Brazing In Manufacturing Process . There are six fundamentals of brazing that every brazer should follow to ensure. brazing is a method of joining two pieces of metal together with a third, molten filler metal. these brazing procedures boil down the brazing process to six basic steps. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. Each step in the process is relatively. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. Of all the methods available for metal.

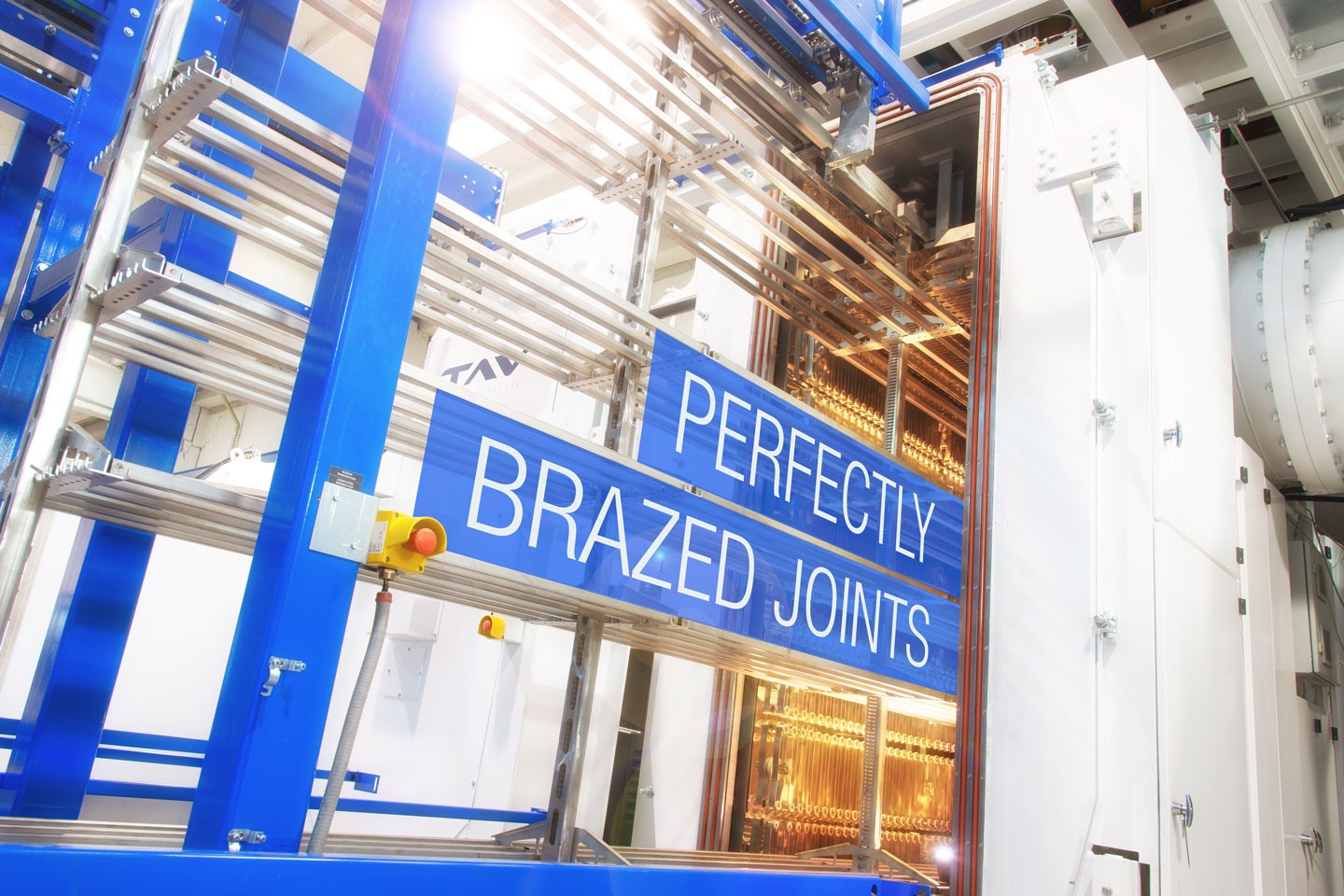

from www.tav-vacuumfurnaces.com

The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. Each step in the process is relatively. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. There are six fundamentals of brazing that every brazer should follow to ensure. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. these brazing procedures boil down the brazing process to six basic steps. Of all the methods available for metal.

Vacuum brazing the guide to perfect brazed joints

Brazing In Manufacturing Process Each step in the process is relatively. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. Each step in the process is relatively. brazing is a method of joining two pieces of metal together with a third, molten filler metal. There are six fundamentals of brazing that every brazer should follow to ensure. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. Of all the methods available for metal. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. these brazing procedures boil down the brazing process to six basic steps. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint.

From www.thefabricator.com

How to braze in a sixstep process Brazing In Manufacturing Process Each step in the process is relatively. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. Of all the methods available for metal. brazing is a method of. Brazing In Manufacturing Process.

From www.youtube.com

Metal Joining Processes Welding, Riveting, Bolting, Brazing, Soldering Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. Each step in the process is relatively. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Of all the methods available for metal. The filler metal has. Brazing In Manufacturing Process.

From dxopyzcdy.blob.core.windows.net

Brazing Manufacturing Process at Freddy Frederick blog Brazing In Manufacturing Process brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. Each step in the process is relatively. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. The filler metal has a lower melting temperature than the parts to be joined to keep the. Brazing In Manufacturing Process.

From cehfsyxq.blob.core.windows.net

Brazing In Manufacturing at Cheryl Brown blog Brazing In Manufacturing Process brazing is a method of joining two pieces of metal together with a third, molten filler metal. Of all the methods available for metal. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. brazing is a process that joins two or more metal surfaces by letting molten. Brazing In Manufacturing Process.

From www.slideshare.net

Manufacturing Process Welding, Brazing & Soldering Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. these brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every brazer should follow to ensure. brazing is a process that joins two or more metal surfaces by letting molten metal flow into. Brazing In Manufacturing Process.

From ultraflexpower.com

Induction brazing using a robot Ultraflex Power Technologies Brazing In Manufacturing Process brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. Each step in the process is relatively. There are six fundamentals of brazing that. Brazing In Manufacturing Process.

From cehfsyxq.blob.core.windows.net

Brazing In Manufacturing at Cheryl Brown blog Brazing In Manufacturing Process Of all the methods available for metal. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. Each step in the process is relatively. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. brazing is a method of joining two pieces of. Brazing In Manufacturing Process.

From www.kaizanaero.com

Brazing and Welding Kaizan Aero Manufacturing Sdn. Bhd. Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. these brazing procedures boil down the brazing process to six basic steps. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The filler metal has a lower melting temperature than the parts to be. Brazing In Manufacturing Process.

From www.dodomachine.com

Copper Pipe Fittings Brazing Manufacturing Solutions Brazing In Manufacturing Process brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the. Brazing In Manufacturing Process.

From www.youtube.com

Brazing Process Animation YouTube Brazing In Manufacturing Process Of all the methods available for metal. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. Each step in the process is relatively. brazing is a method of joining two pieces of metal together with a third, molten filler metal. brazing is a process that joins two or more metal surfaces. Brazing In Manufacturing Process.

From www.radyne.com

What Are The Advantages of Induction Brazing? Radyne Corporation Brazing In Manufacturing Process The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. these brazing procedures boil down the brazing process to six basic steps. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. . Brazing In Manufacturing Process.

From www.iqraquality.com

Brazing Procedure Qualification & Brazer Qualification Services Brazing In Manufacturing Process There are six fundamentals of brazing that every brazer should follow to ensure. Of all the methods available for metal. brazing is a method of joining two pieces of metal together with a third, molten filler metal. Each step in the process is relatively. the brazing production process encompasses several steps including preparation of the workpiece surface prior. Brazing In Manufacturing Process.

From www.youtube.com

Manufacturing process tutorial Brazing Methods YouTube Brazing In Manufacturing Process The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. brazing is a method of joining two pieces of metal together with a third, molten filler metal. the. Brazing In Manufacturing Process.

From dxopyzcdy.blob.core.windows.net

Brazing Manufacturing Process at Freddy Frederick blog Brazing In Manufacturing Process brazing is a method of joining two pieces of metal together with a third, molten filler metal. Each step in the process is relatively. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. There are six fundamentals of brazing that every brazer should follow to ensure. The melting. Brazing In Manufacturing Process.

From cehfsyxq.blob.core.windows.net

Brazing In Manufacturing at Cheryl Brown blog Brazing In Manufacturing Process these brazing procedures boil down the brazing process to six basic steps. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. Each step in the process is relatively. Of all the methods. Brazing In Manufacturing Process.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Brazing In Manufacturing Process brazing is a method of joining two pieces of metal together with a third, molten filler metal. There are six fundamentals of brazing that every brazer should follow to ensure. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. the brazing production process encompasses several steps including. Brazing In Manufacturing Process.

From www.ionix.fi

Laser Brazing Ionix Oy Brazing In Manufacturing Process brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. these brazing procedures boil down the brazing process to six basic steps. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. . Brazing In Manufacturing Process.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Brazing In Manufacturing Process brazing is a method of joining two pieces of metal together with a third, molten filler metal. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. There are six fundamentals of brazing. Brazing In Manufacturing Process.

From www.scribd.com

Brazing Brazing is a metaljoining process in which two or more metal Brazing In Manufacturing Process The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the. Brazing In Manufacturing Process.

From www.tav-vacuumfurnaces.com

Vacuum brazing the guide to perfect brazed joints Brazing In Manufacturing Process The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. brazing is a method of joining two pieces of metal together with a third, molten filler metal. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy). Brazing In Manufacturing Process.

From www.cpvmfg.com

Joining Metals Your Frequently Asked Questions About Brazing, Answered Brazing In Manufacturing Process brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. the brazing production process encompasses several steps including preparation of the workpiece surface prior to. Of all the methods available for metal. There are six fundamentals of brazing that every brazer should follow. Brazing In Manufacturing Process.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing In Manufacturing Process The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. Of all the methods available for metal. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. brazing is a joining process traditionally applied to metals (but also to. Brazing In Manufacturing Process.

From www.fullagartech.com

What are the different methods of brazing? TWI Brazing In Manufacturing Process Of all the methods available for metal. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. brazing is a joining process traditionally applied to metals (but also to ceramics) in. Brazing In Manufacturing Process.

From www.iqtemp.com

Vacuum brazing iQtemp Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. There are six fundamentals of brazing that every brazer should follow to ensure. Of all the methods available for metal. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. brazing is a. Brazing In Manufacturing Process.

From www.slideshare.net

Manufacturing Process Welding, Brazing & Soldering Brazing In Manufacturing Process brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. these brazing procedures boil down the brazing process to six basic steps. Each step in the process is relatively. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal.. Brazing In Manufacturing Process.

From cehfsyxq.blob.core.windows.net

Brazing In Manufacturing at Cheryl Brown blog Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. Of all the methods available for metal. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. Each step in the process is relatively. The filler metal has a lower melting temperature than the. Brazing In Manufacturing Process.

From cehfsyxq.blob.core.windows.net

Brazing In Manufacturing at Cheryl Brown blog Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. Each step in the process is relatively. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. brazing is a method of joining two pieces of metal together with a third, molten filler. Brazing In Manufacturing Process.

From www.wisegeek.com

What is Torch Brazing? (with pictures) Brazing In Manufacturing Process The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. these brazing procedures boil down the brazing process to six basic steps. the brazing production process encompasses several. Brazing In Manufacturing Process.

From www.youtube.com

Manufacturing Process Tutorial Brazed Joints YouTube Brazing In Manufacturing Process The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. these brazing procedures boil down the brazing process to six basic steps. brazing is a process that joins two or more metal surfaces by letting molten metal flow into the joint. brazing is a joining process traditionally. Brazing In Manufacturing Process.

From www.studocu.com

Torch Brazing Introduction to basic manufacturing processes Brazing Brazing In Manufacturing Process these brazing procedures boil down the brazing process to six basic steps. Each step in the process is relatively. Of all the methods available for metal. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. brazing is a method of joining two pieces of metal together with. Brazing In Manufacturing Process.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. There are six fundamentals of brazing that every brazer should follow to ensure. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. brazing is a process that joins two or more metal. Brazing In Manufacturing Process.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Brazing In Manufacturing Process The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. these brazing procedures boil down the brazing process to six basic steps. brazing is a joining process traditionally. Brazing In Manufacturing Process.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Brazing In Manufacturing Process Of all the methods available for metal. Each step in the process is relatively. brazing is a method of joining two pieces of metal together with a third, molten filler metal. these brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every brazer should follow to ensure. brazing. Brazing In Manufacturing Process.

From studylib.net

The Brazing Guide Brazing In Manufacturing Process the brazing production process encompasses several steps including preparation of the workpiece surface prior to. There are six fundamentals of brazing that every brazer should follow to ensure. these brazing procedures boil down the brazing process to six basic steps. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler. Brazing In Manufacturing Process.

From www.dodomachine.com

Automatic Brazing Machine Manufacturing SolutionDoDomachine Brazing In Manufacturing Process brazing is a method of joining two pieces of metal together with a third, molten filler metal. The filler metal has a lower melting temperature than the parts to be joined to keep the workpieces from melting. The melting temperature of the filler material is about 600°c but lower than the melting temperature of the parent metal. Each step. Brazing In Manufacturing Process.