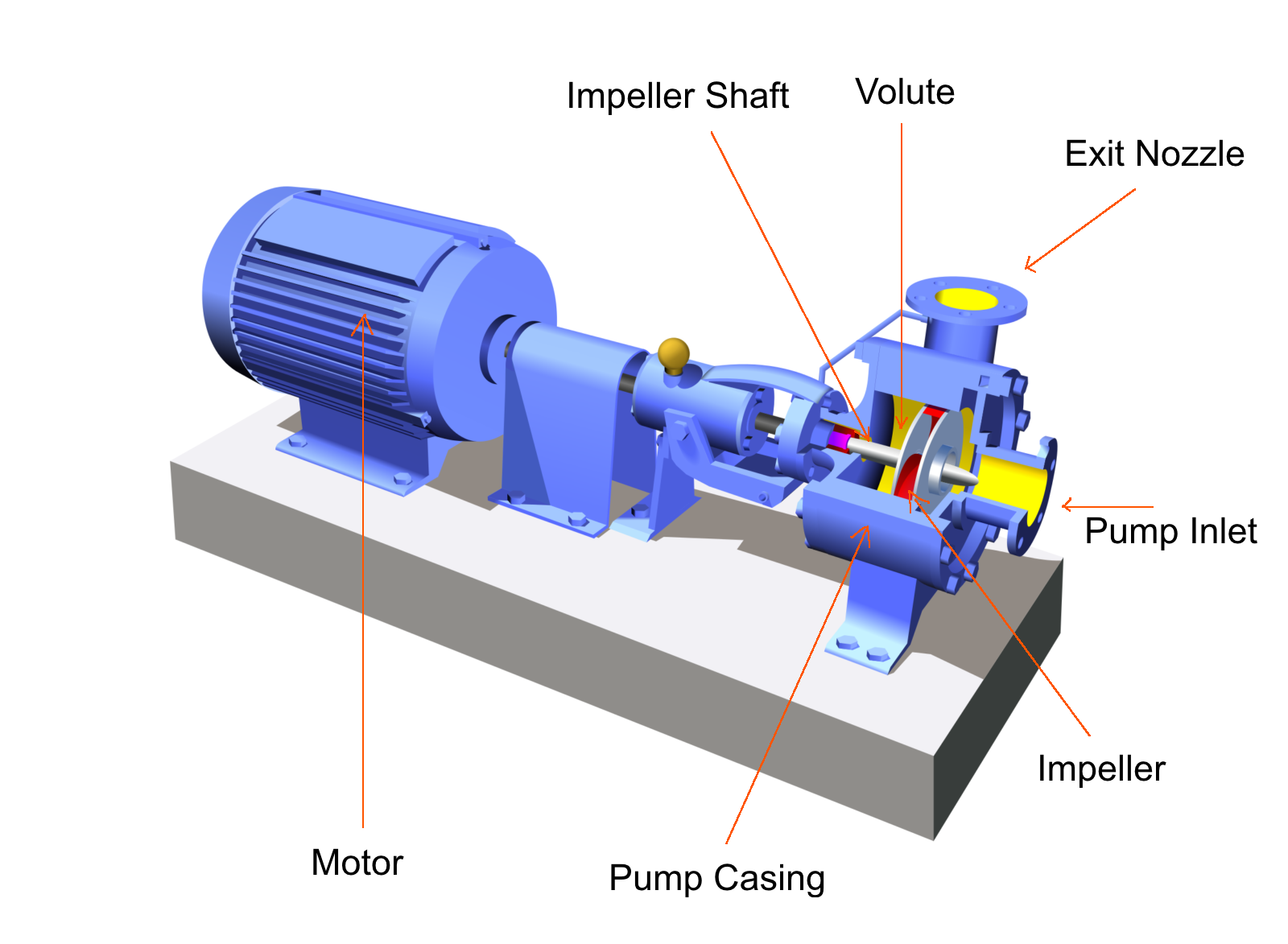

Centrifugal Pump Suction Piping Design . Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. An important aspect of pump hydraulic system design is the suction or inlet conditions. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction The design of suction piping for all pumps is critical for the performance and health of the pump. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Disregard for proper allowances can result in vortices,.

from acoem.us

An important aspect of pump hydraulic system design is the suction or inlet conditions. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction The design of suction piping for all pumps is critical for the performance and health of the pump. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Disregard for proper allowances can result in vortices,.

Basics of Centrifugal Pumps Know Your Machines Acoem USA

Centrifugal Pump Suction Piping Design The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. The design of suction piping for all pumps is critical for the performance and health of the pump. An important aspect of pump hydraulic system design is the suction or inlet conditions. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. Disregard for proper allowances can result in vortices,. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction

From theconstructor.org

Centrifugal Pump Components, Working, Types and Application Centrifugal Pump Suction Piping Design Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. An important aspect of pump hydraulic system design is the suction or inlet conditions. The design. Centrifugal Pump Suction Piping Design.

From makepipingeasy.com

Pump Piping Design Considerations Make Piping Easy Centrifugal Pump Suction Piping Design The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Pump suction piping shall be arranged such that the flow is as smooth. Centrifugal Pump Suction Piping Design.

From thepipingtalk.com

Standard pump piping routing & considerations for pump piping Centrifugal Pump Suction Piping Design An important aspect of pump hydraulic system design is the suction or inlet conditions. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction. Centrifugal Pump Suction Piping Design.

From mungfali.com

Pump Piping Layout Centrifugal Pump Suction Piping Design Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. An important aspect of pump hydraulic system design is the suction or inlet conditions. Disregard for proper allowances can result. Centrifugal Pump Suction Piping Design.

From www.pumpindustry.com.au

Centrifugal pumps Pump Industry Magazine Centrifugal Pump Suction Piping Design An important aspect of pump hydraulic system design is the suction or inlet conditions. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction The first step. Centrifugal Pump Suction Piping Design.

From thepipingtalk.com

Standard pump piping routing & considerations for pump piping Centrifugal Pump Suction Piping Design Disregard for proper allowances can result in vortices,. The design of suction piping for all pumps is critical for the performance and health of the pump. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction An important aspect of pump hydraulic system design is the suction or inlet. Centrifugal Pump Suction Piping Design.

From makepipingeasy.com

Pump Piping Design Considerations Make Piping Easy Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to. Centrifugal Pump Suction Piping Design.

From www.iqs.co.th

Article Centrifugal Pump Suction Pipeline Design and Construction Centrifugal Pump Suction Piping Design Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and. Centrifugal Pump Suction Piping Design.

From www.sintechpumps.com

Guide for Installing Centrifugal Pumps Sintech Pumps Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Disregard for. Centrifugal Pump Suction Piping Design.

From www.pipingguide.net

How to do Pump Piping with Layout Explained PIPING GUIDE Centrifugal Pump Suction Piping Design In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Disregard for proper allowances can result in vortices,. An important aspect of pump hydraulic system design is the suction or inlet conditions. The design of suction piping for all pumps is critical for the performance. Centrifugal Pump Suction Piping Design.

From www.pipingguide.net

How to do Pump Piping with Layout Explained PIPING GUIDE Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable. Centrifugal Pump Suction Piping Design.

From mavink.com

Centrifugal Pump Suction Piping Design Centrifugal Pump Suction Piping Design An important aspect of pump hydraulic system design is the suction or inlet conditions. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. The design of suction piping for all pumps is critical for the performance and health of the pump. Disregard for proper allowances can result in vortices,. The. Centrifugal Pump Suction Piping Design.

From americhemsystems.com

Design of Suction Piping for Centrifugal Pumps AmeriChem Systems, Inc. Centrifugal Pump Suction Piping Design Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The design of suction piping for all pumps is critical for the performance and health of the pump. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. In. Centrifugal Pump Suction Piping Design.

From www.deppmann.com

Hydronic Pump Piping and Trim Suction Side R. L. Deppmann Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Failure. Centrifugal Pump Suction Piping Design.

From www.youtube.com

PreInstallation Tutorial for NM Series End Suction Centrifugal Pumps Centrifugal Pump Suction Piping Design Disregard for proper allowances can result in vortices,. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. In a centrifugal pump, for example, there is a large drop. Centrifugal Pump Suction Piping Design.

From www.youtube.com

Pump Suction Design Centrifugal Pump Design CalculationCentrifugal Centrifugal Pump Suction Piping Design Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). The first step on the way to the optimal pump is the selection between. Centrifugal Pump Suction Piping Design.

From whatispiping.com

Piping Strainers Applications, Types, Design Standards, Symbol Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive. Centrifugal Pump Suction Piping Design.

From jmpcoblog.com

How to Pick a HVAC Centrifugal Pump Part 3 Mechanical Room Space and Centrifugal Pump Suction Piping Design In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. Pump suction piping shall be arranged such that the flow is as smooth. Centrifugal Pump Suction Piping Design.

From www.vrogue.co

Centrifugal Pump Basics How Centrifugal Pumps Work Wo vrogue.co Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. Failure. Centrifugal Pump Suction Piping Design.

From www.mechanicaltutorial.com

Centrifugal Pump Different Types And Application Of Centrifugal Pump Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. Disregard for proper allowances can result in vortices,. Pump suction piping shall be arranged such that the flow is as. Centrifugal Pump Suction Piping Design.

From mavink.com

Pump Piping Layout Centrifugal Pump Suction Piping Design Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction Disregard for proper allowances can result in vortices,. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. An important aspect of pump hydraulic system design is. Centrifugal Pump Suction Piping Design.

From acoem.us

Basics of Centrifugal Pumps Know Your Machines Acoem USA Centrifugal Pump Suction Piping Design In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). The design of suction piping for all pumps is critical for the performance and health of the pump. Disregard for proper allowances can result in vortices,. An important aspect of pump hydraulic system design is. Centrifugal Pump Suction Piping Design.

From www.vrogue.co

Centrifugal Pump Piping Layout Part 1 Piping Mantra Y vrogue.co Centrifugal Pump Suction Piping Design Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). An important aspect of pump hydraulic system design is the suction or inlet conditions.. Centrifugal Pump Suction Piping Design.

From thepipingtalk.com

Standard pump piping routing & considerations for pump piping Centrifugal Pump Suction Piping Design The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Disregard for proper allowances can result in vortices,. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. Failure to properly design suction piping can lead to several issues. Centrifugal Pump Suction Piping Design.

From dokumen.tips

(PDF) EndSuction Centrifugal Pump · PDF filesystem piping POSITIVELY Centrifugal Pump Suction Piping Design In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Disregard for proper allowances can result in vortices,. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. The design of suction piping. Centrifugal Pump Suction Piping Design.

From www.researchgate.net

1. Main components of a centrifugal pump (Taken from [47]) Download Centrifugal Pump Suction Piping Design An important aspect of pump hydraulic system design is the suction or inlet conditions. Disregard for proper allowances can result in vortices,. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. In a centrifugal pump, for example, there is a large drop in pressure at the impeller. Centrifugal Pump Suction Piping Design.

From www.youtube.com

Suction Pump Installation Piping YouTube Centrifugal Pump Suction Piping Design Disregard for proper allowances can result in vortices,. The design of suction piping for all pumps is critical for the performance and health of the pump. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. The pipe diameter on the suction side should be equal to or. Centrifugal Pump Suction Piping Design.

From trendtechnologyd.blogspot.com

Inspiration 25+ Piping Design Pump Suction Centrifugal Pump Suction Piping Design Disregard for proper allowances can result in vortices,. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. In a centrifugal pump, for example, there is a large drop. Centrifugal Pump Suction Piping Design.

From mavink.com

Centrifugal Pump Suction Piping Design Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. An important aspect of pump hydraulic system design is the suction or inlet conditions. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). The first step. Centrifugal Pump Suction Piping Design.

From sanchangpump.en.made-in-china.com

End Suction Pump, Stainless Steel Centrifugal Pump, Oh1 Type Centrifugal Pump Suction Piping Design In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction The first step on the way to the optimal pump is the selection between. Centrifugal Pump Suction Piping Design.

From www.mechanicalbooster.com

Centrifugal Pump Working Principle, Main Parts with Application Centrifugal Pump Suction Piping Design In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). An important aspect of pump hydraulic system design is the suction or inlet conditions. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to friction. Centrifugal Pump Suction Piping Design.

From www.youtube.com

End Suction Pumps 3D Installation Manual YouTube Centrifugal Pump Suction Piping Design The design of suction piping for all pumps is critical for the performance and health of the pump. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due to. Centrifugal Pump Suction Piping Design.

From makepipingeasy.com

Pump Piping Design Considerations Make Piping Easy Centrifugal Pump Suction Piping Design The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. Failure to properly design suction piping can lead to several issues such as noisy operation, turbulence, head loss due. Centrifugal Pump Suction Piping Design.

From www.pipingguide.net

How to do Pump Piping with Layout Explained PIPING GUIDE Centrifugal Pump Suction Piping Design Disregard for proper allowances can result in vortices,. Pump suction piping shall be arranged such that the flow is as smooth and uniform as practicable at the pump suction nozzle. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. In a centrifugal pump, for example, there is. Centrifugal Pump Suction Piping Design.

From www.piping-designer.com

Centrifugal Pump Installation Centrifugal Pump Suction Piping Design In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). An important aspect of pump hydraulic system design is the suction or inlet conditions. The pipe diameter on the suction side should be equal to or one size larger than the pump inlet. Pump suction. Centrifugal Pump Suction Piping Design.