Zinc Flake Coating Corrosion Resistance . Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. This practical aid examines the following zinc coatings: These flakes work synergistically with the zinc, providing an extra. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film.

from www.atotech.com

Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. These flakes work synergistically with the zinc, providing an extra. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. This practical aid examines the following zinc coatings:

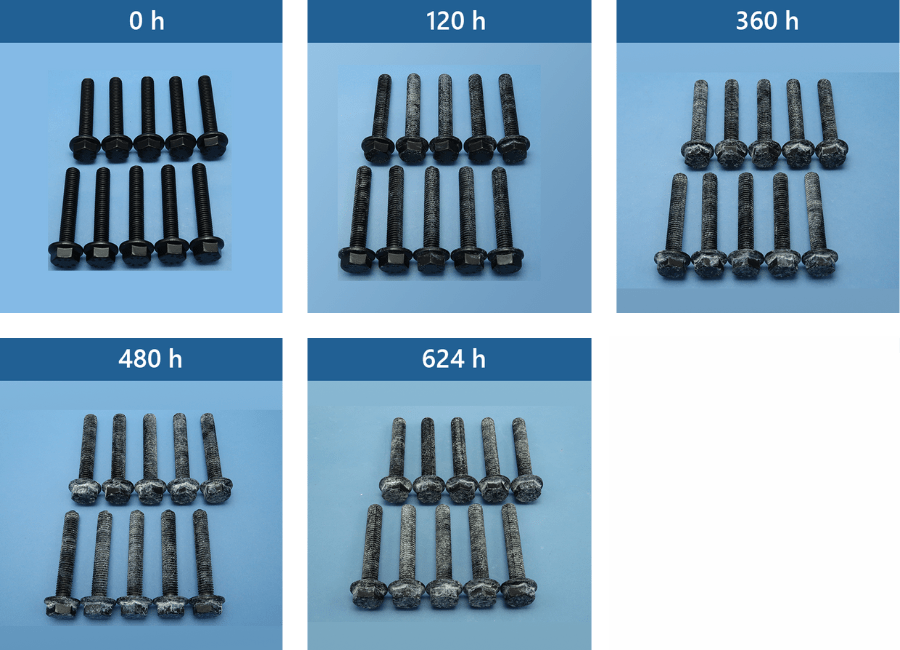

Standard black zinc flake coating Atotech

Zinc Flake Coating Corrosion Resistance Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. This practical aid examines the following zinc coatings: These flakes work synergistically with the zinc, providing an extra. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies.

From www.atotech.com

Standard black zinc flake coating Atotech Zinc Flake Coating Corrosion Resistance Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. This practical aid examines the following zinc coatings: These flakes work. Zinc Flake Coating Corrosion Resistance.

From www.prweb.com

NEI Introduces Selfhealing Anticorrosion Coating for ZincPlated and Zinc Flake Coating Corrosion Resistance Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. These flakes work synergistically with the zinc, providing an extra. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film.. Zinc Flake Coating Corrosion Resistance.

From anochrome.com

Zinc Flake Coatings Anochrome Group Zinc Flake Coating Corrosion Resistance Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. These flakes work synergistically with the zinc, providing an extra. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film.. Zinc Flake Coating Corrosion Resistance.

From www.linkedin.com

Why Choose Zinc Flake Coating Zinc Flake Coating Corrosion Resistance This practical aid examines the following zinc coatings: Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. These flakes work synergistically with the zinc, providing an extra. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Aluminum flakes are frequently incorporated into the. Zinc Flake Coating Corrosion Resistance.

From www.slideserve.com

PPT High Corrosion Resistance Zinc Rich Coating PowerPoint Zinc Flake Coating Corrosion Resistance Based on this approach, tailored coating solutions using zinc flake coatings can be developed. This practical aid examines the following zinc coatings: Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. These flakes work synergistically with the zinc, providing an extra. Aluminum flakes are frequently incorporated into the zinc flake coating. Zinc Flake Coating Corrosion Resistance.

From sendcutsend.com

Zinc Plating vs Powder Coating for Corrosion Resistance SendCutSend Zinc Flake Coating Corrosion Resistance Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. This practical aid examines the following zinc coatings: To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Base coats. Zinc Flake Coating Corrosion Resistance.

From www.zincflakecoatings.com

Corrosion Resistant Zinc Flake Coating Geomet Mechanical Zinc Plating Zinc Flake Coating Corrosion Resistance Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Aluminum flakes are frequently incorporated into the zinc flake. Zinc Flake Coating Corrosion Resistance.

From www.atotech.com

Standard black zinc flake coating Atotech Zinc Flake Coating Corrosion Resistance Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Based on this approach, tailored coating solutions using zinc. Zinc Flake Coating Corrosion Resistance.

From fastenerandfixing.com

Combining excellence in corrosion protection Fastener + Fixing Magazine Zinc Flake Coating Corrosion Resistance Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. This practical aid examines the following zinc coatings: These flakes work synergistically with the zinc, providing an extra. To the base metal, hardness, corrosion resistance, and thickness. Zinc Flake Coating Corrosion Resistance.

From www.indiamart.com

Corundum Solvent Base Zinc Flake Coating System in Pune, Effco Zinc Flake Coating Corrosion Resistance Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. Aluminum flakes are frequently incorporated into the zinc flake coating to. Zinc Flake Coating Corrosion Resistance.

From doogood.com.au

Zinc Flake Doogood Surface Coatings Pty Ltd Zinc Flake Coating Corrosion Resistance These flakes work synergistically with the zinc, providing an extra. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Aluminum flakes. Zinc Flake Coating Corrosion Resistance.

From nordicgalvanizers.com

Corrosion of zinc coatings Nordic Galvanizers Zinc Flake Coating Corrosion Resistance Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. This practical aid examines the following zinc coatings: Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies.. Zinc Flake Coating Corrosion Resistance.

From www.nofmetalcoatings.com

Zinc flake base coats NOF Metal Coatings South America Zinc Flake Coating Corrosion Resistance Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. These flakes work synergistically with the zinc, providing an extra. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. Various. Zinc Flake Coating Corrosion Resistance.

From www.aalberts-st.com

Zinc flake coating for many base materials Aalberts ST Zinc Flake Coating Corrosion Resistance Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. This practical aid examines the following zinc coatings: Various passivation chemistries may be added. Zinc Flake Coating Corrosion Resistance.

From uneedabolt.com

Uneeda Zinc Flake Coating Corrosion Resistance Based on this approach, tailored coating solutions using zinc flake coatings can be developed. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the. Zinc Flake Coating Corrosion Resistance.

From www.atotech.com

Standard silver zinc flake coating Atotech Zinc Flake Coating Corrosion Resistance Based on this approach, tailored coating solutions using zinc flake coatings can be developed. This practical aid examines the following zinc coatings: Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Base coats are the initial. Zinc Flake Coating Corrosion Resistance.

From pt.scribd.com

Zinc flake coating (Geomet Coatings Nof Metal Coatings Group) Rust Zinc Flake Coating Corrosion Resistance Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. These flakes work synergistically with the zinc, providing an extra. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. Zinc sacrificial corrosion. Zinc Flake Coating Corrosion Resistance.

From www.zincflakecoatings.com

Corrosion Resistant Zinc Flake Coating Geomet Mechanical Zinc Plating Zinc Flake Coating Corrosion Resistance Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. These flakes work synergistically with the zinc, providing. Zinc Flake Coating Corrosion Resistance.

From www.ddcoatings.co.uk

Exploring Laminar Flake Coatings Technology Zinc Flake Coating Corrosion Resistance To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. This practical aid examines the following zinc coatings: Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Base coats are. Zinc Flake Coating Corrosion Resistance.

From www.linkedin.com

Why choose zinc flake coating over powder coating? Zinc Flake Coating Corrosion Resistance Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. This practical aid examines the following zinc coatings: Based on this approach, tailored coating solutions using zinc flake coatings can be developed. These flakes work synergistically with the zinc, providing an extra. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the. Zinc Flake Coating Corrosion Resistance.

From nvktechnoshine.com

Zinc Flake Coatings The EcoFriendly Solution for Sustainable Zinc Flake Coating Corrosion Resistance Based on this approach, tailored coating solutions using zinc flake coatings can be developed. This practical aid examines the following zinc coatings: Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. To the base metal,. Zinc Flake Coating Corrosion Resistance.

From www.nofmetalcoatings.com

Zinc flake base coats NOF Metal Coatings Asia Pacific Zinc Flake Coating Corrosion Resistance This practical aid examines the following zinc coatings: Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. These flakes work synergistically with the zinc, providing an extra. Zinc sacrificial corrosion protection is the main. Zinc Flake Coating Corrosion Resistance.

From aumdacro.com

The Breakdown of Zinc Flake Coating Understanding the Components for Zinc Flake Coating Corrosion Resistance Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. These flakes work synergistically with the zinc, providing an extra. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Various passivation chemistries. Zinc Flake Coating Corrosion Resistance.

From www.decc.com

Zinc Flake Coatings Explanation and Benefits DECC Zinc Flake Coating Corrosion Resistance Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. These flakes work synergistically with the zinc, providing an extra. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. To. Zinc Flake Coating Corrosion Resistance.

From pvl.co.uk

Zinc Plating vs. Zinc Flake Coating What’s the Difference? PVL Zinc Flake Coating Corrosion Resistance Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. These flakes work synergistically with the zinc, providing an extra. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic. Zinc Flake Coating Corrosion Resistance.

From www.decc.com

High Temperature Corrosion Resistant Coatings The DECC Company Zinc Flake Coating Corrosion Resistance Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. This practical aid examines the following zinc coatings: To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Based on this. Zinc Flake Coating Corrosion Resistance.

From nvktechnoshine.com

Zinc Flake Coatings The EcoFriendly Solution for Sustainable Zinc Flake Coating Corrosion Resistance Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. This practical aid examines the following zinc coatings: These flakes work synergistically with the zinc, providing an extra. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Based on this approach, tailored coating solutions. Zinc Flake Coating Corrosion Resistance.

From www.mdpi.com

Materials Free FullText Structural Aspects of Decreasing the Zinc Flake Coating Corrosion Resistance Based on this approach, tailored coating solutions using zinc flake coatings can be developed. These flakes work synergistically with the zinc, providing an extra. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. This practical aid. Zinc Flake Coating Corrosion Resistance.

From www.zincflakecoatings.com

High Corrosion Resistance Zinc Flake Coating , White Nanometer Alloy Zinc Flake Coating Corrosion Resistance These flakes work synergistically with the zinc, providing an extra. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties. Zinc Flake Coating Corrosion Resistance.

From www.zincflakecoatings.com

High Corrosion Resistance Zinc Flake Coating , White Nanometer Alloy Zinc Flake Coating Corrosion Resistance Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. This practical aid examines the following zinc coatings: To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Based on this approach, tailored coating solutions using zinc flake coatings can be developed. These flakes work synergistically. Zinc Flake Coating Corrosion Resistance.

From www.zincflakecoatings.com

Corrosion Resistant Zinc Flake Coating Geomet Mechanical Zinc Plating Zinc Flake Coating Corrosion Resistance Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. These flakes work synergistically with the zinc, providing an extra. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance. Zinc Flake Coating Corrosion Resistance.

From www.pioneermetal.com

Zinc Plating vs. Zinc Flake Coating Processes Explained Zinc Flake Coating Corrosion Resistance Various passivation chemistries may be added after electrogalvanizing to improve corrosion resistance, appearance, or other properties of. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. Zinc sacrificial corrosion protection is the main corrosion. Zinc Flake Coating Corrosion Resistance.

From fastenerandfixing.com

Combining excellence in corrosion protection Fastener + Fixing Magazine Zinc Flake Coating Corrosion Resistance This practical aid examines the following zinc coatings: Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. These flakes work synergistically with the zinc, providing an extra. To the base metal, hardness, corrosion resistance, and thickness (figure. Zinc Flake Coating Corrosion Resistance.

From gventerpriseswork.com

Zinc Flake Coating Zinc Flake Coating Corrosion Resistance Based on this approach, tailored coating solutions using zinc flake coatings can be developed. Zinc sacrificial corrosion protection is the main corrosion resistance mechanism of the zinc/aluminium flake coating film. To the base metal, hardness, corrosion resistance, and thickness (figure 2 ) of each zinc coating varies. These flakes work synergistically with the zinc, providing an extra. Aluminum flakes are. Zinc Flake Coating Corrosion Resistance.

From www.corrosionalliance.com

The different types of Zinc filled coatings Corrosion Alliance Zinc Flake Coating Corrosion Resistance Base coats are the initial layer of zinc flake systems that provide corrosion resistance with their cathodic corrosion. These flakes work synergistically with the zinc, providing an extra. This practical aid examines the following zinc coatings: Aluminum flakes are frequently incorporated into the zinc flake coating to bolster its corrosion resistance capabilities. Zinc sacrificial corrosion protection is the main corrosion. Zinc Flake Coating Corrosion Resistance.