Pressure Vacuum Decay . 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. Pressure or partial pressure) • liquid presence near or in a leak path. The process is uncomplicated, relatively inexpensive and easily. The method can be used to identify gross defects and. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. In this method, the component is evacuated (subjected to a. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines.

from sanatron.com

Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. In this method, the component is evacuated (subjected to a. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. The method can be used to identify gross defects and. The process is uncomplicated, relatively inexpensive and easily. Pressure or partial pressure) • liquid presence near or in a leak path. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part.

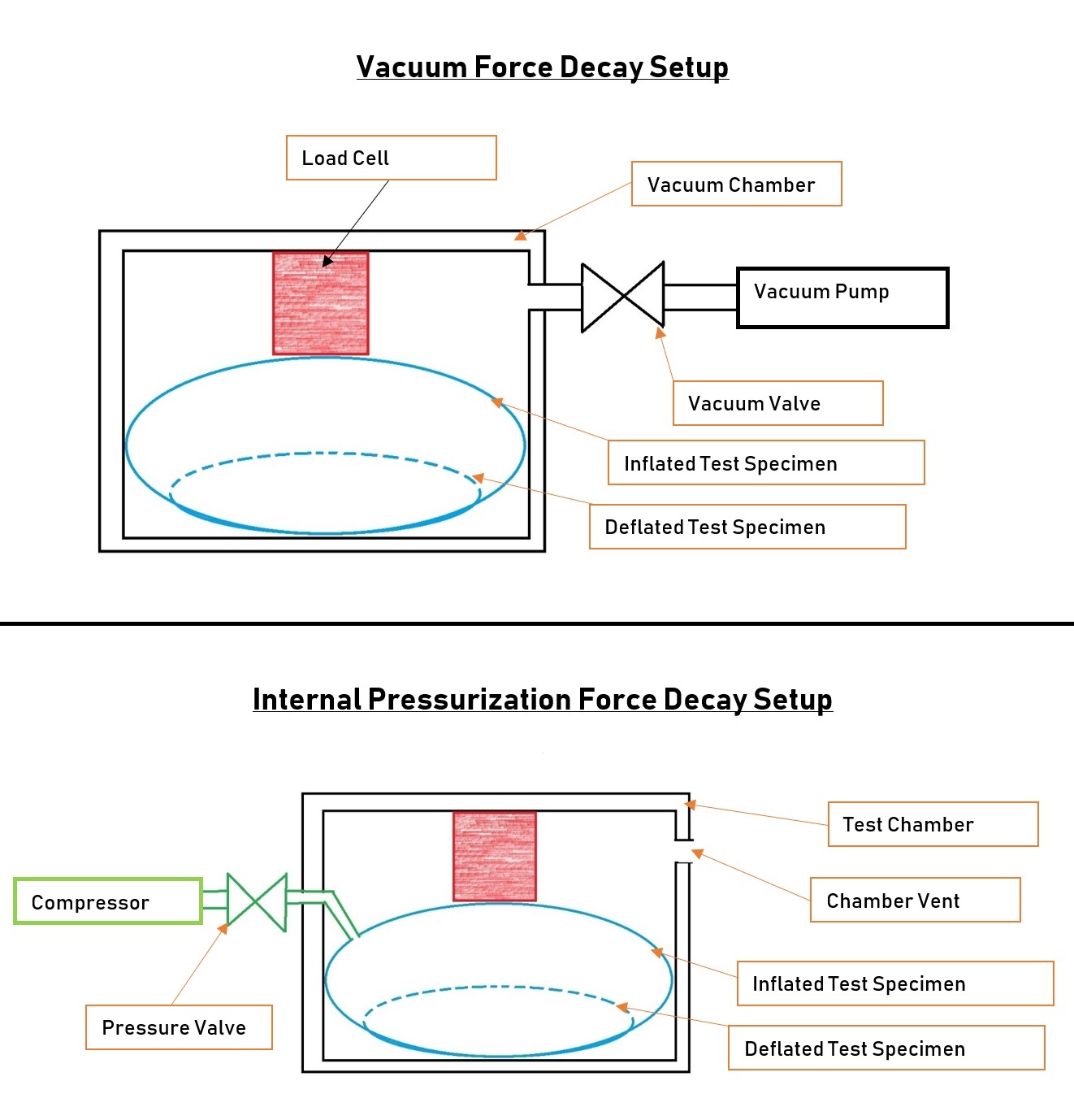

Force Decay Leak Testing

Pressure Vacuum Decay The process is uncomplicated, relatively inexpensive and easily. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. Pressure or partial pressure) • liquid presence near or in a leak path. The process is uncomplicated, relatively inexpensive and easily. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. The method can be used to identify gross defects and. In this method, the component is evacuated (subjected to a. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the.

From sepha.com

Vacuum Decay Test Nondestructive & Deterministic CCIT Pressure Vacuum Decay • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing.. Pressure Vacuum Decay.

From www.cincinnati-test.com

Pressure Decay dP and dP/dT Leak Test Pressure Vacuum Decay Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. Pressure. Pressure Vacuum Decay.

From www.researchgate.net

Pressure decay in the process of measuring permeability Download Pressure Vacuum Decay 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay. Pressure Vacuum Decay.

From vacuumtechnology.com

Vacuum Decay Vacuum Technology Inc. Pressure Vacuum Decay • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. The method can be used to identify gross defects and. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. The process is uncomplicated, relatively inexpensive and easily.. Pressure Vacuum Decay.

From www.researchgate.net

Two natural ways an uplifted vacuum can decay. The decay process is Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. In this method, the component is evacuated (subjected to a. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. The process is uncomplicated, relatively inexpensive and. Pressure Vacuum Decay.

From www.norm-makine.com

Leak Testing Machine Normtech Özel Makina İmalatı Pressure Vacuum Decay • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. The. Pressure Vacuum Decay.

From bexchange.bonfiglioliengineering.com

International regulations regarding CCIT Vacuum Decay & Pressure Decay Pressure Vacuum Decay 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Vacuum decay testing, or pressure rise testing,. Pressure Vacuum Decay.

From www.researchgate.net

Pressurepulse decay test setup. Download Scientific Diagram Pressure Vacuum Decay Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is. Pressure Vacuum Decay.

From www.sanatron.com

Anatomy of the Pressure Decay, Vacuum Decay, and Force Decay Curve Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. In this method, the component is evacuated (subjected to a. Pressure decay is probably the most widely. Pressure Vacuum Decay.

From www.ulvac.co.th

Differential Pressure Leak Testing System Pressure Vacuum Decay The process is uncomplicated, relatively inexpensive and easily. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. The method can be used to identify gross defects and. Pressure or partial pressure) • liquid presence near or in a leak path. Pressure decay leak testing uses a pressure loss measurement to identify a specific. Pressure Vacuum Decay.

From ceoimlut.blob.core.windows.net

Pressure Vacuum Decay at Les Pacheco blog Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. The process is uncomplicated, relatively inexpensive and easily. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Pressure or partial pressure) • liquid presence near or in. Pressure Vacuum Decay.

From www.wilco.com

Nondestructive leak testing with differential pressure technology Pressure Vacuum Decay In this method, the component is evacuated (subjected to a. The method can be used to identify gross defects and. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. Pressure or partial pressure) • liquid presence near or in a leak path. Pressure decay leak testing uses a pressure loss measurement to identify. Pressure Vacuum Decay.

From vacuumtechnology.com

Pressure Decay Vacuum Technology Inc. Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one. Pressure Vacuum Decay.

From www.pinterest.com.au

False Vacuum Theory FunSubstance Amazing science facts, Cool Pressure Vacuum Decay The method can be used to identify gross defects and. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. Pressure or partial pressure) • liquid presence near or in a leak path. Pressure decay is probably the most widely used method of. Pressure Vacuum Decay.

From www.youtube.com

Vacuum Decay Explained in 3 Minutes YouTube Pressure Vacuum Decay • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. The method can be used to identify. Pressure Vacuum Decay.

From www.uson.com

The Relationship Between Pressure Decay & Leak Rate Pressure Vacuum Decay In this method, the component is evacuated (subjected to a. The process is uncomplicated, relatively inexpensive and easily. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample. Pressure Vacuum Decay.

From leakplus.com

Vacuum Decay & Pressure Test for Leak Dectection Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. • monitor the pressure in the chamber by highly sensitive sensors. Pressure Vacuum Decay.

From www.researchgate.net

Pressure decay evaluation for the core sample at different Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if. Pressure Vacuum Decay.

From www.semanticscholar.org

Figure 4 from False vacuum decay after inflation Semantic Scholar Pressure Vacuum Decay Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. • monitor the pressure in the chamber by highly sensitive sensors. Pressure Vacuum Decay.

From vac-eng.com

Vacuum Decay vs. Pressure Decay Testing VES Pressure Vacuum Decay In this method, the component is evacuated (subjected to a. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. The. Pressure Vacuum Decay.

From labinsights.nl

Hoe schakel je over van dyetesten naar pressure/vacuum decay Pressure Vacuum Decay Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. The method can be used to identify gross defects and. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure. Pressure Vacuum Decay.

From www.sanatron.com

Anatomy of the Pressure Decay, Vacuum Decay, and Force Decay Curve Pressure Vacuum Decay Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Pressure. Pressure Vacuum Decay.

From www.medicalexpo.com

Differential pressure decay leak tester F670 Ateq vacuum / for Pressure Vacuum Decay Pressure or partial pressure) • liquid presence near or in a leak path. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. In this method, the component is evacuated (subjected to a. It is a simple test. Pressure Vacuum Decay.

From lts.lacotech.com

Pressure/Vacuum Decay Pressure Vacuum Decay The process is uncomplicated, relatively inexpensive and easily. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. The method can be used to identify gross defects and. • monitor the pressure in the chamber by. Pressure Vacuum Decay.

From www.youtube.com

Introductory Fluid Mechanics L4 p4 Absolute, Gage, Vacuum Pressure Pressure Vacuum Decay Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. The process. Pressure Vacuum Decay.

From sanatron.com

Force Decay Leak Testing Pressure Vacuum Decay The process is uncomplicated, relatively inexpensive and easily. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. 3). Pressure Vacuum Decay.

From www.setra.com

How to Conduct a Pressure Decay Leak Detection Test Pressure Vacuum Decay In this method, the component is evacuated (subjected to a. Pressure or partial pressure) • liquid presence near or in a leak path. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. Vacuum decay testing, or pressure rise testing, operates on the. Pressure Vacuum Decay.

From educatelux.com

How Vacuum Decay Would Destroy The Universe Educational Videos Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. • monitor the pressure in the chamber by highly sensitive sensors. Pressure Vacuum Decay.

From www.pti-ccit.com

Understanding Pressure Decay Leak Testing Pressure Vacuum Decay • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. Pressure decay is probably the most widely. Pressure Vacuum Decay.

From www.researchgate.net

The evolution of certain quantities of the vacuum system. The Pressure Vacuum Decay 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in the chamber by highly sensitive sensors 5) if a. Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. In this method, the component is evacuated (subjected to a. • monitor the pressure in the chamber. Pressure Vacuum Decay.

From www.iflscience.com

The Most Spectacular Way The Universe Might End? Meet "Vacuum Decay Pressure Vacuum Decay • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. Pressure or partial pressure) • liquid presence near or in a leak path. The process is uncomplicated, relatively inexpensive and easily. In this method, the component is evacuated (subjected to a. 3) lock vacuum. Pressure Vacuum Decay.

From www.semanticscholar.org

Figure 1 from New bounds on vacuum decay in de Sitter space Semantic Pressure Vacuum Decay Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. The process is uncomplicated, relatively inexpensive and easily. Pressure or partial. Pressure Vacuum Decay.

From www.youtube.com

05 Evap Pressure Vacuum Decay Leak Test YouTube Pressure Vacuum Decay It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. 3) lock vacuum / pressure supply from the inside. Pressure Vacuum Decay.

From www.semanticscholar.org

Figure 1 from False vacuum decay after inflation Semantic Scholar Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. Pressure decay is probably the most widely used method of leak testing in manufacturing production lines. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. 3) lock vacuum / pressure supply from the inside of. Pressure Vacuum Decay.

From sanatron.com

Anatomy of the Pressure Decay, Vacuum Decay, and Force Decay Curve Pressure Vacuum Decay Vacuum decay testing, or pressure rise testing, operates on the opposite principle of pressure decay testing. • monitor the pressure in the chamber by highly sensitive sensors • if a mass transfer is possible between the inside of the sample and the. 3) lock vacuum / pressure supply from the inside of the chamber 4) monitor the pressure change in. Pressure Vacuum Decay.