Oil Lubrication System Design . The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. The engine’s lubrication system is. The oil levels in system containers are subjected to. What is an automatic lubrication system for bearings? Tank breathers play an important role in the filtering system of a hydraulic unit. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. Engine lubrication system analysis and oil pump design optimization. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. In this article, a detailed computational. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission.

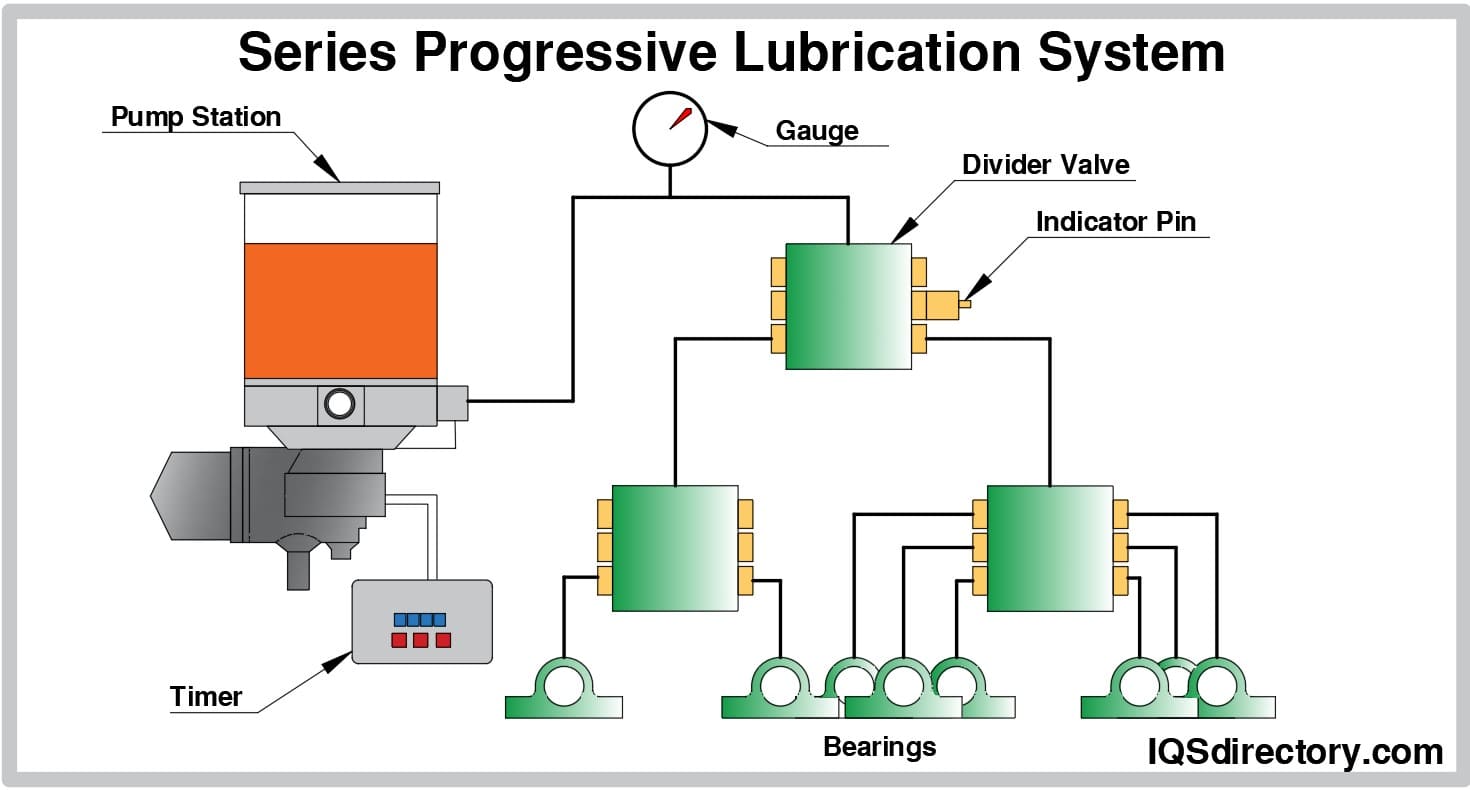

from www.iqsdirectory.com

The engine’s lubrication system is. What is an automatic lubrication system for bearings? The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. In this article, a detailed computational. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. Engine lubrication system analysis and oil pump design optimization. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. The oil levels in system containers are subjected to. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst.

Lubricating System Types, Uses, Features and Benefits

Oil Lubrication System Design The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. The engine’s lubrication system is. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The oil levels in system containers are subjected to. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. Tank breathers play an important role in the filtering system of a hydraulic unit. In this article, a detailed computational. Engine lubrication system analysis and oil pump design optimization. What is an automatic lubrication system for bearings? The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst.

From www.stle.org

Lubrication Fundamentals Oil Lubrication System Design Engine lubrication system analysis and oil pump design optimization. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The engine’s lubrication system is. The oil levels in system containers are subjected to. An accurate simulation. Oil Lubrication System Design.

From www.heavyequipmentguide.ca

Automated lubrication the next logical step for preventative maintenance Oil Lubrication System Design The oil levels in system containers are subjected to. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. Tank breathers play an important role in the filtering system of a hydraulic unit. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. What is an automatic lubrication. Oil Lubrication System Design.

From shipfever.com

Ship's Main Engine Lubricating Oil System An Easy Guide Oil Lubrication System Design An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. The engine’s lubrication system is. The oil levels in system containers are subjected to. In this article, a detailed computational. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. Modern engines work harder and run hotter and consequently place. Oil Lubrication System Design.

From detoxicrecenze.com

Engine Lubrication System Diagram My Wiring DIagram Oil Lubrication System Design An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The oil levels in system containers are subjected. Oil Lubrication System Design.

From cmaengineers.com.au

Oil Lubrication System Design CMA Engineering Oil Lubrication System Design The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The oil levels in system containers. Oil Lubrication System Design.

From www.youtube.com

Main Lubricating Oil System YouTube Oil Lubrication System Design Tank breathers play an important role in the filtering system of a hydraulic unit. Engine lubrication system analysis and oil pump design optimization. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The. Oil Lubrication System Design.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Oil Lubrication System Design The oil levels in system containers are subjected to. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. Tank breathers play an important role in the filtering system of a hydraulic unit. An accurate simulation model of the lubrication system is essential for early design of the heavy truck. Oil Lubrication System Design.

From www.youtube.com

lube oil system line diagram of lube oil system in ships YouTube Oil Lubrication System Design A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The engine’s lubrication system is. The oil levels in system containers are subjected to. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. What is an automatic lubrication system for bearings? Engine lubrication system analysis and oil pump design. Oil Lubrication System Design.

From rbcbearings.in

Oil circulation lubrication systems RBC Bearings Oil Lubrication System Design Tank breathers play an important role in the filtering system of a hydraulic unit. In this article, a detailed computational. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. The engine’s lubrication system is. The primary purpose of the lubrication system is to lubricate sliding surfaces and. Oil Lubrication System Design.

From www.evkey.com

Oil Lubrication System design install assemble Oil Lubrication System Design An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. Engine lubrication system analysis and oil pump design optimization. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. The lubrication system comprises various components, including the oil pump, oil pan, oil. Oil Lubrication System Design.

From www.pinterest.com

Lubricants, Oil pan, Car mechanic Oil Lubrication System Design In this article, a detailed computational. Engine lubrication system analysis and oil pump design optimization. What is an automatic lubrication system for bearings? Tank breathers play an important role in the filtering system of a hydraulic unit. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. The primary purpose of the. Oil Lubrication System Design.

From blog.softinway.com

[en]Gas Turbine Lubrication Systems[] Turbomachinery blog Oil Lubrication System Design An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. Tank breathers play an important role in the filtering system of a hydraulic unit. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. The engine’s lubrication system is. In. Oil Lubrication System Design.

From www.aircraftsystemstech.com

Aircraft Systems Aircraft Turbine Engine Lubrication System Components Oil Lubrication System Design The engine’s lubrication system is. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. A typical automatic system (grease or oil) includes a pump, controller/timer,. Oil Lubrication System Design.

From www.youtube.com

Central Lubrication System for the CNC YouTube Oil Lubrication System Design Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. Tank breathers play an important role in the filtering system of a hydraulic unit. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,.. Oil Lubrication System Design.

From www.mdpi.com

Applied Sciences Free FullText CFDBased Investigation of Oil Lubrication System Design The engine’s lubrication system is. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. In this article, a detailed computational. A typical automatic. Oil Lubrication System Design.

From www.heritagepartscentre.com

Lessons in lubrication Engine Oil Explained Oil Lubrication System Design Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. Engine lubrication system analysis and oil pump design optimization. What is an automatic lubrication system for bearings? A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. Tank breathers play an important role in the filtering. Oil Lubrication System Design.

From www.machinerylubrication.com

Centralized Grease Lubrication Systems Explained Oil Lubrication System Design An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. The oil levels in system containers are subjected to. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. Tank breathers play an important role in the filtering. Oil Lubrication System Design.

From www.youtube.com

How is an Aircraft Engine Lubricated? Engine Oil System in 3 minutes Oil Lubrication System Design In this article, a detailed computational. The oil levels in system containers are subjected to. Tank breathers play an important role in the filtering system of a hydraulic unit. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. An accurate simulation model of the lubrication system is essential for. Oil Lubrication System Design.

From www.researchgate.net

Schematic diagram of main gearbox oilguiding splash lubrication system Oil Lubrication System Design An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. Engine lubrication system analysis and oil pump design optimization. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the. Oil Lubrication System Design.

From www.researchgate.net

New lubrication system configurationcylinder head oil bypass with Oil Lubrication System Design What is an automatic lubrication system for bearings? The engine’s lubrication system is. Tank breathers play an important role in the filtering system of a hydraulic unit. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. The lubrication system comprises various components, including the oil pump, oil. Oil Lubrication System Design.

From www.enginelabs.com

Pros and Cons of A Dry Sump Engine Oiling System Oil Lubrication System Design The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. The engine’s lubrication system is. Tank breathers play an important role in the filtering system of a hydraulic unit. Engine lubrication system analysis and oil pump design optimization. The oil levels in system containers are subjected to. An accurate simulation. Oil Lubrication System Design.

From mappingmemories.ca

Matemáticas Toro Espacioso bearing lubrication system hombro al revés Oil Lubrication System Design In this article, a detailed computational. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. Engine lubrication system analysis and oil pump design optimization. Tank breathers play an important role in the filtering system of a hydraulic unit. Modern engines work harder and run hotter and consequently place more demands on. Oil Lubrication System Design.

From www.machinerylubrication.com

Add Oil Circulation to Gear and Bearing Sumps for Greater Reliability Oil Lubrication System Design In this article, a detailed computational. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. The oil levels in system containers are subjected to. Tank breathers play an important role in the filtering system of a hydraulic unit. Modern engines work harder and run hotter and consequently place more demands on. Oil Lubrication System Design.

From www.youtube.com

Engine lubrication system / How does it work? (3D animation) YouTube Oil Lubrication System Design Tank breathers play an important role in the filtering system of a hydraulic unit. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. The engine’s lubrication system is. In this article, a detailed computational. What is an automatic lubrication system for bearings? The oil levels in system. Oil Lubrication System Design.

From theaviationscience.blogspot.com

𝐖𝐞𝐭𝐒𝐮𝐦𝐩 𝐎𝐢𝐥 𝐒𝐲𝐬𝐭𝐞𝐦 Oil Lubrication System Design Engine lubrication system analysis and oil pump design optimization. The engine’s lubrication system is. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. The oil levels in system containers are subjected to. What is an automatic lubrication system for bearings? In this article, a detailed computational. Tank breathers play. Oil Lubrication System Design.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Oil Lubrication System Design An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. The engine’s lubrication system is. The oil levels in system containers are subjected to. Tank breathers play an important role in the filtering system of a hydraulic unit. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce. Oil Lubrication System Design.

From www.machinerylubrication.com

Centralized Grease Lubrication Systems Explained Oil Lubrication System Design The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. The engine’s lubrication system is. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. Engine lubrication system analysis and oil pump design optimization. Tank breathers. Oil Lubrication System Design.

From hdnaturewallpaperfullscreen.blogspot.com

[Get 24+] Schematic Diagram Lubricating Oil System Oil Lubrication System Design In this article, a detailed computational. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. What is an automatic lubrication system for bearings? Tank breathers play an important role in the filtering system of a hydraulic unit. Modern engines work harder and run hotter and consequently place more demands. Oil Lubrication System Design.

From cmaengineers.com.au

Oil Lubrication System Design CMA Engineering Oil Lubrication System Design What is an automatic lubrication system for bearings? A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. Tank breathers play an important role in the filtering system of a hydraulic unit. In this article, a detailed computational. The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst.. Oil Lubrication System Design.

From www.aircraftsystemstech.com

Aircraft Reciprocating Engine Lubrication Systems Oil Lubrication System Design The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. What is an automatic lubrication system for bearings? The engine’s lubrication system is. An accurate simulation model of the lubrication system is essential for early design of the heavy truck transmission. The oil levels in system containers are subjected to.. Oil Lubrication System Design.

From www.woerner.de

OilAir Lubrication System Woerner Oil Lubrication System Design The primary purpose of the lubrication system is to lubricate sliding surfaces and reduce friction losses in the engine, whilst. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. Modern engines work harder and run hotter and consequently place more demands on the engine oil and the design of the lubrication. What is an automatic lubrication system. Oil Lubrication System Design.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Oil Lubrication System Design What is an automatic lubrication system for bearings? Engine lubrication system analysis and oil pump design optimization. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The engine’s lubrication system is. Tank breathers play an important role in the filtering system of a hydraulic unit. The oil levels in system containers are subjected to. The primary purpose. Oil Lubrication System Design.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Oil Lubrication System Design A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. What is an automatic lubrication system for bearings? Engine lubrication system analysis and oil pump design optimization. An accurate simulation model of the lubrication. Oil Lubrication System Design.

From xkldase.edu.vn

Details more than 119 ring oil lubrication best xkldase.edu.vn Oil Lubrication System Design What is an automatic lubrication system for bearings? In this article, a detailed computational. Engine lubrication system analysis and oil pump design optimization. The engine’s lubrication system is. The oil levels in system containers are subjected to. Tank breathers play an important role in the filtering system of a hydraulic unit. The primary purpose of the lubrication system is to. Oil Lubrication System Design.

From www.bijurdelimon.com

Automated Chain Lubrication Systems Bijur Delimon International Oil Lubrication System Design The engine’s lubrication system is. In this article, a detailed computational. A typical automatic system (grease or oil) includes a pump, controller/timer, lubricant. The lubrication system comprises various components, including the oil pump, oil pan, oil filter, oil passages, oil pressure relief valve, and oil pressure sensor,. Engine lubrication system analysis and oil pump design optimization. Tank breathers play an. Oil Lubrication System Design.