Define Calibration Pharmacy . Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. While validation is done to verify the consistency of predictable results of the. Calibration is crucial for justifying qualification and validation. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard.

from www.thelabstore.co.uk

Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration is crucial for justifying qualification and validation. While validation is done to verify the consistency of predictable results of the. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably.

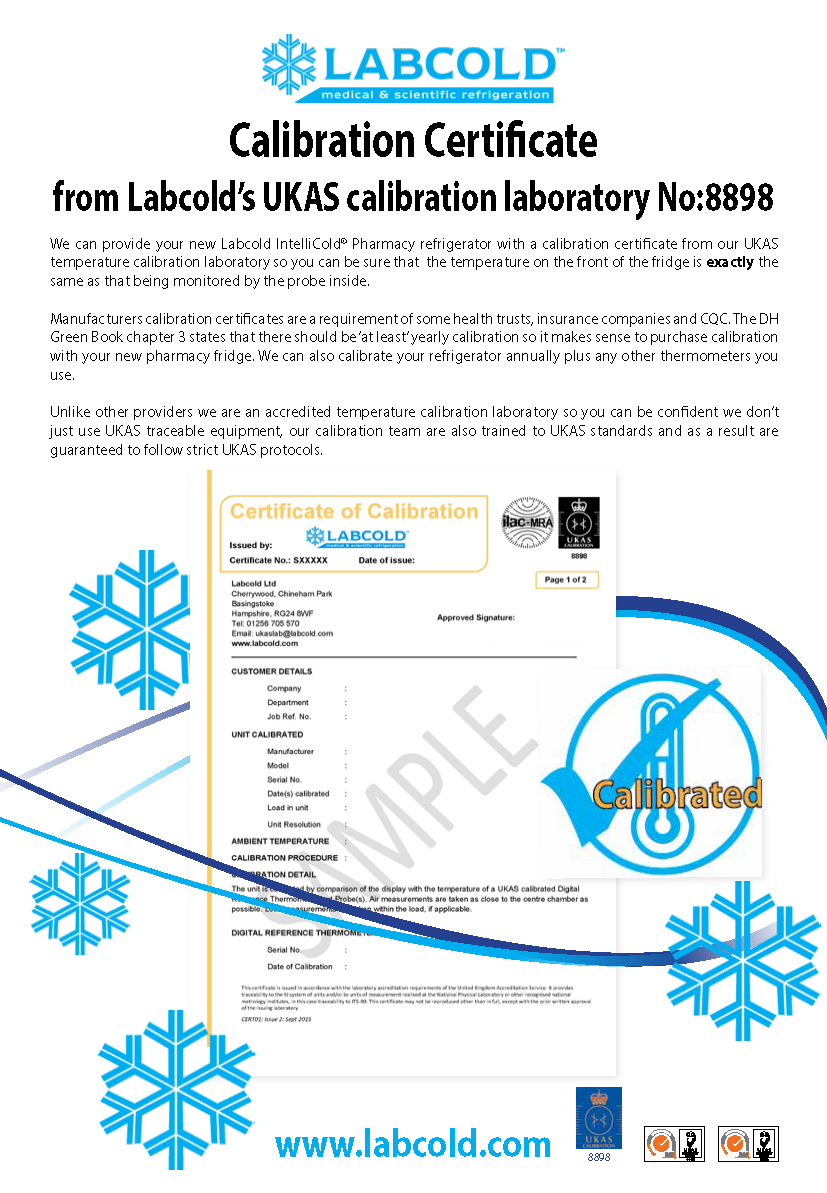

Labcold CALIB1PTLAB UKAS Calibration Certificate for Pharmacy Refrigeration

Define Calibration Pharmacy Calibration is crucial for justifying qualification and validation. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. While validation is done to verify the consistency of predictable results of the. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration is crucial for justifying qualification and validation.

From us.flukecal.com

Why is Calibration Important? Fluke Define Calibration Pharmacy Calibration is crucial for justifying qualification and validation. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. While validation is done to verify the consistency of predictable results of the. Calibration can be defined as the technique of correcting or. Define Calibration Pharmacy.

From automationcommunity.com

Instrument Calibration Questions and Answers Define Calibration Pharmacy Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. While validation is done to verify the consistency of predictable. Define Calibration Pharmacy.

From www.youtube.com

Introduction to Calibration Definition, types, purpose, Procedure of Define Calibration Pharmacy While validation is done to verify the consistency of predictable results of the. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration is crucial for justifying qualification and validation. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration can be defined as the technique of correcting or. Define Calibration Pharmacy.

From www.scribd.com

Calibration Procedure. Calibration Quality Assurance Define Calibration Pharmacy Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. While validation is done to verify the consistency of predictable results of the. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate. Define Calibration Pharmacy.

From www.studocu.com

HPLC calibration Pharmacy notes High Performance Liquid Define Calibration Pharmacy Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is done to nullify or remove the deviation by. Define Calibration Pharmacy.

From www.prweb.com

Live inar from Pharmaceutical Technology and METTLER TOLEDO on Define Calibration Pharmacy Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is crucial for justifying qualification and validation. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. It should be performed periodically to. Define Calibration Pharmacy.

From www.slideserve.com

PPT Calibration methods PowerPoint Presentation, free download ID Define Calibration Pharmacy Calibration is crucial for justifying qualification and validation. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. While validation is done to verify. Define Calibration Pharmacy.

From www.pctonline.com

The Importance of Calibration Pest Control Technology Define Calibration Pharmacy Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable. Define Calibration Pharmacy.

From www.slideshare.net

Calibration Define Calibration Pharmacy Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration is crucial for justifying qualification and validation. Calibration determines if a device or instrument is producing accurate results within the specified. Define Calibration Pharmacy.

From www.slideserve.com

PPT Calibration and Detection Limits PowerPoint Presentation, free Define Calibration Pharmacy Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is done to ensure the correct operation of equipment. Define Calibration Pharmacy.

From www.pharmacytimes.com

The Role of Compounding Pharmacies in the Ketamine Therapy Field Define Calibration Pharmacy Calibration is crucial for justifying qualification and validation. While validation is done to verify the consistency of predictable results of the. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration determines if a device or instrument is producing accurate. Define Calibration Pharmacy.

From www.youtube.com

Calibration Definition and general principles of calibration YouTube Define Calibration Pharmacy While validation is done to verify the consistency of predictable results of the. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is crucial for justifying qualification and validation. Calibration is done to ensure the correct operation of equipment. Define Calibration Pharmacy.

From sdmcalibrations.com

Mass Calibration Services SDM Calibrations LLC Define Calibration Pharmacy Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration determines if a device. Define Calibration Pharmacy.

From www.vrogue.co

What Is Calibration And Why Is It So Important vrogue.co Define Calibration Pharmacy It should be performed periodically to identify equipment drift and ensure accuracy. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. While validation is done to verify the consistency of predictable results of the. Calibration is done to nullify or. Define Calibration Pharmacy.

From www.ge.com

Calibration Planning Define Calibration Pharmacy Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. It should be performed periodically to identify equipment drift and ensure accuracy. While validation. Define Calibration Pharmacy.

From www.youtube.com

The Calibration Process in the Pharmaceutical Industry YouTube Define Calibration Pharmacy Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration is crucial for justifying qualification and validation. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. While validation is done to verify. Define Calibration Pharmacy.

From sicweb.com

CALIBRATION What Is the Principle of Calibrations Define Calibration Pharmacy While validation is done to verify the consistency of predictable results of the. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is crucial for justifying qualification and validation. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable. Define Calibration Pharmacy.

From www.thelabstore.co.uk

Labcold CALIB1PTLAB UKAS Calibration Certificate for Pharmacy Refrigeration Define Calibration Pharmacy Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is crucial for justifying qualification and validation. Calibration is done to nullify or remove the deviation by comparing with a reference. Define Calibration Pharmacy.

From www.globalcalibration.in

Thermal Calibration Facility Global Calibration Define Calibration Pharmacy Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is crucial for justifying qualification and validation. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. It should be performed periodically to identify equipment drift and ensure accuracy. While validation. Define Calibration Pharmacy.

From www.vrogue.co

Calibration Procedures vrogue.co Define Calibration Pharmacy Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. It should be performed periodically to identify equipment drift and ensure accuracy. While validation. Define Calibration Pharmacy.

From www.slideshare.net

Calibration Define Calibration Pharmacy Calibration is crucial for justifying qualification and validation. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is. Define Calibration Pharmacy.

From fyoizjubi.blob.core.windows.net

Define Calibration Data at John Avalos blog Define Calibration Pharmacy While validation is done to verify the consistency of predictable results of the. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration can be defined as the technique of correcting or setting a measuring. Define Calibration Pharmacy.

From www.slideserve.com

PPT Pipette Calibration PowerPoint Presentation, free download ID Define Calibration Pharmacy Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is crucial for justifying qualification and validation. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. While validation is done to verify. Define Calibration Pharmacy.

From www.studocu.com

Calibration ma'am manual B. Pharmacy Studocu Define Calibration Pharmacy It should be performed periodically to identify equipment drift and ensure accuracy. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. While validation is done to verify the consistency of predictable results of the. Calibration is done to ensure the. Define Calibration Pharmacy.

From mungfali.com

What Is A Calibration Curve Define Calibration Pharmacy It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. While validation. Define Calibration Pharmacy.

From www.isixsigma.com

Why Calibration is Essential for Quality Control Define Calibration Pharmacy While validation is done to verify the consistency of predictable results of the. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration. Define Calibration Pharmacy.

From mavink.com

Calibration Diagram Define Calibration Pharmacy Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration is crucial for justifying qualification and validation. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration determines if a device or. Define Calibration Pharmacy.

From www.sealcalibration.co.uk

Pharmacy Seal Calibration Define Calibration Pharmacy Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. While validation is done to. Define Calibration Pharmacy.

From www.youtube.com

Calibration, Validation, Qualification and Verification YouTube Define Calibration Pharmacy It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is crucial for justifying qualification and validation. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is done to nullify or remove the deviation by comparing. Define Calibration Pharmacy.

From www.slideshare.net

Calibration Define Calibration Pharmacy Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. It should be performed periodically to identify equipment drift and ensure accuracy. Calibration determines if a device or instrument is producing accurate. Define Calibration Pharmacy.

From www.qualitydigest.com

Equipment Calibration The What’s, Why’s, and How’s Quality Digest Define Calibration Pharmacy Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is crucial for justifying qualification and validation. While validation is done to verify. Define Calibration Pharmacy.

From www.bharatagritech.com

What Is Calibration? Definition, Importance, Types,, 40 OFF Define Calibration Pharmacy Calibration is crucial for justifying qualification and validation. While validation is done to verify the consistency of predictable results of the. Calibration is done to nullify or remove the deviation by comparing with a reference or know standard. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration. Define Calibration Pharmacy.

From www.precisa.co.uk

UKAS Lab Scales Calibration and Balance Calibration Services Precisa Define Calibration Pharmacy Calibration determines if a device or instrument is producing accurate results within the specified limits compared to those produced by a traceable standard over an appropriate range of measurements. Calibration is crucial for justifying qualification and validation. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is done to nullify or. Define Calibration Pharmacy.

From www.alamy.com

Set of metal weights for scales and the calibration test. Weight set Define Calibration Pharmacy It should be performed periodically to identify equipment drift and ensure accuracy. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration determines if a device or instrument is producing accurate. Define Calibration Pharmacy.

From www.youtube.com

Calibration of instruments in pharmaceutical industry How to perform Define Calibration Pharmacy It should be performed periodically to identify equipment drift and ensure accuracy. Calibration is done to ensure the correct operation of equipment or a process according to operating specifications. Calibration is crucial for justifying qualification and validation. Calibration can be defined as the technique of correcting or setting a measuring device by adjusting it to match a dependably. Calibration determines. Define Calibration Pharmacy.