Hydraulic Injection Molding Pressure . Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. In this article, we will explain what. Thus, the act of injection is essentially about. It directly affects the quality, efficiency and cost of the final product. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Injection pressure is one of the most important parameters in injection molding. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. Learn about injection pressure, a crucial parameter in injection molding that affects the quality and consistency of the final product. Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis.

from www.pioneerplastics.com

It directly affects the quality, efficiency and cost of the final product. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Injection pressure is one of the most important parameters in injection molding. Thus, the act of injection is essentially about. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. In this article, we will explain what. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas.

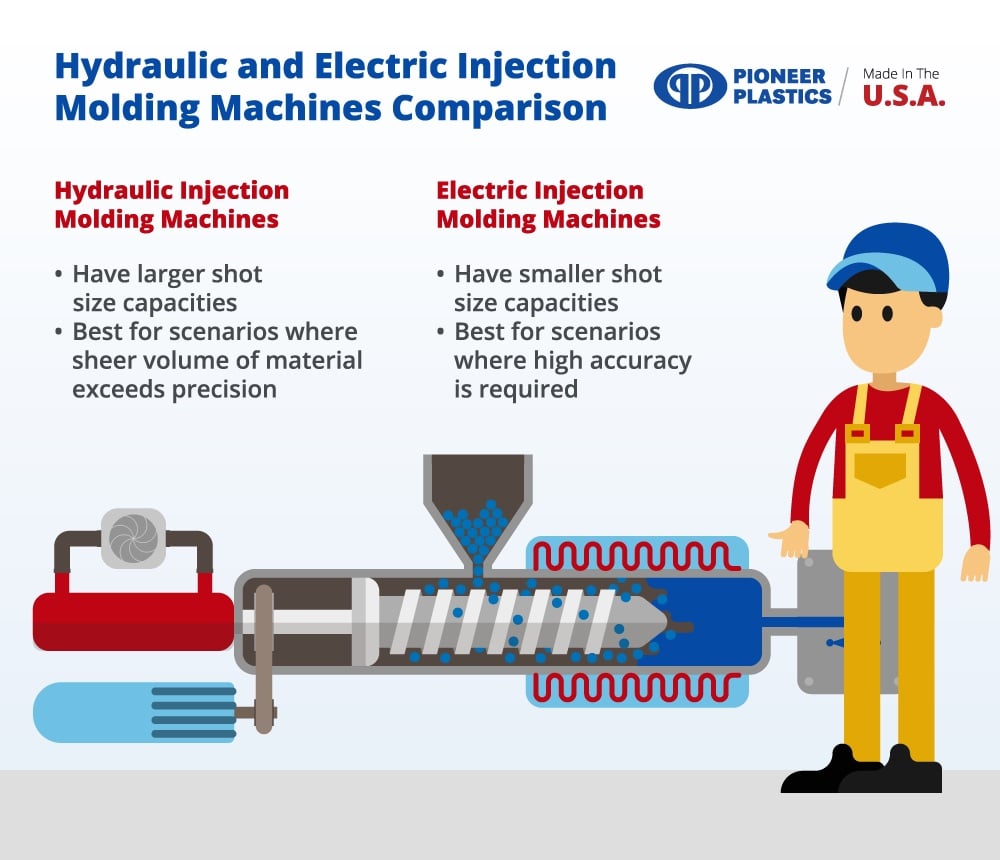

Hydraulic and Electric Injection Molding Machines

Hydraulic Injection Molding Pressure Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. It directly affects the quality, efficiency and cost of the final product. In this article, we will explain what. Thus, the act of injection is essentially about. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. Learn about injection pressure, a crucial parameter in injection molding that affects the quality and consistency of the final product. Injection pressure is one of the most important parameters in injection molding. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set.

From www.basilius.com

Hydraulics Systems for Injection Molds Basilius Inc. Hydraulic Injection Molding Pressure Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. Injection pressure is one of the most important parameters in injection molding. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. The machine must generate a force (hydraulic pressure during injection) greater than. Hydraulic Injection Molding Pressure.

From motioncontrol.blog

Eliminate Hydraulic Energy Conversion Loss With Efficient Large Hydraulic Injection Molding Pressure The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. In this article, we will explain what. Thus, the act of injection is essentially about. It directly affects. Hydraulic Injection Molding Pressure.

From upmold.com

Injection Mold Hydraulic And Pneumatic Standards Upmold Technology Hydraulic Injection Molding Pressure Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. Thus, the act of injection is essentially about. Clamping force is an application on the molder where. Hydraulic Injection Molding Pressure.

From www.youtube.com

PNEUMATIC & HYDRAULIC CYLINDER CALCULATION Injection Mould YouTube Hydraulic Injection Molding Pressure Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas.. Hydraulic Injection Molding Pressure.

From www.wsmcmold.com

Injection molding pressure curve Composites compression molding and Hydraulic Injection Molding Pressure Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. It directly affects the quality, efficiency and cost of the final product. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. Injection pressure is one of the most important parameters in injection molding. Given the. Hydraulic Injection Molding Pressure.

From china-plastic-injection-molding.com

How Does Plastic Injection Molding Work? Hydraulic Injection Molding Pressure Injection pressure is one of the most important parameters in injection molding. Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. Thus, the act of injection is essentially about. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the. Hydraulic Injection Molding Pressure.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Hydraulic Injection Molding Pressure Injection pressure is one of the most important parameters in injection molding. Learn about injection pressure, a crucial parameter in injection molding that affects the quality and consistency of the final product. Thus, the act of injection is essentially about. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short. Hydraulic Injection Molding Pressure.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer Hydraulic Injection Molding Pressure Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Learn how to calculate the injection weight, volume, pressure and speed of. Hydraulic Injection Molding Pressure.

From www.youtube.com

injection molding how to calculate clamping force YouTube Hydraulic Injection Molding Pressure Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Injection pressure is one of the most important parameters in injection molding. It directly affects the quality, efficiency and cost of the final product. Thus, the act of injection is essentially about. The machine must generate a force (hydraulic pressure during injection) greater. Hydraulic Injection Molding Pressure.

From www.researchgate.net

The composition, appearance, and process of a hydraulic... Download Hydraulic Injection Molding Pressure Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. Find out how to calculate it, what factors influence it, and how to adjust it. Hydraulic Injection Molding Pressure.

From predictabledesigns.com

Introduction to Injection Molding Hydraulic Injection Molding Pressure Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. In this article, we will explain what. Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific. Hydraulic Injection Molding Pressure.

From favpng.com

Injection Molding Machine Injection Moulding Low Pressure Molding, PNG Hydraulic Injection Molding Pressure Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. Injection pressure is one of the most important parameters in injection molding. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. In this article, we will explain what. Clamping force is an. Hydraulic Injection Molding Pressure.

From prototool.com

Injection Molding Pressure Speed and Force Balance Prototool Hydraulic Injection Molding Pressure Thus, the act of injection is essentially about. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Learn how to calculate. Hydraulic Injection Molding Pressure.

From www.researchgate.net

(a) Schematic illustration of the hydraulic injection system. (b Hydraulic Injection Molding Pressure Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. Thus, the act of injection is essentially about. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. In this article, we will explain. Hydraulic Injection Molding Pressure.

From www.energysavinginjectionmoldingmachine.com

Hydraulic Injection Molding Machine High Pressure Polyurethane Foam Hydraulic Injection Molding Pressure In this article, we will explain what. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. Thus, the act of injection is essentially about. Learn about injection pressure, a crucial parameter in injection molding that affects the quality and consistency of the final product. Learn how to calculate the injection. Hydraulic Injection Molding Pressure.

From polymeracademy.com

CLAMPING SYSTEM OF INJECTION MOULDING Hydraulic Injection Molding Pressure Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Find out how to calculate it, what factors influence it, and how to adjust it for different materials. Hydraulic Injection Molding Pressure.

From favpng.com

Injection Molding Machine Hydraulics Injection Moulding Silicone, PNG Hydraulic Injection Molding Pressure The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. Thus, the act of injection is essentially about. It directly affects the quality, efficiency and cost of the. Hydraulic Injection Molding Pressure.

From www.jazzmold.com

Injection molding machine setting Archives Plastic Injection Mold Factory Hydraulic Injection Molding Pressure Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold. Hydraulic Injection Molding Pressure.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Hydraulic Injection Molding Pressure Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Thus, the act of injection is essentially about. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. In this article, we will explain. Hydraulic Injection Molding Pressure.

From www.pioneerplastics.com

Hydraulic and Electric Injection Molding Machines Hydraulic Injection Molding Pressure The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Injection pressure is one of the most important parameters in injection molding. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis.. Hydraulic Injection Molding Pressure.

From www.shenzhoumachinery.net

China Customized Hydraulic Injection Molding Machine Manufacturers Hydraulic Injection Molding Pressure In this article, we will explain what. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Learn how to measure and minimize the pressure loss in the flow path of. Hydraulic Injection Molding Pressure.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Hydraulic Injection Molding Pressure Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. It directly affects the quality, efficiency and cost of the final product. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. Learn about. Hydraulic Injection Molding Pressure.

From www.plasticmoulds.net

Operation Cycle Of Injection Molding Hydraulic Injection Molding Pressure Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. Injection pressure is one of the most important parameters in injection molding. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. It directly affects the quality,. Hydraulic Injection Molding Pressure.

From www.plastic-injectionmoldingmachine.com

Low Pressure Hydraulic Plastic Injection Molding Machine Small Type Hydraulic Injection Molding Pressure Thus, the act of injection is essentially about. Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. The machine must generate a force (hydraulic pressure during injection) greater than or equal to. Hydraulic Injection Molding Pressure.

From www.plastic-injectionmoldingmachine.com

Low Pressure Hydraulic Plastic Injection Molding Machine Small Type Hydraulic Injection Molding Pressure In this article, we will explain what. Injection pressure is one of the most important parameters in injection molding. Learn about injection pressure, a crucial parameter in injection molding that affects the quality and consistency of the final product. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Learn. Hydraulic Injection Molding Pressure.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Hydraulic Injection Molding Pressure Given the following information, for a hydraulically actuated injection moulding machine, calculate the specific injection pressure used with a set. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. In this article, we will explain what. Clamping force is an application on the. Hydraulic Injection Molding Pressure.

From www.researchgate.net

Schematic of the injection molding process. In the filling stage, a Hydraulic Injection Molding Pressure Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. The machine must generate. Hydraulic Injection Molding Pressure.

From cnhaijiang.en.made-in-china.com

Hydraulic Plastic Injection Moulding Horizontal Molding High Pressure Hydraulic Injection Molding Pressure Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Thus, the act of injection is essentially about. Find out the factors that affect the clamping force, injection rate and injection speed in. Hydraulic Injection Molding Pressure.

From www.daobenmachinery.com

Decoding Molding Machine Hydraulic Pressure Sensor Failures Hydraulic Injection Molding Pressure The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection cycle. Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Find out. Hydraulic Injection Molding Pressure.

From www.researchgate.net

Schematic of a typical hydraulic injection moulding machine. Download Hydraulic Injection Molding Pressure In this article, we will explain what. Find out the factors that affect the clamping force, injection rate and injection speed in injection molding. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. It directly affects the quality, efficiency and cost of the final product. Thus, the. Hydraulic Injection Molding Pressure.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Hydraulic Injection Molding Pressure The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Find out how to calculate it, what factors influence it, and how to adjust it for different materials and applications. Clamping force is an application on the molder where hydraulic pressure must be carefully maintained during the injection. Hydraulic Injection Molding Pressure.

From www.alamy.com

Electric hydraulic injection molding machine at plastic exhibition Hydraulic Injection Molding Pressure Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Injection pressure is one of the most important parameters in injection molding. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Learn about injection pressure, a crucial parameter in injection. Hydraulic Injection Molding Pressure.

From businessnewscalifornia.wordpress.com

Injection Molding How It Works And What Are The Advantages Business Hydraulic Injection Molding Pressure The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. It directly affects the quality, efficiency and cost of the final product.. Hydraulic Injection Molding Pressure.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Hydraulic Injection Molding Pressure It directly affects the quality, efficiency and cost of the final product. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold flow analysis. The machine must generate a force (hydraulic pressure during injection) greater than or equal to this resistance to fill the mold cavity.. Hydraulic Injection Molding Pressure.

From www.imcgrupo.com

Clamping force in injection molding IMC Grupo Hydraulic Injection Molding Pressure Learn how to calculate the injection weight, volume, pressure and speed of plastic parts using various formulas. Injection pressure is one of the most important parameters in injection molding. In this article, we will explain what. Learn how to measure and minimize the pressure loss in the flow path of injection molded parts by making short shots and using mold. Hydraulic Injection Molding Pressure.