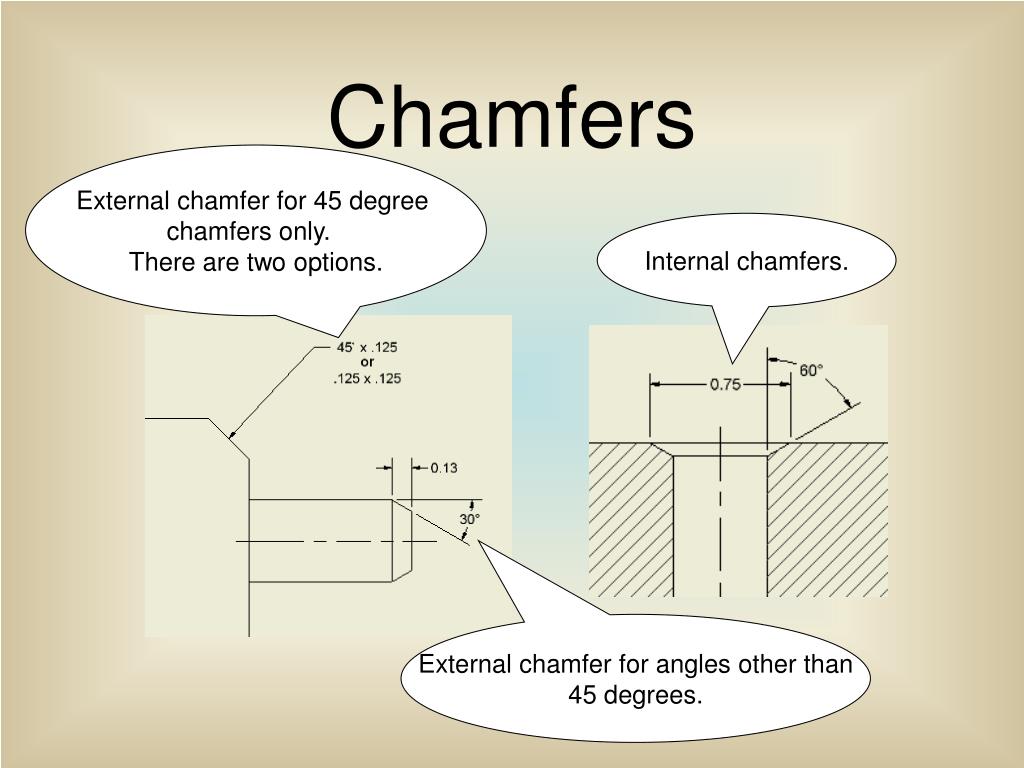

How To Calculate A 45 Degree Chamfer . Mastering the creation of chamfers is. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. Part with a chamfered edge. In the picture of a triangle below,. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Chamfer width = side length / √2. If the chamfer width is 5 mm. It is an essential tool for. For example, your 1.500 chamfer. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770.

from www.slideserve.com

In the picture of a triangle below,. Part with a chamfered edge. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. If the chamfer width is 5 mm. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. Chamfer width = side length / √2. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. For example, your 1.500 chamfer.

PPT Dimensioning Standards PowerPoint Presentation, free download

How To Calculate A 45 Degree Chamfer Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. It is an essential tool for. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. Mastering the creation of chamfers is. If the chamfer width is 5 mm. In the picture of a triangle below,. Chamfer width = side length / √2. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. Part with a chamfered edge. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. For example, your 1.500 chamfer. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle.

From www.cutwel.co.uk

45 Degree Indexable Chamfer Multi Mill CEC45 Series (Korloy) Cutwel How To Calculate A 45 Degree Chamfer Chamfer width = side length / √2. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. If the chamfer width is 5 mm. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. Part with a chamfered edge. Converting between leg length and face width can. How To Calculate A 45 Degree Chamfer.

From www.youtube.com

How to Make a 45 Degree Chamfer Tool for a Lathe, The Old School Way How To Calculate A 45 Degree Chamfer If the chamfer width is 5 mm. Part with a chamfered edge. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. Chamfer width = side length / √2. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfer angle. How To Calculate A 45 Degree Chamfer.

From calculatorshub.net

45 Degree Chamfer Calculator Online How To Calculate A 45 Degree Chamfer Mastering the creation of chamfers is. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. If the chamfer width is 5 mm. Chamfers can be dimensioned in two ways, either by. How To Calculate A 45 Degree Chamfer.

From exokfmiaq.blob.core.windows.net

How To Use Chamfer Router Bit at Jennifer Spicer blog How To Calculate A 45 Degree Chamfer Part with a chamfered edge. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. The length of the “c” side represents the face width of the chamfer and is measured. How To Calculate A 45 Degree Chamfer.

From www.youtube.com

Lathe set up to cut 30 Degree chamfer or 60 degree included angle YouTube How To Calculate A 45 Degree Chamfer Part with a chamfered edge. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. Chamfer width = side length / √2. For example, your 1.500 chamfer. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. If the. How To Calculate A 45 Degree Chamfer.

From eziil.com

Chamfering 101 Types, Dimensions & Callout How To Calculate A 45 Degree Chamfer If the chamfer width is 5 mm. It is an essential tool for. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Chamfer angle (a) is the angle between the chamfer surface and the. How To Calculate A 45 Degree Chamfer.

From microfabricator.com

EASY GUIDE TO CHAMFER MILLS, CUTTERS & ROUTER BITS [ FEEDS/SPEEDS, AND How To Calculate A 45 Degree Chamfer It is an essential tool for. If the chamfer width is 5 mm. In the picture of a triangle below,. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfer angle (a) is the. How To Calculate A 45 Degree Chamfer.

From werk24.io

Symbols used in Technical Drawings How To Calculate A 45 Degree Chamfer If the chamfer width is 5 mm. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. In the picture of a triangle below,. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part. How To Calculate A 45 Degree Chamfer.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. How To Calculate A 45 Degree Chamfer For example, your 1.500 chamfer. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. Chamfer width = side length / √2. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. The length of the “c” side represents the face width of the chamfer and is. How To Calculate A 45 Degree Chamfer.

From www.metalworkingfun.com

MetalworkingFun Forum Dovetail and Chamfer Measurement How To Calculate A 45 Degree Chamfer Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Mastering the creation of chamfers is. Part with a chamfered edge. In the picture of a triangle below,. Chamfer angle (a) is. How To Calculate A 45 Degree Chamfer.

From www.routertooling.co.uk

Chamfer TCT 45° x 41mm x 1/2 Shank F How To Calculate A 45 Degree Chamfer In the picture of a triangle below,. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. It is an essential tool for. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. If the chamfer width is 5 mm.. How To Calculate A 45 Degree Chamfer.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics How To Calculate A 45 Degree Chamfer In the picture of a triangle below,. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. For example, your 1.500 chamfer. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Chamfer width = side length /. How To Calculate A 45 Degree Chamfer.

From www.youtube.com

I'd में angle में chamfer कैसे लगाए how to calculate chamfer angle How To Calculate A 45 Degree Chamfer Part with a chamfered edge. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Chamfer width = side length / √2. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. If the chamfer width is 5 mm.. How To Calculate A 45 Degree Chamfer.

From www.kitplanes.com

Chamfers and Tapers KITPLANES How To Calculate A 45 Degree Chamfer Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Chamfer width = side length / √2. It is an essential tool for. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. Converting between leg length and face width can be done by. How To Calculate A 45 Degree Chamfer.

From www.youtube.com

How to cut chamfer with G01 code How to calculate chamfer coordinate How To Calculate A 45 Degree Chamfer Part with a chamfered edge. Chamfer width = side length / √2. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Mastering the creation of chamfers is. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain. How To Calculate A 45 Degree Chamfer.

From gbwonggbwong.wixsite.com

0090// Chamfer Dimensioning How To Calculate A 45 Degree Chamfer Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. For example, your 1.500 chamfer. If the chamfer width is 5 mm. It is an essential tool for.. How To Calculate A 45 Degree Chamfer.

From exoblwevx.blob.core.windows.net

How To Make Chamfer Degree at Vera Pope blog How To Calculate A 45 Degree Chamfer It is an essential tool for. Part with a chamfered edge. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Mastering the creation of chamfers is. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. If the chamfer width is. How To Calculate A 45 Degree Chamfer.

From www.slideserve.com

PPT Dimensioning Standards PowerPoint Presentation, free download How To Calculate A 45 Degree Chamfer Part with a chamfered edge. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. If the chamfer width is. How To Calculate A 45 Degree Chamfer.

From www.youtube.com

Mastercam Tip Chamfer any angle with a 45° Chamfering Tool YouTube How To Calculate A 45 Degree Chamfer The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. Part with a chamfered edge. Chamfer width = side length / √2. Mastering the creation of chamfers is. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. The most common way to spec a. How To Calculate A 45 Degree Chamfer.

From rsvautomotive.co.uk

chamfering Tool makes It a Workhorse Facing New Lathe 45 Degree Turning How To Calculate A 45 Degree Chamfer The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. It is an essential tool for. Chamfer width = side length / √2. The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. Chamfers are a key feature in machining, essential for. How To Calculate A 45 Degree Chamfer.

From ubicaciondepersonas.cdmx.gob.mx

45 Degree Chamfer Cutter ubicaciondepersonas.cdmx.gob.mx How To Calculate A 45 Degree Chamfer Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. It is an essential tool for. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfer width = side length / √2. The most common way to spec a chamfer is by giving its leg length size and the. How To Calculate A 45 Degree Chamfer.

From www.youtube.com

cnc programming how to make chamfer program chamfer with angle How To Calculate A 45 Degree Chamfer If the chamfer width is 5 mm. Part with a chamfered edge. Chamfer width = side length / √2. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. Chamfers are a key feature. How To Calculate A 45 Degree Chamfer.

From www.researchgate.net

Cutting edge chamfer. Chamfer width w, and chamfer angle γ Download How To Calculate A 45 Degree Chamfer The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. It is an essential tool for. If the chamfer width is 5 mm. For example, your 1.500 chamfer. Part with a chamfered edge. Chamfer width = side length / √2. The most common way to spec a chamfer is by giving. How To Calculate A 45 Degree Chamfer.

From www.cncknowledge.in

CNC KNOWLEDGE How To Calculate A 45 Degree Chamfer Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. For example, your 1.500 chamfer. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. Part with a chamfered edge. If the chamfer width is 5 mm. Chamfers can be. How To Calculate A 45 Degree Chamfer.

From klaatucee.blob.core.windows.net

What Is A Chamfer Hole at McBride blog How To Calculate A 45 Degree Chamfer If the chamfer width is 5 mm. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Mastering the creation of chamfers is. Take the diameter of the required chamfer, subtract the. How To Calculate A 45 Degree Chamfer.

From fyokrsvnz.blob.core.windows.net

What Is The Point Of A Chamfer at Julia Owens blog How To Calculate A 45 Degree Chamfer Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. The length of the “c” side represents the face width of the chamfer and is measured along the. How To Calculate A 45 Degree Chamfer.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria How To Calculate A 45 Degree Chamfer Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. If the chamfer width is 5 mm. For example, your 1.500 chamfer. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. The length of the “c” side represents the face width of the. How To Calculate A 45 Degree Chamfer.

From www.youtube.com

कोई भी Angle में Chamfer का Value ऐसे निकालें how to calculate 30 How To Calculate A 45 Degree Chamfer Mastering the creation of chamfers is. Chamfer angle (a) is the angle between the chamfer surface and the adjacent surface. The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the. How To Calculate A 45 Degree Chamfer.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. How To Calculate A 45 Degree Chamfer Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. If the chamfer width is 5 mm. In the picture of a triangle below,. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. The most common way to spec a. How To Calculate A 45 Degree Chamfer.

From uquid.com

BEYOND TCM 45 Degree Chamfering Cutter Milling 12 16 20 25mm C1620110 How To Calculate A 45 Degree Chamfer The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Chamfer width = side length / √2. Take the diameter of the required chamfer, subtract the hole size, divide. How To Calculate A 45 Degree Chamfer.

From forums.autodesk.com

35 degrees chamfer with 45 degrees chamfer mill Autodesk Community How To Calculate A 45 Degree Chamfer The most common way to spec a chamfer is by giving its leg length size and the chamfer angle. It is an essential tool for. Mastering the creation of chamfers is. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. For example, your 1.500 chamfer. Chamfer width. How To Calculate A 45 Degree Chamfer.

From www.alibaba.com

45 Degree Chamfering Mill Indexable End Mill Cnc Carbide Face Milling How To Calculate A 45 Degree Chamfer The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Part with a chamfered edge. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain. How To Calculate A 45 Degree Chamfer.

From vibadirect.com

Dimension Guidelines ViBaDirect How To Calculate A 45 Degree Chamfer In the picture of a triangle below,. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the face width. If the chamfer width is 5 mm. Take the diameter of the required chamfer, subtract the hole size, divide by 2, then divide by.8770. For example, your 1.500 chamfer. The. How To Calculate A 45 Degree Chamfer.

From ubicaciondepersonas.cdmx.gob.mx

45 Degree Chamfer Cutter ubicaciondepersonas.cdmx.gob.mx How To Calculate A 45 Degree Chamfer The length of the “c” side represents the face width of the chamfer and is measured along the hypotenuse. In the picture of a triangle below,. Part with a chamfered edge. Mastering the creation of chamfers is. It is an essential tool for. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfers. How To Calculate A 45 Degree Chamfer.

From ubicaciondepersonas.cdmx.gob.mx

45 Degree Chamfer Cutter ubicaciondepersonas.cdmx.gob.mx How To Calculate A 45 Degree Chamfer Mastering the creation of chamfers is. It is an essential tool for. For example, your 1.500 chamfer. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Converting between leg length and face width can be done by multiplying the leg length value by 1.414 to obtain the. How To Calculate A 45 Degree Chamfer.