Casting Process Is Preferred For Parts Having . The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. Assemble these patterns onto a gating system The investment casting process or lost wax process has the following steps: Produce expendable wax, plastic, or polystyrene patterns. This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. What are the different types of metal casting processes and which casting process should you use to manufacture your metal part?. It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,.

from www.xmzldjx.com

The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Assemble these patterns onto a gating system It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. What are the different types of metal casting processes and which casting process should you use to manufacture your metal part?. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. Produce expendable wax, plastic, or polystyrene patterns. The investment casting process or lost wax process has the following steps: The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes.

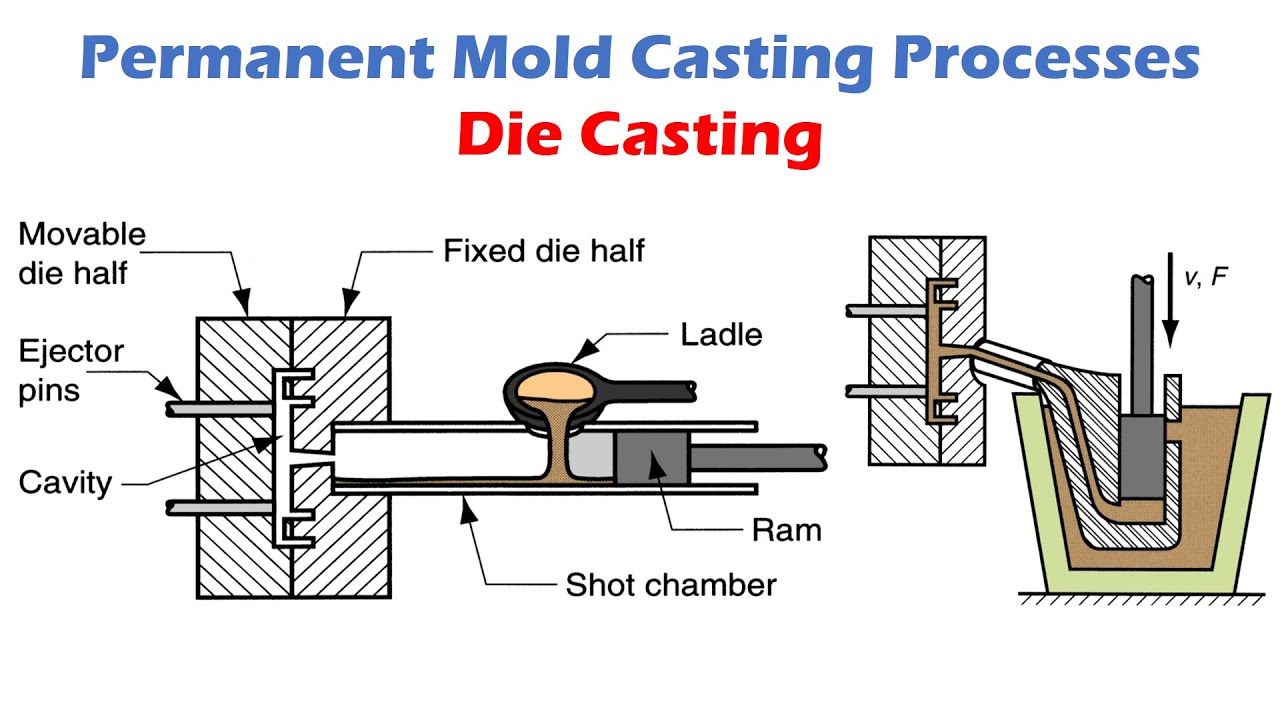

About Die Casting Process(I)

Casting Process Is Preferred For Parts Having The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Assemble these patterns onto a gating system What are the different types of metal casting processes and which casting process should you use to manufacture your metal part?. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. The investment casting process or lost wax process has the following steps: Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. Produce expendable wax, plastic, or polystyrene patterns.

From www.iqsdirectory.com

Zinc Die Casting What Is It? How Is it Made? Advantages Casting Process Is Preferred For Parts Having The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Produce expendable wax, plastic, or polystyrene patterns. Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. The investment casting process or lost wax process has the following. Casting Process Is Preferred For Parts Having.

From www.investmentcastchina.com

Precision Casting Services in China CFS Foundry Casting Process Is Preferred For Parts Having Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. The investment casting process or lost wax process has the following steps: The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the. Casting Process Is Preferred For Parts Having.

From www.alibaba.com

Die Casting Process Powder Coating Shell Parts Casting Carbon Cast Iron Casting Process Is Preferred For Parts Having Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Assemble these patterns onto a. Casting Process Is Preferred For Parts Having.

From kerone.com

Different Types of Casting Process and Uses Casting Process Is Preferred For Parts Having This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. The casting process is the first step. Casting Process Is Preferred For Parts Having.

From ar.inspiredpencil.com

Die Casting Process Casting Process Is Preferred For Parts Having Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. Produce expendable wax, plastic, or polystyrene patterns. Assemble these patterns onto a gating system The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. The casting process is. Casting Process Is Preferred For Parts Having.

From techqualitypedia.com

Sand Casting Sand casting process Sand casting mould Casting Process Is Preferred For Parts Having Assemble these patterns onto a gating system The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. Produce expendable wax, plastic, or polystyrene patterns. The casting process is. Casting Process Is Preferred For Parts Having.

From www.uskoreahotlink.com

Exploring Casting Processes for Automotive Parts, Pumps, and Valves Casting Process Is Preferred For Parts Having Assemble these patterns onto a gating system The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such. Casting Process Is Preferred For Parts Having.

From www.comsol.fr

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Casting Process Is Preferred For Parts Having The investment casting process or lost wax process has the following steps: The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. What are the different types of. Casting Process Is Preferred For Parts Having.

From www.iqsdirectory.com

Investment Casting What Is It? How Does It Work? Uses Casting Process Is Preferred For Parts Having This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. The casting process is the first step of manufacturing, and it creates complex metal. Casting Process Is Preferred For Parts Having.

From www.hengkecasting.com

Best Investment Casting Manufacturers 2024 Casting Process Is Preferred For Parts Having The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. It is a process in which liquefied material, such as molten. Casting Process Is Preferred For Parts Having.

From www.in3dtec.com

10 different types of metal casting process IN3DTEC Prototyping Casting Process Is Preferred For Parts Having The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. What are the different types of metal casting processes and which casting process should you use to manufacture your metal. Casting Process Is Preferred For Parts Having.

From get-it-made.co.uk

Aluminium Die Casting Guide Get It Made Casting Process Is Preferred For Parts Having The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. The investment casting process or lost wax process has the following steps: Lost foam casting is a casting process in which foam is used as the pattern as opposed. Casting Process Is Preferred For Parts Having.

From www.pinterest.com

Continuous Casting Process It cast, Continuity, Under pressure Casting Process Is Preferred For Parts Having Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. The casting process is the manufacturing process in which molten material such as metal is. Casting Process Is Preferred For Parts Having.

From www.researchgate.net

Scheme of the steel casting process Download Scientific Diagram Casting Process Is Preferred For Parts Having It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. Assemble these patterns onto a gating system This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. Produce expendable wax, plastic, or polystyrene patterns. The investment casting. Casting Process Is Preferred For Parts Having.

From www.researchgate.net

A schematic diagram of the continuous casting process. Download Casting Process Is Preferred For Parts Having The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. The investment casting process or. Casting Process Is Preferred For Parts Having.

From www.qimingcasting.com

Casting Process Wear Parts For Industry Qiming Casting Casting Process Is Preferred For Parts Having The investment casting process or lost wax process has the following steps: Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. This makes forging. Casting Process Is Preferred For Parts Having.

From www.sputtertargets.net

An Introduction to Metal Casting Process Stanford Advanced Materials Casting Process Is Preferred For Parts Having The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Assemble these patterns onto a gating system The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. This makes forging the. Casting Process Is Preferred For Parts Having.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Casting Process Is Preferred For Parts Having Assemble these patterns onto a gating system The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Casting is typically used. Casting Process Is Preferred For Parts Having.

From toolgrindcoat.com

What Is Die Casting Manufacturing? Casting Process Is Preferred For Parts Having The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. The casting process is the. Casting Process Is Preferred For Parts Having.

From castman.co.kr

Modelling of an industrial die casting process for the production of Casting Process Is Preferred For Parts Having This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. What are the different types of metal casting processes and which casting process should you use to manufacture your metal part?. Lost foam casting is a casting process in which foam is used as the pattern as opposed. Casting Process Is Preferred For Parts Having.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Casting Process Is Preferred For Parts Having The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. The investment casting process or lost wax process has the following steps: Produce expendable wax, plastic, or polystyrene patterns. Lost foam casting is a casting process in which foam. Casting Process Is Preferred For Parts Having.

From www.researchgate.net

Schematic of continuous casting process Download Scientific Diagram Casting Process Is Preferred For Parts Having Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Assemble these patterns onto a gating system Casting is typically used to create intricate solid shapes of having. Casting Process Is Preferred For Parts Having.

From www.omicroncasting.com

5 Different Methods Used in Casting Casting Process Is Preferred For Parts Having It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. Produce expendable wax, plastic, or polystyrene patterns. The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. The investment casting process or lost wax process has the following steps: Casting is. Casting Process Is Preferred For Parts Having.

From ideal-stainless.com

Precision Casting Casting Process Is Preferred For Parts Having Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. Lost foam casting is a casting process in which foam is used as the pattern. Casting Process Is Preferred For Parts Having.

From www.versa-bar.com

Advantages of the Continuous Casting Process Benefits of Cast Iron Casting Process Is Preferred For Parts Having This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. The casting process is the manufacturing process in which molten material such as metal. Casting Process Is Preferred For Parts Having.

From www.machinemfg.com

Unveiling the Secrets of the Die Casting Process A Complete Guide Casting Process Is Preferred For Parts Having The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. The investment casting process or lost wax process has the following steps: What are the different types of. Casting Process Is Preferred For Parts Having.

From americancastingco.com

Investment Casting Process Steps and Flow Chart American Casting Company Casting Process Is Preferred For Parts Having Produce expendable wax, plastic, or polystyrene patterns. What are the different types of metal casting processes and which casting process should you use to manufacture your metal part?. The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. It is a process in which liquefied material, such as molten metal, is poured. Casting Process Is Preferred For Parts Having.

From www.xmzldjx.com

About Die Casting Process(I) Casting Process Is Preferred For Parts Having Produce expendable wax, plastic, or polystyrene patterns. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range of applications,. What are the different types of metal casting processes and which casting process should you use to manufacture your metal part?. Lost foam casting is a casting process in. Casting Process Is Preferred For Parts Having.

From www.ascentcast.com

Casting Manufacturing Process Low volume Casting Ascent Casting Casting Process Is Preferred For Parts Having The casting process is the first step of manufacturing, and it creates complex metal shapes for countless applications. Lost foam casting is a casting process in which foam is used as the pattern as opposed to the normal materials, such as wax. The casting process is the manufacturing process in which molten material such as metal is poured into the. Casting Process Is Preferred For Parts Having.

From www.smlease.com

Different types of metal casting in Manufacturing SMLease Design Casting Process Is Preferred For Parts Having It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Produce expendable wax, plastic, or polystyrene patterns. Lost. Casting Process Is Preferred For Parts Having.

From mechanicstips.blogspot.com

Die Casting Process MechanicsTips Casting Process Is Preferred For Parts Having Produce expendable wax, plastic, or polystyrene patterns. The investment casting process or lost wax process has the following steps: This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. Assemble these patterns onto a gating system It is a process in which liquefied material, such as molten metal,. Casting Process Is Preferred For Parts Having.

From www.thelibraryofmanufacturing.com

Semicentrifugal Casting Casting Process Is Preferred For Parts Having The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. What are the different types of metal casting processes and which casting process should you use to manufacture your metal part?. This makes forging the preferred method when producing. Casting Process Is Preferred For Parts Having.

From www.ace-mold.com

Die Casting Mould Material for Industrial Applications Casting Process Is Preferred For Parts Having Produce expendable wax, plastic, or polystyrene patterns. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or. Casting is typically used to create intricate solid shapes of having many details and cast products are found in a wide range. Casting Process Is Preferred For Parts Having.

From www.fullstopindia.com

Steel Casting in Automotive Manufacturing Benefits and Applications Casting Process Is Preferred For Parts Having The investment casting process or lost wax process has the following steps: Assemble these patterns onto a gating system This makes forging the preferred method when producing parts that need to handle high stress, like those used in cars or airplanes. It is a process in which liquefied material, such as molten metal, is poured into the cavity of a. Casting Process Is Preferred For Parts Having.

From www.sputtertargets.net

An Introduction to Metal Casting Process Stanford Advanced Materials Casting Process Is Preferred For Parts Having The investment casting process or lost wax process has the following steps: It is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed. Assemble these patterns onto a gating system The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Casting Process Is Preferred For Parts Having.