Air Plug Gauge Tolerance Chart . Calculate the full tolerance of the product feature. Snded plug gauges with relation to the workpiece tolerance. Standard plug and ring gage classes for product tolerances. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. The difference between the high and low. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. To calculate the gage tolerance using the 10% product tolerance rule: Each air plug gauge requires two setting rings to set the air plug on the read out unit. Enter the part tolerance, material condition, and. In the above case 0.0001” is classified as a z. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. The chart of product tolerances for plain plug and.

from www.a-egauges.co.uk

In the above case 0.0001” is classified as a z. Standard plug and ring gage classes for product tolerances. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. The difference between the high and low. Each air plug gauge requires two setting rings to set the air plug on the read out unit. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. Snded plug gauges with relation to the workpiece tolerance. Calculate the full tolerance of the product feature.

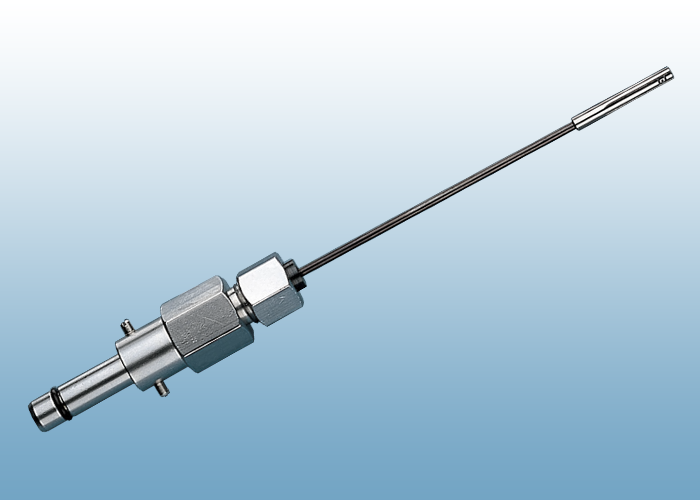

A&E Gauges Ltd Air Plug Gauges

Air Plug Gauge Tolerance Chart The chart of product tolerances for plain plug and. Snded plug gauges with relation to the workpiece tolerance. To calculate the gage tolerance using the 10% product tolerance rule: In the above case 0.0001” is classified as a z. Standard plug and ring gage classes for product tolerances. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Enter the part tolerance, material condition, and. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. The difference between the high and low. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Calculate the full tolerance of the product feature. The chart of product tolerances for plain plug and.

From www.judgetool.com

Thread Plug Gages METRIC Hardened Steel Judge Tool & Gage Air Plug Gauge Tolerance Chart Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Enter the part tolerance, material condition, and. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Calculate the full tolerance of the. Air Plug Gauge Tolerance Chart.

From mavink.com

Plug Gauge Tolerance Chart Air Plug Gauge Tolerance Chart Snded plug gauges with relation to the workpiece tolerance. Enter the part tolerance, material condition, and. To calculate the gage tolerance using the 10% product tolerance rule: This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. In the. Air Plug Gauge Tolerance Chart.

From vdocuments.mx

Tolerance Chart BS 969 1982 [PDF Document] Air Plug Gauge Tolerance Chart The difference between the high and low. In the above case 0.0001” is classified as a z. Calculate the full tolerance of the product feature. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. To calculate the gage tolerance using the 10% product tolerance rule: The chart of product tolerances. Air Plug Gauge Tolerance Chart.

From grmetrology.com

Plug Gage Calibration GR Metrology Air Plug Gauge Tolerance Chart This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. Standard plug and ring gage classes for product tolerances. Snded plug gauges with relation to the workpiece tolerance. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Ansi/asme. Air Plug Gauge Tolerance Chart.

From suyashprecision.com

SUYASH PRECISION Air Plug Gauge Tolerance Chart Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Calculate the full tolerance of the product feature. The difference between the high and low. Standard plug and ring gage classes for product tolerances. Enter the part tolerance, material condition, and. Each air plug gauge requires two setting rings to set the air plug on the read out. Air Plug Gauge Tolerance Chart.

From accurateengg.com

Air Plug Gauges Accurate Engineering Air Plug Gauge Tolerance Chart The chart of product tolerances for plain plug and. The difference between the high and low. Enter the part tolerance, material condition, and. Standard plug and ring gage classes for product tolerances. Snded plug gauges with relation to the workpiece tolerance. In the above case 0.0001” is classified as a z. Calculate the full tolerance of the product feature. This. Air Plug Gauge Tolerance Chart.

From bceweb.org

Plug Gauge Tolerance Chart A Visual Reference of Charts Chart Master Air Plug Gauge Tolerance Chart Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. Standard plug and ring gage classes for product tolerances. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Enter the part tolerance, material condition, and. Ansi/asme b89.1.5 provides a tolerance chart to define the. Air Plug Gauge Tolerance Chart.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Air Plug Gauge Tolerance Chart Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Enter the part tolerance, material condition, and. The chart of product tolerances for plain plug and. This chart shows the tolerance limits for pin and ring gages in inches and. Air Plug Gauge Tolerance Chart.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Air Plug Gauge Tolerance Chart Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. The difference between the high and low. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. Each air plug gauge requires two setting rings to set the air plug on the read out unit. The chart of product tolerances for. Air Plug Gauge Tolerance Chart.

From mungfali.com

Gage Block Tolerance Chart Air Plug Gauge Tolerance Chart Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. The difference between the high and low. The chart of product tolerances for plain plug and. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Learn how to design plug and ring gauges for fixed. Air Plug Gauge Tolerance Chart.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Air Plug Gauge Tolerance Chart Calculate the full tolerance of the product feature. Standard plug and ring gage classes for product tolerances. In the above case 0.0001” is classified as a z. The chart of product tolerances for plain plug and. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. To calculate the gage tolerance using the. Air Plug Gauge Tolerance Chart.

From www.sumipol.com

THREAD LIMIT PLUG GAUGE (ISO TYPE JIS / GPNP) Sumipol Air Plug Gauge Tolerance Chart This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Each air plug gauge requires two setting rings to set the air plug on the read out unit. The chart of product tolerances for plain plug and. Standard plug and ring gage classes for product tolerances. This standard. Air Plug Gauge Tolerance Chart.

From mavink.com

Gage Makers Tolerance Chart Air Plug Gauge Tolerance Chart Calculate the full tolerance of the product feature. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Enter the part tolerance, material condition, and. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Snded plug gauges with relation. Air Plug Gauge Tolerance Chart.

From willrich.com

Mahr Federal Dimensionair Air Gage Dial type Willrich Precision Instruments Air Plug Gauge Tolerance Chart Enter the part tolerance, material condition, and. The chart of product tolerances for plain plug and. To calculate the gage tolerance using the 10% product tolerance rule: The difference between the high and low. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. This standard specifies the. Air Plug Gauge Tolerance Chart.

From mrpranav.com

Air Gauging Overview Quality Digest Air Plug Gauge Tolerance Chart Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. The chart of product tolerances for plain plug and. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Snded plug gauges with relation to the workpiece tolerance. Ansi/asme b89.1.5 provides. Air Plug Gauge Tolerance Chart.

From bceweb.org

Spline Tolerance Chart A Visual Reference of Charts Chart Master Air Plug Gauge Tolerance Chart This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. The chart of product tolerances for plain plug and. Each air plug gauge requires two setting rings to set. Air Plug Gauge Tolerance Chart.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Air Plug Gauge Tolerance Chart This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. Calculate the full tolerance of the product feature. The chart of product tolerances for plain plug and. The difference between the high and low. Standard plug and ring gage classes for product tolerances. Enter the part tolerance, material condition, and. Each. Air Plug Gauge Tolerance Chart.

From titangage.com

Thread Ring & Setting Plug Gages Titan Gage Air Plug Gauge Tolerance Chart This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. The difference between the high and low. Calculate the full tolerance of the product feature. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. In the above case. Air Plug Gauge Tolerance Chart.

From www.pmiis.com.my

SK Plain Plug Gauge Air Plug Gauge Tolerance Chart Each air plug gauge requires two setting rings to set the air plug on the read out unit. Standard plug and ring gage classes for product tolerances. The difference between the high and low. The chart of product tolerances for plain plug and. Calculate the full tolerance of the product feature. Ansi/asme b89.1.5 provides a tolerance chart to define the. Air Plug Gauge Tolerance Chart.

From pacchlist.weebly.com

Iso 2768 hole tolerance table pacchlist Air Plug Gauge Tolerance Chart The difference between the high and low. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. Standard plug and ring gage classes for product tolerances. In the above case 0.0001” is classified as a z. The chart of product tolerances for plain plug and. Calculate the full tolerance of the product feature.. Air Plug Gauge Tolerance Chart.

From mavink.com

Plug Gauge Tolerance Chart Air Plug Gauge Tolerance Chart Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. In the above case 0.0001” is classified as a z. Snded plug gauges with relation to the workpiece tolerance. Each air. Air Plug Gauge Tolerance Chart.

From www.scribd.com

10. Gage Tolerances PDF Air Plug Gauge Tolerance Chart This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Ansi/asme. Air Plug Gauge Tolerance Chart.

From www.zynitectools.com

Plug Ring Gauges zynitectools Air Plug Gauge Tolerance Chart To calculate the gage tolerance using the 10% product tolerance rule: Standard plug and ring gage classes for product tolerances. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Calculate. Air Plug Gauge Tolerance Chart.

From www.a-egauges.co.uk

A&E Gauges Ltd Air Plug Gauges Air Plug Gauge Tolerance Chart In the above case 0.0001” is classified as a z. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. The chart of product tolerances for plain plug and. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Enter the part tolerance,. Air Plug Gauge Tolerance Chart.

From bceweb.org

Plug Gauge Tolerance Chart A Visual Reference of Charts Chart Master Air Plug Gauge Tolerance Chart Standard plug and ring gage classes for product tolerances. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Snded plug gauges with relation to the workpiece tolerance. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. This chart shows the tolerance limits for pin and ring gages. Air Plug Gauge Tolerance Chart.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Air Plug Gauge Tolerance Chart This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. The chart of product tolerances for plain plug and. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. To calculate the gage tolerance using the 10% product tolerance rule: Snded plug gauges with relation to. Air Plug Gauge Tolerance Chart.

From bceweb.org

Plug Gauge Tolerance Chart A Visual Reference of Charts Chart Master Air Plug Gauge Tolerance Chart Standard plug and ring gage classes for product tolerances. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. The chart of product tolerances for plain plug and. Snded plug gauges. Air Plug Gauge Tolerance Chart.

From nabgauge.com

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge Air Plug Gauge Tolerance Chart Each air plug gauge requires two setting rings to set the air plug on the read out unit. To calculate the gage tolerance using the 10% product tolerance rule: The difference between the high and low. Snded plug gauges with relation to the workpiece tolerance. This chart shows the tolerance limits for pin and ring gages in inches and millimeters,. Air Plug Gauge Tolerance Chart.

From www.a-egauges.co.uk

A&E Gauges Ltd Air Plug Gauges Air Plug Gauge Tolerance Chart Standard plug and ring gage classes for product tolerances. Calculate the full tolerance of the product feature. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. The chart of product tolerances for plain plug and. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on. Air Plug Gauge Tolerance Chart.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Air Plug Gauge Tolerance Chart Standard plug and ring gage classes for product tolerances. Each air plug gauge requires two setting rings to set the air plug on the read out unit. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based. Air Plug Gauge Tolerance Chart.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Air Plug Gauge Tolerance Chart Snded plug gauges with relation to the workpiece tolerance. Enter the part tolerance, material condition, and. Standard plug and ring gage classes for product tolerances. To calculate the gage tolerance using the 10% product tolerance rule: Each air plug gauge requires two setting rings to set the air plug on the read out unit. Learn how to design plug and. Air Plug Gauge Tolerance Chart.

From mavink.com

Plug Gauge Tolerance Chart Air Plug Gauge Tolerance Chart This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and direction. Snded plug gauges with relation to the workpiece tolerance. Enter the part tolerance, material condition, and. Calculate the full tolerance of the product feature. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. To calculate. Air Plug Gauge Tolerance Chart.

From mavink.com

Plug Gauge Tolerance Chart Air Plug Gauge Tolerance Chart Calculate the full tolerance of the product feature. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. This chart shows the tolerance limits for pin and ring gages in inches and millimeters, based on the tolerance class and. Air Plug Gauge Tolerance Chart.

From mungfali.com

Plain Plug Gauge Tolerance Chart Air Plug Gauge Tolerance Chart Calculate the full tolerance of the product feature. The chart of product tolerances for plain plug and. In the above case 0.0001” is classified as a z. Ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Snded plug gauges with relation to the workpiece tolerance. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges,. Air Plug Gauge Tolerance Chart.

From mungfali.com

Plain Plug Gauge Tolerance Chart Air Plug Gauge Tolerance Chart The difference between the high and low. This standard specifies the gauge allowances and manufacturing tolerances for plain gauges, ring gauges and reference discs for outside. In the above case 0.0001” is classified as a z. Learn how to design plug and ring gauges for fixed limit gauging of holes and external diameters. The chart of product tolerances for plain. Air Plug Gauge Tolerance Chart.