Of What Use Is The Flux In Arc Welding Electrodes . Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Why do you need to use this chemical agent? The wire is fed from a coil through the. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrodes are suitable for both wet and. The flux in the electrode protects the weld area from atmospheric gases. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things.

from pt.slideshare.net

The flux in the electrode protects the weld area from atmospheric gases. The wire is fed from a coil through the. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Why do you need to use this chemical agent? The electrodes are suitable for both wet and.

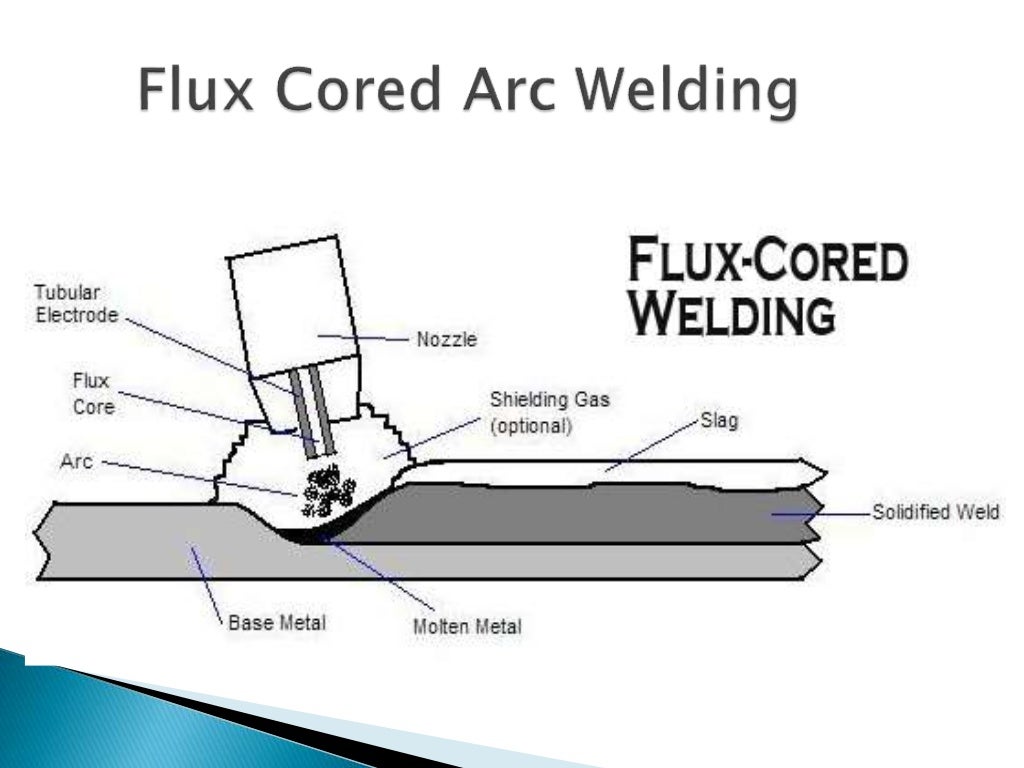

Flux cored arc welding ppt

Of What Use Is The Flux In Arc Welding Electrodes Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The flux in the electrode protects the weld area from atmospheric gases. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical agent? The electrodes are suitable for both wet and. The wire is fed from a coil through the.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Of What Use Is The Flux In Arc Welding Electrodes Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The wire is fed from a coil through the. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical agent? The flux in the electrode protects the. Of What Use Is The Flux In Arc Welding Electrodes.

From blog.thepipingmart.com

What is Flux Cored Arc Welding? Uses and Working Of What Use Is The Flux In Arc Welding Electrodes The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The electrodes are suitable for both wet and. Simply put, welding flux is a chemical agent that you use in the welding process to get. Of What Use Is The Flux In Arc Welding Electrodes.

From mewelding.com

Fluxcored Arc Welding Electrodes Of What Use Is The Flux In Arc Welding Electrodes Why do you need to use this chemical agent? The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Submerged arc welding (saw) uses two separate consumables, the solid wire. Of What Use Is The Flux In Arc Welding Electrodes.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Of What Use Is The Flux In Arc Welding Electrodes Why do you need to use this chemical agent? Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The wire is fed from a coil through the. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrodes. Of What Use Is The Flux In Arc Welding Electrodes.

From pt.slideshare.net

Flux cored arc welding ppt Of What Use Is The Flux In Arc Welding Electrodes Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The wire is fed from a coil through the. Why do you need to use this chemical agent? The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Simply put,. Of What Use Is The Flux In Arc Welding Electrodes.

From www.cruxweld.com

Welding Electrodes Learn About Its Types and Uses cruxweld Of What Use Is The Flux In Arc Welding Electrodes Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The flux in the electrode protects the weld area from atmospheric gases. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The wire is fed from a coil through the. The electrode coating can. Of What Use Is The Flux In Arc Welding Electrodes.

From fabrication-welding.blogspot.com

Fabricationwelding SMAW & FCAW Of What Use Is The Flux In Arc Welding Electrodes Why do you need to use this chemical agent? Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The flux in the electrode protects the weld area from atmospheric gases. The wire is fed. Of What Use Is The Flux In Arc Welding Electrodes.

From www.slideserve.com

PPT Flux Cored Arc Welding (FCAW) PowerPoint Presentation ID518171 Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Why do you need to use this chemical agent? The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The electrodes are suitable for both wet and. The flux in. Of What Use Is The Flux In Arc Welding Electrodes.

From www.youtube.com

How to Weld Flux Cored Arc Welding Basics YouTube Of What Use Is The Flux In Arc Welding Electrodes The wire is fed from a coil through the. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Submerged arc welding (saw) uses two separate consumables, the solid wire. Of What Use Is The Flux In Arc Welding Electrodes.

From weldnotes.com

What is Flux Cored Arc Welding (FCAW)? Of What Use Is The Flux In Arc Welding Electrodes The wire is fed from a coil through the. The flux in the electrode protects the weld area from atmospheric gases. The electrodes are suitable for both wet and. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Simply put, welding flux is a chemical agent that you use. Of What Use Is The Flux In Arc Welding Electrodes.

From weldingpros.net

Flux Core Welding (FCAW) Welding Process Explained in Detail Of What Use Is The Flux In Arc Welding Electrodes The electrodes are suitable for both wet and. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The electrode coating can help stabilize the arc, create smooth weld appearance,. Of What Use Is The Flux In Arc Welding Electrodes.

From www.weldinghandbook.com

Welding Electrodes Coatings and Classifications The Welding Handbook Of What Use Is The Flux In Arc Welding Electrodes The electrodes are suitable for both wet and. The wire is fed from a coil through the. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you. Of What Use Is The Flux In Arc Welding Electrodes.

From mewelding.com

FluxCored Arc Welding Equipment Of What Use Is The Flux In Arc Welding Electrodes The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The flux in the electrode. Of What Use Is The Flux In Arc Welding Electrodes.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Of What Use Is The Flux In Arc Welding Electrodes The electrodes are suitable for both wet and. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Why do you need to use this chemical agent? The flux in the electrode protects the weld area from atmospheric gases. The wire is fed from a coil through the. Submerged arc. Of What Use Is The Flux In Arc Welding Electrodes.

From mechanicaljungle.com

How to weld with flux core? What Is Shielding Gas Used for Fluxes Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Why do you need to use this chemical agent? The wire is fed from a coil through the. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrode. Of What Use Is The Flux In Arc Welding Electrodes.

From www.researchgate.net

The electric arc causes melting of both electrode and the parent plate Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The flux in the electrode. Of What Use Is The Flux In Arc Welding Electrodes.

From weldingzilla.com

Why Welding Electrodes Are Coated With Flux? Of What Use Is The Flux In Arc Welding Electrodes The electrodes are suitable for both wet and. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical agent? Submerged arc welding. Of What Use Is The Flux In Arc Welding Electrodes.

From www.youtube.com

Carbon Electrode Arc Welding Process with Non Consumable Carbon Of What Use Is The Flux In Arc Welding Electrodes The flux in the electrode protects the weld area from atmospheric gases. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Electrode welding, or stick welding, uses electrode rods covered in a flux, each. Of What Use Is The Flux In Arc Welding Electrodes.

From www.cwbgroup.org

How It Works What is a flux in welding and what are the ingredients of Of What Use Is The Flux In Arc Welding Electrodes Why do you need to use this chemical agent? The electrodes are suitable for both wet and. The wire is fed from a coil through the. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The flux in the electrode protects the weld area from atmospheric gases. Simply put, welding flux is a chemical. Of What Use Is The Flux In Arc Welding Electrodes.

From weldingheadquarters.com

The Complete Guide to FluxCored Arc Welding Welding Headquarters Of What Use Is The Flux In Arc Welding Electrodes Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The electrodes are suitable for both wet and. The flux in the electrode protects the weld area from atmospheric gases. The wire is fed from. Of What Use Is The Flux In Arc Welding Electrodes.

From materialwelding.com

Flux Cored Arc Welding (FCAW) Of What Use Is The Flux In Arc Welding Electrodes Why do you need to use this chemical agent? The flux in the electrode protects the weld area from atmospheric gases. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The wire is fed from a coil through the. Submerged arc welding (saw) uses two separate consumables, the solid. Of What Use Is The Flux In Arc Welding Electrodes.

From sw.edu

FCAW Flux Cored Arc Welding Test SWCCSouthwest Virginia Community Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The flux in the electrode protects the weld area from atmospheric gases. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical. Of What Use Is The Flux In Arc Welding Electrodes.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Of What Use Is The Flux In Arc Welding Electrodes Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical agent? Simply put, welding flux is a chemical agent that you use. Of What Use Is The Flux In Arc Welding Electrodes.

From mewelding.com

Fluxcored Arc Welding Electrodes Of What Use Is The Flux In Arc Welding Electrodes Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The wire is fed from. Of What Use Is The Flux In Arc Welding Electrodes.

From workshopinsider.com

Insider's Guide to FluxCored Arc Welding (FCAW) Insider Of What Use Is The Flux In Arc Welding Electrodes Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. Why do you need to use this chemical agent? The flux in the electrode protects the weld area from atmospheric gases. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other. Of What Use Is The Flux In Arc Welding Electrodes.

From www.nsrp.org

Flux Cored Electrode for Welding HY100 and HSLA100 NSRP Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The wire is fed from a coil through the. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has. Of What Use Is The Flux In Arc Welding Electrodes.

From www.youtube.com

Differences between Gas Metal Arc Welding (GMAW) and FluxCored Arc Of What Use Is The Flux In Arc Welding Electrodes Why do you need to use this chemical agent? Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The electrodes are suitable for both wet and. The flux in the electrode protects the weld area from atmospheric gases. The electrode coating can help stabilize the arc, create smooth weld. Of What Use Is The Flux In Arc Welding Electrodes.

From www.steelsupplylp.com

Welding Processes Steel Supply LP Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The wire is fed from. Of What Use Is The Flux In Arc Welding Electrodes.

From www.midalloy.com

Welding Flux Sub Arc Fluxes Of What Use Is The Flux In Arc Welding Electrodes The electrodes are suitable for both wet and. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. The wire is fed from a coil through the. Why do you need to use this chemical agent? The flux in the electrode protects the weld area from atmospheric gases. Simply put,. Of What Use Is The Flux In Arc Welding Electrodes.

From alchetron.com

Flux cored arc welding Alchetron, The Free Social Encyclopedia Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The electrodes are suitable for both wet and. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate. Of What Use Is The Flux In Arc Welding Electrodes.

From waterwelders.com

What Does Flux Do in Welding? Beginner's Guide 2024 WaterWelders Of What Use Is The Flux In Arc Welding Electrodes The electrodes are suitable for both wet and. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical agent? Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The wire is fed from a coil through. Of What Use Is The Flux In Arc Welding Electrodes.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Of What Use Is The Flux In Arc Welding Electrodes Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical agent? Simply put, welding flux is a chemical agent that you use in the welding process to. Of What Use Is The Flux In Arc Welding Electrodes.

From blog.thepipingmart.com

What is Flux Core Arc Welding Machine? Uses and Working Of What Use Is The Flux In Arc Welding Electrodes Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The flux in the electrode protects the weld area from atmospheric gases. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. The electrode coating can help stabilize the arc,. Of What Use Is The Flux In Arc Welding Electrodes.

From slidetodoc.com

CHAPTER 12 Flux Cored Arc Welding Equipment Setup Of What Use Is The Flux In Arc Welding Electrodes Submerged arc welding (saw) uses two separate consumables, the solid wire electrode, and the flux. The electrodes are suitable for both wet and. The wire is fed from a coil through the. The electrode coating can help stabilize the arc, create smooth weld appearance, and increase the deposition rate among other things. Why do you need to use this chemical. Of What Use Is The Flux In Arc Welding Electrodes.

From mechanicaljungle.com

How to weld with flux core? What Is Shielding Gas Used for Fluxes Of What Use Is The Flux In Arc Welding Electrodes The flux in the electrode protects the weld area from atmospheric gases. Simply put, welding flux is a chemical agent that you use in the welding process to get proper welding results. The wire is fed from a coil through the. The electrodes are suitable for both wet and. Submerged arc welding (saw) uses two separate consumables, the solid wire. Of What Use Is The Flux In Arc Welding Electrodes.