Casting Process Line . During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Mold cavity is produced having the desired shape and size of the part. Metal casting enables the production of simple to complex parts that meet a variety of needs. Six basic steps of casting. The most widely used method for small to medium. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow.

from www.satvikengineers.com

The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Mold cavity is produced having the desired shape and size of the part. Six basic steps of casting. Metal casting enables the production of simple to complex parts that meet a variety of needs. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. The most widely used method for small to medium.

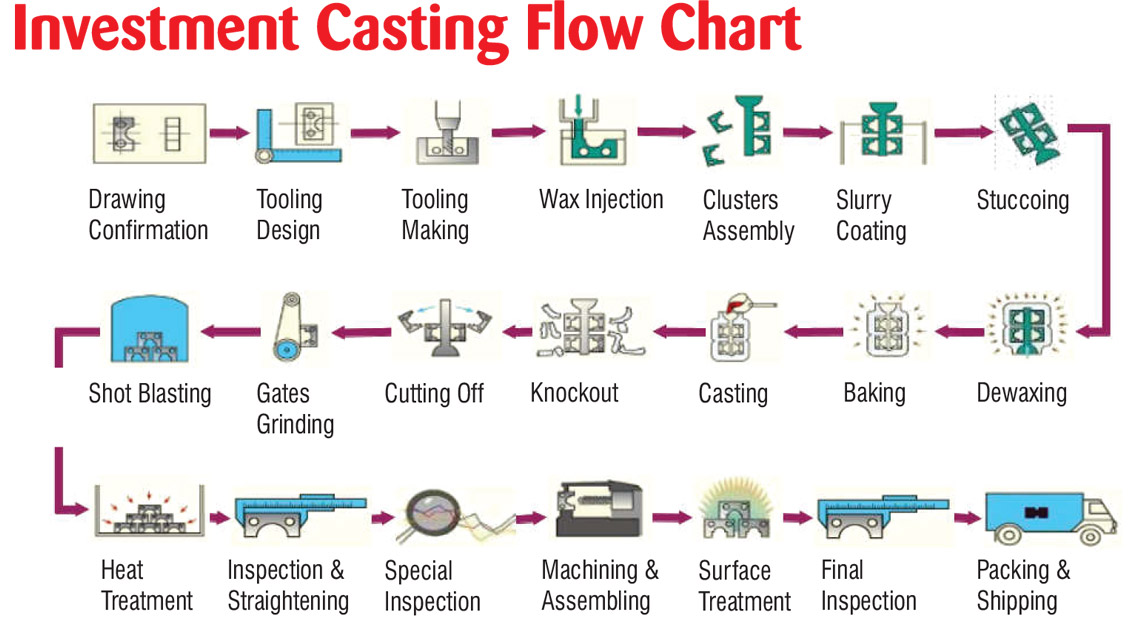

Investment Casting Flow Chart Satvik Engineers

Casting Process Line Mold cavity is produced having the desired shape and size of the part. The most widely used method for small to medium. Mold cavity is produced having the desired shape and size of the part. Metal casting enables the production of simple to complex parts that meet a variety of needs. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. Six basic steps of casting. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user.

From www.youtube.com

Die Casting Permanent Mold Casting Processes. YouTube Casting Process Line Metal casting enables the production of simple to complex parts that meet a variety of needs. The most widely used method for small to medium. Six basic steps of casting. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. The process consists of pouring molten metal into a mold. Casting Process Line.

From www.researchgate.net

Show Illustration of Continuous Casting Process [6]. Download Scientific Diagram Casting Process Line Mold cavity is produced having the desired shape and size of the part. The most widely used method for small to medium. Six basic steps of casting. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. There are different types of casting processes, and each process has its own advantages and disadvantages. Casting Process Line.

From altair.com

Emerging Technologies and Design for Manufacturing The Metal Casting Process Casting Process Line Six basic steps of casting. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. The most widely used method for small to medium. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. The process consists of pouring. Casting Process Line.

From www.mwes.com

Automated Casting Finishing Production Line Midwest Engineered Systems Casting Process Line During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. Mold cavity is produced having the desired shape and size of the part. Six basic steps of casting. The most widely used method for small to medium. Metal casting enables the production of simple to complex parts that meet. Casting Process Line.

From www.youtube.com

Investment Casting Process Working Animation Manufacturing Processes Lecture By Shubham Kola Casting Process Line In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. Metal casting enables the production of simple to complex parts that meet a variety of needs. The most widely used method for small to medium. There are different types of casting processes, and each process has. Casting Process Line.

From machiningtoday.com

Casting 101 Understanding the 12 Different Types of Casting Processes Casting Process Line Six basic steps of casting. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. The most widely used method for small to medium. Mold cavity is produced having the desired shape and size of the part. Metal casting enables the production of simple to complex parts that meet. Casting Process Line.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Casting Process Line There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a. Casting Process Line.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Process Line During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. Six basic steps of casting. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. Metal casting enables the production of simple to complex parts that meet a variety. Casting Process Line.

From www.youtube.com

Casting Process Terminology Types Pattern Making Core Making ENGINEERING STUDY Casting Process Line Six basic steps of casting. Metal casting enables the production of simple to complex parts that meet a variety of needs. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Mold cavity is produced having the desired shape and size of the part. The most widely used method for small to medium.. Casting Process Line.

From www.researchgate.net

1. Casting Process flow chart. Download Scientific Diagram Casting Process Line Mold cavity is produced having the desired shape and size of the part. Six basic steps of casting. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. The most widely used method. Casting Process Line.

From qdantai.en.made-in-china.com

High Quality VProcess Casting Moulding Production Line for Cast Steel Iron Aluminum China Casting Process Line Mold cavity is produced having the desired shape and size of the part. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. Six basic steps of casting. During. Casting Process Line.

From americancastingco.com

Investment Casting Process Steps and Flow Chart American Casting Company Casting Process Line Six basic steps of casting. Mold cavity is produced having the desired shape and size of the part. Metal casting enables the production of simple to complex parts that meet a variety of needs. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. The most widely used method for. Casting Process Line.

From me-resetsg.blogspot.com

Mechanical Engineering Centrifugal Casting Casting Process Line During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. The process consists of pouring molten metal into a mold containing a cavity of the. Casting Process Line.

From www.youtube.com

Aluminium Billet Casting Process Alüminyum Billet Döküm YouTube Casting Process Line The process consists of pouring molten metal into a mold containing a cavity of the desired shape. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a. Casting Process Line.

From www.topgrid.co

Casting Process A Brief Guide by Topgrid Topgrid Casting Process Line During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. The most widely used method for small to medium. Metal casting enables the production of simple to complex parts that meet a variety of needs. Six basic steps of casting. The process consists of pouring molten metal into a. Casting Process Line.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Process Line The most widely used method for small to medium. Six basic steps of casting. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Mold cavity is produced having the desired shape and size of the part. Metal casting enables the production of simple to complex parts that meet a variety of needs.. Casting Process Line.

From www.researchgate.net

Schematic of continuous casting process Download Scientific Diagram Casting Process Line The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Metal casting enables the production of simple to complex parts that meet a variety of needs. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. There are different types of casting. Casting Process Line.

From kaijiefoundrymachine.en.made-in-china.com

SemiAutomatic V Process Casting Line China Two Station Car Molding Line and V Process Casting Casting Process Line The process consists of pouring molten metal into a mold containing a cavity of the desired shape. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains. Casting Process Line.

From www.iqsdirectory.com

Types of Casting Processes Casting Methods Casting Process Line In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Mold cavity is produced having the desired shape and size of the part. There are different types of casting. Casting Process Line.

From fluids.leeds.ac.uk

Fluid Dynamics of the Continuous Casting of Steel Leeds Institute for Fluid Dynamics Casting Process Line During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. In metalworking. Casting Process Line.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Process Line Metal casting enables the production of simple to complex parts that meet a variety of needs. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a. Casting Process Line.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Process Line Metal casting enables the production of simple to complex parts that meet a variety of needs. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Six basic steps of casting. The most widely used method for small to medium. Mold cavity is produced having the desired shape and size of the part.. Casting Process Line.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Casting Process Line Mold cavity is produced having the desired shape and size of the part. Metal casting enables the production of simple to complex parts that meet a variety of needs. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. The most widely used method for small. Casting Process Line.

From cwmdiecast.com

What is High Pressure Die Casting? — Chicago White Metal Casting, Inc. Casting Process Line The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Metal casting enables the production of simple to complex parts that meet a variety of needs. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. Mold cavity is. Casting Process Line.

From www.smlease.com

Different types of metal casting in Manufacturing SMLease Design Casting Process Line There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. Metal casting enables the production of simple to complex parts that meet a variety of needs. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. During the sand casting process, the material. Casting Process Line.

From www.researchgate.net

A schematic stir casting set up [1] Download Scientific Diagram Casting Process Line The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Six basic steps of casting. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. There are different types of casting processes, and each process has its own advantages. Casting Process Line.

From www.researchgate.net

A schematic diagram of the continuous casting process. Download Scientific Diagram Casting Process Line Six basic steps of casting. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. The most widely used method for small to medium. In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. There. Casting Process Line.

From www.youtube.com

Gating System Parts in Casting Process [Pattern, Mold, Gate, Sprue, Runner, Cope, Drag] YouTube Casting Process Line There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. The most widely used method for small to medium. Mold cavity is produced having the desired shape and size of the part. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Six. Casting Process Line.

From www.researchgate.net

Scheme of the steel casting process Download Scientific Diagram Casting Process Line There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. The most widely used method for small to medium. Metal casting enables the production of simple to complex parts. Casting Process Line.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download ID6659367 Casting Process Line The process consists of pouring molten metal into a mold containing a cavity of the desired shape. Mold cavity is produced having the desired shape and size of the part. Metal casting enables the production of simple to complex parts that meet a variety of needs. The most widely used method for small to medium. In metalworking and jewelry making,. Casting Process Line.

From kerone.com

Different Types of Casting Process and Uses Casting Process Line The process consists of pouring molten metal into a mold containing a cavity of the desired shape. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. Mold cavity is produced having the desired shape and size of the part. There are different types of casting processes, and each. Casting Process Line.

From www.comsol.fr

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Casting Process Line Mold cavity is produced having the desired shape and size of the part. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. Metal casting enables the production of simple to complex. Casting Process Line.

From www.omicroncasting.com

5 Different Methods Used in Casting Casting Process Line In metalworking and jewelry making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow. The process consists of pouring molten metal into a mold containing a cavity of the desired shape. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to. Casting Process Line.

From extrudesign.com

What are the different Casting processes? ExtruDesign Casting Process Line The most widely used method for small to medium. There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. Metal casting enables the production of simple to complex parts that meet a variety of needs. In metalworking and jewelry making, casting is a process in which a liquid metal is. Casting Process Line.

From www.satvikengineers.com

Investment Casting Flow Chart Satvik Engineers Casting Process Line There are different types of casting processes, and each process has its own advantages and disadvantages as per the user. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the. Six basic steps of casting. The most widely used method for small to medium. Metal casting enables the production. Casting Process Line.