Just In Time Jit Method . The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”.

from www.alamy.com

Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand.

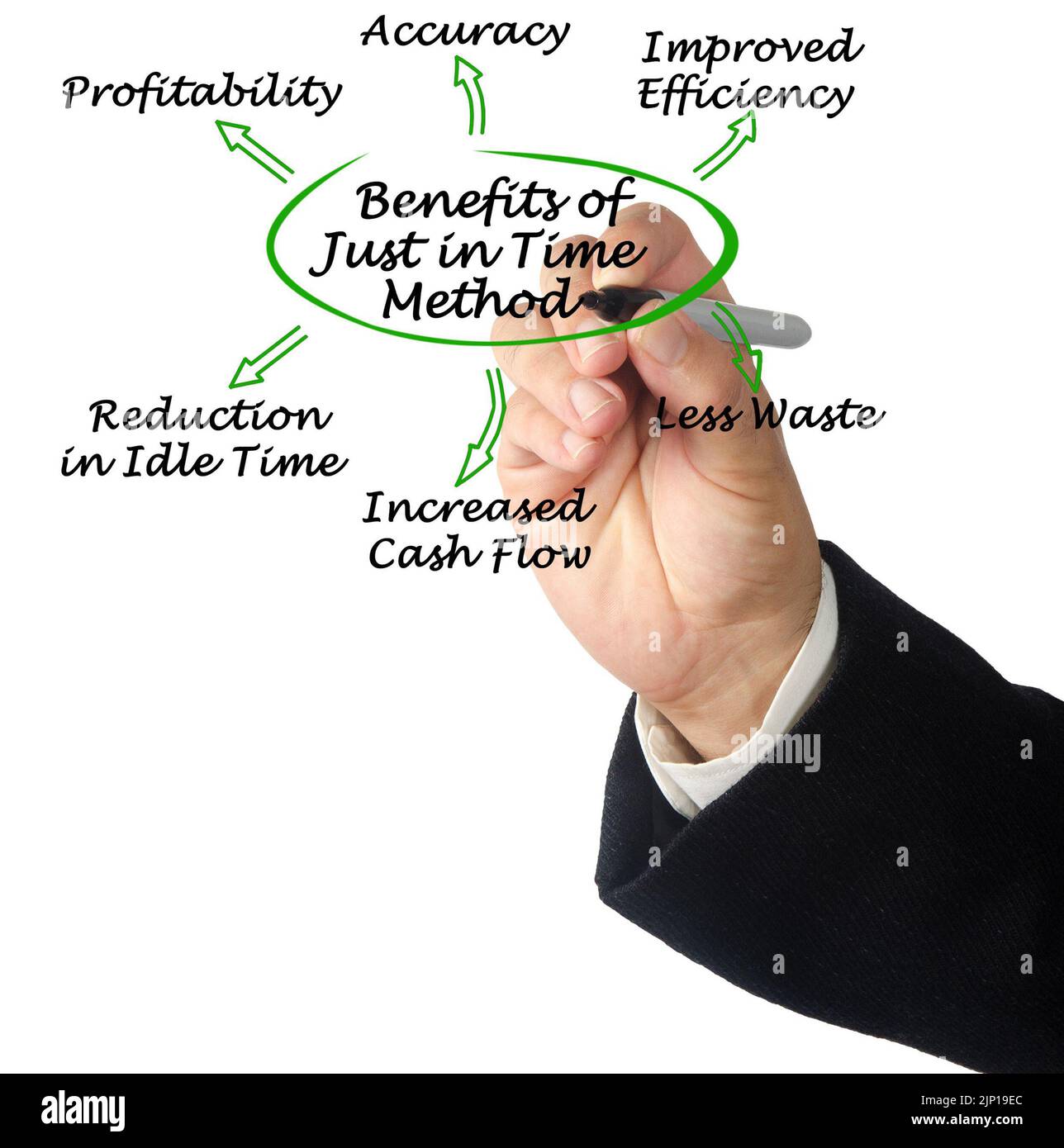

Benefits of Just in Time (JIT) Method Stock Photo Alamy

Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”.

From jobpro.web.za

How Just In Time Is Driven By The Job JobPRO Manufacturing Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From www.impactfirst.co

Just in Time (JIT) Definition & 8 Application Steps Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From eliteextra.com

Just In Time (JIT) Delivery The Ultimate Guide Elite EXTRA Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From zhenhub.com

What is JustinTime Inventory (JIT) ZhenHub Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From www.amsc-usa.com

JustInTime Inventory Management What It Is and How It Works Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From stock.adobe.com

JIT or just in time as effective inventory management method outline Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From studiousguy.com

JustInTime with Examples StudiousGuy Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From thelogisticstimes.com

The Pros and Cons of Implementing a JustInTime (JIT) Logistics Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.scribd.com

Just in Time (JIT) Strategy PDF Lean Manufacturing Supply Chain Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.presentationeze.com

JIT Manufacturing Informaton & Training Just In Time Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.netsuite.com

JustinTime Inventory (JIT) Defined A 2023 Guide NetSuite Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.wallstreetmojo.com

JustInTime (JIT) Meaning, Example, Advantages/Disadvantages Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.warehousingexpress.com

Five Major Benefits Of Justintime Jit Process Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.consuunt.com

JustInTime Manufacturing explained with Examples JIT vs JIC Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.deskera.com

What is Justintime (JIT) Inventory? Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.alamy.com

Benefits of Just in Time (JIT) Method Stock Photo Alamy Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From khatabook.com

Understanding JIT Just In Time Inventory Management Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.slideserve.com

PPT Principles and Practices of Lean Manufacturing PowerPoint Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From www.alamy.com

Benefits of Just in Time (JIT) Method Stock Photo Alamy Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.youtube.com

JustinTime Manufacturing (JIT) Lean Six Sigma Complete Course Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From khatabook.com

Understanding JIT Just In Time Inventory Management Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.slideshare.net

PPT ON Just in time technique (JIT) Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From bdtextilemates.blogspot.com

What Is Just in time (JIT) ? Goals And Objectives of JIT Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.alamy.com

Benefits of Just in Time (JIT) Method Stock Photo Alamy Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.slideserve.com

PPT Chapter 5 AIS and Business Processes Part II PowerPoint Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From www.youtube.com

What is JustinTime (JIT) Lean Manufacturing ? JustinTime Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.alamy.com

Benefits of Just in Time (JIT) Method Stock Photo Alamy Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From www.supplychainindiajobs.com

What is Just in Time manufacturing (JIT)? Supply Chain India Jobs Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.alamy.com

JIT just in time production strategy on the memo Stock Photo Alamy Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.youtube.com

JustInTime (JIT) inventory strategy in supply chain management Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.

From www.beyondlean.com

JIT ( Just In Time ) Production, Slash your inventory costs Just In Time Jit Method Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Just In Time Jit Method.

From www.presentationeze.com

JIT. Just In Time PresentationEZE Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From discover.hubpages.com

JustinTime (JIT) Manufacturing HubPages Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.slideshare.net

Just In Time Production (JIT) Just In Time Jit Method Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Just In Time Jit Method.

From www.amsc-usa.com

JustInTime Inventory Management What It Is and How It Works Just In Time Jit Method The jit method of inventory control involves creating, storing and tracking enough orders to supply demand. Jit is an inventory management method that focuses on keeping as little inventory on hand as possible. Businesses use this strategy to increase efficiency and decrease waste by only receiving goods when they need them, “just in time”. Just In Time Jit Method.