Overlay Measurement Semiconductor . Overlay and alignment function takes place in the lithography scanner. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Total variation as measured line 1. In simple terms, overlay is accomplished by adjusting both the wafer stage. Why we care about measurement systems analysis (msa) which process has less variability? The systems deliver superior measurement performance with overlay and cd. In addition to defect inspection, directed self. Overlay is one of the most critical process control steps of semiconductor manufacturing technology.

from www.eumetrys.com

Total variation as measured line 1. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In simple terms, overlay is accomplished by adjusting both the wafer stage. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. In addition to defect inspection, directed self. The systems deliver superior measurement performance with overlay and cd. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Overlay and alignment function takes place in the lithography scanner. Why we care about measurement systems analysis (msa) which process has less variability?

Automated CD & Overlay measurement EUMETRYS

Overlay Measurement Semiconductor The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Overlay and alignment function takes place in the lithography scanner. Total variation as measured line 1. In addition to defect inspection, directed self. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. The systems deliver superior measurement performance with overlay and cd. In simple terms, overlay is accomplished by adjusting both the wafer stage. Why we care about measurement systems analysis (msa) which process has less variability?

From www.researchgate.net

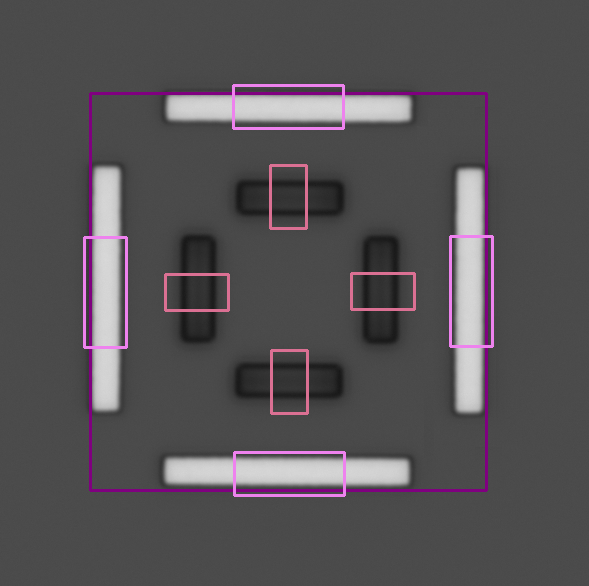

(a) Top, 3D, and crosssectional view of the OCD model and the overlay Overlay Measurement Semiconductor Overlay and alignment function takes place in the lithography scanner. Total variation as measured line 1. In simple terms, overlay is accomplished by adjusting both the wafer stage. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Why we care about measurement systems analysis (msa) which process. Overlay Measurement Semiconductor.

From advancedspectral.com

CD Overlay & Metrology Systems for Semiconductor and MEMs AST Overlay Measurement Semiconductor Lithography’s metrology challenges include defectivity, overlay, and template inspection. In addition to defect inspection, directed self. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Why we care about measurement systems analysis (msa) which process has less variability? Overlay is one of the most critical process control. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304913 PCB Y5304912 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor Total variation as measured line 1. In simple terms, overlay is accomplished by adjusting both the wafer stage. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Why we care about measurement systems analysis (msa) which process has less variability? Overlay and alignment function takes place in the lithography scanner. The systems deliver superior measurement. Overlay Measurement Semiconductor.

From www.eumetrys.com

Automated CD & Overlay measurement EUMETRYS Overlay Measurement Semiconductor In addition to defect inspection, directed self. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Why we care about measurement systems analysis (msa) which process has less variability? The systems deliver superior measurement performance with overlay and cd. Total variation as measured line 1. In simple terms, overlay is accomplished by adjusting both the. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304913 PCB Y5304912 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Why we care about measurement systems analysis (msa) which process has less variability? Total variation as measured line 1. In addition to defect inspection, directed self. Lithography’s metrology challenges include defectivity, overlay, and template inspection. In simple terms,. Overlay Measurement Semiconductor.

From eureka.patsnap.com

Overlay measurement method and system in integrated circuit chip Overlay Measurement Semiconductor Overlay and alignment function takes place in the lithography scanner. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Total variation as measured line 1. The systems deliver superior measurement performance with overlay and cd. In simple terms, overlay is accomplished by adjusting both the wafer stage.. Overlay Measurement Semiconductor.

From www.eumetrys.com

Automated CD & Overlay measurement EUMETRYS Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. Overlay and alignment function takes place in the lithography scanner. In addition to defect inspection, directed self. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Why we care about measurement systems analysis (msa) which process has less variability? Total variation as measured line 1. Overlay is one of the. Overlay Measurement Semiconductor.

From www.eumetrys.com

Optical metrology system for CD and overlay measurement EUMETRYS Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Total variation as measured line 1. In addition to defect inspection, directed self. In. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304913 PCB Y5304912 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. In simple terms, overlay is accomplished by adjusting both the wafer stage. Overlay and alignment function takes place in the lithography scanner. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Why we care about measurement systems analysis (msa) which process has less variability? Total variation as measured line 1.. Overlay Measurement Semiconductor.

From www.zeiss.com

High precision overlay and registration metrology for the semiconductor Overlay Measurement Semiconductor In addition to defect inspection, directed self. In simple terms, overlay is accomplished by adjusting both the wafer stage. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Total variation as measured line 1. Why we care about measurement systems analysis (msa) which process has less. Overlay Measurement Semiconductor.

From www.spiedigitallibrary.org

Review of scanning electron microscopebased overlay measurement beyond Overlay Measurement Semiconductor The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In simple terms, overlay is accomplished by adjusting both the wafer stage. The systems deliver superior measurement performance with overlay and cd. In addition to defect inspection, directed self. Why we care about measurement systems analysis (msa) which. Overlay Measurement Semiconductor.

From spie.org

Nanoimprint lithography and nanodefect management for semiconductor Overlay Measurement Semiconductor Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Lithography’s metrology challenges include defectivity, overlay, and template inspection. In simple terms, overlay is accomplished by adjusting both the wafer stage. Why we care about measurement systems analysis (msa) which process has less variability? Total variation as measured line 1. The systems deliver superior measurement performance. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304913 PCB Y5304912 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. In addition to defect inspection, directed self. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Total variation as measured line 1. Overlay and alignment function takes place in the lithography scanner. The ivs series provides. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304913 PCB Y5304912 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor Overlay and alignment function takes place in the lithography scanner. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. In addition to defect inspection, directed self. The systems deliver superior measurement performance with overlay and cd. In simple terms, overlay is accomplished by adjusting both the wafer stage. Why we care about measurement systems analysis. Overlay Measurement Semiconductor.

From www.spiedigitallibrary.org

Review of scanning electron microscopebased overlay measurement beyond Overlay Measurement Semiconductor Lithography’s metrology challenges include defectivity, overlay, and template inspection. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Why we care about measurement systems analysis (msa) which process has less variability? Total variation. Overlay Measurement Semiconductor.

From sst.semiconductor-digest.com

Patterned wafer geometry grouping for improved overlay control Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In addition to defect inspection, directed self. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Total variation as measured line 1. In. Overlay Measurement Semiconductor.

From www.spiedigitallibrary.org

Review of scanning electron microscopebased overlay measurement beyond Overlay Measurement Semiconductor In simple terms, overlay is accomplished by adjusting both the wafer stage. Total variation as measured line 1. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In addition to defect inspection, directed self. Overlay and alignment function takes place in the lithography scanner. Overlay is one. Overlay Measurement Semiconductor.

From semiconductorspares.com

Nikon 300mm Wafer Inspection Stage Chuck NRM3100 Overlay Measurement Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. Total variation as measured line 1. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Why we care about measurement systems analysis (msa) which process has less variability? In addition to defect inspection, directed self. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. The. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304911 PCB Y5304910 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor Why we care about measurement systems analysis (msa) which process has less variability? The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In addition to defect inspection, directed self. Lithography’s metrology challenges include defectivity, overlay, and template inspection. The systems deliver superior measurement performance with overlay and. Overlay Measurement Semiconductor.

From www.toray-eng.com

Overlay measurement system "OM7000H" Optical Semiconductor Wafer Overlay Measurement Semiconductor In simple terms, overlay is accomplished by adjusting both the wafer stage. The systems deliver superior measurement performance with overlay and cd. In addition to defect inspection, directed self. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Total variation as measured line 1. Lithography’s metrology challenges include defectivity, overlay, and template inspection. The ivs. Overlay Measurement Semiconductor.

From www.spiedigitallibrary.org

Review of scanning electron microscopebased overlay measurement beyond Overlay Measurement Semiconductor Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Lithography’s metrology challenges include defectivity, overlay, and template inspection. In simple terms, overlay is accomplished by adjusting both the wafer stage. Total variation as measured line 1. Overlay and alignment function takes place in the lithography scanner. The ivs series provides optical overlay and cd metrology. Overlay Measurement Semiconductor.

From spie.org

For semiconductor manufacture, pattern alignment requires subnanometer Overlay Measurement Semiconductor Overlay is one of the most critical process control steps of semiconductor manufacturing technology. In addition to defect inspection, directed self. The systems deliver superior measurement performance with overlay and cd. Lithography’s metrology challenges include defectivity, overlay, and template inspection. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced. Overlay Measurement Semiconductor.

From sst.semiconductor-digest.com

Patterned wafer geometry grouping for improved overlay control Overlay Measurement Semiconductor Overlay and alignment function takes place in the lithography scanner. Total variation as measured line 1. In simple terms, overlay is accomplished by adjusting both the wafer stage. The systems deliver superior measurement performance with overlay and cd. Why we care about measurement systems analysis (msa) which process has less variability? In addition to defect inspection, directed self. Overlay is. Overlay Measurement Semiconductor.

From www.spiedigitallibrary.org

Review of scanning electron microscopebased overlay measurement beyond Overlay Measurement Semiconductor The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. Overlay and alignment function takes place in the lithography scanner. Lithography’s metrology challenges include defectivity, overlay, and template inspection. In addition to defect inspection,. Overlay Measurement Semiconductor.

From www.jos.ac.cn

Selection of DBO measurement wavelength for bottom mark asymmetry based Overlay Measurement Semiconductor The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Overlay and alignment function takes place in the lithography scanner. In addition to defect inspection, directed self. Total variation as measured line 1. Lithography’s metrology challenges include defectivity, overlay, and template inspection. The systems deliver superior measurement performance. Overlay Measurement Semiconductor.

From www.eetimes.com

Overlay Metrology Challenges for Advanced Memory ICs EE Times Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. In addition to defect inspection, directed self. Why we care about measurement systems analysis (msa) which process has less variability? The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Overlay is one of the most critical process. Overlay Measurement Semiconductor.

From www.google.com.au

Patent US7582538 Method of overlay measurement for alignment of Overlay Measurement Semiconductor The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. The systems deliver superior measurement performance with overlay and cd. Overlay and alignment function takes place in the lithography scanner. Overlay is one of the most critical process control steps of semiconductor manufacturing technology. In simple terms, overlay. Overlay Measurement Semiconductor.

From www.spiedigitallibrary.org

Review of scanning electron microscopebased overlay measurement beyond Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. Overlay and alignment function takes place in the lithography scanner. In simple terms, overlay is accomplished by adjusting both the wafer stage. Lithography’s metrology challenges include defectivity, overlay, and template inspection. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304911 PCB Y5304910 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor Lithography’s metrology challenges include defectivity, overlay, and template inspection. The systems deliver superior measurement performance with overlay and cd. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In simple terms, overlay is accomplished by adjusting both the wafer stage. Overlay and alignment function takes place in. Overlay Measurement Semiconductor.

From www.semanticscholar.org

A Semiconductor Photolithography Overlay Analysis System Using Image Overlay Measurement Semiconductor Overlay is one of the most critical process control steps of semiconductor manufacturing technology. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. Overlay and alignment function takes place in the lithography scanner. In addition to defect inspection, directed self. Why we care about measurement systems analysis. Overlay Measurement Semiconductor.

From www.sec.gov

Addressing challenge 1 OverlayHow to position lines with 2 nm Overlay Measurement Semiconductor Overlay and alignment function takes place in the lithography scanner. The systems deliver superior measurement performance with overlay and cd. Why we care about measurement systems analysis (msa) which process has less variability? In addition to defect inspection, directed self. In simple terms, overlay is accomplished by adjusting both the wafer stage. The ivs series provides optical overlay and cd. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304911 PCB Y5304910 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor Overlay is one of the most critical process control steps of semiconductor manufacturing technology. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In simple terms, overlay is accomplished by adjusting both the wafer stage. Lithography’s metrology challenges include defectivity, overlay, and template inspection. Total variation as. Overlay Measurement Semiconductor.

From www.layla-ec.com

1000000091_144484806394 NRM3100 300mm Wafer Overlay Measurement System Overlay Measurement Semiconductor In addition to defect inspection, directed self. The systems deliver superior measurement performance with overlay and cd. Why we care about measurement systems analysis (msa) which process has less variability? Overlay is one of the most critical process control steps of semiconductor manufacturing technology. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf,. Overlay Measurement Semiconductor.

From www.spiedigitallibrary.org

Techniques for improving overlay accuracy by using device correlated Overlay Measurement Semiconductor The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In simple terms, overlay is accomplished by adjusting both the wafer stage. Why we care about measurement systems analysis (msa) which process has less variability? Total variation as measured line 1. Overlay is one of the most critical. Overlay Measurement Semiconductor.

From semiconductorspares.com

BioRad Y5304913 PCB Y5304912 Quaestor Q7 Overlay Measurement System W Overlay Measurement Semiconductor The systems deliver superior measurement performance with overlay and cd. Total variation as measured line 1. In addition to defect inspection, directed self. The ivs series provides optical overlay and cd metrology for the compound semi, power device, rf, mems, led and advanced packaging markets. In simple terms, overlay is accomplished by adjusting both the wafer stage. Overlay and alignment. Overlay Measurement Semiconductor.