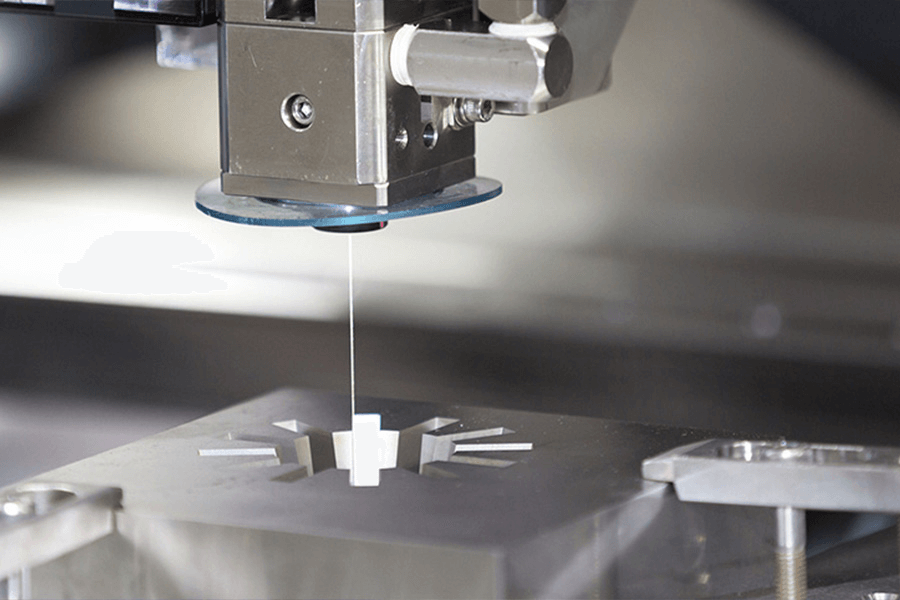

Wire Edm Vs Machining . Extreme, that has been developed to take wire edm. Common materials you can cut with the wire edm machine include aluminum, titanium, steel, brass, and graphite. Instead, edm uses an electric current to create sparks that are capable of eroding the workpiece. While it offers unmatched precision, wire edm can be slower than other machining techniques. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Sinker edm and wire edm, exploring the differences. — this type of edm has proven to be a major problem solver for most manufacturers in the machining industry. — there are three types of edm: the basic principle behind wire edm is electrical conductivity between the wire and the workpiece. Sinker edm, wire edm, and fast hole drilling edm. — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. — wire edm offers several advantages over traditional machining: in this article, we will take a closer look at two popular forms of edm: Wire edm, also known as wire. It can easily cut hard, brittle, or delicate.

from www.3erp.com

Can create complex shapes, smooth finishes, and high precision. Common materials you can cut with the wire edm machine include aluminum, titanium, steel, brass, and graphite. — this type of edm has proven to be a major problem solver for most manufacturers in the machining industry. Extreme, that has been developed to take wire edm. — electrical discharge machining, or the edm wire cutting process, uses controlled and rapidly repeating. Instead, edm uses an electric current to create sparks that are capable of eroding the workpiece. — wire edm technology can be applied in a variety of ways, from crafting complex shapes to producing parts with. — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. — the pace: The wire conducts the electrical charge to the material causing microscopic erosion of the material at desired locations.

Sinker EDM vs wire EDM Main differences and applications

Wire Edm Vs Machining Sinker edm and wire edm, exploring the differences. — volume production: Sinker edm and wire edm, exploring the differences. wire electrical discharge machining (wedm) uses a metallic wire to cut or shape a workpiece, often a conductive material,. Extreme, that has been developed to take wire edm. — the main difference between edm and ordinary machining is that edm does not require physical contact between the tool and the workpiece in order to make a cut. — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. Can create complex shapes, smooth finishes, and high precision. in this article, we will take a closer look at two popular forms of edm: A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Instead, edm uses an electric current to create sparks that are capable of eroding the workpiece. — there are three types of edm: Wire edm vs hole drilling edm Slow, expensive, and limited to conductive materials. — key takeaways. — wire edm offers several advantages over traditional machining:

From www.team-mfg.com

Understanding Wire EDM Cutting Mechanism and Diverse Applications Wire Edm Vs Machining — electrical discharge machining, or the edm wire cutting process, uses controlled and rapidly repeating. Sinker edm, wire edm, and fast hole drilling edm. Can create complex shapes, smooth finishes, and high precision. — volume production: — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. Instead, edm uses an electric. Wire Edm Vs Machining.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Edm Vs Machining A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. wire electrical discharge machining (wedm) uses a metallic wire to cut or shape a workpiece, often a conductive material,. Sinker edm and wire edm, exploring the differences. While it offers unmatched precision, wire edm can be slower than other machining techniques. —. Wire Edm Vs Machining.

From electricalworkbook.com

What is Wire EDM (Wire Electric Discharge Machining)? Process, Diagram Wire Edm Vs Machining Sinker edm, wire edm, and fast hole drilling edm. Extreme, that has been developed to take wire edm. wire electrical discharge machining (wedm) uses a metallic wire to cut or shape a workpiece, often a conductive material,. — there are three types of edm: makino has introduced a new wire edm machine, the u6 h.e.a.t. Wire edm. Wire Edm Vs Machining.

From www.researchgate.net

Detail diagram of the wirecut EDM method and its responses Download Wire Edm Vs Machining — key takeaways. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. — electrical discharge machining, or the edm wire cutting process, uses controlled and rapidly repeating. Extreme, that has been developed to take wire edm. — wire edm offers several advantages over traditional machining: Sinker edm and wire edm,. Wire Edm Vs Machining.

From www.ctemag.com

EDM focus turns to throughput, ease of use, automation Cutting Tool Wire Edm Vs Machining — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material by. makino has introduced a new wire edm machine, the u6 h.e.a.t. Can create complex shapes, smooth finishes, and high precision. It can easily cut hard, brittle, or delicate. Instead, edm uses an electric current to. Wire Edm Vs Machining.

From www.cdn-inc.com

EDM Process Types of EDM Machining & Applications Wire Edm Vs Machining — the pace: — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material by. — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. — this type of edm has proven to be a major problem solver for. Wire Edm Vs Machining.

From reads.alibaba.com

The Differences Between Laser Cutting and Wire EDM Reads Wire Edm Vs Machining — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. wire electrical discharge machining (wedm) uses a metallic wire to cut or shape a workpiece, often a conductive material,. — wire edm technology. Wire Edm Vs Machining.

From www.cermac.com

3 Ways To Utilize Wire EDM Machining CerMac Inc CNC Machining Wire Edm Vs Machining — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. the basic principle behind wire edm is electrical conductivity between the wire and the workpiece. Instead, edm uses an electric current to create sparks. Wire Edm Vs Machining.

From www.outtechus.com

Difference between Conventional EDM and Wire EDM Machining OutTechUs Wire Edm Vs Machining — wire edm technology can be applied in a variety of ways, from crafting complex shapes to producing parts with. — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material by. Wire edm, also known as wire. While it offers unmatched precision, wire edm can be. Wire Edm Vs Machining.

From www.3erp.com

Sinker EDM vs wire EDM Main differences and applications Wire Edm Vs Machining Wire edm is a faster and more efficient production process than sinker edm. — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. Instead, edm uses an electric current to create sparks that are capable. Wire Edm Vs Machining.

From okdor.com

What is the Difference Between EDM and Wire Cut EDM? Wire Edm Vs Machining — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. While it offers unmatched precision, wire edm can be slower than other machining techniques. — the main difference between edm and ordinary machining is. Wire Edm Vs Machining.

From www.rapiddirect.com

Sinker EDM vs Wire EDM Machining Key Differences and Applications Wire Edm Vs Machining Can create complex shapes, smooth finishes, and high precision. in this article, we will take a closer look at two popular forms of edm: — wire edm technology can be applied in a variety of ways, from crafting complex shapes to producing parts with. — this article delves into the core differences between sinker and wire edm,. Wire Edm Vs Machining.

From www.arbisermachine.com

Waterjet Cutting vs. Wire EDM A Comparison Arbiser Machine Wire Edm Vs Machining Wire edm, also known as wire. — wire edm technology can be applied in a variety of ways, from crafting complex shapes to producing parts with. — key takeaways. Slow, expensive, and limited to conductive materials. — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. — volume production: . Wire Edm Vs Machining.

From www.canadianmetalworking.com

Understanding the power of wire EDM Wire Edm Vs Machining — electrical discharge machining, or the edm wire cutting process, uses controlled and rapidly repeating. Extreme, that has been developed to take wire edm. — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies.. Wire Edm Vs Machining.

From pacdiecast.com

Die Casting Electrical Discharge Machining Capabilities (EDM) Wire Edm Vs Machining Extreme, that has been developed to take wire edm. makino has introduced a new wire edm machine, the u6 h.e.a.t. — this type of edm has proven to be a major problem solver for most manufacturers in the machining industry. — there are three types of edm: Common materials you can cut with the wire edm machine. Wire Edm Vs Machining.

From www.speakmechanical.com

Wire cut EDM vs Conventional EDM Speak Mechanical Wire Edm Vs Machining Sinker edm and wire edm, exploring the differences. The wire conducts the electrical charge to the material causing microscopic erosion of the material at desired locations. Wire edm, also known as wire. wire electrical discharge machining (wedm) uses a metallic wire to cut or shape a workpiece, often a conductive material,. — volume production: Can create complex shapes,. Wire Edm Vs Machining.

From www.youtube.com

Wire EDM Machining YouTube Wire Edm Vs Machining A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. wire electrical discharge machining (wedm) uses a metallic wire to cut or shape a workpiece, often a conductive material,. Common materials you can cut with the wire edm machine include aluminum, titanium, steel, brass, and graphite. — the main difference between edm. Wire Edm Vs Machining.

From advancedprecisionmachine.com

Wire EDM Services from Advanced Precision Machining LLC Wire Edm Vs Machining — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. Wire edm is a faster and more efficient production process than sinker edm. Sinker edm and wire edm, exploring the differences. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. It can easily cut hard, brittle,. Wire Edm Vs Machining.

From www.rapiddirect.com

What's Wire EDM? Precision Machining for Intricate Parts Wire Edm Vs Machining — there are three types of edm: — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. — this type of edm has proven to be a major problem solver for most manufacturers. Wire Edm Vs Machining.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Vs Machining — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. Slow, expensive, and limited to conductive materials. the basic principle behind wire edm is electrical conductivity between the wire and the workpiece. —. Wire Edm Vs Machining.

From www.practicalmachinist.com

Infographic a Comparison between Laser Cutter and Wire EDM Practical Wire Edm Vs Machining the basic principle behind wire edm is electrical conductivity between the wire and the workpiece. in this article, we will take a closer look at two popular forms of edm: The wire conducts the electrical charge to the material causing microscopic erosion of the material at desired locations. Sinker edm, wire edm, and fast hole drilling edm. Sinker. Wire Edm Vs Machining.

From designconundrum.com

EDM vs. Conventional Machining Which is Best for Your Project? Wire Edm Vs Machining Wire edm, also known as wire. Slow, expensive, and limited to conductive materials. — there are three types of edm: — key takeaways. It can easily cut hard, brittle, or delicate. — volume production: — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material. Wire Edm Vs Machining.

From www.rapiddirect.com

Sinker EDM vs Wire EDM Machining Key Differences and Applications Wire Edm Vs Machining Wire edm is a faster and more efficient production process than sinker edm. — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. the basic principle behind wire edm is electrical conductivity between the wire and the workpiece. Wire edm vs hole drilling edm Sinker edm, wire edm, and fast hole drilling. Wire Edm Vs Machining.

From an-prototype.com

EDM Machining Services Wire EDM Machining ANPrototype Wire Edm Vs Machining Extreme, that has been developed to take wire edm. — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material by. Wire edm is a faster and more efficient production process than sinker edm. Instead, edm uses an electric current to create sparks that are capable of eroding. Wire Edm Vs Machining.

From leadrp.net

Wire EDM Vs Sinker EDM The Differences Between The Two EDM Machining Wire Edm Vs Machining — this article delves into the core differences between sinker and wire edm, providing a clear understanding of their respective use cases and applications, essential for manufacturers navigating the complex landscape of machining technologies. Wire edm, also known as wire. Slow, expensive, and limited to conductive materials. — the pace: — this type of edm has proven. Wire Edm Vs Machining.

From www.iqsdirectory.com

Sinker EDM Components, Types, Applications, and Advantages Wire Edm Vs Machining — the pace: A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material by. Sinker edm and wire edm, exploring the differences. the basic principle behind wire edm is. Wire Edm Vs Machining.

From mechanicalinventions.blogspot.com

Electrical Discharge Machining (EDM) Principles Mechanical Engineering Wire Edm Vs Machining While it offers unmatched precision, wire edm can be slower than other machining techniques. — the main difference between edm and ordinary machining is that edm does not require physical contact between the tool and the workpiece in order to make a cut. — wire edm technology can be applied in a variety of ways, from crafting complex. Wire Edm Vs Machining.

From prototype-shortrun.com

What is Wire EDM Electrical Discharge Machining American Wire EDM Wire Edm Vs Machining — the main difference between edm and ordinary machining is that edm does not require physical contact between the tool and the workpiece in order to make a cut. The wire conducts the electrical charge to the material causing microscopic erosion of the material at desired locations. — volume production: Wire edm is a faster and more efficient. Wire Edm Vs Machining.

From prototype-shortrun.com

The Advantages of Using Wire EDM Machining Wire Edm Vs Machining — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. — the pace: — key takeaways. Wire edm vs hole drilling edm While it offers unmatched precision, wire edm can be slower than other machining techniques. It can easily cut hard, brittle, or delicate. in this article, we will take. Wire Edm Vs Machining.

From northwestwireedm.com

Wire EDM Services Wire EDM by Northwest Wire EDM Wire Edm Vs Machining — volume production: — the main difference between edm and ordinary machining is that edm does not require physical contact between the tool and the workpiece in order to make a cut. — the pace: Common materials you can cut with the wire edm machine include aluminum, titanium, steel, brass, and graphite. Sinker edm and wire edm,. Wire Edm Vs Machining.

From fg-machine.com

Precision Machining Shop CNC Machining, Wire EDM & More Wire Edm Vs Machining Sinker edm and wire edm, exploring the differences. — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material by. — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. — the main difference between edm and ordinary machining is. Wire Edm Vs Machining.

From www.cncsourced.com

Wire EDM A Complete Guide to Wire Electric Discharge Machining Wire Edm Vs Machining — the pace: While it offers unmatched precision, wire edm can be slower than other machining techniques. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. — wire edm offers unmatched tolerance when compared to cnc machining, laser cutters, and plasma cutters. — wire edm offers several advantages over traditional. Wire Edm Vs Machining.

From www.iqsdirectory.com

EDM Machining Components, Types, Applications, and Advantages Wire Edm Vs Machining — volume production: — wire cutting electrical discharge machining, commonly referred to as wire cut edm, uses a wire as the “cutter” and erodes material by. makino has introduced a new wire edm machine, the u6 h.e.a.t. the basic principle behind wire edm is electrical conductivity between the wire and the workpiece. Extreme, that has been. Wire Edm Vs Machining.

From www.youtube.com

Differences between Die Sinking EDM and WireEDM. YouTube Wire Edm Vs Machining While it offers unmatched precision, wire edm can be slower than other machining techniques. Slow, expensive, and limited to conductive materials. — wire edm offers several advantages over traditional machining: wire electrical discharge machining (wedm) uses a metallic wire to cut or shape a workpiece, often a conductive material,. — volume production: It can easily cut hard,. Wire Edm Vs Machining.

From www.absolutewireedm.com

How Wire EDM Works Missouri's Wire EDM machine shop Wire Edm Vs Machining the basic principle behind wire edm is electrical conductivity between the wire and the workpiece. The wire conducts the electrical charge to the material causing microscopic erosion of the material at desired locations. Wire edm is a faster and more efficient production process than sinker edm. makino has introduced a new wire edm machine, the u6 h.e.a.t. Wire. Wire Edm Vs Machining.