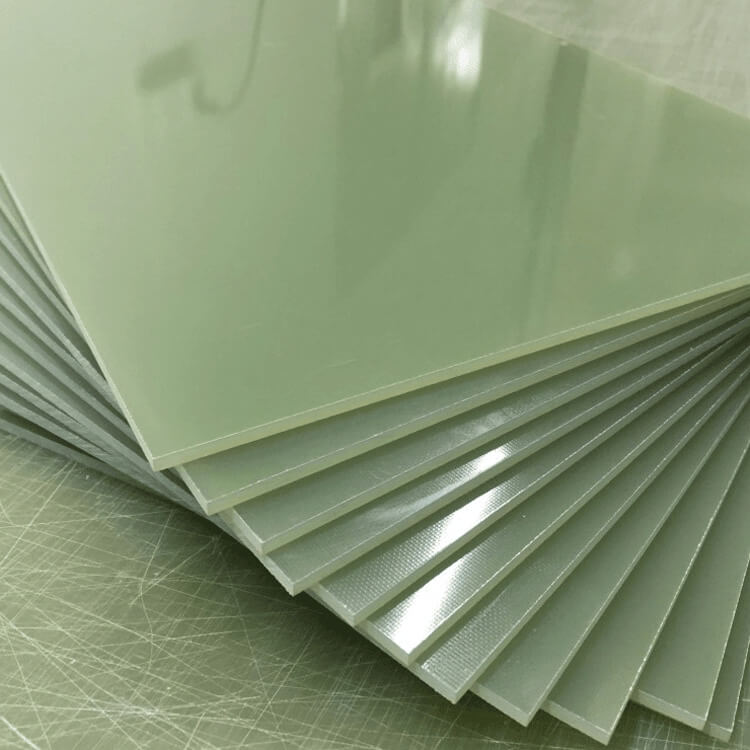

Epoxy Fiberglass Laminate . Polyester, vinyl ester or epoxy. It is created by stacking multiple layers of glass. The most popular resins are polyester, vinyl ester and epoxy. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. There are three types of resin that can be used for laminates: Resin holds the reinforcement together and helps it conform to the wanted shape. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength.

from fr4material.com

Polyester, vinyl ester or epoxy. The most popular resins are polyester, vinyl ester and epoxy. It is created by stacking multiple layers of glass. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. Resin holds the reinforcement together and helps it conform to the wanted shape. The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. There are three types of resin that can be used for laminates:

G10 Epoxy Fiberglass Laminate Sheet FR4 Material

Epoxy Fiberglass Laminate The most popular resins are polyester, vinyl ester and epoxy. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. Polyester, vinyl ester or epoxy. There are three types of resin that can be used for laminates: It is created by stacking multiple layers of glass. The most popular resins are polyester, vinyl ester and epoxy. The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. Resin holds the reinforcement together and helps it conform to the wanted shape.

From www.alibaba.com

Competitive Price 3240 Epoxy Fiberglass Laminate Sheet Buy Fiberglass Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. There are three types of resin that can be used for laminates: This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Resin holds the. Epoxy Fiberglass Laminate.

From fr4material.com

EPGC201 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate The most popular resins are polyester, vinyl ester and epoxy. Polyester, vinyl ester or epoxy. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. Resin holds the reinforcement together and helps. Epoxy Fiberglass Laminate.

From www.ztelecgroup.com

G11 high temperature epoxy resin fiberglass laminated sheet Epoxy Fiberglass Laminate The most popular resins are polyester, vinyl ester and epoxy. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. Resin holds the reinforcement together and helps it conform to the wanted shape. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated. Epoxy Fiberglass Laminate.

From fr4material.com

G11 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate It is created by stacking multiple layers of glass. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. There are three types of resin that can be used for laminates: The most popular resins are polyester, vinyl ester and epoxy. Reinforcements include fiberglass cloth, fiberglass mat, carbon. Epoxy Fiberglass Laminate.

From fr4material.com

G11 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Polyester, vinyl ester or epoxy. The first step in making a fiberglass laminate is choosing the right resin and fiberglass for. Epoxy Fiberglass Laminate.

From www.gpo3fiberglasssheet.com

EPGC204 Epoxy Glass Laminate Sheet / Fibreglass Epoxy Laminate Sheets Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. The most popular resins are polyester, vinyl ester and epoxy. The first step in making. Epoxy Fiberglass Laminate.

From chifengproducts.en.alibaba.com

Fr5 G11 Fr4 G10 3240 Honglei High Quality 4x8 Fiberglass Sheet/epoxy Epoxy Fiberglass Laminate This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. Polyester, vinyl ester or epoxy. The most popular resins are polyester, vinyl ester and epoxy.. Epoxy Fiberglass Laminate.

From www.indiamart.com

Epoxy Fiberglass Laminate Sheet g10, Thickness 0.53MM at Rs 250/kg in Epoxy Fiberglass Laminate Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. It is created by stacking multiple layers of glass. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. The most popular resins are polyester, vinyl ester and epoxy. There are three types of resin that can be. Epoxy Fiberglass Laminate.

From fr4material.com

FR4 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of. Epoxy Fiberglass Laminate.

From www.indiamart.com

Epoxy Fiberglass Laminate Sheet, Thickness 4mm at Rs 380/kg in Vadodara Epoxy Fiberglass Laminate The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. The most popular resins are polyester, vinyl ester and epoxy. Polyester, vinyl ester or epoxy. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build. Epoxy Fiberglass Laminate.

From www.alibaba.com

Epoxy Fiberglass Laminate G9/g10/fr4 Sheet/rod/tube Cnc Fabrication Epoxy Fiberglass Laminate There are three types of resin that can be used for laminates: It is created by stacking multiple layers of glass. Resin holds the reinforcement together and helps it conform to the wanted shape. The most popular resins are polyester, vinyl ester and epoxy. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination. Epoxy Fiberglass Laminate.

From www.bossgoo.com

3240 Epoxy Fiberglass Laminate Sheet Insulation Material, High Quality Epoxy Fiberglass Laminate Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. It is created by stacking multiple layers of glass. There are three types of resin that can be used for laminates: This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Polyester, vinyl ester or epoxy. Resin holds the reinforcement together and helps. Epoxy Fiberglass Laminate.

From fr4material.com

G10 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Polyester, vinyl ester or epoxy. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build. Epoxy Fiberglass Laminate.

From www.cfrp-tstar.com

FRP Laminate Sheet Epoxy Fiberglass Laminate Resin holds the reinforcement together and helps it conform to the wanted shape. The most popular resins are polyester, vinyl ester and epoxy. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. There are three types of. Epoxy Fiberglass Laminate.

From www.hnyousun.com

3240Epoxy Fiberglass Cloth Laminated sheet Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary. Epoxy Fiberglass Laminate.

From www.youtube.com

Laminating with Fiberglass & Epoxy The Basics YouTube Epoxy Fiberglass Laminate Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Resin holds the reinforcement together and helps it conform to the wanted shape. G10 sheets, also known as g 10 fr4. Epoxy Fiberglass Laminate.

From www.indiamart.com

Epoxy Fiberglass Laminate Sheet, Thickness 4mm at Rs 380/kg in Vadodara Epoxy Fiberglass Laminate There are three types of resin that can be used for laminates: The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. Polyester, vinyl ester or epoxy. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. The most popular resins are polyester, vinyl ester. Epoxy Fiberglass Laminate.

From www.tradeindia.com

G10, Fr4 Epoxy Fiberglass Laminate Sheet at Price Range 8.929.5 USD Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. It is created by stacking multiple layers of glass. Polyester, vinyl ester or epoxy. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Resin. Epoxy Fiberglass Laminate.

From www.ecplaza.net

Epoxy Fiberglass Laminated Resin Sheets FR4/ G10/ G11 Insulation Sheets Epoxy Fiberglass Laminate The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. Resin holds the reinforcement together and helps it conform to the wanted shape. It is created by stacking multiple layers of glass. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a. Epoxy Fiberglass Laminate.

From fr4material.com

G11 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. Polyester, vinyl ester or epoxy. Resin holds the reinforcement together and helps it conform to the wanted shape. It is created by stacking multiple layers of glass. The first step in making a fiberglass laminate is choosing the. Epoxy Fiberglass Laminate.

From www.sunriseccl.com.cn

Ultra Thick Epoxy Resin Fiberglass FR4/G10 Laminate Sheet/Plate Buy Epoxy Fiberglass Laminate There are three types of resin that can be used for laminates: Resin holds the reinforcement together and helps it conform to the wanted shape. It is created by stacking multiple layers of glass. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with. Epoxy Fiberglass Laminate.

From www.autexinsulation.com

Epoxy Fiberglass Laminate Sheet Manufacturer,Supplier,Wholesaler In Epoxy Fiberglass Laminate Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. It is created by stacking multiple layers of glass. The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. There are three types of resin that can be used for. Epoxy Fiberglass Laminate.

From fr4material.com

FR4 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. It is created by stacking multiple layers of glass. The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. The most popular resins are. Epoxy Fiberglass Laminate.

From www.harnawa.in

Glass Epoxy Sheets Glass Epoxy Sheet 3240 Manufacturer from Mumbai Epoxy Fiberglass Laminate Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. There are three types of resin that can be used for laminates: Resin holds the reinforcement together and helps it conform to the wanted shape. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. It is created. Epoxy Fiberglass Laminate.

From gpo3-manufacturer.en.made-in-china.com

15mm Thick Fr4 G10 Laminated Epoxy Fiberglass Sheet China Fiber Glass Epoxy Fiberglass Laminate The first step in making a fiberglass laminate is choosing the right resin and fiberglass for your project. There are three types of resin that can be used for laminates: G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Resin holds. Epoxy Fiberglass Laminate.

From dir.indiamart.com

Epoxy Fiberglass Sheet G10 sheet Latest Price, Manufacturers & Suppliers Epoxy Fiberglass Laminate The most popular resins are polyester, vinyl ester and epoxy. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. It is created by stacking multiple layers of glass. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using. Epoxy Fiberglass Laminate.

From fr4material.com

EPGC203 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate Resin holds the reinforcement together and helps it conform to the wanted shape. Polyester, vinyl ester or epoxy. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. It is created by stacking multiple layers of glass. There are three types of. Epoxy Fiberglass Laminate.

From fr4material.com

G11 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate Polyester, vinyl ester or epoxy. There are three types of resin that can be used for laminates: Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Resin holds the reinforcement together. Epoxy Fiberglass Laminate.

From fr4material.com

G11 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. Polyester, vinyl ester or epoxy. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. The most popular resins are polyester, vinyl ester and epoxy. There are three types of resin. Epoxy Fiberglass Laminate.

From www.indiamart.com

Epoxy Fiberglass Laminate Sheet at Rs 150/kilogram इपोक्सी लैमिनेटेड Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. It is created by stacking multiple layers of glass. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. Polyester,. Epoxy Fiberglass Laminate.

From fr4material.com

FR4 Epoxy Fiberglass Laminate Sheet FR4 Material Epoxy Fiberglass Laminate Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. Resin holds the reinforcement together and helps it conform to the wanted shape. It is created by stacking multiple layers of glass. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. There are three types of resin that can be used for. Epoxy Fiberglass Laminate.

From www.alibaba.com

Epoxy Glass Laminate Sheet,Epoxy Glass Fiber Sheet Fr4,Fr4 Epoxy Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. The most popular resins are polyester, vinyl ester and epoxy.. Epoxy Fiberglass Laminate.

From www.ec21.com

Epoxy Fiberglass Laminate Sheet 3240 from Wuxi Chifeng Metal Products Epoxy Fiberglass Laminate G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. The most popular resins are polyester, vinyl ester and epoxy. There are three types of resin that can be used for laminates: It is created by stacking multiple layers of glass. Customers. Epoxy Fiberglass Laminate.

From www.youtube.com

Building a Fiberglass & Epoxy Laminate Mold YouTube Epoxy Fiberglass Laminate Polyester, vinyl ester or epoxy. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build or repair a fiberglass laminate. This sheet is made of glass fiber cloth impregnated with brominated epoxy resin and heated and pressurized. Resin holds the reinforcement together and helps it conform to the wanted shape. Reinforcements include fiberglass. Epoxy Fiberglass Laminate.

From www.indiamart.com

Color Coated G10 Laminate Epoxy Fiberglass Sheet, Thickness 5 mm at Rs Epoxy Fiberglass Laminate Polyester, vinyl ester or epoxy. Reinforcements include fiberglass cloth, fiberglass mat, carbon fiber and aramid. G10 sheets, also known as g 10 fr4 glass epoxy sheets, are constructed using a combination of solid laminates of fiberglass prepreg and epoxy resin with high strength. Customers frequently ask us how to calculate the amount of fiberglass fabric or epoxy necessary to build. Epoxy Fiberglass Laminate.