Module Of Spur Gear Formula . Teeth per millimeter of pitch diameter. M = 2 * c / (m + z) 2 * c / (m + z). Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. understanding gear profile and gear module. Spur gear design formula for geometry, pitch, tooth clearance and. This is where the gear’s speed is measured. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. The geometry of a simple spur gear tooth is complex. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. The module (m) of a spur gear is calculated using the formula: The major diameter of the gear. The module is crucial because it directly. it is calculated by dividing the reference diameter of the gear by the number of teeth. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth.

from gearcutting.blogspot.com

it is calculated by dividing the reference diameter of the gear by the number of teeth. M = 2 * c / (m + z) 2 * c / (m + z). The major diameter of the gear. understanding gear profile and gear module. The geometry of a simple spur gear tooth is complex. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. The module (m) of a spur gear is calculated using the formula: This is where the gear’s speed is measured.

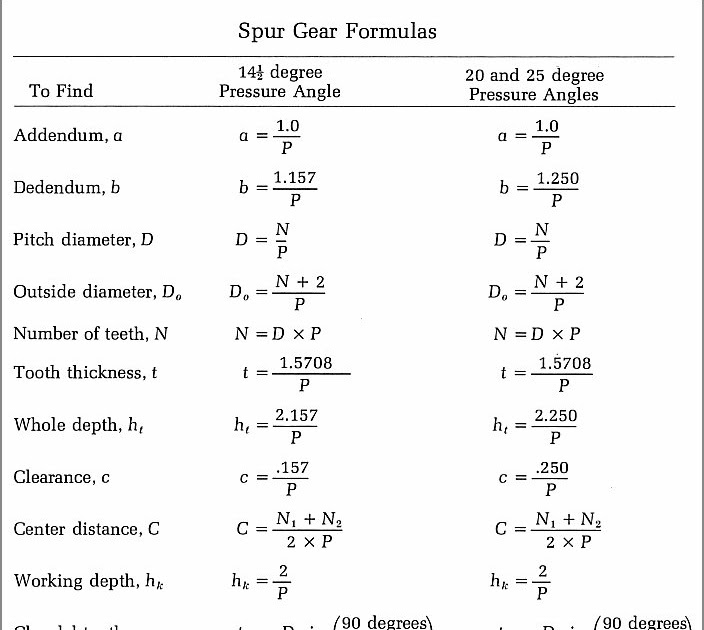

Gear Manufacturing (By Cutting) Spur Gear Formulas

Module Of Spur Gear Formula The geometry of a simple spur gear tooth is complex. The module is crucial because it directly. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. understanding gear profile and gear module. M = 2 * c / (m + z) 2 * c / (m + z). Spur gear design formula for geometry, pitch, tooth clearance and. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. This is where the gear’s speed is measured. The module (m) of a spur gear is calculated using the formula: it is calculated by dividing the reference diameter of the gear by the number of teeth. The major diameter of the gear. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The geometry of a simple spur gear tooth is complex. Teeth per millimeter of pitch diameter.

From www.youtube.com

Spur gear calculation, Design Details Spur Gear Formula spur gear Module Of Spur Gear Formula Spur gear design formula for geometry, pitch, tooth clearance and. it is calculated by dividing the reference diameter of the gear by the number of teeth. understanding gear profile and gear module. The geometry of a simple spur gear tooth is complex. Teeth per millimeter of pitch diameter. Numerous dimensional parameters define the shape of the tooth profile,. Module Of Spur Gear Formula.

From functionbay.com

Geometric Entities Module Of Spur Gear Formula The module is crucial because it directly. This is where the gear’s speed is measured. understanding gear profile and gear module. M = 2 * c / (m + z) 2 * c / (m + z). it is calculated by dividing the reference diameter of the gear by the number of teeth. Numerous dimensional parameters define the. Module Of Spur Gear Formula.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Module Of Spur Gear Formula The module (m) of a spur gear is calculated using the formula: Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth.. Module Of Spur Gear Formula.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Module Of Spur Gear Formula The module (m) of a spur gear is calculated using the formula: the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Spur gear design formula for geometry,. Module Of Spur Gear Formula.

From rubybpo.weebly.com

Fillet radius of spur gear formula rubybpo Module Of Spur Gear Formula The module (m) of a spur gear is calculated using the formula: This is where the gear’s speed is measured. The geometry of a simple spur gear tooth is complex. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The module is crucial. Module Of Spur Gear Formula.

From www.youtube.com

CALCULATION RACK AND SPUR GEAR EXCEL FORMULA YouTube Module Of Spur Gear Formula understanding gear profile and gear module. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. M = 2 * c. Module Of Spur Gear Formula.

From gearcutting.blogspot.com

Gear Manufacturing (By Cutting) Spur Gear Formulas Module Of Spur Gear Formula Teeth per millimeter of pitch diameter. M = 2 * c / (m + z) 2 * c / (m + z). This is where the gear’s speed is measured. The module (m) of a spur gear is calculated using the formula: Spur gear design formula for geometry, pitch, tooth clearance and. it is calculated by dividing the reference. Module Of Spur Gear Formula.

From drivetrainhub.com

Spur Gears Geometry of spur gears and gear meshes Module Of Spur Gear Formula in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. This is where the gear’s speed is measured. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. The module (m) of a spur gear is calculated using. Module Of Spur Gear Formula.

From exovpltat.blob.core.windows.net

Spur Gear Formula Module at Robert Beck blog Module Of Spur Gear Formula the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Teeth per millimeter of pitch diameter. M = 2 * c /. Module Of Spur Gear Formula.

From www.youtube.com

Spur Gear Tooth Profile Drawing Problem Spur gear design YouTube Module Of Spur Gear Formula The major diameter of the gear. M = 2 * c / (m + z) 2 * c / (m + z). Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Spur gear design formula for geometry, pitch, tooth clearance and. in. Module Of Spur Gear Formula.

From www.youtube.com

Lewis Beam Strength Equation Design of Spur, Helical, Bevel and Worm Module Of Spur Gear Formula The major diameter of the gear. it is calculated by dividing the reference diameter of the gear by the number of teeth. The geometry of a simple spur gear tooth is complex. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. M = 2 * c /. Module Of Spur Gear Formula.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Module Of Spur Gear Formula The module (m) of a spur gear is calculated using the formula: Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. M = 2 * c / (m + z) 2 * c / (m + z). The module is crucial because it. Module Of Spur Gear Formula.

From studylib.net

Design of Spur Gears Module Of Spur Gear Formula understanding gear profile and gear module. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The major diameter of the gear. The module is crucial because it directly. Spur gear design formula for geometry, pitch, tooth clearance and. The circle, the radius. Module Of Spur Gear Formula.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Module Of Spur Gear Formula The module (m) of a spur gear is calculated using the formula: it is calculated by dividing the reference diameter of the gear by the number of teeth. The module is crucial because it directly. This is where the gear’s speed is measured. The geometry of a simple spur gear tooth is complex. understanding gear profile and gear. Module Of Spur Gear Formula.

From exovpltat.blob.core.windows.net

Spur Gear Formula Module at Robert Beck blog Module Of Spur Gear Formula Spur gear design formula for geometry, pitch, tooth clearance and. The module is crucial because it directly. The major diameter of the gear. it is calculated by dividing the reference diameter of the gear by the number of teeth. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where. Module Of Spur Gear Formula.

From khkgears.net

Gear Backlash KHK Gears Module Of Spur Gear Formula M = 2 * c / (m + z) 2 * c / (m + z). This is where the gear’s speed is measured. The geometry of a simple spur gear tooth is complex. understanding gear profile and gear module. Spur gear design formula for geometry, pitch, tooth clearance and. it is calculated by dividing the reference diameter. Module Of Spur Gear Formula.

From www.mech4study.com

Gear Terminology Basic Definition Used in Gear Mech4study Module Of Spur Gear Formula The geometry of a simple spur gear tooth is complex. The module is crucial because it directly. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at. Module Of Spur Gear Formula.

From exovpltat.blob.core.windows.net

Spur Gear Formula Module at Robert Beck blog Module Of Spur Gear Formula Spur gear design formula for geometry, pitch, tooth clearance and. The module (m) of a spur gear is calculated using the formula: Teeth per millimeter of pitch diameter. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. in the previous pages, we introduced the basics of gears,. Module Of Spur Gear Formula.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks YouTube Module Of Spur Gear Formula Spur gear design formula for geometry, pitch, tooth clearance and. understanding gear profile and gear module. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. M = 2 * c / (m + z) 2 * c / (m + z). in the previous pages, we. Module Of Spur Gear Formula.

From lesamiesdemayalabeille.blogspot.com

Spur Gear Formula Spur Gear Design Project lesamiesdemayalabeille Module Of Spur Gear Formula in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Spur gear design formula for geometry, pitch, tooth clearance and. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. Teeth per millimeter of pitch diameter. The circle,. Module Of Spur Gear Formula.

From khkgears.net

Basic Gear Terminology and Calculation KHK Gears Module Of Spur Gear Formula it is calculated by dividing the reference diameter of the gear by the number of teeth. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Teeth per millimeter of pitch diameter. The geometry of a simple spur gear tooth is complex. The. Module Of Spur Gear Formula.

From optibda.weebly.com

Fillet radius of spur gear formula optibda Module Of Spur Gear Formula M = 2 * c / (m + z) 2 * c / (m + z). The geometry of a simple spur gear tooth is complex. This is where the gear’s speed is measured. The module is crucial because it directly. The module (m) of a spur gear is calculated using the formula: Numerous dimensional parameters define the shape of. Module Of Spur Gear Formula.

From www.automotioncomponents.co.uk

Automotion Components Spur Gears Technical Page Automotion Module Of Spur Gear Formula the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. understanding gear profile and gear module. This is where the gear’s speed is measured. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Numerous dimensional parameters. Module Of Spur Gear Formula.

From www.slideserve.com

PPT Blueprint Reading for the Machine Trades, Sixth Edition Unit 15 Module Of Spur Gear Formula Spur gear design formula for geometry, pitch, tooth clearance and. the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. The circle, the radius of which is equal. Module Of Spur Gear Formula.

From www.mechanicdrive.com

Spur gear calculation Module Of Spur Gear Formula the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. The geometry of a simple spur gear tooth is complex. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. The major diameter of the gear. The. Module Of Spur Gear Formula.

From www.jsumo.com

Wheel Side Spur Gear (1 Module 30 Tooth) Gears Jsumo Module Of Spur Gear Formula M = 2 * c / (m + z) 2 * c / (m + z). The geometry of a simple spur gear tooth is complex. it is calculated by dividing the reference diameter of the gear by the number of teeth. The module is crucial because it directly. Teeth per millimeter of pitch diameter. understanding gear profile. Module Of Spur Gear Formula.

From exomlxlma.blob.core.windows.net

Module Of Helical Gear Formula at Latasha Horton blog Module Of Spur Gear Formula M = 2 * c / (m + z) 2 * c / (m + z). The module (m) of a spur gear is calculated using the formula: Teeth per millimeter of pitch diameter. The geometry of a simple spur gear tooth is complex. it is calculated by dividing the reference diameter of the gear by the number of. Module Of Spur Gear Formula.

From www.pdfkurs.com

formule accélération angulaire Module Of Spur Gear Formula The geometry of a simple spur gear tooth is complex. it is calculated by dividing the reference diameter of the gear by the number of teeth. The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. Spur gear design formula for geometry, pitch, tooth clearance and. understanding. Module Of Spur Gear Formula.

From eng-shady-mohsen.blogspot.com

Eng. Shady Mohsen blog Involute spur gear design Module Of Spur Gear Formula The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. This is where the gear’s speed is measured. The module (m) of a. Module Of Spur Gear Formula.

From www.yogiemachinery.com

Formula for calculating the modulus of the gear rack Industry Module Of Spur Gear Formula Spur gear design formula for geometry, pitch, tooth clearance and. Teeth per millimeter of pitch diameter. The major diameter of the gear. understanding gear profile and gear module. in the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. the module of a spur gear, often symbolized as ‘m’,. Module Of Spur Gear Formula.

From fractory.com

Types of Gears Gear Parameters & Tooth Profiles Fractory Module Of Spur Gear Formula it is calculated by dividing the reference diameter of the gear by the number of teeth. The module (m) of a spur gear is calculated using the formula: the module of a spur gear, often symbolized as ‘m’, is the ratio of pitch diameter to the number of teeth. This is where the gear’s speed is measured. Numerous. Module Of Spur Gear Formula.

From exovpltat.blob.core.windows.net

Spur Gear Formula Module at Robert Beck blog Module Of Spur Gear Formula The geometry of a simple spur gear tooth is complex. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Teeth per millimeter of pitch diameter. This is where the gear’s speed is measured. The module is crucial because it directly. The major diameter. Module Of Spur Gear Formula.

From studylib.net

Gears Module Of Spur Gear Formula This is where the gear’s speed is measured. understanding gear profile and gear module. The module (m) of a spur gear is calculated using the formula: Spur gear design formula for geometry, pitch, tooth clearance and. Teeth per millimeter of pitch diameter. The major diameter of the gear. Numerous dimensional parameters define the shape of the tooth profile, determine. Module Of Spur Gear Formula.

From math.stackexchange.com

trigonometry How can you calculate the module of a gear Module Of Spur Gear Formula The module (m) of a spur gear is calculated using the formula: Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The module is crucial because it directly. it is calculated by dividing the reference diameter of the gear by the number. Module Of Spur Gear Formula.

From qlerobh.weebly.com

Spur gear formulas qlerobh Module Of Spur Gear Formula The circle, the radius of which is equal to the distance from the center of the gear to the pitch point. This is where the gear’s speed is measured. Spur gear design formula for geometry, pitch, tooth clearance and. it is calculated by dividing the reference diameter of the gear by the number of teeth. The module is crucial. Module Of Spur Gear Formula.