Rover K Series Head Bolt Torque Sequence . 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to.

from mungfali.com

yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts)

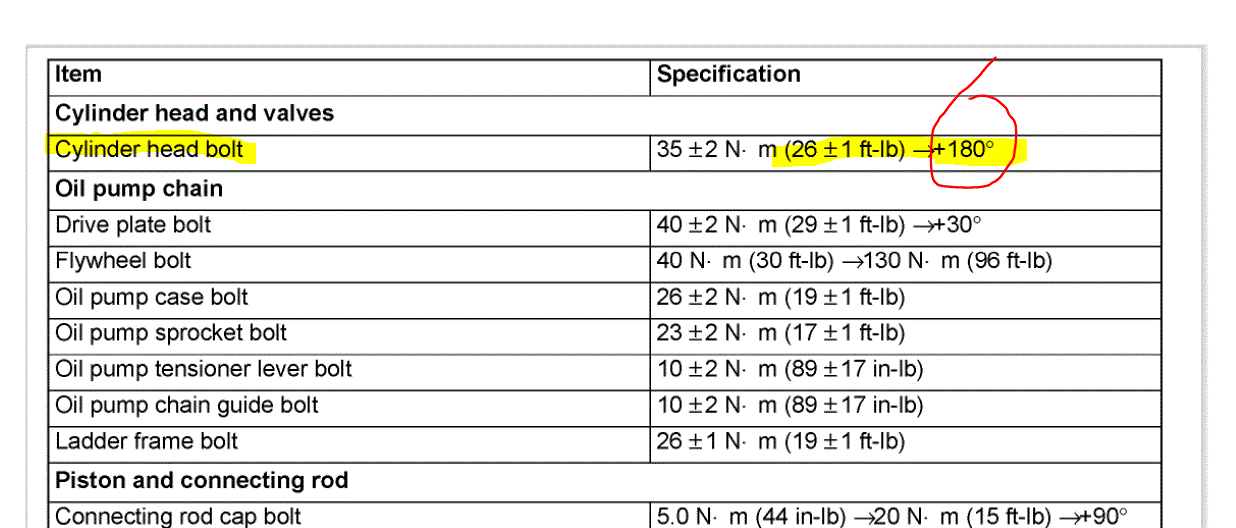

Cylinder Head Bolt Torque Chart

Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same.

From www.2carpros.com

Head Bolt Torque Specs and Sequence? Looking for Torque Specs and... Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. the procedure is to turn them thru an. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolt Torque and Sequence Head Bolt Sequence Diagram Honda Rover K Series Head Bolt Torque Sequence for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. yep, so on the standard or mls with shim it's torque to 20nm. Rover K Series Head Bolt Torque Sequence.

From www.mgexp.com

Head bolt torque sequence? MGB & GT Forum The MG Experience Rover K Series Head Bolt Torque Sequence page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all. Rover K Series Head Bolt Torque Sequence.

From www.redmansenginecentre.co.uk

Rover K Series Head Bolts Redmans Engine Centre Ltd Rover K Series Head Bolt Torque Sequence page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts). Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolts Torque Sequence? My Haynes Manual Says to Tighten the Rover K Series Head Bolt Torque Sequence page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. 39nm (29ft/lbs), 90 deg +. Rover K Series Head Bolt Torque Sequence.

From www.youtube.com

How to torque up a rover/mg k series cylinder head YouTube Rover K Series Head Bolt Torque Sequence yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. for those of you that've replaced your own. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolts Torque Sequence? My Haynes Manual Says to Tighten the Rover K Series Head Bolt Torque Sequence the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a. Rover K Series Head Bolt Torque Sequence.

From www.redmansenginecentre.co.uk

Rover K Series Head Bolts Redmans Engine Centre Ltd Rover K Series Head Bolt Torque Sequence the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. tighten all of. Rover K Series Head Bolt Torque Sequence.

From exolauhcd.blob.core.windows.net

Bbc Chevy Head Bolt Torque Sequence at Arthur William blog Rover K Series Head Bolt Torque Sequence for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) the procedure is. Rover K Series Head Bolt Torque Sequence.

From mungfali.com

Cylinder Head Torque Sequence Rover K Series Head Bolt Torque Sequence bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. the procedure is to turn them thru an. Rover K Series Head Bolt Torque Sequence.

From dxozuxypj.blob.core.windows.net

What Is The Torque On Cylinder Head Bolts at John Clark blog Rover K Series Head Bolt Torque Sequence for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. yep, so on the standard or mls with. Rover K Series Head Bolt Torque Sequence.

From www.eliseparts.com

Head Bolt Socket K Series EliseParts Rover K Series Head Bolt Torque Sequence the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. yep, so on. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolts Torque Specs I Need to Know How Much Headboltstorque... Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Torque Specs Head Torque Specs and Sequence for Car Listed Rover K Series Head Bolt Torque Sequence page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts). Rover K Series Head Bolt Torque Sequence.

From help.summitracing.com

How do I install my Gen 3 Hemi Cylinder Heads? · Help Center Rover K Series Head Bolt Torque Sequence 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. for those of. Rover K Series Head Bolt Torque Sequence.

From americanprime.com.br

Torque Spec And Sequence For The Head Bolts, 58 OFF Rover K Series Head Bolt Torque Sequence the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) tighten all of the head bolts to. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Torque Spec and Sequence for the Head Bolts Rover K Series Head Bolt Torque Sequence 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. page 19 engine k series 1.8 vvc. Rover K Series Head Bolt Torque Sequence.

From forums.mg-rover.org

HGF Advice kseries Forums Rover K Series Head Bolt Torque Sequence 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. bolts such as the head bolts and. Rover K Series Head Bolt Torque Sequence.

From mavink.com

Cylinder Head Bolt Torque Chart Rover K Series Head Bolt Torque Sequence for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. yep, so on the standard or mls with shim it's torque to 20nm. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolt Torque Head Bolt Torque Specifications and Sequence Rover K Series Head Bolt Torque Sequence page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. for those of you that've replaced your own head gaskets on the subject. Rover K Series Head Bolt Torque Sequence.

From mungfali.com

Cylinder Head Bolt Torque Chart Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. for those of you that've replaced your own head gaskets on the subject engine (na or sc. Rover K Series Head Bolt Torque Sequence.

From wehelpcheapessaydownload.web.fc2.com

What is the best way to torque head bolts correctly Rover K Series Head Bolt Torque Sequence 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. bolts such as. Rover K Series Head Bolt Torque Sequence.

From www.redmansenginecentre.co.uk

Rover K Series Head Bolts Redmans Engine Centre Ltd Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. page 19 engine k series 1.8 vvc. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Torque Sequence for Head Bolts Needed Need to Know the Torque Rover K Series Head Bolt Torque Sequence bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. yep, so on the standard or mls with. Rover K Series Head Bolt Torque Sequence.

From mavink.com

30 Bolt Torque Sequence Rover K Series Head Bolt Torque Sequence the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. . Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolt Torque Specs and Sequence? Looking for Torque Specs and... Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. . Rover K Series Head Bolt Torque Sequence.

From www.youtube.com

How to Torque Cylinder Head Bolts, basic cylinder head torque sequence Rover K Series Head Bolt Torque Sequence for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. the procedure is. Rover K Series Head Bolt Torque Sequence.

From mavink.com

Cylinder Head Bolt Torque Chart Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. yep, so on the standard or mls with shim it's torque to 20nm. Rover K Series Head Bolt Torque Sequence.

From exooogrew.blob.core.windows.net

Head Bolt Torque Spec at Jose Vara blog Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. bolts such as the head bolts and big end bolts are given an. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolt Torque Specs and Sequence? Looking for Torque Specs and... Rover K Series Head Bolt Torque Sequence tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. 39nm. Rover K Series Head Bolt Torque Sequence.

From exolauhcd.blob.core.windows.net

Bbc Chevy Head Bolt Torque Sequence at Arthur William blog Rover K Series Head Bolt Torque Sequence for those of you that've replaced your own head gaskets on the subject engine (na or sc is the same. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. bolts such as the head bolts and big end bolts are given an initial torque to settle. Rover K Series Head Bolt Torque Sequence.

From www.redmansenginecentre.co.uk

Rover K Series Head Bolts Redmans Engine Centre Ltd Rover K Series Head Bolt Torque Sequence the procedure is to turn them thru an angle which stretches them angle/360 times thread pitch. 39nm (29ft/lbs), 90 deg + 90 deg (one extra 90 deg on new bolts) bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Torque Sequence for Head Bolts Needed Need to Know the Torque Rover K Series Head Bolt Torque Sequence page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. tighten all of the head bolts to 20nm, using the numbered sequence provided above ^^ once all are tightened to. the procedure is to turn them thru an angle which stretches them angle/360. Rover K Series Head Bolt Torque Sequence.

From www.2carpros.com

Head Bolts Torque Sequence? My Haynes Manual Says to Tighten the Rover K Series Head Bolt Torque Sequence bolts such as the head bolts and big end bolts are given an initial torque to settle the joint into a starting position and are then tightened using an. yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. for those of you that've replaced your own. Rover K Series Head Bolt Torque Sequence.

From mavink.com

Cylinder Head Bolt Torque Chart Rover K Series Head Bolt Torque Sequence yep, so on the standard or mls with shim it's torque to 20nm in the correct tightening sequence, then 180. page 19 engine k series 1.8 vvc figure 16 • place a strip of plastigage across each inlet camshaft journal, then carefully fit the. tighten all of the head bolts to 20nm, using the numbered sequence provided. Rover K Series Head Bolt Torque Sequence.