Non Flux Core Welding Wire . flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. That’s because the wire core. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. In terms of flexibility and. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. The flux inside the wire melts during welding and protects the weld pool from air and contamination. This type of wire has a hollow center filled with flux.

from weldguru.com

That’s because the wire core. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. In terms of flexibility and. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. The flux inside the wire melts during welding and protects the weld pool from air and contamination. This type of wire has a hollow center filled with flux.

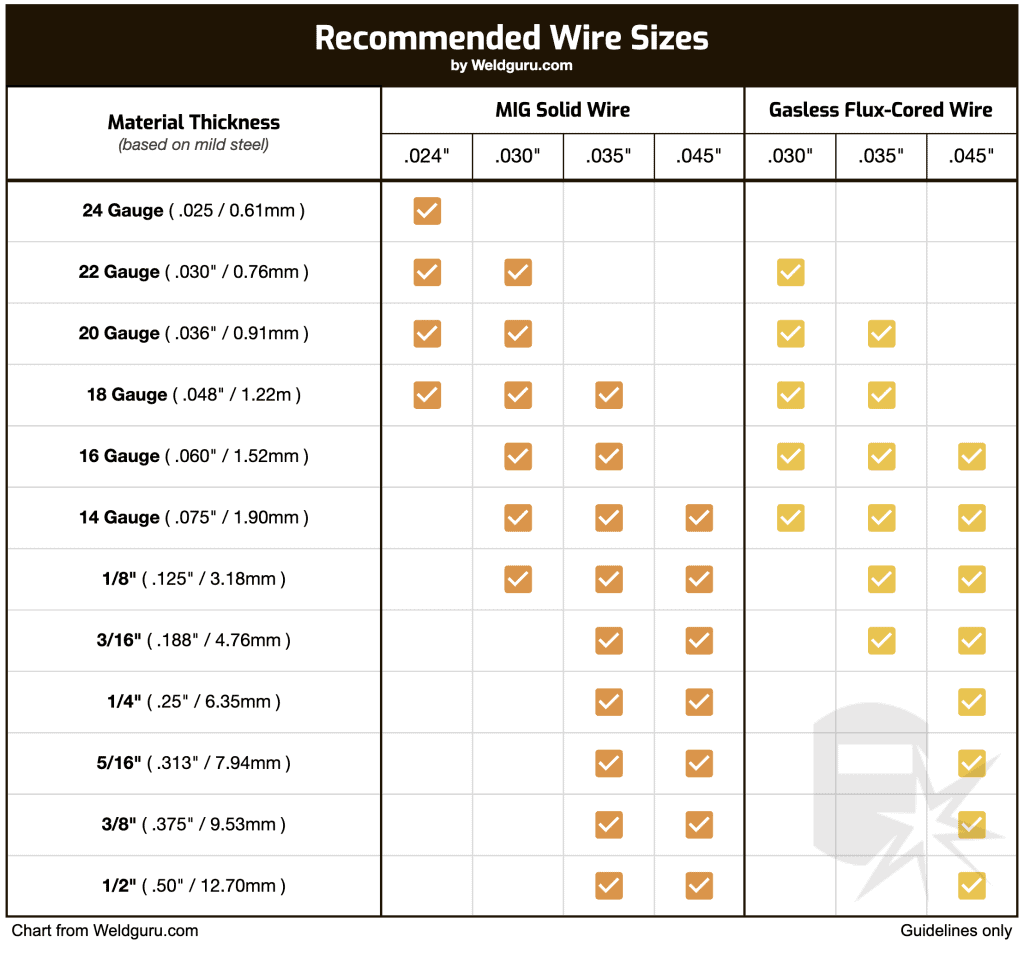

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Non Flux Core Welding Wire Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. That’s because the wire core. In terms of flexibility and. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. This type of wire has a hollow center filled with flux. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. The flux inside the wire melts during welding and protects the weld pool from air and contamination. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma.

From www.lazada.com.ph

POWERHOUSE Stainless Steel Self Shielding Flux Cored Wire Cable for MIG Non Flux Core Welding Wire The flux inside the wire melts during welding and protects the weld pool from air and contamination. This type of wire has a hollow center filled with flux. In terms of flexibility and. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. the aws specification aws a5.18 covers. Non Flux Core Welding Wire.

From en.nst.no

Non alloyed flux cored wires NST Norsk Sveiseteknikk Non Flux Core Welding Wire Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. This type of wire has a hollow center filled with flux. That’s because the wire core. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire.. Non Flux Core Welding Wire.

From georgemacdonald.z19.web.core.windows.net

Flux Core Wire Vs Solid Wire Non Flux Core Welding Wire the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. This type of wire has a hollow center filled with flux. flux core wire. Non Flux Core Welding Wire.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Non Flux Core Welding Wire The flux inside the wire melts during welding and protects the weld pool from air and contamination. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. That’s because the wire core. Using “cored” wire allows a mig welder to skip the tank of co2 or. Non Flux Core Welding Wire.

From mwwiretec.com

FLUX CORED WELDING WIRES MW WIRETEC PRIVATE LIMITED Non Flux Core Welding Wire Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. The flux inside the wire melts during welding and protects the weld pool from air and contamination. That’s because the wire core. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel. Non Flux Core Welding Wire.

From www.amazon.co.uk

Amazon.co.uk Flux Core Welding Wire Non Flux Core Welding Wire solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. Using “cored” wire allows a mig welder to skip the tank of co2 or argon. Non Flux Core Welding Wire.

From www.aliexpress.com

0.5KG Spool MIG Gasless Fluxes Core Welding Wire Nongas Soldering Rods Non Flux Core Welding Wire flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. In terms of flexibility and. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. This type of wire has a hollow center filled with flux.. Non Flux Core Welding Wire.

From beginnerweldingguide.com

MIG + Flux Core Welding Wire Size Chart Beginner Welding Guide Non Flux Core Welding Wire The flux inside the wire melts during welding and protects the weld pool from air and contamination. This type of wire has a hollow center filled with flux. That’s because the wire core. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. solid wire and cored wire are. Non Flux Core Welding Wire.

From www.tianqiaowelding.com

News Basic knowledge of flux cored wire arc welding Non Flux Core Welding Wire That’s because the wire core. This type of wire has a hollow center filled with flux. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. flux core wire. Non Flux Core Welding Wire.

From www.farinaweldtec.com

0.8mm 0.9mm A5.20 AWS E71T11 Gasless Flux Cored Welding Wire high quality Non Flux Core Welding Wire Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. The flux inside the wire melts during welding and protects the weld pool from air and contamination. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core. Non Flux Core Welding Wire.

From www.aliexpress.com

1KGSpoolMIGGaslessFluxesCoreWeldingWireNongasSolderingRods Non Flux Core Welding Wire This type of wire has a hollow center filled with flux. The flux inside the wire melts during welding and protects the weld pool from air and contamination. That’s because the wire core. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. solid wire and cored wire are. Non Flux Core Welding Wire.

From wearplatesupplier.en.made-in-china.com

Cost Efficient Abrasion Resistant Layer Overlay Welding Wire Flux Core Non Flux Core Welding Wire This type of wire has a hollow center filled with flux. The flux inside the wire melts during welding and protects the weld pool from air and contamination. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. In terms of flexibility and. Using “cored” wire allows a mig welder. Non Flux Core Welding Wire.

From www.ebay.com

Clarke Mild Steel Mig Welding Wire 0.9mm (Flux Cored No Gas 0.45kg Non Flux Core Welding Wire the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. flux core wire typically has a higher deposition rate than solid wire, which means. Non Flux Core Welding Wire.

From www.weldingcity.com

WeldingCity® E71TGS 2lb 0.030" Gasless Fluxcored MIG Welding Wire 4 Non Flux Core Welding Wire flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. This type of wire has a hollow center filled with flux. The flux inside the wire melts during welding and protects the weld pool from air and contamination. Using “cored” wire allows a mig welder to. Non Flux Core Welding Wire.

From www.northerntool.com

Hobart FluxCored Welding Wire — E71T11 Carbon Steel, .030in., 2Lb Non Flux Core Welding Wire That’s because the wire core. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. The flux inside the wire melts during welding and protects the weld pool from air and contamination. In terms of flexibility and. flux core wire typically has a higher. Non Flux Core Welding Wire.

From dxocnvbsq.blob.core.windows.net

How To Weld Wire Without Welder at Christine Lopez blog Non Flux Core Welding Wire the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. Using “cored” wire allows a mig welder to skip the tank. Non Flux Core Welding Wire.

From bahamas.desertcart.com

Buy Metal Universal Welding Wire 1.6mma, Flux Core Welding Wire Non Flux Core Welding Wire That’s because the wire core. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. The flux inside the wire melts during welding and protects the weld pool from air. Non Flux Core Welding Wire.

From samdex.eu

Low Alloy FluxCored Wires SAMDEX Non Flux Core Welding Wire That’s because the wire core. The flux inside the wire melts during welding and protects the weld pool from air and contamination. In terms of flexibility and. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. Using “cored” wire allows a mig welder to skip the tank of co2. Non Flux Core Welding Wire.

From www.shantimetal.com

Benefits of Using Flux Core Welding Wire in Various Industries Non Flux Core Welding Wire In terms of flexibility and. That’s because the wire core. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. the aws specification aws a5.18. Non Flux Core Welding Wire.

From www.electronicsandyou.com

Cored Solder Wire Rosin Flux Cored Solder Wire Non Flux Core Welding Wire That’s because the wire core. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. In terms of flexibility and. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. the aws specification aws a5.18. Non Flux Core Welding Wire.

From www.harborfreight.com

0.030 in. E71TGS Flux Core Welding Wire, 2.00 lbs. Roll Non Flux Core Welding Wire This type of wire has a hollow center filled with flux. In terms of flexibility and. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. the aws specification. Non Flux Core Welding Wire.

From royalweldingwires.com

Order Flux Cored Wires JACKSUN E71T 1C Royal Welding Wires Non Flux Core Welding Wire solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. The flux inside the wire melts during welding and protects the weld pool from air and contamination. In terms of flexibility and. This type of wire has a hollow center filled with flux. the aws specification aws a5.18 covers. Non Flux Core Welding Wire.

From www.lazada.com.ph

0.5KG Spool MIG Gasless Fluxes Core Welding Wire Nongas Soldering Rods Non Flux Core Welding Wire The flux inside the wire melts during welding and protects the weld pool from air and contamination. In terms of flexibility and. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. This type of wire has a hollow center filled with flux. the aws specification aws a5.18 covers. Non Flux Core Welding Wire.

From www.indiamart.com

1.2MM MS Flux Cored Welding Wire, Thickness 1.2 mm, Grade 71T1 at Rs Non Flux Core Welding Wire Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. That’s because the wire core. In terms of flexibility and. This type of wire has a hollow center filled with flux. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages. Non Flux Core Welding Wire.

From wespec.net

Flux Cored Welding Wire Manufacturing from A to Z by WESPEC Non Flux Core Welding Wire the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. The flux inside the wire melts during welding and protects the weld pool from air. Non Flux Core Welding Wire.

From www.farinaweldtec.com

AWS E71T1 FARINA flux cored welding wire 1kg Non Flux Core Welding Wire the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. That’s because the wire core. solid wire and cored wire. Non Flux Core Welding Wire.

From www.youtube.com

Flux Core vs. Solid Wire and Gas Shield MIG Welding Comparison YouTube Non Flux Core Welding Wire In terms of flexibility and. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. This type of wire has a hollow center filled with flux. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and. Non Flux Core Welding Wire.

From www.ganpatind.com

Find the Best Flux Cored Wire for Your Welding Applications Non Flux Core Welding Wire The flux inside the wire melts during welding and protects the weld pool from air and contamination. solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core. Non Flux Core Welding Wire.

From hunanxunzhuo.en.made-in-china.com

NonGas Welding Wire E71tGS Gasless Flux Cored Wire Dia. 030 Inch 2Lb Non Flux Core Welding Wire Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. The flux inside the wire melts during welding and protects the weld pool from air and contamination. In terms of flexibility and. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel. Non Flux Core Welding Wire.

From www.royalarc.in

All You Need to Know About Flux Cored Wires Different Types and Non Flux Core Welding Wire This type of wire has a hollow center filled with flux. The flux inside the wire melts during welding and protects the weld pool from air and contamination. flux core wire typically has a higher deposition rate than solid wire, which means that you can weld faster with flux core wire. Using “cored” wire allows a mig welder to. Non Flux Core Welding Wire.

From www.harborfreight.com

0.030 in. E71TGS Flux Core Welding Wire, 10.00 lb. Roll Non Flux Core Welding Wire Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. flux core wire typically has a higher deposition rate than solid wire, which means. Non Flux Core Welding Wire.

From www.vlr.eng.br

MIG Flux Core Welding Wire Types Specification (with Chart) Weld Guru Non Flux Core Welding Wire This type of wire has a hollow center filled with flux. the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. solid wire and. Non Flux Core Welding Wire.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Non Flux Core Welding Wire the aws specification aws a5.18 covers both solid, composite stranded and cored wires comprising six carbon steel filler metals for mag, tig and plasma. The flux inside the wire melts during welding and protects the weld pool from air and contamination. flux core wire typically has a higher deposition rate than solid wire, which means that you can. Non Flux Core Welding Wire.

From vi.aliexpress.com

MIGGaslessFluxesCoreWeldingWireNongasSolderingRodsE71TGS0 Non Flux Core Welding Wire solid wire and cored wire are two popular options used in welding applications, each with its distinct advantages and. In terms of flexibility and. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. This type of wire has a hollow center filled with flux. That’s because the wire. Non Flux Core Welding Wire.

From www.tsawelding.co.za

Hardfacing Flux Cored MIG Wire 60HRC 1.2mm (15Kg Spool) — TSA Welding Non Flux Core Welding Wire In terms of flexibility and. This type of wire has a hollow center filled with flux. Using “cored” wire allows a mig welder to skip the tank of co2 or argon and weld without the gas. The flux inside the wire melts during welding and protects the weld pool from air and contamination. That’s because the wire core. flux. Non Flux Core Welding Wire.