Cooling Tower Blowdown Valve . blowdown treatment and reuse. Piping, condenser, cooling tower losses, and valves. a blowdown valve is a valve that opens to release water from cooling water systems. for the tower piping circuit, the pump must overcome the piping flow friction loss; When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. The blowdown helps maintain the water quality within acceptable limits and prevent the build Management of this blowdown is one of the key. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. A large quantity of blowdown water is generated when operating cooling towers. It is usually trigger by a cooling tower controller or another piece of mechanical.

from www.maximasteamworks.com

Piping, condenser, cooling tower losses, and valves. for the tower piping circuit, the pump must overcome the piping flow friction loss; a blowdown valve is a valve that opens to release water from cooling water systems. It is usually trigger by a cooling tower controller or another piece of mechanical. Management of this blowdown is one of the key. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. The blowdown helps maintain the water quality within acceptable limits and prevent the build A large quantity of blowdown water is generated when operating cooling towers. blowdown treatment and reuse.

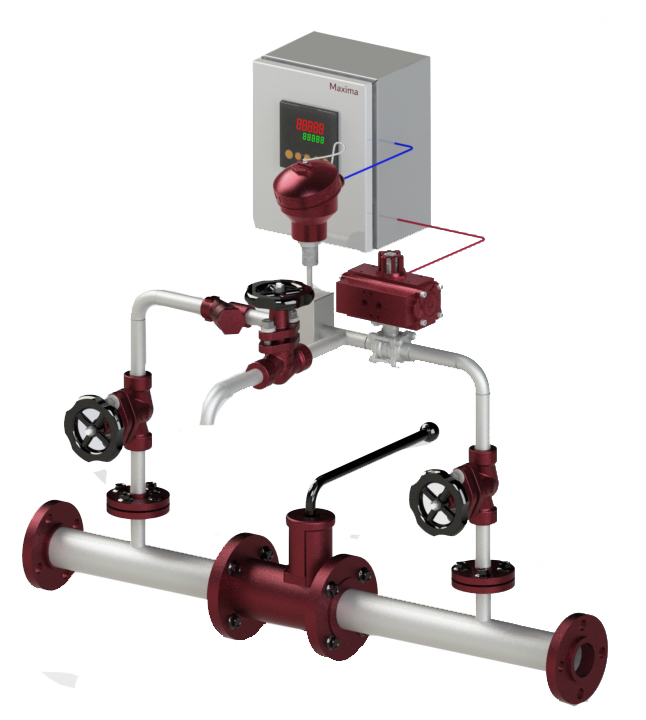

Automatic Blowdown Systems Maxima Steam Works

Cooling Tower Blowdown Valve When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. Management of this blowdown is one of the key. Piping, condenser, cooling tower losses, and valves. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. for the tower piping circuit, the pump must overcome the piping flow friction loss; The blowdown helps maintain the water quality within acceptable limits and prevent the build blowdown treatment and reuse. It is usually trigger by a cooling tower controller or another piece of mechanical. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. A large quantity of blowdown water is generated when operating cooling towers. a blowdown valve is a valve that opens to release water from cooling water systems.

From ceunpvje.blob.core.windows.net

Water Treatment Process For Cooling Towers at Truman Taylor blog Cooling Tower Blowdown Valve for the tower piping circuit, the pump must overcome the piping flow friction loss; The blowdown helps maintain the water quality within acceptable limits and prevent the build A large quantity of blowdown water is generated when operating cooling towers. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. blowdown treatment. Cooling Tower Blowdown Valve.

From www.lenntech.com

Boiler blowdown Cooling Tower Blowdown Valve A large quantity of blowdown water is generated when operating cooling towers. blowdown treatment and reuse. Management of this blowdown is one of the key. The blowdown helps maintain the water quality within acceptable limits and prevent the build for the tower piping circuit, the pump must overcome the piping flow friction loss; a blowdown valve is. Cooling Tower Blowdown Valve.

From lakewoodinstruments.com

Cooling Tower & Boiler Blowdown Valve Lakewood Instruments Cooling Tower Blowdown Valve cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. Management of this blowdown is one of the key. A large quantity of blowdown water is generated when operating cooling towers. It is usually trigger by. Cooling Tower Blowdown Valve.

From www.bundor.com

Cooling tower system valves_Bundor valve Cooling Tower Blowdown Valve cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. Piping, condenser, cooling tower losses, and valves. a blowdown valve is a valve that opens to release water from cooling water systems. The blowdown helps. Cooling Tower Blowdown Valve.

From supplyline.com

Lakewood Instruments 1167437 9505 Cooling Tower Blowdown Valve 2 Cooling Tower Blowdown Valve Piping, condenser, cooling tower losses, and valves. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. for the. Cooling Tower Blowdown Valve.

From chemicalengineeringworld.com

Blowdown Valve Working and Types Chemical Engineering World Cooling Tower Blowdown Valve blowdown treatment and reuse. a blowdown valve is a valve that opens to release water from cooling water systems. A large quantity of blowdown water is generated when operating cooling towers. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. Piping, condenser, cooling tower losses, and valves. It is usually trigger. Cooling Tower Blowdown Valve.

From spxcooling.com

HC Crossflow Valve SPX Cooling Towers Cooling Tower Blowdown Valve A large quantity of blowdown water is generated when operating cooling towers. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. blowdown treatment and reuse. It is usually trigger by a cooling tower controller. Cooling Tower Blowdown Valve.

From www.heylneomeris.com

Blowdown cooling towers Heyl Neomeris Cooling Tower Blowdown Valve The blowdown helps maintain the water quality within acceptable limits and prevent the build A large quantity of blowdown water is generated when operating cooling towers. a blowdown valve is a valve that opens to release water from cooling water systems. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a. Cooling Tower Blowdown Valve.

From qrcvalves.com

Blowdown Valve Working Principle, Types, Diagram, Applications Cooling Tower Blowdown Valve Piping, condenser, cooling tower losses, and valves. Management of this blowdown is one of the key. for the tower piping circuit, the pump must overcome the piping flow friction loss; When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. The blowdown helps maintain the water quality within acceptable limits and prevent the. Cooling Tower Blowdown Valve.

From www.indiamart.com

Cooling Tower Valve at best price in Ranipet by Ferrum Engineers ID Cooling Tower Blowdown Valve When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. The blowdown helps maintain the water quality within acceptable limits and prevent the build Management of this blowdown is one of the key. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to. Cooling Tower Blowdown Valve.

From collections.naturalsciences.org

Blowdown Valve Working Principle, Types, Diagram,, 51 OFF Cooling Tower Blowdown Valve It is usually trigger by a cooling tower controller or another piece of mechanical. blowdown treatment and reuse. Management of this blowdown is one of the key. a blowdown valve is a valve that opens to release water from cooling water systems. Piping, condenser, cooling tower losses, and valves. The blowdown helps maintain the water quality within acceptable. Cooling Tower Blowdown Valve.

From constructandcommission.com

COOLING TOWER Piping Layout And Diagrams Cooling Tower Blowdown Valve a blowdown valve is a valve that opens to release water from cooling water systems. Piping, condenser, cooling tower losses, and valves. blowdown treatment and reuse. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the. Cooling Tower Blowdown Valve.

From cannonwater.com

Effective Cooling Tower Shutdown Tips Offered Cannon Water Technology Cooling Tower Blowdown Valve Management of this blowdown is one of the key. blowdown treatment and reuse. Piping, condenser, cooling tower losses, and valves. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the. Cooling Tower Blowdown Valve.

From watertreatment.qualichem.com

Using Cooling Tower Blowdown QualiChem Water Treatment Cooling Tower Blowdown Valve blowdown treatment and reuse. Piping, condenser, cooling tower losses, and valves. Management of this blowdown is one of the key. It is usually trigger by a cooling tower controller or another piece of mechanical. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. a blowdown valve is a valve that opens. Cooling Tower Blowdown Valve.

From theengineeringmindset.com

How Cooling Towers work The Engineering Mindset Cooling Tower Blowdown Valve a blowdown valve is a valve that opens to release water from cooling water systems. blowdown treatment and reuse. The blowdown helps maintain the water quality within acceptable limits and prevent the build When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. cooling tower blowdown refers to the process of. Cooling Tower Blowdown Valve.

From www.keepital.com

RTK Rapid Action Boiler Blowdown Valves High Pressure, PV 6291 E/ HV Cooling Tower Blowdown Valve The blowdown helps maintain the water quality within acceptable limits and prevent the build for the tower piping circuit, the pump must overcome the piping flow friction loss; Piping, condenser, cooling tower losses, and valves. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. A large quantity of blowdown water is generated. Cooling Tower Blowdown Valve.

From www.multicontroller.shop

Cooling towers blowdown Multicontroller Shop Cooling Tower Blowdown Valve a blowdown valve is a valve that opens to release water from cooling water systems. A large quantity of blowdown water is generated when operating cooling towers. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the. Cooling Tower Blowdown Valve.

From www.maximasteamworks.com

Automatic Blowdown Systems Maxima Steam Works Cooling Tower Blowdown Valve a blowdown valve is a valve that opens to release water from cooling water systems. for the tower piping circuit, the pump must overcome the piping flow friction loss; Management of this blowdown is one of the key. A large quantity of blowdown water is generated when operating cooling towers. Piping, condenser, cooling tower losses, and valves. It. Cooling Tower Blowdown Valve.

From www.chryssafidis.com

Blowdown valves Automatic blow down systems, Spirax Sarco Cooling Tower Blowdown Valve blowdown treatment and reuse. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. A large quantity of blowdown water is generated when operating cooling towers. The blowdown helps maintain the water quality within acceptable limits and prevent the build for the tower piping circuit, the pump must overcome the piping flow. Cooling Tower Blowdown Valve.

From www.watertechonline.com

Cooling Tower Blowdown Treatment Using an Inclined Plate Clarifier Cooling Tower Blowdown Valve The blowdown helps maintain the water quality within acceptable limits and prevent the build It is usually trigger by a cooling tower controller or another piece of mechanical. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the. Cooling Tower Blowdown Valve.

From coolingtowerbeteizu.blogspot.com

Cooling Tower Blowdown Cooling Tower Cooling Tower Blowdown Valve The blowdown helps maintain the water quality within acceptable limits and prevent the build When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. a blowdown valve is a valve that opens to release water from cooling water systems. It is usually trigger by a cooling tower controller or another piece of mechanical.. Cooling Tower Blowdown Valve.

From www.duboischemicals.com

Summer Is Heating Up Top 5 Ways To Save On Cooling Tower Bleed Cooling Tower Blowdown Valve When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. blowdown treatment and reuse. A large quantity of blowdown water is generated when operating cooling towers. for the tower piping circuit, the pump must overcome the piping flow friction loss; Management of this blowdown is one of the key. cooling tower. Cooling Tower Blowdown Valve.

From www.mepblog.com

Cooling Tower Pumping and Piping Guide Cooling Tower Blowdown Valve cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. blowdown treatment and reuse. Management of this blowdown is one of the key. for the tower piping circuit, the pump must overcome the piping. Cooling Tower Blowdown Valve.

From www.honminggroup.com

Cooling Tower Float Valve hongming Cooling Tower Blowdown Valve When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. The blowdown helps maintain the water quality within acceptable limits and prevent the build blowdown treatment and reuse. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of. Cooling Tower Blowdown Valve.

From www.lenntech.com

Cooling tower blowdown Cooling Tower Blowdown Valve A large quantity of blowdown water is generated when operating cooling towers. for the tower piping circuit, the pump must overcome the piping flow friction loss; blowdown treatment and reuse. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and. Cooling Tower Blowdown Valve.

From www.promagenviro.com

Lakewood 9500 Series Cooling Water Blowdown Valve Cooling Tower Blowdown Valve a blowdown valve is a valve that opens to release water from cooling water systems. Management of this blowdown is one of the key. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. The blowdown helps maintain the water quality within acceptable limits and prevent the build blowdown treatment and reuse.. Cooling Tower Blowdown Valve.

From qrcvalves.com

Blowdown Valve Working Principle, Types, Diagram, Applications Cooling Tower Blowdown Valve cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. A large quantity of blowdown water is generated when operating cooling towers. blowdown treatment and reuse. It is usually trigger by a cooling tower controller. Cooling Tower Blowdown Valve.

From www.hardwaremise.com.my

SS 304 Float Valve High Flow Adjustable Arm Fully Stainless Steel Cooling Tower Blowdown Valve for the tower piping circuit, the pump must overcome the piping flow friction loss; Piping, condenser, cooling tower losses, and valves. The blowdown helps maintain the water quality within acceptable limits and prevent the build a blowdown valve is a valve that opens to release water from cooling water systems. A large quantity of blowdown water is generated. Cooling Tower Blowdown Valve.

From coolingchiwayake.blogspot.com

Cooling Cooling Tower Blowdown Cooling Tower Blowdown Valve It is usually trigger by a cooling tower controller or another piece of mechanical. A large quantity of blowdown water is generated when operating cooling towers. for the tower piping circuit, the pump must overcome the piping flow friction loss; blowdown treatment and reuse. Piping, condenser, cooling tower losses, and valves. When water evaporates from the tower, dissolved. Cooling Tower Blowdown Valve.

From constructandcommission.com

COOLING TOWER Piping Layout And Diagrams Cooling Tower Blowdown Valve When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. A large quantity of blowdown water is generated when operating cooling towers. a blowdown valve is a valve that opens to release water from cooling water systems. Piping, condenser, cooling tower losses, and valves. blowdown treatment and reuse. The blowdown helps maintain. Cooling Tower Blowdown Valve.

From instructionswaterheater.blogspot.com

Water heater manual Automatic boiler blowdown valve Cooling Tower Blowdown Valve for the tower piping circuit, the pump must overcome the piping flow friction loss; It is usually trigger by a cooling tower controller or another piece of mechanical. The blowdown helps maintain the water quality within acceptable limits and prevent the build blowdown treatment and reuse. Management of this blowdown is one of the key. A large quantity. Cooling Tower Blowdown Valve.

From www.vrogue.co

Why Do Cooling Towers Have A Blowdown Valve Aircondlo vrogue.co Cooling Tower Blowdown Valve Management of this blowdown is one of the key. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. for the tower piping circuit, the pump must overcome the piping flow friction loss; The blowdown. Cooling Tower Blowdown Valve.

From www.youtube.com

All About Cooling Tower Blowdown Complete Chiller Systems Course Cooling Tower Blowdown Valve It is usually trigger by a cooling tower controller or another piece of mechanical. cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. a blowdown valve is a valve that opens to release water. Cooling Tower Blowdown Valve.

From www.kapilsteels.com

What is a Blowdown Valve? Types, Uses and Benefits Cooling Tower Blowdown Valve cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride, and silica) are. It is usually trigger by a cooling tower controller or. Cooling Tower Blowdown Valve.

From aircondlounge.com

Why Do Cooling Towers Have a Blowdown Valve? aircondlounge Cooling Tower Blowdown Valve cooling tower blowdown refers to the process of discharging a portion of the circulating water from a cooling tower to control the concentration of dissolved solids and other impurities in the cooling water. The blowdown helps maintain the water quality within acceptable limits and prevent the build When water evaporates from the tower, dissolved solids (such as calcium, magnesium,. Cooling Tower Blowdown Valve.