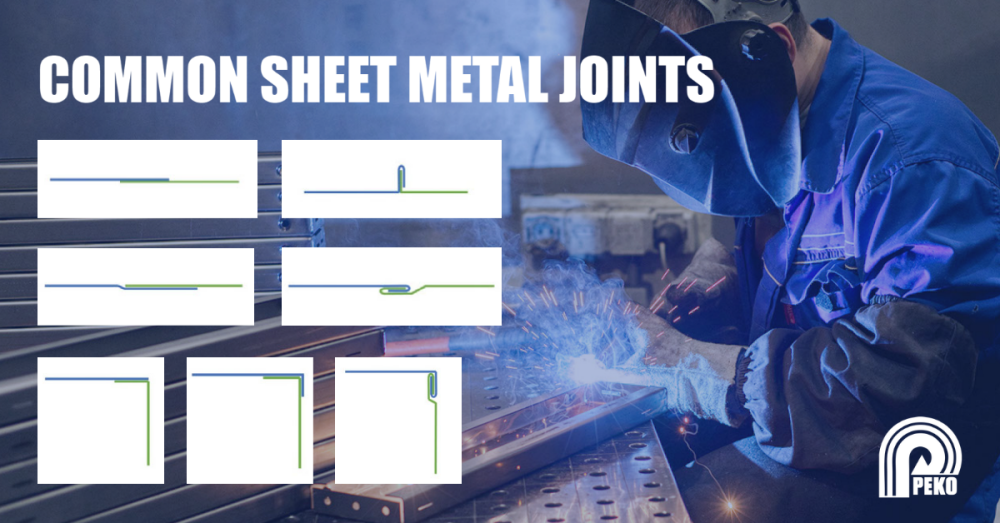

Types Of Sheet Metal Joining Process . Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Forming a lap joint involves overlapping two edges in a specific manner. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. If you call out a.

from www.pekoprecision.com

To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. If you call out a. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Forming a lap joint involves overlapping two edges in a specific manner.

Sheet Metal Joints & Seams 5 Types Used in Welded Fabrications

Types Of Sheet Metal Joining Process Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Forming a lap joint involves overlapping two edges in a specific manner. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. If you call out a. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material.

From animalia-life.club

Metal Joining Process Types Of Sheet Metal Joining Process To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Forming a lap joint involves overlapping two edges in a specific manner. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry.. Types Of Sheet Metal Joining Process.

From 2-men-tech.blogspot.com

Methods of joining metals Types Of Sheet Metal Joining Process Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. If you call out a. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Sheet metal joining methods include both temporary. Types Of Sheet Metal Joining Process.

From fractory.com

Sheet Metal Hemming Hem Types & Processes Explained Fractory Types Of Sheet Metal Joining Process Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. To determine the best. Types Of Sheet Metal Joining Process.

From mepacademy.com

Sheet Metal Joints MEP Academy Types Of Sheet Metal Joining Process Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Forming a lap joint involves overlapping two edges in a specific manner. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. If you. Types Of Sheet Metal Joining Process.

From animalia-life.club

Metal Joining Process Types Of Sheet Metal Joining Process Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Forming a lap joint involves overlapping two edges in a specific manner.. Types Of Sheet Metal Joining Process.

From www.vrogue.co

Types Of Metal Joining Methods Telescopic Tube vrogue.co Types Of Sheet Metal Joining Process Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Sheet metal joining methods. Types Of Sheet Metal Joining Process.

From www.youtube.com

Metal Joining Processes Welding, Riveting, Bolting, Brazing, Soldering Types Of Sheet Metal Joining Process Forming a lap joint involves overlapping two edges in a specific manner. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry.. Types Of Sheet Metal Joining Process.

From www.cdn-inc.com

Sheet Metal Process Ultimate Guide 2019 w/ Cost Examples Types Of Sheet Metal Joining Process Forming a lap joint involves overlapping two edges in a specific manner. If you call out a. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material. Types Of Sheet Metal Joining Process.

From blog.thepipingmart.com

Metal Joining Processes An Overview Types Of Sheet Metal Joining Process Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. If you call out a. Forming a lap joint involves overlapping two edges in a specific manner. Sheet metal joining methods include. Types Of Sheet Metal Joining Process.

From www.researchgate.net

(PDF) Sheet metal joining process selector Types Of Sheet Metal Joining Process Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. If you call out a. Metal sheets are cut into specific shapes. Types Of Sheet Metal Joining Process.

From www.youtube.com

18 types of bending operations in sheet metal Sheet metal bending Types Of Sheet Metal Joining Process Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. If you call out a. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Metal sheets are cut into specific shapes using techniques. Types Of Sheet Metal Joining Process.

From www.scribd.com

Different Types of Metal Joining Welding Chemistry Types Of Sheet Metal Joining Process To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. If you call out a. Forming a lap joint involves overlapping two. Types Of Sheet Metal Joining Process.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Types Of Sheet Metal Joining Process Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Today we will look at 5 common types of fabricated sheet metal. Types Of Sheet Metal Joining Process.

From www.youtube.com

What are Joining Processes (metalworking)? YouTube Types Of Sheet Metal Joining Process Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Sheet metal joining methods include both temporary and permanent solutions as well as those. Types Of Sheet Metal Joining Process.

From in.pinterest.com

Different Types of Sheet Metal Operations [Explained] Sheet metal Types Of Sheet Metal Joining Process Forming a lap joint involves overlapping two edges in a specific manner. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. If you call out a. To determine the best weld. Types Of Sheet Metal Joining Process.

From www.tbkmetal.com

7 Best Common Types Of Sheet Metal Joints (Sheet Metal Joining Techniques) Types Of Sheet Metal Joining Process Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Forming a lap joint involves overlapping two edges in a specific manner. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Today we. Types Of Sheet Metal Joining Process.

From animalia-life.club

Metal Joining Process Types Of Sheet Metal Joining Process Forming a lap joint involves overlapping two edges in a specific manner. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness.. Types Of Sheet Metal Joining Process.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Types Of Sheet Metal Joining Process Forming a lap joint involves overlapping two edges in a specific manner. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Sheet metal joining is an essential process in the fabrication. Types Of Sheet Metal Joining Process.

From blog.thepipingmart.com

What is Bolting in Metal Joining? Types Of Sheet Metal Joining Process Forming a lap joint involves overlapping two edges in a specific manner. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Sheet metal joining is an essential process in the fabrication. Types Of Sheet Metal Joining Process.

From www.researchgate.net

Schematics of the joining process. Download Scientific Diagram Types Of Sheet Metal Joining Process Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. If you call out a. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet. Types Of Sheet Metal Joining Process.

From www.smlease.com

How to Join Sheet metal Parts ? SMLease Design Types Of Sheet Metal Joining Process Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. If you call out a. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional. Types Of Sheet Metal Joining Process.

From artizono.com

Sheet Metal Joining Techniques A Comprehensive Guide Artizono Types Of Sheet Metal Joining Process To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Sheet metal joining methods include both temporary and permanent solutions as well as those. Types Of Sheet Metal Joining Process.

From www.machinemfg.com

Sheet Metal Forming Processes and Equipment MachineMfg Types Of Sheet Metal Joining Process Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Forming a. Types Of Sheet Metal Joining Process.

From www.machinemfg.com

Sheet Metal Joining Process The Ultimate Guide MachineMFG Types Of Sheet Metal Joining Process Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. If you call out a. Forming a lap joint involves overlapping two edges in a specific manner. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Sheet metal joining is an. Types Of Sheet Metal Joining Process.

From www.hardwareinterviews.fyi

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI Types Of Sheet Metal Joining Process If you call out a. Forming a lap joint involves overlapping two edges in a specific manner. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. To determine the. Types Of Sheet Metal Joining Process.

From www.slideshare.net

Metal Joining Process Types Of Sheet Metal Joining Process Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. If you call out a. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional. Types Of Sheet Metal Joining Process.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Types Of Sheet Metal Joining Process If you call out a. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Forming a lap joint involves overlapping two edges in. Types Of Sheet Metal Joining Process.

From eziil.com

Basics of Metal Forming Process An Ultimate Guide Types Of Sheet Metal Joining Process If you call out a. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and. Types Of Sheet Metal Joining Process.

From www.tbkmetal.com

7 Best Common Types Of Sheet Metal Joints (Sheet Metal Joining Techniques) Types Of Sheet Metal Joining Process Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. Forming a lap joint involves overlapping two edges in a specific manner. If you call out a. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. To determine the best weld for a. Types Of Sheet Metal Joining Process.

From www.studypool.com

SOLUTION Chapter 4 metal joining processes Studypool Types Of Sheet Metal Joining Process Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. Forming a lap joint involves overlapping two edges in a specific manner. If you call out a. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Sheet metal joining. Types Of Sheet Metal Joining Process.

From animalia-life.club

Metal Joining Process Types Of Sheet Metal Joining Process Forming a lap joint involves overlapping two edges in a specific manner. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. If you call out a. Today we will look at 5 common types of fabricated sheet metal joints that are. Types Of Sheet Metal Joining Process.

From www.tbkmetal.com

7 Best Common Types Of Sheet Metal Joints (Sheet Metal Joining Techniques) Types Of Sheet Metal Joining Process To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Forming a lap joint involves overlapping two edges in a specific manner. If you call out a. Sheet metal joining is an essential process in the fabrication of various products and structures. Types Of Sheet Metal Joining Process.

From www.intechopen.com

Figure 1. Types Of Sheet Metal Joining Process Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre. To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. If you call out a. Forming a lap joint involves overlapping two. Types Of Sheet Metal Joining Process.

From www.pekoprecision.com

Sheet Metal Joints & Seams 5 Types Used in Welded Fabrications Types Of Sheet Metal Joining Process Sheet metal joining is an essential process in the fabrication of various products and structures using sheet material. If you call out a. Forming a lap joint involves overlapping two edges in a specific manner. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. To determine the best weld. Types Of Sheet Metal Joining Process.

From www.mepskills.com

TYPES OF METAL JOINING METHODS Types Of Sheet Metal Joining Process To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness. Metal sheets are cut into specific shapes using techniques like shearing, plasma cutting, laser cutting, or waterjet cutting. Forming a lap joint involves overlapping two edges in a specific manner. Sheet metal. Types Of Sheet Metal Joining Process.