Sheet Metal Extruded Hole Formula . creating an extruded hole using a punching process requires extreme pressure/force. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. This article discusses the effects of die design. hole extrusions start with a punched hole in a flat surface of the sheetmetal. Extruded holes very close to the part edge. part i explored the effects of the working material as well as the edge condition of the prepierced hole. The limitation to the height is simply the metal’s limit. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less.

from www.pandamfg.com

The limitation to the height is simply the metal’s limit. Extruded holes very close to the part edge. hole extrusions start with a punched hole in a flat surface of the sheetmetal. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. creating an extruded hole using a punching process requires extreme pressure/force. part i explored the effects of the working material as well as the edge condition of the prepierced hole. This article discusses the effects of die design.

Sheet Metal Introduction Panda Manufacturing Consulting Company

Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. Extruded holes very close to the part edge. This article discusses the effects of die design. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. The limitation to the height is simply the metal’s limit. hole extrusions start with a punched hole in a flat surface of the sheetmetal. part i explored the effects of the working material as well as the edge condition of the prepierced hole. creating an extruded hole using a punching process requires extreme pressure/force. unipunch tooling can be used to simultaneously punch a hole and extrude the material down.

From extrudedrisuran.blogspot.com

Extruded Extruded Hole Sheet Metal Extruded Hole Formula creating an extruded hole using a punching process requires extreme pressure/force. This article discusses the effects of die design. Extruded holes very close to the part edge. hole extrusions start with a punched hole in a flat surface of the sheetmetal. part i explored the effects of the working material as well as the edge condition of. Sheet Metal Extruded Hole Formula.

From www.chegg.com

Solved Given A direct extrusion operation with an extrusion Sheet Metal Extruded Hole Formula This article discusses the effects of die design. part i explored the effects of the working material as well as the edge condition of the prepierced hole. creating an extruded hole using a punching process requires extreme pressure/force. The limitation to the height is simply the metal’s limit. unipunch tooling can be used to simultaneously punch a. Sheet Metal Extruded Hole Formula.

From www.thelibraryofmanufacturing.com

Metal Extrusion Sheet Metal Extruded Hole Formula creating an extruded hole using a punching process requires extreme pressure/force. Extruded holes very close to the part edge. hole extrusions start with a punched hole in a flat surface of the sheetmetal. part i explored the effects of the working material as well as the edge condition of the prepierced hole. The limitation to the height. Sheet Metal Extruded Hole Formula.

From www.pandamfg.com

Sheet Metal Introduction Panda Manufacturing Consulting Company Sheet Metal Extruded Hole Formula unipunch tooling can be used to simultaneously punch a hole and extrude the material down. hole extrusions start with a punched hole in a flat surface of the sheetmetal. creating an extruded hole using a punching process requires extreme pressure/force. The limitation to the height is simply the metal’s limit. inadequate clearance makes a hole with. Sheet Metal Extruded Hole Formula.

From dfmpro.com

DFMPro provides Sheet Metal Design Guidelines Sheet Metal Extruded Hole Formula unipunch tooling can be used to simultaneously punch a hole and extrude the material down. Extruded holes very close to the part edge. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. hole extrusions start with a punched hole in a flat surface of the. Sheet Metal Extruded Hole Formula.

From unipunch.com

Metal Extruded Hole Punch Tooling UniPunch Sheet Metal Extruded Hole Formula part i explored the effects of the working material as well as the edge condition of the prepierced hole. This article discusses the effects of die design. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. unipunch tooling can be used to simultaneously punch a. Sheet Metal Extruded Hole Formula.

From www.thefabricator.com

R&D Update Edge fracture in hole extrusion and flanging, Part I Sheet Metal Extruded Hole Formula The limitation to the height is simply the metal’s limit. This article discusses the effects of die design. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. Extruded holes very close. Sheet Metal Extruded Hole Formula.

From www.guptapermold.com

Designing For Aluminum Extrusion Gupta Permold Co. Sheet Metal Extruded Hole Formula Extruded holes very close to the part edge. The limitation to the height is simply the metal’s limit. creating an extruded hole using a punching process requires extreme pressure/force. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. part i explored the effects of the. Sheet Metal Extruded Hole Formula.

From www.metalformingmagazine.com

Tooling by Design Hole ExtrusionsPart 3 MetalForming Magazine Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. hole extrusions start with a punched hole in a flat surface of the sheetmetal. The limitation to the height is simply the metal’s limit. This article discusses the effects of die design. part i explored the. Sheet Metal Extruded Hole Formula.

From www.youtube.com

Creo Parametric Sheetmetal Punch Form Reference Models YouTube Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. creating an extruded hole using a punching process requires extreme pressure/force. Extruded holes very close to the part edge. This article discusses the effects of die design. part i explored the effects of the working material. Sheet Metal Extruded Hole Formula.

From www.youtube.com

اتعلم سوليد ورك بالتفاصيل Sheet Metal Extruded Cut /Simple Hole YouTube Sheet Metal Extruded Hole Formula hole extrusions start with a punched hole in a flat surface of the sheetmetal. creating an extruded hole using a punching process requires extreme pressure/force. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. unipunch tooling can be used to simultaneously punch a hole. Sheet Metal Extruded Hole Formula.

From www.scribd.com

Aluminium Extrusion Design Guide Extrusion Metals Sheet Metal Extruded Hole Formula This article discusses the effects of die design. part i explored the effects of the working material as well as the edge condition of the prepierced hole. Extruded holes very close to the part edge. hole extrusions start with a punched hole in a flat surface of the sheetmetal. inadequate clearance makes a hole with small rollover. Sheet Metal Extruded Hole Formula.

From localrevive.com

Sheet Metal Fabrication 101 A Basic Knowledge Guide RapidDirect Blog (2022) Sheet Metal Extruded Hole Formula part i explored the effects of the working material as well as the edge condition of the prepierced hole. The limitation to the height is simply the metal’s limit. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. creating an extruded hole using a punching. Sheet Metal Extruded Hole Formula.

From www.vowin.cn

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal Parts Bend Reliefs, Hole Sheet Metal Extruded Hole Formula unipunch tooling can be used to simultaneously punch a hole and extrude the material down. part i explored the effects of the working material as well as the edge condition of the prepierced hole. Extruded holes very close to the part edge. creating an extruded hole using a punching process requires extreme pressure/force. hole extrusions start. Sheet Metal Extruded Hole Formula.

From www.youtube.com

Sheet metal design guidelines Minimum Distance Between Extruded Holes, Sheet metal design rules Sheet Metal Extruded Hole Formula creating an extruded hole using a punching process requires extreme pressure/force. part i explored the effects of the working material as well as the edge condition of the prepierced hole. The limitation to the height is simply the metal’s limit. hole extrusions start with a punched hole in a flat surface of the sheetmetal. inadequate clearance. Sheet Metal Extruded Hole Formula.

From forums.autodesk.com

Extruded hole iFeature Autodesk Community Sheet Metal Extruded Hole Formula hole extrusions start with a punched hole in a flat surface of the sheetmetal. The limitation to the height is simply the metal’s limit. Extruded holes very close to the part edge. part i explored the effects of the working material as well as the edge condition of the prepierced hole. unipunch tooling can be used to. Sheet Metal Extruded Hole Formula.

From www.eng-tips.com

Extrusion Hole Size Industrial/Mfg engineering general discussion EngTips Sheet Metal Extruded Hole Formula Extruded holes very close to the part edge. part i explored the effects of the working material as well as the edge condition of the prepierced hole. hole extrusions start with a punched hole in a flat surface of the sheetmetal. The limitation to the height is simply the metal’s limit. creating an extruded hole using a. Sheet Metal Extruded Hole Formula.

From www.techsteel.net

Tech Steel & Materials What is Metal Extrusion Types, Processes & Characteristics Sheet Metal Extruded Hole Formula hole extrusions start with a punched hole in a flat surface of the sheetmetal. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. Extruded holes very close to the part. Sheet Metal Extruded Hole Formula.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. Extruded holes very close to the part edge. creating an extruded hole using a punching process requires extreme pressure/force. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. hole. Sheet Metal Extruded Hole Formula.

From homepage.cs.uiowa.edu

The U of Iowa's DEC PDP8 Restoration Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. The limitation to the height is simply the metal’s limit. This article discusses the effects of die design. hole extrusions start with a punched hole in a flat surface of the sheetmetal. creating an extruded hole. Sheet Metal Extruded Hole Formula.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Sheet Metal Extruded Hole Formula unipunch tooling can be used to simultaneously punch a hole and extrude the material down. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. The limitation to the height is simply the metal’s limit. hole extrusions start with a punched hole in a flat surface. Sheet Metal Extruded Hole Formula.

From www.mdpi.com

Metals Free FullText Die Defects and Die Corrections in Metal Extrusion Sheet Metal Extruded Hole Formula unipunch tooling can be used to simultaneously punch a hole and extrude the material down. hole extrusions start with a punched hole in a flat surface of the sheetmetal. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. This article discusses the effects of die. Sheet Metal Extruded Hole Formula.

From www.youtube.com

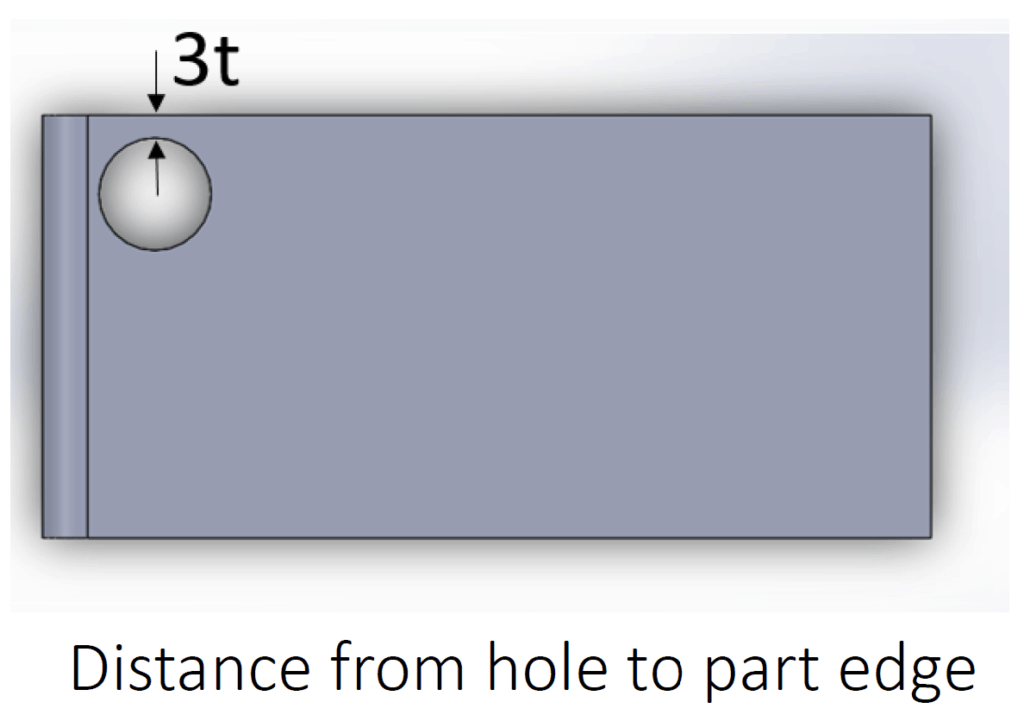

Sheet Metal Design Guidelines Part 01 Minimum Distance from Extruded Hole to Part Edge YouTube Sheet Metal Extruded Hole Formula creating an extruded hole using a punching process requires extreme pressure/force. This article discusses the effects of die design. The limitation to the height is simply the metal’s limit. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. Extruded holes very close to the part edge. hole extrusions start with a. Sheet Metal Extruded Hole Formula.

From www.thefabricator.com

R&D Update Edge fracture in hole extrusion and flanging, Part I Sheet Metal Extruded Hole Formula Extruded holes very close to the part edge. hole extrusions start with a punched hole in a flat surface of the sheetmetal. The limitation to the height is simply the metal’s limit. part i explored the effects of the working material as well as the edge condition of the prepierced hole. This article discusses the effects of die. Sheet Metal Extruded Hole Formula.

From www.youtube.com

Sheetmetal Flat length Calculation (Theory Vs. Solidworks) YouTube Sheet Metal Extruded Hole Formula This article discusses the effects of die design. part i explored the effects of the working material as well as the edge condition of the prepierced hole. Extruded holes very close to the part edge. The limitation to the height is simply the metal’s limit. hole extrusions start with a punched hole in a flat surface of the. Sheet Metal Extruded Hole Formula.

From unipunch.com

Metal Extruded Hole Punch Tooling UniPunch Sheet Metal Extruded Hole Formula unipunch tooling can be used to simultaneously punch a hole and extrude the material down. The limitation to the height is simply the metal’s limit. hole extrusions start with a punched hole in a flat surface of the sheetmetal. Extruded holes very close to the part edge. creating an extruded hole using a punching process requires extreme. Sheet Metal Extruded Hole Formula.

From www.youtube.com

SolidWorks Sheet Metal Offset Extruded Cut Fill Pattern Exercise solidworks YouTube Sheet Metal Extruded Hole Formula hole extrusions start with a punched hole in a flat surface of the sheetmetal. Extruded holes very close to the part edge. This article discusses the effects of die design. part i explored the effects of the working material as well as the edge condition of the prepierced hole. The limitation to the height is simply the metal’s. Sheet Metal Extruded Hole Formula.

From www.pandamfg.com

Sheet Metal Introduction Panda Manufacturing Consulting Company Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. creating an extruded hole using a punching process requires extreme pressure/force. hole extrusions start with a punched hole in a flat surface of the sheetmetal. This article discusses the effects of die design. part i. Sheet Metal Extruded Hole Formula.

From www.hardwareinterviews.fyi

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI Sheet Metal Extruded Hole Formula creating an extruded hole using a punching process requires extreme pressure/force. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. part i explored the effects of the working material as well as the edge condition of the prepierced hole. This article discusses the effects of. Sheet Metal Extruded Hole Formula.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Extruded Hole Formula part i explored the effects of the working material as well as the edge condition of the prepierced hole. This article discusses the effects of die design. Extruded holes very close to the part edge. The limitation to the height is simply the metal’s limit. creating an extruded hole using a punching process requires extreme pressure/force. inadequate. Sheet Metal Extruded Hole Formula.

From www.mdpi.com

Metals Free FullText Die Defects and Die Corrections in Metal Extrusion Sheet Metal Extruded Hole Formula The limitation to the height is simply the metal’s limit. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. This article discusses the effects of die design. Extruded holes very close. Sheet Metal Extruded Hole Formula.

From www.researchgate.net

How to increase the stiffness of a perforated metal sheet? Can extrusion of holes in perforated Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. Extruded holes very close to the part edge. part i explored the effects of the working material as well as the edge condition of the prepierced hole. This article discusses the effects of die design. The limitation. Sheet Metal Extruded Hole Formula.

From cncfirst.com

Sheet Metal Design Guide for Product Manufacturing cncfirst Sheet Metal Extruded Hole Formula inadequate clearance makes a hole with small rollover (a) and steep fracture (c) so that the profile is more or less. The limitation to the height is simply the metal’s limit. This article discusses the effects of die design. Extruded holes very close to the part edge. part i explored the effects of the working material as well. Sheet Metal Extruded Hole Formula.

From www.metalformingmagazine.com

Hole ExtrusionsPart 3 MetalForming Magazine Article Sheet Metal Extruded Hole Formula Extruded holes very close to the part edge. hole extrusions start with a punched hole in a flat surface of the sheetmetal. part i explored the effects of the working material as well as the edge condition of the prepierced hole. creating an extruded hole using a punching process requires extreme pressure/force. inadequate clearance makes a. Sheet Metal Extruded Hole Formula.

From www.eng-tips.com

Extrusion Hole Size Industrial/Mfg engineering general discussion EngTips Sheet Metal Extruded Hole Formula part i explored the effects of the working material as well as the edge condition of the prepierced hole. hole extrusions start with a punched hole in a flat surface of the sheetmetal. This article discusses the effects of die design. unipunch tooling can be used to simultaneously punch a hole and extrude the material down. . Sheet Metal Extruded Hole Formula.