Coupling Size Calculation . 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Select correct service factor (s.f.) from the chart below. Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Other factors to consider are. Coupling selection procedure | complete guide to coupling sizing calculation | all. St series safety couplings are designed to decouple machine.

from www.myxxgirl.com

The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Other factors to consider are. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Select correct service factor (s.f.) from the chart below. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. St series safety couplings are designed to decouple machine. Coupling selection procedure | complete guide to coupling sizing calculation | all. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque.

3000 Coupling Dimensions My XXX Hot Girl

Coupling Size Calculation Select correct service factor (s.f.) from the chart below. Other factors to consider are. St series safety couplings are designed to decouple machine. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Select correct service factor (s.f.) from the chart below. Coupling selection procedure | complete guide to coupling sizing calculation | all. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque.

From www.myxxgirl.com

3000 Coupling Dimensions My XXX Hot Girl Coupling Size Calculation The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Coupling selection procedure | complete guide to coupling sizing calculation | all. Other factors to. Coupling Size Calculation.

From www.mpjainco.com

ASME B16.11 Threaded Reducing Coupling Manufacturers, Stainless Steel Coupling Size Calculation One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. Select correct service factor (s.f.) from the chart below. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. 48 rows perform calculations according. Coupling Size Calculation.

From mungfali.com

Rotex Spider Coupling Size Chart Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. St series safety couplings are designed to decouple machine. 48 rows perform calculations according to. Coupling Size Calculation.

From www.coupling.pl

ISO72411B 40 size G1 1/2'' quick coupling Coupling Size Calculation Coupling selection procedure | complete guide to coupling sizing calculation | all. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Shaft couplings are used for power and torque transmission. Coupling Size Calculation.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Size Calculation 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Select correct service factor (s.f.) from the chart below. Other factors to consider are. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Shaft couplings are. Coupling Size Calculation.

From www.amtcorp.cn

Universal Coupling Coupling Size Calculation Other factors to consider are. St series safety couplings are designed to decouple machine. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Coupling selection procedure. Coupling Size Calculation.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. 48 rows perform calculations according to the following design procedure in order to select the proper shaft. Coupling Size Calculation.

From www.flexiblecouplingchina.com

F Type Tyre Rubber CouplingFlexible Coupling Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Select correct service factor (s.f.) from the chart below. Other factors to consider. Coupling Size Calculation.

From mavink.com

Coupling Dimensions Chart Coupling Size Calculation The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Other factors to consider are. St series safety couplings are designed to decouple machine. 48. Coupling Size Calculation.

From www.brighthubengineering.com

What are Bibby Couplings? Coupling Size Calculation The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Other factors to consider are. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. Coupling selection procedure | complete guide to coupling sizing calculation |. Coupling Size Calculation.

From www.myxxgirl.com

Coupling Dimensions Chart My XXX Hot Girl Coupling Size Calculation 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Coupling selection procedure | complete guide to coupling sizing calculation | all. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Select correct service factor (s.f.). Coupling Size Calculation.

From ponasa.clinica180grados.es

Spider Coupling Size Chart Ponasa Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. St series safety couplings are designed to decouple machine. Other factors to consider. Coupling Size Calculation.

From www.drivecomponentsllc.com

Tire Couplings Drive Components Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. St series safety couplings are designed to decouple machine. Select correct service factor (s.f.) from the chart below. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength. Coupling Size Calculation.

From williammrodden.github.io

Lovejoy Coupling Size Chart Coupling Size Calculation Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Coupling selection procedure | complete guide to coupling sizing calculation | all. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. Shaft couplings. Coupling Size Calculation.

From design.udlvirtual.edu.pe

Pipe Coupling Size Chart Pdf Design Talk Coupling Size Calculation St series safety couplings are designed to decouple machine. Other factors to consider are. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and. Coupling Size Calculation.

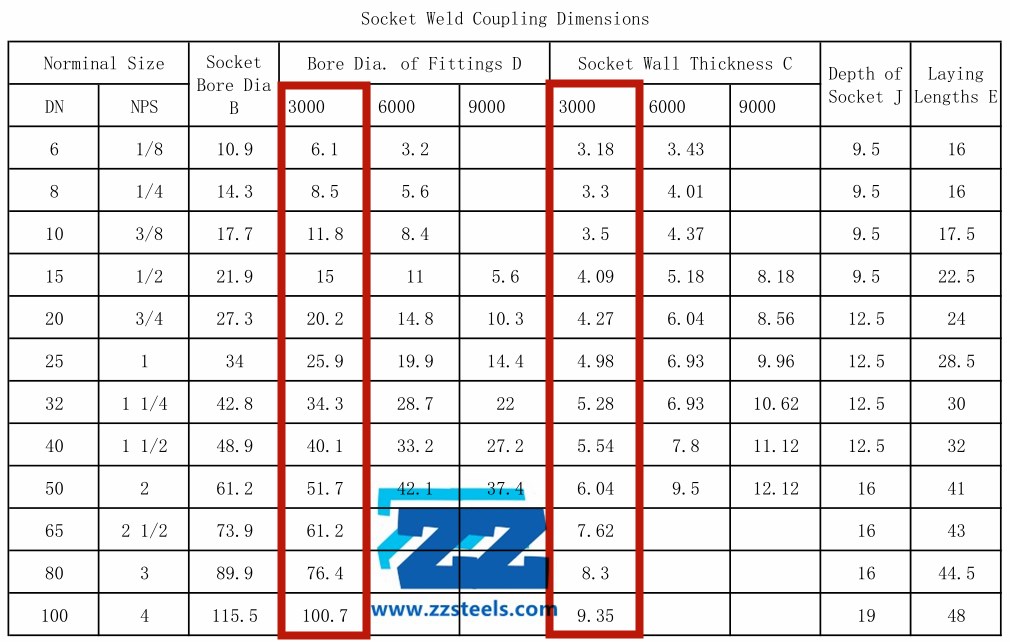

From hardhatengineer.com

Pipe Coupling Dimensions Socket Weld & Threaded Couplings Coupling Size Calculation One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Other factors to consider are. The coupling must be sized so that, typically, the stress does not exceed 10 percent of. Coupling Size Calculation.

From www.youtube.com

jaw coupling size calculation YouTube Coupling Size Calculation Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Select correct service factor (s.f.) from the chart below. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Other factors to. Coupling Size Calculation.

From blog.thepipingmart.com

What Does Coupling Mean? Various Coupling Types ThePipingMart Blog Coupling Size Calculation 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. St series safety couplings are designed to decouple machine. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. Select correct service factor (s.f.) from the chart below. Coupling selection procedure. Coupling Size Calculation.

From www.truongquoctesaigon.edu.vn

PVC Pipe Fittings Sizes And Dimensions Guide (Diagrams And Charts Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. St series safety couplings are designed to decouple machine. Coupling selection procedure | complete guide to coupling. Coupling Size Calculation.

From mechanicaljungle.com

What Is a Coupling? How Does a Shaft Coupling Work? Types of Shaft Coupling Size Calculation Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Coupling selection procedure | complete guide to coupling sizing calculation | all. One. Coupling Size Calculation.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Other factors to consider are. Coupling selection procedure | complete guide to coupling sizing calculation. Coupling Size Calculation.

From www.yekhwa.com

SCoupling Coupling Size Calculation The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Select correct service factor (s.f.) from the chart below. Based on the calculation for horsepower (hp) indicated in equation. Coupling Size Calculation.

From dokumen.tips

(DOCX) Tyre Couplings DOKUMEN.TIPS Coupling Size Calculation One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Other factors to consider are. Shaft couplings are used for power and torque transmission. Coupling Size Calculation.

From mungfali.com

NPT Coupling Size Chart Coupling Size Calculation The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Other factors to consider are. One key component of sizing and selecting nearly every coupling is calculating the nominal. Coupling Size Calculation.

From www.sl-sprockets.com

Rubber Couplings SHEY LEE Sprockets Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Other factors to consider are. Coupling selection procedure | complete guide to coupling sizing calculation | all. Select correct service factor (s.f.) from the chart below. One key component of sizing and selecting nearly every coupling is calculating. Coupling Size Calculation.

From www.exportersindia.com

industrial gear coupling at Best Price in Kolkata ID 201990 SHRI Coupling Size Calculation Select correct service factor (s.f.) from the chart below. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Other factors to consider are. Coupling selection. Coupling Size Calculation.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Size Calculation The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Select correct service factor (s.f.) from the chart below. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Based on the calculation for horsepower (hp) indicated in equation. Coupling Size Calculation.

From www.researchgate.net

Flow chart of heat transfer coupling calculation. Download Scientific Coupling Size Calculation Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. One key component of sizing and selecting nearly every coupling is calculating. Coupling Size Calculation.

From www.youtube.com

Flexible Gear Coupling Gap in mm How Much Gap Should Be Kept in Gear Coupling Size Calculation Shaft couplings are used for power and torque transmission between two rotating shafts such as on motors and pumps, compressors, and generators. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. The coupling must be sized so that, typically, the stress does not exceed. Coupling Size Calculation.

From srmaterial.com

Coupling & Coupling Stock Sunrise Materials Ltd. Coupling Size Calculation Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Select correct service factor (s.f.) from the chart below. One key component. Coupling Size Calculation.

From www.zzsteels.com

Threaded Coupling 3/4” BSPP Class 3000 Stainless Steel 316L ZIZI Coupling Size Calculation Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. One key component of sizing and selecting nearly every coupling is calculating the nominal torque as well as the design torque. Shaft couplings are used for power and torque transmission between two rotating shafts such. Coupling Size Calculation.

From www.appliedalloys.com.au

Full Coupling pdf Applied Alloys International Coupling Size Calculation Coupling selection procedure | complete guide to coupling sizing calculation | all. Other factors to consider are. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Based on. Coupling Size Calculation.

From www.bvchains.com

Gear couplings,Gear Coupling Manufacturer,India Coupling Size Calculation St series safety couplings are designed to decouple machine. 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on hp, torque and shaft speed. Shaft couplings are used for power and torque. Coupling Size Calculation.

From www.new-line.com

DIN Imperial Couplings Size Chart Coupling Size Calculation 48 rows perform calculations according to the following design procedure in order to select the proper shaft coupling. St series safety couplings are designed to decouple machine. Coupling selection procedure | complete guide to coupling sizing calculation | all. Other factors to consider are. Shaft couplings are used for power and torque transmission between two rotating shafts such as on. Coupling Size Calculation.

From www.youtube.com

Gear Coupling size Calculation How to find Gear Coupling Size Gear Coupling Size Calculation Other factors to consider are. Coupling selection procedure | complete guide to coupling sizing calculation | all. The coupling must be sized so that, typically, the stress does not exceed 10 percent of the ultimate tensile strength of the material. Based on the calculation for horsepower (hp) indicated in equation 1, the proper sizing of couplings is highly dependent on. Coupling Size Calculation.