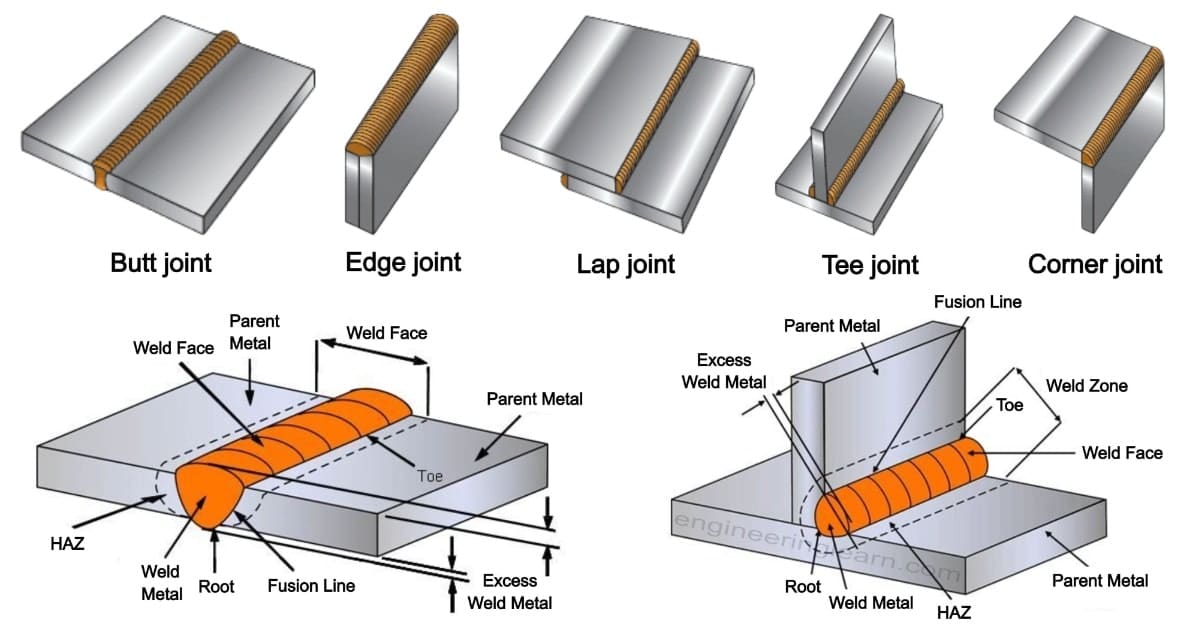

Welding Corner Joints . But those metals do not form a t shape, unlike a tee joint. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. To make a corner joint, a welder must bond two metal pieces. The resulting materials form an l shape. A corner joint is any joint in welding where two pieces of material are joined at a right angle. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. They will form an l shape because the ends of. A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. We’ll cover the following welding joint types in this guide: Consider the type of metal. It is an easy to assemble joint, the.

from engineeringlearn.com

But those metals do not form a t shape, unlike a tee joint. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. A corner joint is any joint in welding where two pieces of material are joined at a right angle. They will form an l shape because the ends of. It is an easy to assemble joint, the. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. We’ll cover the following welding joint types in this guide: There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. To make a corner joint, a welder must bond two metal pieces. Consider the type of metal.

Type of Welding Joints Applications, Advantages & Disadvantages

Welding Corner Joints Consider the type of metal. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. A corner joint is any joint in welding where two pieces of material are joined at a right angle. The resulting materials form an l shape. They will form an l shape because the ends of. A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. We’ll cover the following welding joint types in this guide: But those metals do not form a t shape, unlike a tee joint. It is an easy to assemble joint, the. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. To make a corner joint, a welder must bond two metal pieces. Consider the type of metal. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Welding Corner Joints The resulting materials form an l shape. A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig. Welding Corner Joints.

From www.techtransfer.com

Introduction to Welding Technology Transfer Services Welding Corner Joints The resulting materials form an l shape. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. Consider the type of metal. A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. They will form an l shape because the ends of. A corner. Welding Corner Joints.

From weldinglogic.com

Flare Bevel Weld Overview, Symbol, Size, Callout & More Welding Logic Welding Corner Joints The resulting materials form an l shape. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. It is an easy to assemble joint, the. Consider the type of metal. To make a corner joint, a welder must bond two metal pieces. A welded joint is created by joining two materials together. Welding Corner Joints.

From www.youtube.com

Tips for TIG Welding Outside Corner Joints YouTube Welding Corner Joints To make a corner joint, a welder must bond two metal pieces. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The resulting materials form an l shape. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form. Welding Corner Joints.

From magswitch.com

Welding Angle Essential Tools for Precision Metalwork Welding Corner Joints Consider the type of metal. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. A welded joint is created by joining two materials together that. Welding Corner Joints.

From www.grainews.ca

How to weld corner joints Grainews Welding Corner Joints There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. The resulting materials form an l shape. The corner joint welding is used to join two members that are located at approximately right angle. Welding Corner Joints.

From primeweld.com

A Guide to Weld Joints PrimeWeld Welding Corner Joints There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. To make a corner joint, a welder must bond two metal pieces. But those metals do. Welding Corner Joints.

From www.youtube.com

CORNER JOINT NO WELDING YouTube Welding Corner Joints There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. To make a corner joint, a welder must bond two metal pieces. We’ll cover the following welding joint types in this guide: A corner joint is any joint in welding where two pieces of material are joined at a right angle. The. Welding Corner Joints.

From www.youtube.com

How to TIG Weld Corner joints and Lap joints YouTube Welding Corner Joints The resulting materials form an l shape. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. To make a corner joint, a welder must bond. Welding Corner Joints.

From mewelding.com

Corner Joint Welding All You Need To Know Welding Corner Joints We’ll cover the following welding joint types in this guide: The resulting materials form an l shape. To make a corner joint, a welder must bond two metal pieces. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. A corner joint is any joint in welding where two pieces of material. Welding Corner Joints.

From loepbcscw.blob.core.windows.net

Brittle Welded Joint at Frank Gibson blog Welding Corner Joints They will form an l shape because the ends of. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. To make a corner joint, a welder must bond two metal pieces. A corner joint is any joint in welding where two pieces of material are joined at a right angle. But. Welding Corner Joints.

From mechanicalbasics.com

Welding Joint Welding Joint Types, Advantages, Application Welding Corner Joints A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The resulting materials form an l shape. But those metals do not form a t shape, unlike a tee joint. A corner joint is. Welding Corner Joints.

From www.mig-welding.co.uk

TIG Tutorial Outside Corner Weld Welding Corner Joints Consider the type of metal. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. To make a corner joint, a welder must bond two metal pieces. It is an easy to assemble joint, the. They will form an l shape because the ends. Welding Corner Joints.

From ar.inspiredpencil.com

Fillet Weld Failure Welding Corner Joints There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. It is an easy to assemble joint, the. The resulting materials form an l shape. A. Welding Corner Joints.

From blog.thepipingmart.com

What is Corner Joint Weld? Uses and Working Welding Corner Joints The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. A corner joint is any joint in welding where two pieces of material are joined at. Welding Corner Joints.

From www.instructables.com

Welding Joints and Beyond 10 Steps Instructables Welding Corner Joints The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. To make a corner joint, a welder must bond two metal pieces. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. There are various welding. Welding Corner Joints.

From www.weldingtipsandtricks.com

TIG Welding Outside Corner Joints Cold rolled Steel Welding Corner Joints To make a corner joint, a welder must bond two metal pieces. It is an easy to assemble joint, the. But those metals do not form a t shape, unlike a tee joint. A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. Consider the type of metal. There are various types. Welding Corner Joints.

From www.cwbgroup.org

How It Works What is a Backing Strip for a Welded Joint? CWB Group Welding Corner Joints A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. There are various types of weld joints with varied weld joint configurations, each with its own welding symbols. But those metals do not form. Welding Corner Joints.

From primeweld.com

A Guide to Weld Joints PrimeWeld Welding Corner Joints They will form an l shape because the ends of. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. To make a corner joint, a welder must bond two metal pieces. The resulting materials form an l shape. It is an easy to assemble joint, the. Consider the type of metal.. Welding Corner Joints.

From www.youtube.com

Welding Square Tubing at 90 Degrees Joint Preparation, the 3 ways I Welding Corner Joints But those metals do not form a t shape, unlike a tee joint. To make a corner joint, a welder must bond two metal pieces. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. A corner joint is any joint in welding where two pieces of material are joined at a. Welding Corner Joints.

From engineeringlearn.com

Type of Welding Joints Applications, Advantages & Disadvantages Welding Corner Joints Consider the type of metal. We’ll cover the following welding joint types in this guide: There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. They will form an l shape because the ends of. It is an easy to assemble joint, the. The resulting materials form an l shape. A corner. Welding Corner Joints.

From gioncxyhe.blob.core.windows.net

How To Weld 45 Degree Angles at Jeffrey Maurer blog Welding Corner Joints The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. They will form an l shape because the ends of. We’ll cover the following welding joint types in this guide: The resulting materials form an l shape. There are various welding methods available for. Welding Corner Joints.

From www.youtube.com

How to Weld Corner Joints YouTube Welding Corner Joints Consider the type of metal. The resulting materials form an l shape. A corner joint is any joint in welding where two pieces of material are joined at a right angle. A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. It is an easy to assemble joint, the. To make a. Welding Corner Joints.

From www.theengineerspost.com

Types of Welding Joints (Explained in detail) Pictures PDF Welding Corner Joints But those metals do not form a t shape, unlike a tee joint. To make a corner joint, a welder must bond two metal pieces. A corner joint is any joint in welding where two pieces of material are joined at a right angle. They will form an l shape because the ends of. We’ll cover the following welding joint. Welding Corner Joints.

From www.youtube.com

4 DIFFERENT WAYS TO WELD BOX SECTION CORNERS. SQUARE TUBE 90 YouTube Welding Corner Joints A corner joint is any joint in welding where two pieces of material are joined at a right angle. But those metals do not form a t shape, unlike a tee joint. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The resulting materials form an l shape. We’ll cover the. Welding Corner Joints.

From blog.thepipingmart.com

Advantages and Disadvantages of Corner Joint Welding Welding Corner Joints To make a corner joint, a welder must bond two metal pieces. Consider the type of metal. We’ll cover the following welding joint types in this guide: A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. They will form an l shape because the ends of. The resulting materials form an. Welding Corner Joints.

From www.grainews.ca

How to weld corner joints Grainews Welding Corner Joints Consider the type of metal. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. A corner joint is any joint in welding where two pieces of material are joined at a right angle. The resulting materials form an l shape. The corner joint welding is used to join two members that. Welding Corner Joints.

From www.youtube.com

Understanding Weld Joints Butt, Lap, T, Edge & Corner Joints Explained Welding Corner Joints The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. A corner joint is any joint in welding where two pieces of material are joined at a right angle. There are various welding methods available for corner joints, such as stick welding, mig welding,. Welding Corner Joints.

From www.youtube.com

How to Weld Mitered Corners YouTube Welding Corner Joints There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The resulting materials form an l shape. A corner joint is any joint in welding where two pieces of material are joined at a right angle. Consider the type of metal. It is an easy to assemble joint, the. But those metals. Welding Corner Joints.

From www.youtube.com

Mig welding outside corner joints YouTube Welding Corner Joints A corner joint is any joint in welding where two pieces of material are joined at a right angle. The resulting materials form an l shape. A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. We’ll cover the following welding joint types in this guide: To make a corner joint, a. Welding Corner Joints.

From engineersfield.com

Weld Joint and Weld Types Engineersfield Welding Corner Joints A welded joint is created by joining two materials together that are similar or dissimilar while applying pressure. But those metals do not form a t shape, unlike a tee joint. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. They will form. Welding Corner Joints.

From gioviwkyn.blob.core.windows.net

Forms And Surfaces Bevel at Cargill blog Welding Corner Joints They will form an l shape because the ends of. Consider the type of metal. We’ll cover the following welding joint types in this guide: To make a corner joint, a welder must bond two metal pieces. There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The corner joint welding is. Welding Corner Joints.

From www.youtube.com

How to Grind Inside Corners Welding & Furniture Making YouTube Welding Corner Joints Consider the type of metal. They will form an l shape because the ends of. The resulting materials form an l shape. To make a corner joint, a welder must bond two metal pieces. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’.. Welding Corner Joints.

From manualwiringorphaned.z21.web.core.windows.net

Welding Diagrams And Symbols Welding Corner Joints There are various welding methods available for corner joints, such as stick welding, mig welding, or tig welding. The resulting materials form an l shape. But those metals do not form a t shape, unlike a tee joint. They will form an l shape because the ends of. It is an easy to assemble joint, the. There are various types. Welding Corner Joints.

From www.grainews.ca

How to weld corner joints Grainews Welding Corner Joints To make a corner joint, a welder must bond two metal pieces. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. The resulting materials form an l shape. Consider the type of metal. There are various welding methods available for corner joints, such. Welding Corner Joints.