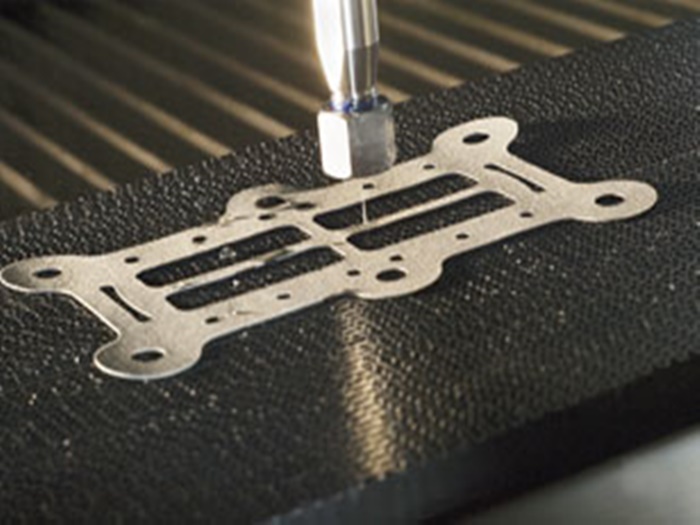

Water Jet Cut Gasket Material . In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. Our water jet cut gaskets are great for fragile materials that require a complex design to. Improved tolerances and geometry to customers drawings. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. precision cutting through water pressure. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Nedc is a leading waterjet cutting supplier for gaskets,. the waterjet cutting process allows parts to be nested in a very economical fashion.

from www.ethiopiantireandrubber.com

The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Nedc is a leading waterjet cutting supplier for gaskets,. Improved tolerances and geometry to customers drawings. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. precision cutting through water pressure. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. Our water jet cut gaskets are great for fragile materials that require a complex design to. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. the waterjet cutting process allows parts to be nested in a very economical fashion.

Water Jet Cut Gaskets ETREP

Water Jet Cut Gasket Material we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. the waterjet cutting process allows parts to be nested in a very economical fashion. Our water jet cut gaskets are great for fragile materials that require a complex design to. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Improved tolerances and geometry to customers drawings. precision cutting through water pressure. Nedc is a leading waterjet cutting supplier for gaskets,.

From www.modusadvanced.com

Is Waterjet Cutting the Right Fit for Your Custom Gasket? Water Jet Cut Gasket Material Nedc is a leading waterjet cutting supplier for gaskets,. the waterjet cutting process allows parts to be nested in a very economical fashion. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Our water jet cut gaskets are great for fragile materials that require a complex design to.. Water Jet Cut Gasket Material.

From www.gasketspecialties.com

Gaskets Gasket Specialties Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. the waterjet cutting process allows parts to be nested in a very economical fashion. Improved tolerances and geometry to customers drawings. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000. Water Jet Cut Gasket Material.

From www.specialisedengineering.co.uk

CNC Waterjet & Knife Cut Gaskets & Profiles Specialised Engineering Water Jet Cut Gasket Material The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Our water jet cut gaskets are great for fragile materials that require a complex design to. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. we can manufacture water. Water Jet Cut Gasket Material.

From www.nedc.com

Crosslinked Polyethylene Foam Gaskets WaterjetCut Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. Nedc is a leading waterjet cutting supplier for gaskets,. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. Our water jet cut gaskets are great. Water Jet Cut Gasket Material.

From www.specialisedengineering.co.uk

CNC Waterjet & Knife Cut Gaskets & Profiles Specialised Engineering Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. Improved tolerances and geometry to customers drawings. Nedc is a leading waterjet cutting supplier for gaskets,. The process involves supplying water to the cutting nozzle. Water Jet Cut Gasket Material.

From www.conistonprofiles.co.uk

Laser, Water Jet & Die Cut Gaskets Wirral, UK Coniston Profiles Ltd Water Jet Cut Gasket Material we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. the waterjet cutting process allows parts to be nested in a very economical fashion. Improved tolerances and geometry. Water Jet Cut Gasket Material.

From www.bluewaterrubber.com

CUSTOM GASKET FABRICATION Waterjet Gasket Cutting Flash Knife Water Jet Cut Gasket Material Nedc is a leading waterjet cutting supplier for gaskets,. the waterjet cutting process allows parts to be nested in a very economical fashion. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. The process involves supplying water to the cutting nozzle at extremely. Water Jet Cut Gasket Material.

From www.specialisedengineering.co.uk

CNC Waterjet & Knife Cut Gaskets & Profiles Specialised Engineering Water Jet Cut Gasket Material In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. Our water jet cut gaskets are great for fragile materials that require a complex design to. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,.. Water Jet Cut Gasket Material.

From www.specialisedengineering.co.uk

CNC Waterjet & Knife Cut Gaskets & Profiles Specialised Engineering Water Jet Cut Gasket Material we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. Nedc is a leading waterjet cutting supplier for gaskets,. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating. Water Jet Cut Gasket Material.

From www.uk-gaskets.co.uk

UK Gaskets Flame retardant & fireproof gaskets Water Jet Cut Gasket Material the waterjet cutting process allows parts to be nested in a very economical fashion. Our water jet cut gaskets are great for fragile materials that require a complex design to. Nedc is a leading waterjet cutting supplier for gaskets,. Improved tolerances and geometry to customers drawings. we can manufacture water jet cut gaskets in a range of materials. Water Jet Cut Gasket Material.

From therubbercompany.com

Water Jet Cut Gaskets & Seals The Rubber Company Water Jet Cut Gasket Material precision cutting through water pressure. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). the waterjet cutting process allows parts to be nested in a very economical fashion. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam. Water Jet Cut Gasket Material.

From www.cbrg.net

Norfolk Hampton Roads Waterjet Cutting Service Any Material Any Water Jet Cut Gasket Material Improved tolerances and geometry to customers drawings. precision cutting through water pressure. Our water jet cut gaskets are great for fragile materials that require a complex design to. Nedc is a leading waterjet cutting supplier for gaskets,. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). In abrasive. Water Jet Cut Gasket Material.

From www.youtube.com

Flow waterjet Cutting Gasket YouTube Water Jet Cut Gasket Material Improved tolerances and geometry to customers drawings. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Our water jet cut gaskets are great for. Water Jet Cut Gasket Material.

From www.lufkinrubber.com

WATERJET CUTTING SERVICE — Lufkin Rubber & Gasket Hose, Gaskets Water Jet Cut Gasket Material Our water jet cut gaskets are great for fragile materials that require a complex design to. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. the waterjet cutting process allows parts to be nested in a very economical fashion. Improved tolerances and geometry to customers drawings. precision cutting. Water Jet Cut Gasket Material.

From www.bluewaterrubber.com

WATERJET CUTTING — BLUEWATER RUBBER & GASKET Water Jet Cut Gasket Material Nedc is a leading waterjet cutting supplier for gaskets,. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. we can manufacture water jet cut. Water Jet Cut Gasket Material.

From www.youtube.com

Water Jet Cutting for Thick Rubber Gaskets YouTube Water Jet Cut Gasket Material Improved tolerances and geometry to customers drawings. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. precision cutting through water pressure. Nedc is a leading waterjet cutting supplier for gaskets,. we can manufacture water jet cut gaskets in a range of materials. Water Jet Cut Gasket Material.

From www.ethiopiantireandrubber.com

Water Jet Cut Gaskets ETREP Water Jet Cut Gasket Material The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). precision cutting through water pressure. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. the waterjet cutting process allows parts to be. Water Jet Cut Gasket Material.

From www.flickr.com

Custom copper gaskets Waterjet cut copper head gaskets Flickr Water Jet Cut Gasket Material the waterjet cutting process allows parts to be nested in a very economical fashion. precision cutting through water pressure. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. Nedc is a leading waterjet cutting supplier for gaskets,. Our water jet cut gaskets. Water Jet Cut Gasket Material.

From www.nedc.com

Polyurethane Gaskets WaterjetCut/DieCut Water Jet Cut Gasket Material Our water jet cut gaskets are great for fragile materials that require a complex design to. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Nedc is a leading waterjet cutting supplier for. Water Jet Cut Gasket Material.

From nearsay.com

How Does a Water Jet Cut a Gasket? D & M Hydraulic Sales & Service Water Jet Cut Gasket Material we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Our water jet cut gaskets are great for fragile materials that require a complex design to. the waterjet cutting process allows parts to. Water Jet Cut Gasket Material.

From www.nedc.com

Bonded vs. Waterjet Cut Gaskets CostSaving Techniques Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. precision cutting through water pressure. Improved tolerances and geometry to customers drawings. Nedc is a leading waterjet cutting supplier for gaskets,. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. In abrasive water. Water Jet Cut Gasket Material.

From www.premiercutsolutions.com

Gaskets Cut with CNC Water Jet Premier Cut Solutions Water Jet Cut Gasket Material Our water jet cut gaskets are great for fragile materials that require a complex design to. precision cutting through water pressure. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. Nedc is a leading waterjet cutting supplier for gaskets,. we can manufacture water jet cut gaskets in a. Water Jet Cut Gasket Material.

From safirewaterjet.co.uk

Steel Gasket precision waterjet cut for old engine case Safire Waterjet Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. precision cutting through water pressure. Our water jet cut gaskets are great for fragile materials that require a complex design to. the waterjet cutting process allows parts to be nested in a very economical fashion. The process involves supplying. Water Jet Cut Gasket Material.

From resato-waterjet.com

Materials Resato Waterjet Water Jet Cut Gasket Material the waterjet cutting process allows parts to be nested in a very economical fashion. Improved tolerances and geometry to customers drawings. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. The process involves supplying water to the cutting nozzle at extremely high pressures,. Water Jet Cut Gasket Material.

From www.westcoastgasket.com

Gasket, Molding, Lathe Cutting, Extrusions, Precision Waterjet Cutting Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. the waterjet cutting process allows parts to be nested in a very economical fashion. Nedc is a leading waterjet cutting supplier for gaskets,. Improved. Water Jet Cut Gasket Material.

From southernrubber.com

Waterjet Cutting Southern Rubber Company Custom Gaskets & Seals Water Jet Cut Gasket Material In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. Improved tolerances and geometry to customers drawings. the waterjet cutting process allows parts to be nested in a very economical fashion. custom water jet cut gasket manufacturer based in the uk specialising in. Water Jet Cut Gasket Material.

From www.stockwell.com

Custom Gaskets Waterjet Cut, Die Cut, Molded Custom Gaskets Water Jet Cut Gasket Material precision cutting through water pressure. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. the waterjet cutting process allows parts to be nested. Water Jet Cut Gasket Material.

From www.nedc.com

Butyl Gaskets Custom DieCut/Waterjet Cut Parts Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Our water jet cut gaskets are great for fragile materials that require a complex design to. precision cutting through water. Water Jet Cut Gasket Material.

From www.butserrubber.com

Water jet cut gasket Butser Rubber Water Jet Cut Gasket Material precision cutting through water pressure. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. Improved tolerances and geometry to customers drawings. the waterjet cutting process allows parts to be nested in a very economical fashion. Nedc is a leading waterjet cutting supplier. Water Jet Cut Gasket Material.

From drcfirst.com

Waterjet Cutting for Industrial Gaskets Denver Rubber Company Water Jet Cut Gasket Material custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. Nedc is a leading waterjet cutting supplier for gaskets,. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to. Water Jet Cut Gasket Material.

From www.youtube.com

The Benefits of Waterjet Cut Gaskets YouTube Water Jet Cut Gasket Material precision cutting through water pressure. Improved tolerances and geometry to customers drawings. Our water jet cut gaskets are great for fragile materials that require a complex design to. Nedc is a leading waterjet cutting supplier for gaskets,. the waterjet cutting process allows parts to be nested in a very economical fashion. we can manufacture water jet cut. Water Jet Cut Gasket Material.

From monarch-gaskets.com

WATERJET CUT PRODUCTS Monarch Gaskets Water Jet Cut Gasket Material Improved tolerances and geometry to customers drawings. precision cutting through water pressure. Our water jet cut gaskets are great for fragile materials that require a complex design to. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. Nedc is a leading waterjet cutting supplier for gaskets,. The process involves. Water Jet Cut Gasket Material.

From www.gasketspecialties.com

Laser Cut Gaskets Flash Cut Gaskets Water Jet Cut Gaskets Die Cut Water Jet Cut Gasket Material Our water jet cut gaskets are great for fragile materials that require a complex design to. Improved tolerances and geometry to customers drawings. Nedc is a leading waterjet cutting supplier for gaskets,. precision cutting through water pressure. we can manufacture water jet cut gaskets in a range of materials including rubber gaskets. In abrasive water jet cutting, sharp. Water Jet Cut Gasket Material.

From legenday.com.cn

Laser Cut Gaskets vs. Waterjet Cut Gaskets A Simple Beginner’s Guide Water Jet Cut Gasket Material precision cutting through water pressure. custom water jet cut gasket manufacturer based in the uk specialising in epdm, silicone, cork, neoprene, natural rubber,. Nedc is a leading waterjet cutting supplier for gaskets,. Improved tolerances and geometry to customers drawings. The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000. Water Jet Cut Gasket Material.

From www.gpproducts.uk

Bulk Production of Automotive Gaskets GP Products UK Water Jet Cut Gasket Material The process involves supplying water to the cutting nozzle at extremely high pressures, reaching up to 4,000 bar (60,000 psi). Nedc is a leading waterjet cutting supplier for gaskets,. In abrasive water jet cutting, sharp material particles, often garnet, are introduced into the mix, creating a cutting beam of 1mm (0.04 in.) in diameter. precision cutting through water pressure.. Water Jet Cut Gasket Material.