Dc Inductor Design Using Gapped Cores . There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. This method allows the correct. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. It recommends that first, designers determine the permeability that. Inductors, designed in this handbook, are banded together. To minimize stray flux, it is very important that the winding distribution conforms to the gap. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications.

from lcmagnetics.blogspot.com

To minimize stray flux, it is very important that the winding distribution conforms to the gap. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. This method allows the correct. It recommends that first, designers determine the permeability that. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. Inductors, designed in this handbook, are banded together. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor.

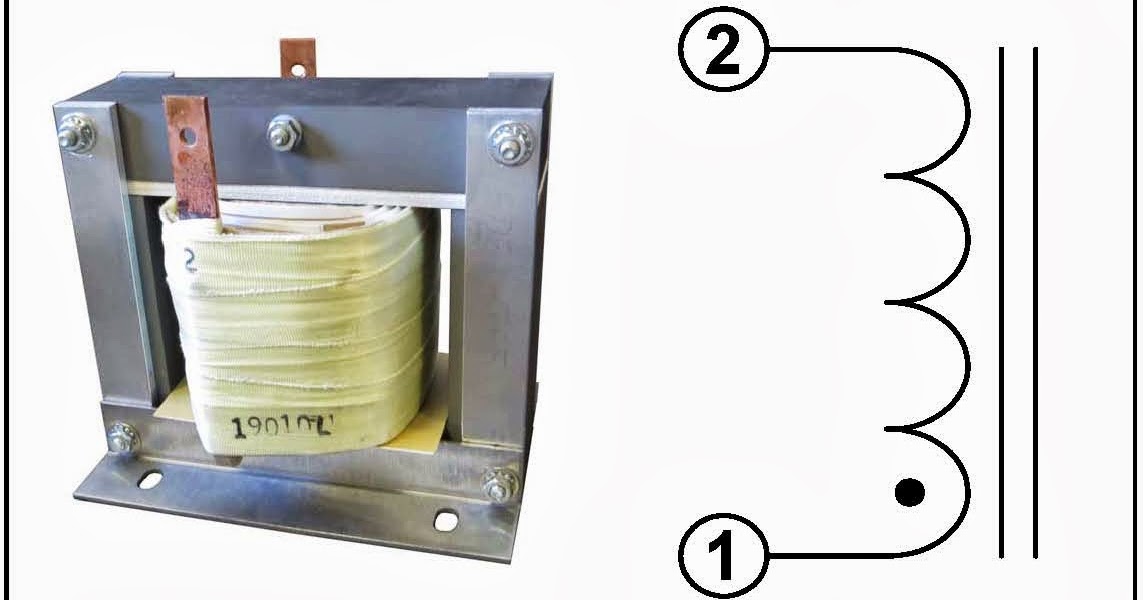

L/C Gapped Inductor, 0.5 mH, 55 A RMS, P/N 19010L

Dc Inductor Design Using Gapped Cores This method allows the correct. To minimize stray flux, it is very important that the winding distribution conforms to the gap. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. This method allows the correct. Inductors, designed in this handbook, are banded together. It recommends that first, designers determine the permeability that. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap.

From mectips.com

Transformer and Inductor Design Handbook Mechanical Engineering Dc Inductor Design Using Gapped Cores This method allows the correct. Inductors, designed in this handbook, are banded together. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. To minimize stray flux, it. Dc Inductor Design Using Gapped Cores.

From www.mag-inc.com

Inductor Cores Material and Shape Choices Dc Inductor Design Using Gapped Cores To minimize stray flux, it is very important that the winding distribution conforms to the gap. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. To compare their merits, the first design example will. Dc Inductor Design Using Gapped Cores.

From electronoobs.com

Tutorial Flyback DC converter coupled inductor theory Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. Inductors, designed in this handbook, are banded together. To minimize stray flux, it is very important that the winding distribution conforms to the gap. It recommends that first, designers determine the permeability that. This method allows the correct. In this article, we explore the. Dc Inductor Design Using Gapped Cores.

From www.semanticscholar.org

Figure 1 from material comparisons for highcurrent gapped and gapless foil wound Dc Inductor Design Using Gapped Cores There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. This method allows the correct. It recommends that first, designers determine the permeability that. The author has. Dc Inductor Design Using Gapped Cores.

From www.youtube.com

Deep dive into an approximate inductor design using two alternative cores Corrected YouTube Dc Inductor Design Using Gapped Cores In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. It recommends that first, designers determine the permeability that. Inductors, designed in this handbook, are banded together. This method allows the correct. To minimize stray flux, it is very important that the winding distribution conforms to the gap. Inductors that carry. Dc Inductor Design Using Gapped Cores.

From dsignwesome.blogspot.com

Ferrite Core Inductor Design Dc Inductor Design Using Gapped Cores Inductors, designed in this handbook, are banded together. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. To minimize stray flux, it is very important that. Dc Inductor Design Using Gapped Cores.

From www.mag-inc.com

Inductor Design with Ferrite Cores Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. This method allows the correct. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. To minimize stray flux, it is very important that the winding distribution conforms to the gap. Inductors, designed in this. Dc Inductor Design Using Gapped Cores.

From passive-components.eu

How to Design an Inductor Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. In this. Dc Inductor Design Using Gapped Cores.

From www.youtube.com

Inductor Design How Inductor core selecting using Area product Method Explained simply YouTube Dc Inductor Design Using Gapped Cores Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. This method allows the correct. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. It recommends that first, designers determine the permeability that. To minimize stray flux, it is very important that the winding distribution. Dc Inductor Design Using Gapped Cores.

From lcmagnetics.blogspot.com

L/C High Current Gapped Inductor, 18.57 uH, 4000 Amps Continuous, P/N 19016L Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. To minimize stray flux, it is very important that the winding distribution conforms to the gap. In this article, we. Dc Inductor Design Using Gapped Cores.

From passive-components.eu

How to Choose the Right Inductor for DCDC Buck Applications Dc Inductor Design Using Gapped Cores Inductors, designed in this handbook, are banded together. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. It recommends that first, designers determine the permeability that.. Dc Inductor Design Using Gapped Cores.

From passive-components.eu

How to Design an Inductor Dc Inductor Design Using Gapped Cores Inductors, designed in this handbook, are banded together. This method allows the correct. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. To compare their merits, the first design. Dc Inductor Design Using Gapped Cores.

From www.semanticscholar.org

Transformer and inductor design handbook Semantic Scholar Dc Inductor Design Using Gapped Cores Inductors, designed in this handbook, are banded together. To minimize stray flux, it is very important that the winding distribution conforms to the gap. This method allows the correct. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. Inductors that carry direct current are used frequently in a wide variety. Dc Inductor Design Using Gapped Cores.

From www.eeupdate.com

High frequency Power Inductor Design DC & AC Electronics/Electrical (EE/EC/EX) Dc Inductor Design Using Gapped Cores This method allows the correct. It recommends that first, designers determine the permeability that. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. To minimize stray flux, it is. Dc Inductor Design Using Gapped Cores.

From www.powerelectronictips.com

How new inductor cores meet demands for smaller, quieter, and more reliable power Dc Inductor Design Using Gapped Cores It recommends that first, designers determine the permeability that. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. Inductors that carry. Dc Inductor Design Using Gapped Cores.

From passive-components.eu

Würth Elektronik How do I select the right inductor for a DC/DC converter design? European Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. In this. Dc Inductor Design Using Gapped Cores.

From lcmagnetics.blogspot.com

L/C Air Core Gapped Inductor, 10 uH, 2500 Amps, P/N 6207L Dc Inductor Design Using Gapped Cores Inductors, designed in this handbook, are banded together. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. To minimize stray flux, it is very important that the winding distribution conforms to the gap. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. There. Dc Inductor Design Using Gapped Cores.

From corefficientsrl.com

What is a Distributed Gap Core? Corefficient Dc Inductor Design Using Gapped Cores To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. Inductors, designed in this handbook, are banded together. It recommends that first, designers determine the permeability that. This method allows the correct. The author has developed a simplified method of designing optimum dc carrying inductors with. Dc Inductor Design Using Gapped Cores.

From www.semanticscholar.org

Figure 10 from A High Frequency Coupled Inductor Design for High Power Density DCDC Converters Dc Inductor Design Using Gapped Cores Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. It recommends that first, designers determine the permeability that. There are significant advantages to be gained by the use of iron alloys and. Dc Inductor Design Using Gapped Cores.

From lcmagnetics.blogspot.com

L/C 200 Amp Gapped Inductor, 130 uH, P/N 18573L1 Dc Inductor Design Using Gapped Cores In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. Inductors, designed in this handbook, are banded together. It recommends that first, designers determine the permeability that. There are significant advantages to be gained by. Dc Inductor Design Using Gapped Cores.

From dokumen.tips

(PDF) TransformerandInductorDesign.pdf DOKUMEN.TIPS Dc Inductor Design Using Gapped Cores This method allows the correct. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. To compare their merits, the first design example will use the core geometry, kg, and. Dc Inductor Design Using Gapped Cores.

From ar.inspiredpencil.com

Laminated Core Inductor Dc Inductor Design Using Gapped Cores To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. Inductors, designed in this handbook, are banded together. To minimize stray flux, it is very important that the winding distribution conforms to the gap. It recommends that first, designers determine the permeability that. In this article,. Dc Inductor Design Using Gapped Cores.

From amicalegc-0607.blogspot.com

☑ Coupled Inductor Air Gap Dc Inductor Design Using Gapped Cores To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. In this article, we explore the advantages of introducing an air gap. Dc Inductor Design Using Gapped Cores.

From www.semanticscholar.org

Figure 1 from Optimal DC gapped inductor design including highfrequency effects Semantic Scholar Dc Inductor Design Using Gapped Cores Inductors, designed in this handbook, are banded together. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. There are significant advantages to be gained by the use of iron alloys and ferrites. Dc Inductor Design Using Gapped Cores.

From studylib.net

Dc Inductor Design Using Gapped Cores Dc Inductor Design Using Gapped Cores Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. It recommends that first, designers determine the permeability that. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. In this article, we explore the advantages of introducing. Dc Inductor Design Using Gapped Cores.

From www.researchgate.net

(PDF) Study of geometrical effects on high frequency winding loss of airgapped power inductor Dc Inductor Design Using Gapped Cores Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. This method allows the correct. Inductors, designed in this handbook, are banded together. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. It recommends that first, designers. Dc Inductor Design Using Gapped Cores.

From manualdatacoppices.z14.web.core.windows.net

Ferrite Core Inductor Design Dc Inductor Design Using Gapped Cores Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. There are significant advantages to be gained by the use of iron alloys and ferrites in the design. Dc Inductor Design Using Gapped Cores.

From www.tdk-electronics.tdk.com

Cores with distributed Air Gaps TDK Electronics TDK Europe Dc Inductor Design Using Gapped Cores It recommends that first, designers determine the permeability that. Inductors, designed in this handbook, are banded together. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. To compare their merits, the first design example will use the core geometry, kg, and the second design will. Dc Inductor Design Using Gapped Cores.

From lcmagnetics.blogspot.com

L/C Gapped Inductor, 0.5 mH, 55 A RMS, P/N 19010L Dc Inductor Design Using Gapped Cores Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. Inductors, designed in this handbook, are banded together. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. To minimize stray flux, it is very important that the winding distribution conforms to the. Dc Inductor Design Using Gapped Cores.

From community.element14.com

DC Inductor Design Basics element14 Community Dc Inductor Design Using Gapped Cores Inductors, designed in this handbook, are banded together. The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. Inductors that carry direct current are used frequently in a wide variety. Dc Inductor Design Using Gapped Cores.

From www.semanticscholar.org

Figure 5 from Design and analysis of the ferrite airgapped cores for a resonant inductor Dc Inductor Design Using Gapped Cores This method allows the correct. Inductors, designed in this handbook, are banded together. Inductors that carry direct current are used frequently in a wide variety of ground, air, and space applications. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. In this article, we explore. Dc Inductor Design Using Gapped Cores.

From www.mag-inc.com

Inductor Cores Material and Shape Choices Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. Inductors, designed in this handbook, are banded together. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. There are significant advantages to be gained by the use of iron. Dc Inductor Design Using Gapped Cores.

From amhvhpl.blogspot.com

Design Of Rf Choke Inductors Using Core Geometry Coefficient Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. In this article, we explore the advantages of introducing an air gap to the magnetic core of an inductor. There. Dc Inductor Design Using Gapped Cores.

From www.semanticscholar.org

Figure 6 from Optimal gapped boost in inductor design for power factor correction applications Dc Inductor Design Using Gapped Cores The author has developed a simplified method of designing optimum dc carrying inductors with powder cores. This method allows the correct. Inductors, designed in this handbook, are banded together. There are significant advantages to be gained by the use of iron alloys and ferrites in the design of power inductors, despite certain disadvantages,. In this article, we explore the advantages. Dc Inductor Design Using Gapped Cores.

From www.researchgate.net

(PDF) DC Inductor Design using the Unique Air Gap Equation Dc Inductor Design Using Gapped Cores To minimize stray flux, it is very important that the winding distribution conforms to the gap. To compare their merits, the first design example will use the core geometry, kg, and the second design will use the area product, ap. Inductors, designed in this handbook, are banded together. It recommends that first, designers determine the permeability that. The author has. Dc Inductor Design Using Gapped Cores.