Gear Design Math . Gear ratios are a core science behind almost every machine in the modern era. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. (inch units applicable for constants) spur gear. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. They can maximize power and efficiency and are based on. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The life of gear depends on multiple factors such as lubrication, manufacturing. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gear design by agma theory:

from www.youtube.com

The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. (inch units applicable for constants) spur gear. The life of gear depends on multiple factors such as lubrication, manufacturing. Gear ratios are a core science behind almost every machine in the modern era. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. They can maximize power and efficiency and are based on. Gear design by agma theory: 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data.

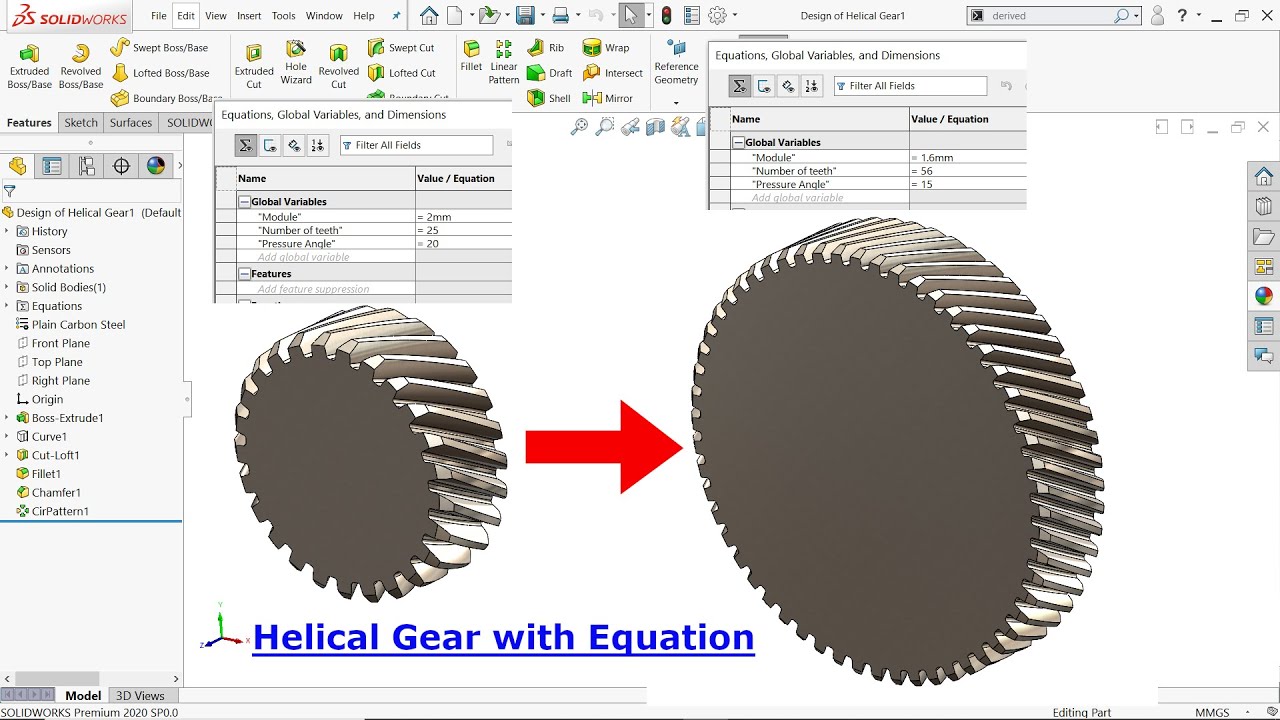

Design Of Helical Gear with Equation in SolidWorks YouTube

Gear Design Math Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The life of gear depends on multiple factors such as lubrication, manufacturing. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. (inch units applicable for constants) spur gear. Gear design by agma theory: Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. They can maximize power and efficiency and are based on. Gear ratios are a core science behind almost every machine in the modern era.

From www.tflex.com

TFLEX Gears Design, analysis and engineering calculation of gears Gear Design Math They can maximize power and efficiency and are based on. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and.. Gear Design Math.

From www.wisc-online.com

Gear Ratio Concepts (Screencast) OER Gear Design Math The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. (inch units applicable for constants) spur gear. Gear ratios are a core science behind almost every machine in the modern era. Gear design by agma theory: The life of gear depends on multiple factors such as lubrication, manufacturing. Gear dimensions are determined in accordance with their. Gear Design Math.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Design Math Gear design by agma theory: They can maximize power and efficiency and are based on. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The life of gear depends on multiple factors such as lubrication, manufacturing. In the previous pages,. Gear Design Math.

From www.pinterest.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gears, Mechanical Gear Design Math Gear design by agma theory: They can maximize power and efficiency and are based on. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. (inch units applicable for constants) spur gear. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. Gear ratios are a core science behind almost every machine. Gear Design Math.

From www.dreamstime.com

Gear Math Logo Icon Vector. Stock Vector Illustration of calculation Gear Design Math In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. Gear design by agma theory:. Gear Design Math.

From blogs.3ds.com

How to Develop a Custom Method for Gear Design Gear Design Math Gear ratios are a core science behind almost every machine in the modern era. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. They can maximize power and efficiency and are based on. (inch units applicable for constants) spur gear. The life of gear depends on multiple factors such as lubrication, manufacturing. Gear design by. Gear Design Math.

From www.worksbysolo.com

Math Gear(s) 3D Printable Learning Aid FREE DOWNLOAD! — Works By Solo Gear Design Math Gear design by agma theory: The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The life of gear depends on multiple factors such as lubrication, manufacturing. Gear dimensions are determined in accordance with their specifications, such as module (m), number. Gear Design Math.

From www.artofit.org

Calculation of gear dimensions Artofit Gear Design Math Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. Gear design by agma theory: 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. They can maximize power and efficiency. Gear Design Math.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Design Math They can maximize power and efficiency and are based on. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The life of gear depends on multiple factors such as lubrication, manufacturing. Gear design by agma theory: Gear dimensions are determined in accordance with their specifications, such as module. Gear Design Math.

From animalia-life.club

Gears Specific Examples Gear Design Math Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gear ratios are a core science behind almost every machine in the modern era. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the previous pages, we introduced the basics of gears, including. Gear Design Math.

From www.youtube.com

solidworks tutorial internal gears design and assembly YouTube Gear Design Math The life of gear depends on multiple factors such as lubrication, manufacturing. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. They can maximize power and efficiency and are based on. (inch units applicable for constants) spur gear. Gear dimensions are determined in accordance with their specifications, such. Gear Design Math.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Gear Design Math They can maximize power and efficiency and are based on. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear. Gear Design Math.

From www.scribd.com

Gear Mathematics For Bevel & Hypoid Gears PDF Gear Kinematics Gear Design Math Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. (inch units applicable for constants) spur gear. They can maximize power and efficiency and are based on. Gear design. Gear Design Math.

From dpoksystems.weebly.com

Worm gear design calculation pdf to excel dpoksystems Gear Design Math They can maximize power and efficiency and are based on. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. The life of gear depends on multiple factors such as lubrication, manufacturing. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gear design by agma. Gear Design Math.

From vectormine.com

Gear ratio vector illustration VectorMine Gear Design Math Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gear design by agma theory: They can maximize power and efficiency and are based on. The life of gear depends on multiple factors such as lubrication, manufacturing. Gear ratios are a core science behind almost every machine in the modern era. Gear dimensions are determined in. Gear Design Math.

From pinshape.com

3D Printed Math Gear(s)Enhanced by Works By Solo Pinshape Gear Design Math 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Learn the basics. Gear Design Math.

From www.youtube.com

Design Of Helical Gear with Equation in SolidWorks YouTube Gear Design Math 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. They can maximize power and efficiency and are based on.. Gear Design Math.

From www.worksbysolo.com

Math Gear(s) 3D Printable Learning Aid FREE DOWNLOAD! — Works By Solo Gear Design Math The life of gear depends on multiple factors such as lubrication, manufacturing. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gear ratios are a core science behind almost every machine in the modern. Gear Design Math.

From www.dreamstime.com

Visual Mechanics or Math Puzzle with Rotating Gears Stock Vector Gear Design Math In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. Gear design by agma theory: The life of gear depends on multiple factors such as lubrication, manufacturing. Gear dimensions are determined in accordance with their. Gear Design Math.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Design Math The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. (inch units applicable for constants) spur gear. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. 40 rows spur gear. Gear Design Math.

From www.pinterest.com

1892 Technical Drawing Gears Antique Math Geometric Mechanical Gear Design Math The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. They can maximize power and efficiency and are based on. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear dimensions are determined in accordance with their specifications, such as module (m), number of. Gear Design Math.

From www.pinterest.com.mx

How to Determine Gear Ratio Mechanical engineering design, Gears Gear Design Math The life of gear depends on multiple factors such as lubrication, manufacturing. Gear design by agma theory: Gear ratios are a core science behind almost every machine in the modern era. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The diametral pitch is 2, and the addendum. Gear Design Math.

From pinshape.com

3D Printed Math Gear(s) by Works By Solo Pinshape Gear Design Math The life of gear depends on multiple factors such as lubrication, manufacturing. (inch units applicable for constants) spur gear. Gear design by agma theory: Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The diametral. Gear Design Math.

From www.youtube.com

Tutorial How to Derive the Formula for the Mechanism Gear Gear Design Math They can maximize power and efficiency and are based on. Gear design by agma theory: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gear ratios are a core science behind almost every machine in the modern era. In the previous pages, we introduced the basics of gears, including. Gear Design Math.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes Gear Design Math Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. They can maximize power and efficiency and are based on. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. (inch units applicable for constants) spur gear. Gear design. Gear Design Math.

From www.youtube.com

Mechanical Design (Part 2 Gear Overview) YouTube Gear Design Math They can maximize power and efficiency and are based on. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gear ratios are a core science behind almost every machine in the modern era. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gear design. Gear Design Math.

From khkgears.net

Know about parameters that determine gear shapes KHK Gear Design Math Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The diametral pitch is 2, and the addendum and dedendum are. Gear Design Math.

From 3d-mds-academy.com

Gear Fundamentals 3DMDS Academy Gear Design Math Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear design by agma theory: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In the previous pages, we introduced. Gear Design Math.

From www.cgtrader.com

Math Gears free 3D model 3D printable CGTrader Gear Design Math Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The life of gear depends on multiple factors such as lubrication, manufacturing. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear. They can maximize power and efficiency. Gear Design Math.

From www.pinterest.com

Math Gears Addition available at Gaming Gear Design Math Gear design by agma theory: Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. They can maximize power and efficiency. Gear Design Math.

From www.comsol.com

Understanding the Different Elements of Gear Modeling COMSOL Blog Gear Design Math (inch units applicable for constants) spur gear. Gear ratios are a core science behind almost every machine in the modern era. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. They can maximize power and efficiency and are based on. Gear dimensions are determined in accordance with their specifications, such as module (m), number of. Gear Design Math.

From www.mymathtables.com

Simple Machines Engineering Formulas Gear Design Math 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gear ratios are a core science behind almost every machine in the modern era. They can maximize power and efficiency and are based on. Learn. Gear Design Math.

From www.worksbysolo.com

Math Gear(s) 3D Printable Learning Aid FREE DOWNLOAD! — Works By Solo Gear Design Math They can maximize power and efficiency and are based on. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. (inch units applicable for constants) spur gear. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,.. Gear Design Math.

From www.pinterest.com

Engineering World on Instagram “Gear ratio 😮 ️💥🔩🛠⚙️ Tag someone to see Gear Design Math In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. They can maximize power and efficiency and are based on. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data.. Gear Design Math.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks YouTube Gear Design Math Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The diametral pitch is 2, and the addendum and dedendum are 1/p and 1.25/p,. The life of gear depends. Gear Design Math.