Rare Earth Magnets Raw Materials . given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. when it comes to rare earth magnets, two major recycling pathways exist. raw material preparation: besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. The first involves ‘indirect’ recycling via traditional. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. The initial step involves procuring and preparing the rare earth metals along with iron,. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets.

from www.aliexpress.com

besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. The initial step involves procuring and preparing the rare earth metals along with iron,. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. when it comes to rare earth magnets, two major recycling pathways exist. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. raw material preparation: The first involves ‘indirect’ recycling via traditional. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling.

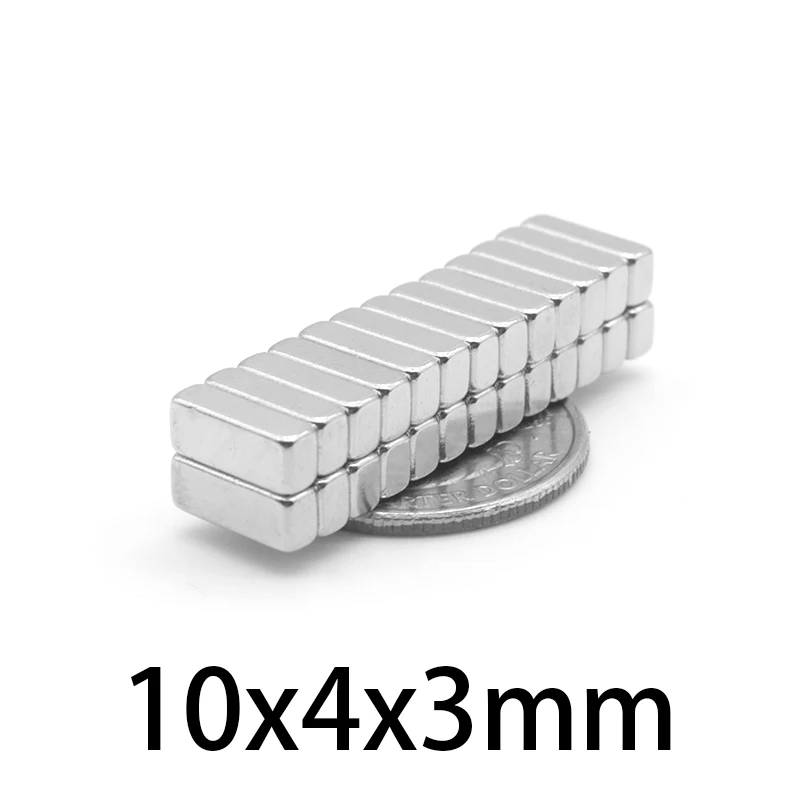

20500pcs 10x4x3 Rare Earth Strong N35 10mmx4mm Block

Rare Earth Magnets Raw Materials The initial step involves procuring and preparing the rare earth metals along with iron,. The initial step involves procuring and preparing the rare earth metals along with iron,. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. The first involves ‘indirect’ recycling via traditional. when it comes to rare earth magnets, two major recycling pathways exist. raw material preparation:

From www.harborfreight.com

Rare Earth Rare Earth Set, 10 Piece Rare Earth Magnets Raw Materials raw material preparation: when it comes to rare earth magnets, two major recycling pathways exist. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. The initial step involves procuring and preparing the rare earth metals along with iron,. The first involves ‘indirect’ recycling via traditional.. Rare Earth Magnets Raw Materials.

From exykkdxft.blob.core.windows.net

What Are Rare Earth Made Of at Shirley Stevenson blog Rare Earth Magnets Raw Materials The initial step involves procuring and preparing the rare earth metals along with iron,. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. The first involves ‘indirect’ recycling via traditional. when it comes to rare earth magnets, two major recycling pathways exist. historically, the development of rare earth permanent magnets. Rare Earth Magnets Raw Materials.

From borates.today

Strength Of Rare Earth Borates Today Rare Earth Magnets Raw Materials raw material preparation: rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. when it comes. Rare Earth Magnets Raw Materials.

From www.tradeindia.com

Rare Earth at Best Price in Mumbai, Maharashtra J. K. Industries Rare Earth Magnets Raw Materials besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. when it comes to rare earth magnets, two major recycling pathways exist. The initial step involves procuring and preparing the. Rare Earth Magnets Raw Materials.

From www.magnet4sale.com

Powerful Rare Earth CMS Rare Earth Magnets Raw Materials rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. The first involves ‘indirect’ recycling via traditional. raw material preparation: given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. when it comes to rare earth magnets, two. Rare Earth Magnets Raw Materials.

From www.zoro.com

MagMate Rare Earth Material, Sintered CMP10006P1N42 Zoro Rare Earth Magnets Raw Materials historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. raw material preparation: rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. The initial step involves. Rare Earth Magnets Raw Materials.

From www.eclipsemagnetics.com

Rare Earth vs Regular Eclipse Rare Earth Magnets Raw Materials when it comes to rare earth magnets, two major recycling pathways exist. The first involves ‘indirect’ recycling via traditional. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. historically, the development of. Rare Earth Magnets Raw Materials.

From www.mining.com

How strong are rare earth Rare Earth Magnets Raw Materials besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. raw material preparation: The first involves ‘indirect’ recycling via traditional. historically, the development of rare earth permanent magnets has been punctuated by supply. Rare Earth Magnets Raw Materials.

From www.aliexpress.com

500pcs 4x1.5mm n50 rare earth strong neodymium disc Rare Earth Magnets Raw Materials besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. The first involves ‘indirect’ recycling via traditional. rare earth magnets are the strongest permanent magnets available and have significantly higher. Rare Earth Magnets Raw Materials.

From www.hmicronpowder.com

Rare earths raw materials) Hosokawa Micron Powder Systems Rare Earth Magnets Raw Materials given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. The initial step involves procuring and preparing the rare earth metals along with iron,. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. rare earth magnets are the strongest. Rare Earth Magnets Raw Materials.

From www.magneticindustry.com

Rare Earth Rare Earth Neodymium Exporter from Chennai Rare Earth Magnets Raw Materials The initial step involves procuring and preparing the rare earth metals along with iron,. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. raw material preparation: when it comes to rare earth magnets, two major recycling pathways exist. besides the four rare earths used. Rare Earth Magnets Raw Materials.

From appliedmagnets.com

Rare Earth 1/4 in x 1/8 in N42 Neodymium Disc Rare Earth Magnets Raw Materials given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. The first involves ‘indirect’ recycling via traditional. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. besides the four rare earths used most commonly in magnets (neodymium, praseodymium,. Rare Earth Magnets Raw Materials.

From greatmagnet.en.made-in-china.com

Rare Earth Super Strong Neodymium Materials Bar Shaped Rare Earth Magnets Raw Materials raw material preparation: The initial step involves procuring and preparing the rare earth metals along with iron,. The first involves ‘indirect’ recycling via traditional. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic.. Rare Earth Magnets Raw Materials.

From www.mscdirect.com

MagMate Rare Earth Holding Shape Cylindrical; Rare Rare Earth Magnets Raw Materials given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. when it comes to rare earth magnets, two major recycling pathways exist. The first involves ‘indirect’ recycling via traditional. The. Rare Earth Magnets Raw Materials.

From www.aliexpress.com

201000pcs 10x5x1 Rare Earth Thickness 1mm Small Rectangular Rare Earth Magnets Raw Materials The first involves ‘indirect’ recycling via traditional. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. The initial step involves procuring and preparing the rare earth metals along with iron,.. Rare Earth Magnets Raw Materials.

From www.cndailymag.com

The preparation process of sintered NdFeB raw material Rare Earth Magnets Raw Materials The initial step involves procuring and preparing the rare earth metals along with iron,. raw material preparation: besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. when it comes to rare earth magnets, two major recycling pathways exist. historically, the development of rare earth permanent magnets has been punctuated. Rare Earth Magnets Raw Materials.

From www.aliexpress.com

501000pcs 5x2 Disc Rare Earth 5x2mm Small Round Rare Earth Magnets Raw Materials rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. when it comes to rare earth magnets, two major recycling pathways exist. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. historically, the development of rare earth. Rare Earth Magnets Raw Materials.

From exyzhicvy.blob.core.windows.net

Rare Earth Uline at Ruben Garcia blog Rare Earth Magnets Raw Materials raw material preparation: The first involves ‘indirect’ recycling via traditional. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. The initial step involves procuring and preparing the rare earth metals along with iron,.. Rare Earth Magnets Raw Materials.

From coinstampsupplies.com

Rare Earth for detecting impurities in precious metals Coin Rare Earth Magnets Raw Materials The first involves ‘indirect’ recycling via traditional. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. when it comes to rare earth magnets, two major recycling pathways exist. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. . Rare Earth Magnets Raw Materials.

From rawmaterials.net

Mini Rare Earth From 3D Printer Rare Earth Magnets Raw Materials besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. The first involves ‘indirect’ recycling via traditional. The initial step involves procuring and preparing the rare earth metals along with iron,. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. rare earth magnets are. Rare Earth Magnets Raw Materials.

From hxebyznml.blob.core.windows.net

Rare Earth Material at William Dewitt blog Rare Earth Magnets Raw Materials besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. when it comes to rare earth magnets, two major recycling pathways exist. historically, the development of rare earth permanent. Rare Earth Magnets Raw Materials.

From www.aliexpress.com

20500pcs 10x4x3 Rare Earth Strong N35 10mmx4mm Block Rare Earth Magnets Raw Materials historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. raw material preparation: given the growing. Rare Earth Magnets Raw Materials.

From www.aliexpress.us

Rare Earth Magnets Raw Materials besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. raw material preparation: when it comes to rare earth magnets, two major recycling pathways exist. The initial step involves procuring and preparing the rare earth metals along with iron,. The first involves ‘indirect’ recycling via traditional. rare earth magnets are. Rare Earth Magnets Raw Materials.

From megaapp.altervista.org

201000pcs 10x5x1 Rare Earth Thickness 1mm Small Rectangular Rare Earth Magnets Raw Materials raw material preparation: rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. The initial step involves procuring and preparing the rare earth metals along with iron,. The first involves ‘indirect’ recycling via traditional. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic.. Rare Earth Magnets Raw Materials.

From www.mscdirect.com

MagMate Rare Earth Disc & Cylinder Rare Earth Metal Type Rare Earth Magnets Raw Materials rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. raw material preparation: historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. The initial step involves. Rare Earth Magnets Raw Materials.

From bestviewsreviews.com

Best Rare Earth of 2024 Bestviewsreviews Rare Earth Magnets Raw Materials given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. when it. Rare Earth Magnets Raw Materials.

From gtekmagnet.com

What is Rare Earth Permanent GTEK Rare Earth Magnets Raw Materials The first involves ‘indirect’ recycling via traditional. when it comes to rare earth magnets, two major recycling pathways exist. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. given the growing demand for. Rare Earth Magnets Raw Materials.

From cnyymag.en.made-in-china.com

Permanent Rare Earth Samarium Cobalt SmCo2 17 Disc Rare Earth Magnets Raw Materials historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. when it comes to rare earth magnets, two major recycling pathways exist. raw material preparation: given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. besides the four. Rare Earth Magnets Raw Materials.

From www.alibaba.com

Super Strong Materials Rare Earth Blocks Ndfeb Rare Earth Magnets Raw Materials rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. when it comes to rare earth magnets, two major recycling pathways exist. raw material preparation: besides the four rare earths used most. Rare Earth Magnets Raw Materials.

From www.first4magnets.com

Rare Earth Rare Earth Magnets Raw Materials The first involves ‘indirect’ recycling via traditional. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. The initial step involves procuring and preparing the rare earth metals along with iron,. when it comes to rare earth magnets, two major recycling pathways exist. besides the four rare earths used most commonly. Rare Earth Magnets Raw Materials.

From www.amazon.com

Super Strong Rare Earth 3x6mm Neodymium Powerful Rare Earth Magnets Raw Materials The initial step involves procuring and preparing the rare earth metals along with iron,. historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix. raw material preparation: rare earth magnets are the strongest permanent. Rare Earth Magnets Raw Materials.

From appliedmagnets.com

Rare Earth 2 in x 1 in x 3/4 in Neodymium Block N42 Rare Earth Magnets Raw Materials rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. when it comes to rare earth magnets, two major recycling pathways exist. raw material preparation: historically, the development of rare earth permanent magnets has been punctuated by supply crises for strategic. The first involves ‘indirect’ recycling via traditional. . Rare Earth Magnets Raw Materials.

From rawmaterials.net

RecordBreaking New Super Made From Rare Earths Rare Earth Magnets Raw Materials given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. raw material preparation: The first involves ‘indirect’ recycling via traditional. historically, the development of rare earth permanent magnets. Rare Earth Magnets Raw Materials.

From www.mscdirect.com

MagMate Rare Earth Disc & Cylinder Rare Earth Metal Type Rare Earth Magnets Raw Materials given the growing demand for rare earth elements and the environmental impact of mining, there is a growing focus on recycling. when it comes to rare earth magnets, two major recycling pathways exist. raw material preparation: rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. historically, the. Rare Earth Magnets Raw Materials.

From www.birmingham.ac.uk

Recycling rare earth University of Birmingham Rare Earth Magnets Raw Materials The first involves ‘indirect’ recycling via traditional. The initial step involves procuring and preparing the rare earth metals along with iron,. raw material preparation: rare earth magnets are the strongest permanent magnets available and have significantly higher performance than ceramic/ferrite magnets. besides the four rare earths used most commonly in magnets (neodymium, praseodymium, dysprosium, and terbium), phoenix.. Rare Earth Magnets Raw Materials.