Pressure Vessel Nozzle Welding . The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. The need for welding automation rises as several heavy fabrication. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). An acceptable vessel examination procedure includes testing the circumferential welds,. The fusion zone in welding is the weld bead itself, and the. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit.

from arvengtraining.com

The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The need for welding automation rises as several heavy fabrication. The fusion zone in welding is the weld bead itself, and the. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). An acceptable vessel examination procedure includes testing the circumferential welds,.

Nozzle Design the Weak point of every equipment Arveng Training & Engineering

Pressure Vessel Nozzle Welding Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The fusion zone in welding is the weld bead itself, and the. An acceptable vessel examination procedure includes testing the circumferential welds,. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The need for welding automation rises as several heavy fabrication.

From arvengtraining.com

Butt Weld Nozzles Arveng Training & Engineering Pressure Vessel Nozzle Welding The fusion zone in welding is the weld bead itself, and the. These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. Hand calculations based on the welding. Pressure Vessel Nozzle Welding.

From www.youtube.com

Pressure Vessel Weld Joint Categories as per ASME Section VIII Div.1 Let'sFab YouTube Pressure Vessel Nozzle Welding This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: The need for welding automation rises as several heavy fabrication. The fusion zone in welding is the weld bead itself, and the. An acceptable vessel examination procedure includes testing the circumferential welds,. These nozzles are often secured to the pressure vessel with fillet. Pressure Vessel Nozzle Welding.

From www.canadianmetalworking.com

Pemamek’s Pema Nozzle designed for heavyduty welding Pressure Vessel Nozzle Welding An acceptable vessel examination procedure includes testing the circumferential welds,. These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The need for welding automation rises as several heavy fabrication. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and. Pressure Vessel Nozzle Welding.

From resources.arcmachines.com

Pressure Vessel Nozzle Welding Pressure Vessel Nozzle Welding An acceptable vessel examination procedure includes testing the circumferential welds,. The need for welding automation rises as several heavy fabrication. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. Knowing and. Pressure Vessel Nozzle Welding.

From resources.arcmachines.com

Pressure Vessel Nozzle Welding Pressure Vessel Nozzle Welding The fusion zone in welding is the weld bead itself, and the. These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The need for welding automation rises as several heavy fabrication. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure. Pressure Vessel Nozzle Welding.

From www.dreamstime.com

Nozzle of Pressure Vessel is Carbon Steel Stock Photo Image of petrochemical, heat 168536962 Pressure Vessel Nozzle Welding This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The need for. Pressure Vessel Nozzle Welding.

From www.dreamstime.com

Nozzle of Pressure Vessel is Carbon Steel Stock Image Image of material, background 168536945 Pressure Vessel Nozzle Welding An acceptable vessel examination procedure includes testing the circumferential welds,. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. These nozzles are often secured to the pressure vessel with fillet welds on. Pressure Vessel Nozzle Welding.

From qizhi2023.en.made-in-china.com

Qizhi CNC Pressure Vessel and Boiler Nozzle Automatic Welding Machine Nozzle Welding Machine Pressure Vessel Nozzle Welding Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). The need for welding automation rises. Pressure Vessel Nozzle Welding.

From mungfali.com

Pressure Vessel Welding Pressure Vessel Nozzle Welding Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). The need for welding automation rises as several heavy fabrication. These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The fusion zone in welding is the weld bead itself, and the.. Pressure Vessel Nozzle Welding.

From www.youtube.com

pressure vessel setin nozzle welding footage YouTube Pressure Vessel Nozzle Welding The need for welding automation rises as several heavy fabrication. The fusion zone in welding is the weld bead itself, and the. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). An acceptable vessel examination procedure includes testing the circumferential welds,. Knowing and meeting applicable welding joint efficiency factors is essential for meeting. Pressure Vessel Nozzle Welding.

From akshayrothe.blogspot.com

INSPECTIONS OF NOZZLES OF PRESSURE VESSELS. FABRICATION & RELATED TERMS Pressure Vessel Nozzle Welding Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). An acceptable vessel examination procedure includes testing the circumferential welds,. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements. Pressure Vessel Nozzle Welding.

From www.linkedin.com

Pressure Vessel Nozzles Pressure Vessel Nozzle Welding An acceptable vessel examination procedure includes testing the circumferential welds,. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). The fusion zone in welding is the weld bead itself, and the. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The need for welding. Pressure Vessel Nozzle Welding.

From forgedcomponents.com

QLip ASME Nozzle Manufacturing Pressure Vessels Components Inc Pressure Vessel Nozzle Welding The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: An acceptable vessel examination procedure includes testing the circumferential welds,. Hand calculations based on the welding research council (wrc) bulletin 107 and finite. Pressure Vessel Nozzle Welding.

From www.youtube.com

Pressure Vessel Design Part3 welding type and Its Symbol on Drawing YouTube Pressure Vessel Nozzle Welding This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. The need for welding automation rises as. Pressure Vessel Nozzle Welding.

From www.dreamstime.com

Fillet Weld of Nozzle for Pressure Vessel Carbon Steel Background Stock Photo Image of Pressure Vessel Nozzle Welding These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The fusion zone in welding is the weld bead itself, and the. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). The following are acceptable types of welded nozzle designs and. Pressure Vessel Nozzle Welding.

From www.youtube.com

Pressure vessel welding method YouTube Pressure Vessel Nozzle Welding Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The need for. Pressure Vessel Nozzle Welding.

From www.youtube.com

ASME VIII Pressure vessel nozzle reinforced pad YouTube Pressure Vessel Nozzle Welding The fusion zone in welding is the weld bead itself, and the. An acceptable vessel examination procedure includes testing the circumferential welds,. These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea).. Pressure Vessel Nozzle Welding.

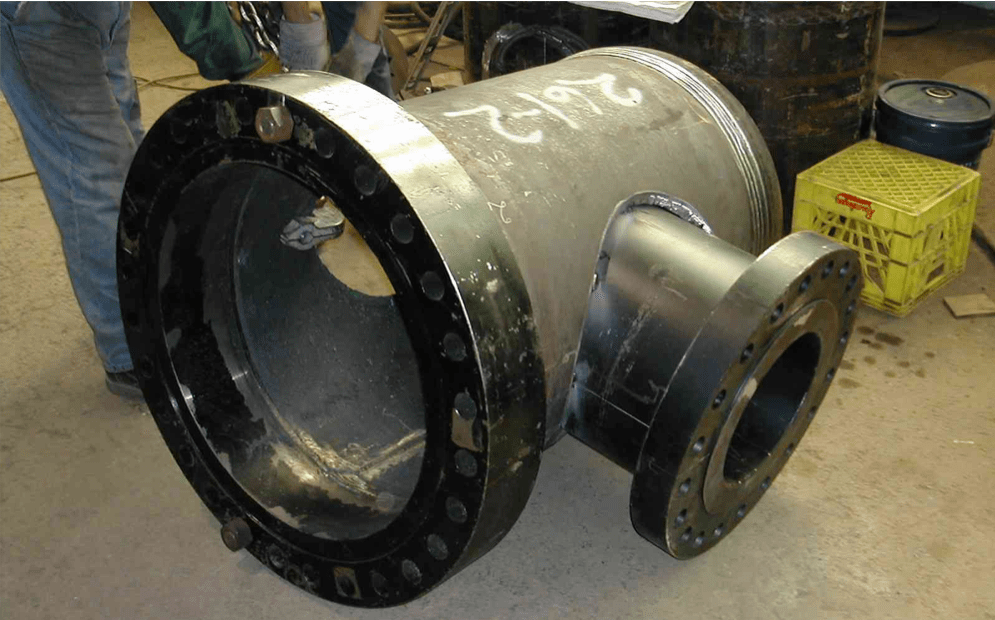

From barclaymechanical.com

Pressure Vessel Nozzle Repair Barclay Mechanical Pressure Vessel Nozzle Welding The need for welding automation rises as several heavy fabrication. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: These nozzles are often secured to the pressure vessel with fillet welds on both the id and. Pressure Vessel Nozzle Welding.

From www.eng-tips.com

Preferred Weld Detail Boiler and Pressure Vessel engineering EngTips Pressure Vessel Nozzle Welding These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The fusion zone in welding is the weld bead itself, and the. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The need for welding automation rises as several. Pressure Vessel Nozzle Welding.

From mavink.com

Pressure Vessel Welding Pressure Vessel Nozzle Welding The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. The need. Pressure Vessel Nozzle Welding.

From www.youtube.com

Pressure Vessel Fabrication Nozzle Marking on Shell and Dish ends in Hindi Part 8 B Let Pressure Vessel Nozzle Welding The fusion zone in welding is the weld bead itself, and the. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). An acceptable vessel examination procedure includes testing the circumferential welds,. Knowing and. Pressure Vessel Nozzle Welding.

From www.dreamstime.com

Nozzle of Pressure Vessel is Carbon Steel Stock Photo Image of asme, pipe 168536930 Pressure Vessel Nozzle Welding These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. An acceptable vessel examination procedure includes testing the circumferential welds,. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: The need for welding automation rises as several heavy fabrication. Knowing. Pressure Vessel Nozzle Welding.

From www.qizhimachine.com

Automatic pressure vessel nozzle welding machine Pressure Vessel Nozzle Welding This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. An acceptable vessel examination procedure includes testing the circumferential welds,. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the. Pressure Vessel Nozzle Welding.

From pveng.com

ASME Methods Blog Pressure Vessel Engineering Pressure Vessel Nozzle Welding The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. The need for welding automation rises as several heavy fabrication. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. These nozzles are often secured to the pressure vessel with fillet welds. Pressure Vessel Nozzle Welding.

From www.researchgate.net

Nozzle welding on pressure vessel (a), model with OWC (b), and cutting (c) Download Scientific Pressure Vessel Nozzle Welding Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The fusion zone in welding is the weld bead itself, and the. The need for welding automation rises as several heavy fabrication. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). These nozzles are often. Pressure Vessel Nozzle Welding.

From www.youtube.com

Pressure Vessel Fabrication Nozzles and Manhole Detailing in Hindi Part8A Let'sFab YouTube Pressure Vessel Nozzle Welding The need for welding automation rises as several heavy fabrication. The fusion zone in welding is the weld bead itself, and the. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The following are acceptable. Pressure Vessel Nozzle Welding.

From www.qizhimachine.com

Automatic pressure vessel nozzle welding machine Pressure Vessel Nozzle Welding Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). An acceptable vessel examination procedure includes testing the circumferential welds,. The need for welding automation rises as several heavy fabrication. The fusion zone in welding is. Pressure Vessel Nozzle Welding.

From qizhi2023.en.made-in-china.com

Qizhi CNC Pressure Vessel/ Boiler Nozzle Automatic Welding MachineQzmah1200 China Nozzle Pressure Vessel Nozzle Welding The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). An acceptable vessel examination procedure includes testing the circumferential welds,. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements. Pressure Vessel Nozzle Welding.

From resources.arcmachines.com

Pressure Vessel Nozzle Welding Pressure Vessel Nozzle Welding These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. An acceptable vessel examination procedure includes testing the circumferential welds,. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. The fusion zone in welding is the weld. Pressure Vessel Nozzle Welding.

From www.youtube.com

Pressure vessel welding 0818029015 YouTube Pressure Vessel Nozzle Welding The fusion zone in welding is the weld bead itself, and the. The need for welding automation rises as several heavy fabrication. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. An acceptable vessel examination procedure includes testing the circumferential welds,. Hand calculations based on the welding research council. Pressure Vessel Nozzle Welding.

From www.zetec.com

PAUT Nozzle Weld Inspection Zetec Pressure Vessel Nozzle Welding An acceptable vessel examination procedure includes testing the circumferential welds,. Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). The need for welding automation rises as several heavy fabrication. These nozzles are often secured to. Pressure Vessel Nozzle Welding.

From arvengtraining.com

Nozzle Design the Weak point of every equipment Arveng Training & Engineering Pressure Vessel Nozzle Welding These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. An acceptable vessel examination procedure includes testing the circumferential welds,. Hand calculations based on the welding research council (wrc) bulletin 107 and finite element analysis (fea). Knowing and meeting applicable welding joint efficiency factors is essential for meeting. Pressure Vessel Nozzle Welding.

From qizhi2023.en.made-in-china.com

Qizhi CNC Pressure Vessel/ Boiler Nozzle Manhole Automatic Welding Machine Nozzle Welding Pressure Vessel Nozzle Welding These nozzles are often secured to the pressure vessel with fillet welds on both the id and od surfaces of the unit. An acceptable vessel examination procedure includes testing the circumferential welds,. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: Hand calculations based on the welding research council (wrc) bulletin 107. Pressure Vessel Nozzle Welding.

From www.istockphoto.com

Weld Joint Of Nozzle In Pressure Vessel Is Carbon Steel Included Flange And Nozzle Neck Assembly Pressure Vessel Nozzle Welding Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. This technical article discusses the two commonly employed methodologies for evaluating pressure vessels subjected to such loads: The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. An acceptable vessel examination procedure. Pressure Vessel Nozzle Welding.

From www.qizhimachine.com

Automatic pressure vessel nozzle welding machine Pressure Vessel Nozzle Welding Knowing and meeting applicable welding joint efficiency factors is essential for meeting the requirements for pressure vessel welding. The fusion zone in welding is the weld bead itself, and the. The following are acceptable types of welded nozzle designs and other connections to pressure vessel shells, heads and other geometries. This technical article discusses the two commonly employed methodologies for. Pressure Vessel Nozzle Welding.