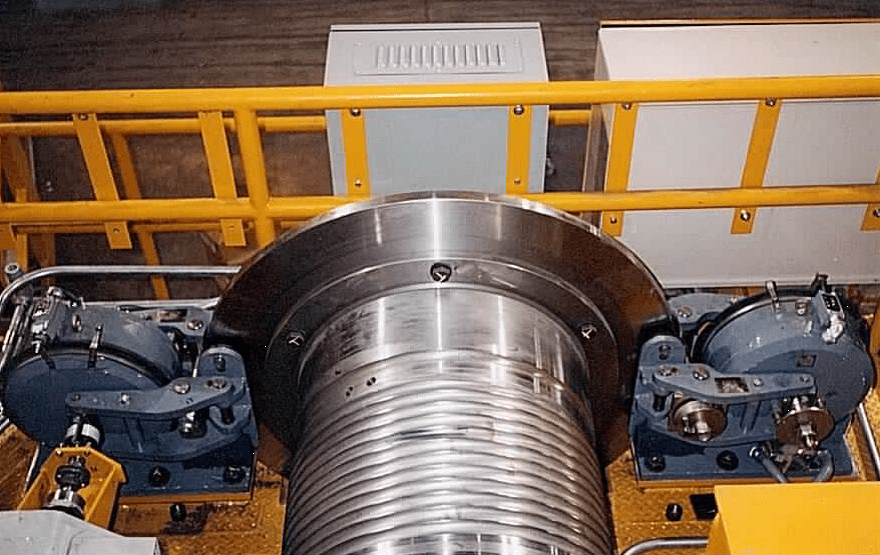

Hydraulic Crane Brake . These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. These brakes are for parking utilization, securing the crane against the wind force. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. In emergency condition they can be operated also as dynamic. Sizes are 6” through 18” with torque. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake cycle rates of greater. Type h manually operated hydraulic brakes for smooth controlled service stops. Contact us to request a.

from kor-pak.com

Contact us to request a. In emergency condition they can be operated also as dynamic. Sizes are 6” through 18” with torque. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake cycle rates of greater. In emergency condition they can be operated also as dynamic. Type h manually operated hydraulic brakes for smooth controlled service stops. These brakes are for parking utilization, securing the crane against the wind force. These brakes are for parking utilization, securing the crane against the wind force.

Emergency Brakes for Cranes

Hydraulic Crane Brake These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. These brakes are for parking utilization, securing the crane against the wind force. Contact us to request a. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. These brakes are for parking utilization, securing the crane against the wind force. Sizes are 6” through 18” with torque. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake cycle rates of greater. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Type h manually operated hydraulic brakes for smooth controlled service stops. In emergency condition they can be operated also as dynamic. In emergency condition they can be operated also as dynamic.

From www.alibaba.com

Electric Hydraulic Brake For Overhead Crane Buy Hydraulic Brake Hydraulic Crane Brake Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. These brakes are for parking utilization, securing the crane against the wind force. Type h manually operated hydraulic brakes for smooth controlled service stops. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. These. Hydraulic Crane Brake.

From www.jingucranebrake.com

China Hydraulic Crane Brake Manufacturers, Suppliers, Factory Golden Hoop Hydraulic Crane Brake Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. In emergency condition they can be operated also as dynamic. These brakes are for parking utilization, securing the crane against the wind force. Our standard compact units are available. Hydraulic Crane Brake.

From www.alibaba.com

Electro Hydraulic Thruster Brake For Eot Crane Buy Crane Drum Brakes Hydraulic Crane Brake These brakes are for parking utilization, securing the crane against the wind force. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Contact us to request a. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes.. Hydraulic Crane Brake.

From www.jingucranebrake.com

Industrial Hydraulic Crane Brake Manufacturers, Suppliers, Factory Hydraulic Crane Brake In emergency condition they can be operated also as dynamic. Contact us to request a. Type h manually operated hydraulic brakes for smooth controlled service stops. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. These brakes are for parking utilization, securing the crane against the wind force. In emergency. Hydraulic Crane Brake.

From www.jingucranebrake.com

China Tower Crane Hydraulic Brake Manufacturers, Suppliers, Factory Hydraulic Crane Brake Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake cycle rates of greater. Sizes are 6” through 18” with torque. In emergency condition they can be operated also as dynamic. Outfit your hoist with the right lift brake system from vertical. Hydraulic Crane Brake.

From www.jingucranebrake.com

ElectroHydraulic Disc Crane Brakes, Suppliers, Factory Golden Hoop Hydraulic Crane Brake Type h manually operated hydraulic brakes for smooth controlled service stops. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. In emergency condition they can be operated. Hydraulic Crane Brake.

From www.anandcontrol.in

Thruster Brake Manufacturer in India EOT Crane Brakes Hydraulic Crane Brake In emergency condition they can be operated also as dynamic. Contact us to request a. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake cycle rates of greater. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and. Hydraulic Crane Brake.

From www.indiamart.com

34 Kg Electro Hydraulic Thruster Brake, For Eot Crane ID 17109272248 Hydraulic Crane Brake The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Type h manually operated hydraulic brakes for smooth controlled service stops. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Our standard compact units are available for brake cycle rates of. Hydraulic Crane Brake.

From www.tradeindia.com

Hydraulic Crane Thruster Brake at Best Price in Greater Noida Maxx Hydraulic Crane Brake In emergency condition they can be operated also as dynamic. These brakes are for parking utilization, securing the crane against the wind force. Sizes are 6” through 18” with torque. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. Our standard compact units are available for brake cycle rates of. Hydraulic Crane Brake.

From www.indiamart.com

Crane Hydraulic Brakes, 400 at Rs 30420 in Faridabad ID 24041648333 Hydraulic Crane Brake Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. Sizes are 6” through 18” with torque. Contact us to request a. These brakes are for parking utilization, securing the crane against the wind force. These brakes consist of a set of brake pads or shoes that are pressed against a. Hydraulic Crane Brake.

From www.chinacranemanufacturer.com

Electric Hydraulic Disc Thruster Brake For Crane Manufacturers and Hydraulic Crane Brake Sizes are 6” through 18” with torque. Contact us to request a. These brakes are for parking utilization, securing the crane against the wind force. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. These brakes consist of. Hydraulic Crane Brake.

From www.jingucranebrake.com

China Hydraulic System Crane Brake Manufacturers, Suppliers, Factory Hydraulic Crane Brake Type h manually operated hydraulic brakes for smooth controlled service stops. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake cycle rates of greater. Sizes are 6” through 18” with torque. Contact us to request a. In emergency condition they can. Hydraulic Crane Brake.

From www.jingucranebrake.com

China Hydraulic Crane Brake System Manufacturers, Suppliers, Factory Hydraulic Crane Brake Type h manually operated hydraulic brakes for smooth controlled service stops. Sizes are 6” through 18” with torque. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Contact us to request a. In emergency condition they can be operated also as dynamic. These brakes are for parking utilization, securing the crane against the wind. Hydraulic Crane Brake.

From www.jingucranebrake.com

YWZ9500/E201 Electro Hydraulic drum brake Hydraulic Crane Brake These brakes are for parking utilization, securing the crane against the wind force. Sizes are 6” through 18” with torque. In emergency condition they can be operated also as dynamic. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. These brakes are for parking utilization, securing. Hydraulic Crane Brake.

From www.jingucranebrake.com

China Hydraulic Crane Brake With Antilock Manufacturers, Suppliers Hydraulic Crane Brake Type h manually operated hydraulic brakes for smooth controlled service stops. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. These brakes are for parking utilization, securing. Hydraulic Crane Brake.

From www.indiamart.com

415 V A.c Crane Hydraulic Thruster Brake, 100400mm at Rs 10000 in Mumbai Hydraulic Crane Brake The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Contact us to request a. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. In emergency condition they can be operated also as dynamic. Our standard compact units are available for brake cycle rates of. Hydraulic Crane Brake.

From www.jingucranebrake.com

YPZ2ElectroHydraulic Disc Crane Brakes, Suppliers, Factory Golden Hoop Hydraulic Crane Brake In emergency condition they can be operated also as dynamic. These brakes are for parking utilization, securing the crane against the wind force. Type h manually operated hydraulic brakes for smooth controlled service stops. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Sizes are 6” through 18” with torque. These brakes are for parking utilization, securing. Hydraulic Crane Brake.

From www.craneskit.com

Crane brake classification, function and working principleDongqi Group Hydraulic Crane Brake Sizes are 6” through 18” with torque. Contact us to request a. These brakes are for parking utilization, securing the crane against the wind force. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Type h manually operated hydraulic brakes for smooth controlled service stops. In. Hydraulic Crane Brake.

From www.jingucranebrake.com

China Hydraulic Crane Brake Systems Manufacturers, Suppliers, Factory Hydraulic Crane Brake The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. These brakes are for parking utilization, securing the crane against the wind force. Sizes are 6” through 18” with torque. In emergency condition they can be operated also as dynamic. Contact us to. Hydraulic Crane Brake.

From www.zybcbrake.com

Hydraulic Crane Brake Manufacturers and Supplier China Factory Hydraulic Crane Brake Contact us to request a. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. Type h manually operated hydraulic brakes for smooth controlled service stops. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. In emergency. Hydraulic Crane Brake.

From www.sevencraneglobal.com

Crane Electro Hydraulic Brake from China Manufacturer Henan Seven Hydraulic Crane Brake Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. In emergency condition they can be operated also as dynamic. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Type h manually operated hydraulic brakes for smooth controlled service stops. These brakes are for parking utilization, securing the. Hydraulic Crane Brake.

From www.jingucranebrake.com

Industrial Hydraulic Crane Brake Manufacturers, Suppliers, Factory Hydraulic Crane Brake The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Type h manually operated hydraulic brakes for smooth controlled service stops. Contact us to request a. In emergency condition they can be operated also as dynamic. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or. Hydraulic Crane Brake.

From kor-pak.com

Emergency Brakes for Cranes Hydraulic Crane Brake These brakes are for parking utilization, securing the crane against the wind force. These brakes are for parking utilization, securing the crane against the wind force. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high. Hydraulic Crane Brake.

From www.zybcbrake.com

ElectroHydraulic Disc Brakes for Zpmc Crane Hydraulic Crane Brake The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Contact us to request a. In emergency condition they can be operated also as dynamic. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered. Hydraulic Crane Brake.

From www.indiamart.com

Electro Hydraulic Thrustor Brakes, For Eot Crane, Up To 400mm, ID Hydraulic Crane Brake These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Contact us to request a. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. These brakes are for parking utilization, securing the crane against the wind force. Outfit your hoist with the right lift. Hydraulic Crane Brake.

From www.indiamart.com

Crane Hydraulic Brake Assembly at Rs 20000/piece Khadakpada Kalyan Hydraulic Crane Brake The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. Type h manually operated hydraulic brakes for smooth controlled service stops. These brakes are for parking utilization, securing the crane against the wind force. These brakes are for parking utilization, securing the crane against the wind force. Contact us to request a. These brakes consist. Hydraulic Crane Brake.

From www.jingucranebrake.com

Industrial Hydraulic Crane Brake Manufacturers, Suppliers, Factory Hydraulic Crane Brake Sizes are 6” through 18” with torque. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. These brakes are for parking utilization, securing the crane against the wind force. Type h manually operated hydraulic brakes for smooth controlled. Hydraulic Crane Brake.

From www.indiamart.com

Shruti Cast Iron Eot Crane Brake With Thruster, For Overhead Cranes at Hydraulic Crane Brake These brakes are for parking utilization, securing the crane against the wind force. Type h manually operated hydraulic brakes for smooth controlled service stops. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units. Hydraulic Crane Brake.

From www.alibaba.com

Electric Hydraulic Brake For Overhead Crane Buy Hydraulic Brake Hydraulic Crane Brake Sizes are 6” through 18” with torque. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. These brakes are for parking utilization, securing the crane against the wind force. Contact us to request a. Type h manually operated hydraulic brakes for smooth controlled service stops. In emergency condition they can be operated also as. Hydraulic Crane Brake.

From www.jingucranebrake.com

China Hydraulic Drum Crane Brake For Bridge Crane Manufacturers Hydraulic Crane Brake In emergency condition they can be operated also as dynamic. In emergency condition they can be operated also as dynamic. These brakes are for parking utilization, securing the crane against the wind force. These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Our standard compact units. Hydraulic Crane Brake.

From www.eventalways.com

Hydraulic Thruster Brakes, INR 10000 Per Piece, TOP CRANE SYSTEM Hydraulic Crane Brake These brakes consist of a set of brake pads or shoes that are pressed against a rotating drum or disc by hydraulic cylinders. Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. In emergency condition they can be operated also as dynamic. Sizes are 6” through 18” with torque. These. Hydraulic Crane Brake.

From www.jingucranebrake.com

Tower crane electrohydraulic propeller brake with antilock braking system Hydraulic Crane Brake Contact us to request a. Hydraulic brakes utilize hydraulic pressure to apply and release the braking force. Type h manually operated hydraulic brakes for smooth controlled service stops. Sizes are 6” through 18” with torque. In emergency condition they can be operated also as dynamic. Our standard compact units are available for brake cycle rates of less than 50 per. Hydraulic Crane Brake.

From www.anandcontrol.in

Thruster Brake Manufacturer in India EOT Crane Brakes Hydraulic Crane Brake Outfit your hoist with the right lift brake system from vertical brakes to industrial duty or custom engineered brakes. These brakes are for parking utilization, securing the crane against the wind force. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake. Hydraulic Crane Brake.

From www.jingucranebrake.com

ElectroHydraulic Disc Brakes for Zpmc Crane Hydraulic Crane Brake These brakes are for parking utilization, securing the crane against the wind force. Our standard compact units are available for brake cycle rates of less than 50 per hour, while our high capacity hydraulic release power units are specified for brake cycle rates of greater. The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking.. Hydraulic Crane Brake.

From www.kinocranes.com

How Overhead Crane Brakes Work A Comprehensive Guide Kino Cranes Hydraulic Crane Brake The hydraulic pressure is controlled by a hydraulic system, allowing for smooth and efficient braking. These brakes are for parking utilization, securing the crane against the wind force. Type h manually operated hydraulic brakes for smooth controlled service stops. These brakes are for parking utilization, securing the crane against the wind force. Contact us to request a. Hydraulic brakes utilize. Hydraulic Crane Brake.