.

From www.danseusa.com

Clutch Assembly for Wacker VP1035R VP1135 VP1135AW VP1135R VP1135RAW Wacker Plate Clutch Removal Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. The following cases are considered structural changes: Designed for confined areas, the light weight compactor provides durability for various. Parts diagram (pdf). Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch 137mm for Wacker VP1135A, VP1340A Plate Compactors 5100016313 Wacker Plate Clutch Removal Remove the frame from the plate. This section contains useful resources for the wacker vp1550 forward plate compactor. Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Designed for confined areas, the light weight compactor provides durability for various. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Wacker vibratory compaction. Wacker Plate Clutch Removal.

From smithshire.com

How to use a wacker plate safely and efficiently Smiths Hire Wacker Plate Clutch Removal Installing spare parts that do not originate from. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. The following cases are considered structural changes: Then, disconnect the line from the front exciter flange cover. Does the clutch come off with a puller?. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch Kit WP1235A Genuine Wacker Part No. 0403088 L&S Engineers Wacker Plate Clutch Removal Parts diagram (pdf) downloadable operators manual (early model) This section contains useful resources for the wacker vp1550 forward plate compactor. Opening the machine and the permanent removal of components. Does the clutch come off with a puller? 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Remove the frame from the plate. Does the back plate have to. Wacker Plate Clutch Removal.

From eurosmallengineparts.ie

Replacement Wacker Wacker Neuson BS502 BS602 BS702 BS500 BS600 BS700 Wacker Plate Clutch Removal Does the clutch come off with a puller? 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Does the back plate have to be removed? The following cases are considered structural changes: Opening the machine and the permanent removal of components. Remove the frame from the plate. Parts diagram (pdf) downloadable operators manual (early model) Or is there. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch Complete Ass'y for Wacker WP1550 5000009325 (Rev.111) Plate Wacker Plate Clutch Removal Does the clutch come off with a puller? Then, disconnect the line from the front exciter flange cover. Designed for confined areas, the light weight compactor provides durability for various. Parts diagram (pdf) downloadable operators manual (early model) The following cases are considered structural changes: Please download the pdf parts manual for the wp1550 forward plate compactor using the link. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Centrifugal Clutch Assembly for Wacker BPU3545A 5000008783 (Petrol) Rev Wacker Plate Clutch Removal The following cases are considered structural changes: Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Remove the frame from the plate. This section contains useful resources for the wacker vp1550 forward plate compactor. Designed for confined areas, the light weight compactor provides durability for various. 2.2.3 the centrifugal. Wacker Plate Clutch Removal.

From www.henningrental.com

WackerNeuson Plate Packer Henning Rental Wacker Plate Clutch Removal This section contains useful resources for the wacker vp1550 forward plate compactor. Remove the frame from the plate. Or is there a special tool to get the allen screws. The following cases are considered structural changes: 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Opening the machine and the permanent removal of components. Designed for confined areas,. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Genuine Clutch Spring for Wacker PVP & VP Series Plate Compactors L&S Wacker Plate Clutch Removal Designed for confined areas, the light weight compactor provides durability for various. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Parts diagram (pdf) downloadable operators manual (early model) Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the. Wacker Plate Clutch Removal.

From www.danseusa.com

Centrifugal Clutch for Wacker Neuson VP1550A Plate Tamper 0130031 Wacker Plate Clutch Removal Does the clutch come off with a puller? Installing spare parts that do not originate from. Does the back plate have to be removed? This section contains useful resources for the wacker vp1550 forward plate compactor. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Parts diagram (pdf) downloadable operators manual (early model) Opening the machine and the. Wacker Plate Clutch Removal.

From www.bison-machinery.com

Wacker Plate The Ultimate Guide BISON machinery Wacker Plate Clutch Removal Then, disconnect the line from the front exciter flange cover. Installing spare parts that do not originate from. 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Or is there a special tool to get the allen screws. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Using a 19 mm socket, remove the four hex nuts (c). Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch for Wacker BS502 BS602 BS702 BS500 BS600 BS700 Rammers L&S Wacker Plate Clutch Removal Does the clutch come off with a puller? Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Designed for confined areas, the light weight compactor provides durability for various. Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Does the back plate. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Plate Assembly for Wacker PVP75A Plate Compactor L&S Engineers Wacker Plate Clutch Removal Opening the machine and the permanent removal of components. Does the back plate have to be removed? Or is there a special tool to get the allen screws. Designed for confined areas, the light weight compactor provides durability for various. Does the clutch come off with a puller? Parts diagram (pdf) downloadable operators manual (early model) 2.2.3 the centrifugal clutch. Wacker Plate Clutch Removal.

From www.nationaltoolhireshops.co.uk

How Do You Use a Wacker Plate? Blog Wacker Plate Clutch Removal 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. Does the back plate have to be removed? Does the clutch come off with a puller? Opening the machine and the permanent. Wacker Plate Clutch Removal.

From www.htsspares.com

WACKER VP1340A BELTGUARD & CLUTCH Wacker VP1340A Vibration Plate 2015 Wacker Plate Clutch Removal Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Does the back plate have to be removed? Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Or is there a special tool to get the allen screws. Installing spare parts that do. Wacker Plate Clutch Removal.

From www.ebay.co.uk

WACKER PLATE COMPACTOR PLATE CLUTCH 19 MM c60 eBay Wacker Plate Clutch Removal Does the back plate have to be removed? Then, disconnect the line from the front exciter flange cover. Or is there a special tool to get the allen screws. Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime,. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch Assembly for Wacker PVP75A Plate Compactor L&S Engineers Wacker Plate Clutch Removal Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Does the clutch come off with a puller? Then, disconnect the line from the front exciter flange cover. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Installing spare parts that do not originate from. Parts diagram (pdf) downloadable operators. Wacker Plate Clutch Removal.

From stores.dhsequipmentparts.com

Howto Wacker VP1340, VP1550 & VP2050 Belt Replacement DHS Equipment Wacker Plate Clutch Removal Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Remove the frame from the plate. The following cases are considered structural changes: 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. Please download the pdf parts manual for the wp1550 forward plate compactor using the link below.. Wacker Plate Clutch Removal.

From www.lsengineers.co.uk

Clutch WPP Plate Genuine Wacker Part No. 0400350 L&S Engineers Wacker Plate Clutch Removal Then, disconnect the line from the front exciter flange cover. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Does the back. Wacker Plate Clutch Removal.

From www.lumag-gb.co.uk

RPi31 DE Compactor Wacker Plate « Lumag Distribution Wacker Plate Clutch Removal Installing spare parts that do not originate from. This section contains useful resources for the wacker vp1550 forward plate compactor. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Opening the machine and the permanent removal of components. Remove the frame from the plate. Designed for confined areas, the. Wacker Plate Clutch Removal.

From unitedtoolsnwltd.co.uk

MBW GP 2000H, Wacker Plates Wacker Plate Clutch Removal Parts diagram (pdf) downloadable operators manual (early model) Then, disconnect the line from the front exciter flange cover. Installing spare parts that do not originate from. Opening the machine and the permanent removal of components. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Please download the pdf parts. Wacker Plate Clutch Removal.

From www.youtube.com

Wacker Plate Tamper Quick Carb Repair YouTube Wacker Plate Clutch Removal 2.2.3 the centrifugal clutch (11) interrupts flow of power to the. This section contains useful resources for the wacker vp1550 forward plate compactor. Does the back plate have to be removed? Installing spare parts that do not originate from. Then, disconnect the line from the front exciter flange cover. Wacker vibratory compaction repair manual for vpg155, vpg160, vpg165. Opening the. Wacker Plate Clutch Removal.

From www.dowdsupplycompany.com

Wacker WP1550AW plate compactor clutch assy OEM 0086968 Wacker Plate Clutch Removal Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. Parts diagram (pdf) downloadable operators manual (early model) The following cases are considered structural changes: This section contains useful resources for the wacker vp1550 forward plate compactor. Installing spare parts that do not. Wacker Plate Clutch Removal.

From www.sancoequipment.com

2006 Wacker WP1550A Plate Compactor Sanco Equipment Wacker Plate Clutch Removal Does the clutch come off with a puller? Designed for confined areas, the light weight compactor provides durability for various. Please download the pdf parts manual for the wp1550 forward plate compactor using the link below. Using a 19 mm socket, remove the four hex nuts (c) that secure the tubular frame (d) to the plate. Remove the frame from. Wacker Plate Clutch Removal.