Rotary Engine Knock Sensor . the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. the knock sensor is an important component of a modern engine that ensures optimal performance and. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. A faulty knock sensor can manifest through symptoms such as: The greater the vibration, the higher the ac voltage and frequency. in today’s video, zach covers the signs and symptoms of a bad knock sensor,. a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing.

from www.mechanicaleducation.com

The greater the vibration, the higher the ac voltage and frequency. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. A faulty knock sensor can manifest through symptoms such as: the knock sensor is an important component of a modern engine that ensures optimal performance and. in today’s video, zach covers the signs and symptoms of a bad knock sensor,. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing. a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage.

Engine Sensors And Types Of Engine Sensors And How They Work

Rotary Engine Knock Sensor the knock sensor is an important component of a modern engine that ensures optimal performance and. the knock sensor is an important component of a modern engine that ensures optimal performance and. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. in today’s video, zach covers the signs and symptoms of a bad knock sensor,. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. A faulty knock sensor can manifest through symptoms such as: The greater the vibration, the higher the ac voltage and frequency. a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage.

From carfromjapan.com

How Does A Knock Sensor Work All You Need To Know CAR FROM JAPAN Rotary Engine Knock Sensor in today’s video, zach covers the signs and symptoms of a bad knock sensor,. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. a knock sensor is built with a piezoelectric crystal inside. Rotary Engine Knock Sensor.

From www.summitracing.com

Standard Motor Products KS446 Standard Motor Knock Sensors Summit Racing Rotary Engine Knock Sensor The greater the vibration, the higher the ac voltage and frequency. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’.. Rotary Engine Knock Sensor.

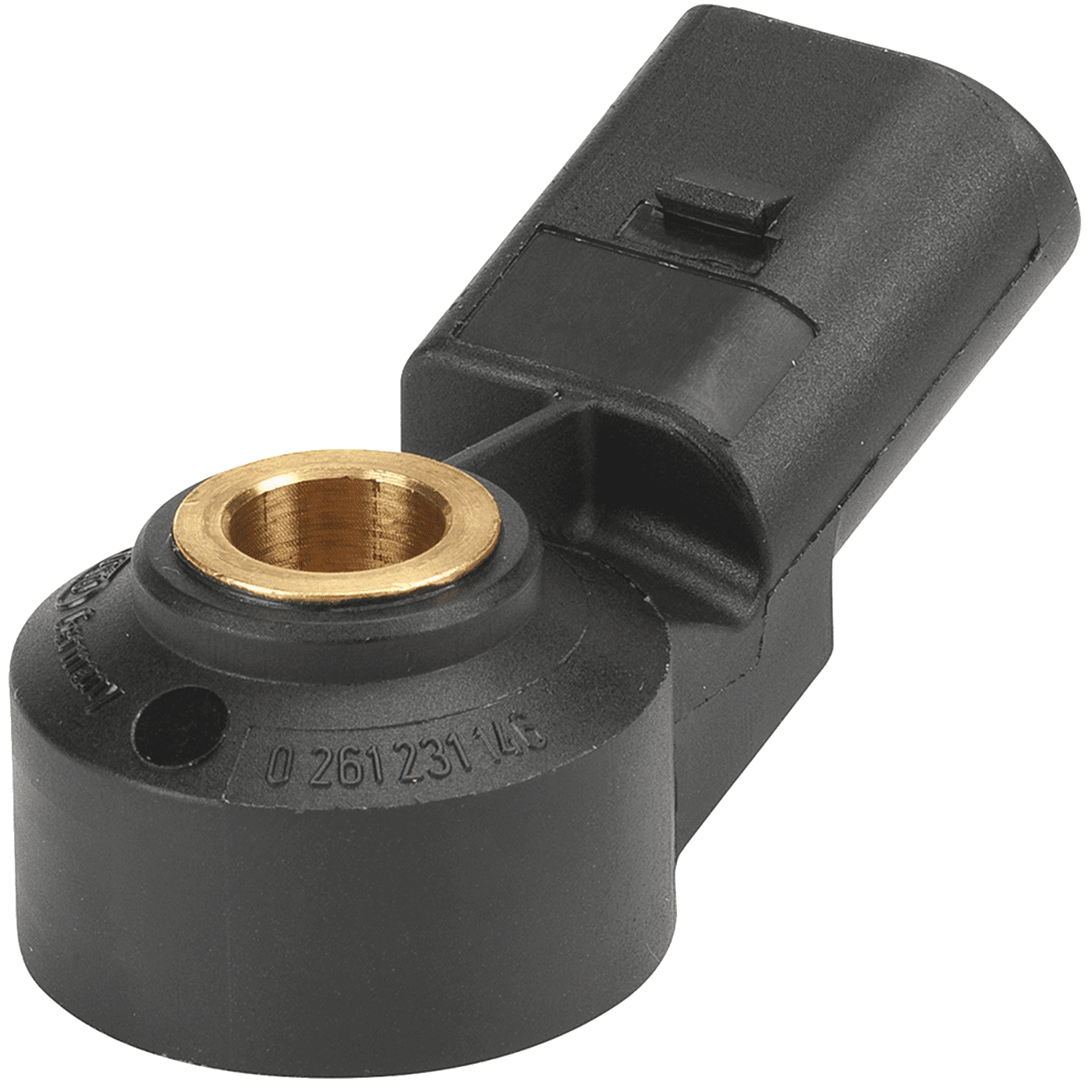

From www.amazon.com

Bosch Automotive Bosch 0261231018 Original Equipment Engine Rotary Engine Knock Sensor the knock sensor is an important component of a modern engine that ensures optimal performance and. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. A faulty knock sensor can manifest through symptoms such as: a knock sensor is an engine component designed to detect engine. Rotary Engine Knock Sensor.

From www.autozone.com

Duralast Knock Sensor SU6151 Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing. the knock sensor is responsible for detecting any. Rotary Engine Knock Sensor.

From motorsport-electronics.co.uk

Knock Sensors Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. A faulty knock sensor can manifest through symptoms such as: in today’s video, zach covers the signs and symptoms of a bad knock sensor,. The. Rotary Engine Knock Sensor.

From repairmachinesorted.z21.web.core.windows.net

Engine Knock Sensor Purpose Rotary Engine Knock Sensor The greater the vibration, the higher the ac voltage and frequency. in today’s video, zach covers the signs and symptoms of a bad knock sensor,. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing. A faulty. Rotary Engine Knock Sensor.

From ricksfreeautorepairadvice.com

What is a knock sensor — How It Works And Why It's Used — Ricks Free Rotary Engine Knock Sensor A faulty knock sensor can manifest through symptoms such as: the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing. the knock sensor is an important component of a modern engine. Rotary Engine Knock Sensor.

From www.rx7club.com

Knock sensor connector to which harness ? Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. in today’s video, zach covers. Rotary Engine Knock Sensor.

From autoplicity.com

Standard Motor Products KS22 Knock Sensor Autoplicity Rotary Engine Knock Sensor The greater the vibration, the higher the ac voltage and frequency. the knock sensor is an important component of a modern engine that ensures optimal performance and. a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. a knock sensor is an engine component designed to detect engine. Rotary Engine Knock Sensor.

From parts.ilmor.com

Engine Knock Sensor with Bolt Electrical & Sensors Ilmor Marine Parts Rotary Engine Knock Sensor a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. in today’s video, zach covers the signs and symptoms of a bad knock sensor,. A faulty knock sensor can manifest through symptoms such as: a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control. Rotary Engine Knock Sensor.

From www.soloparamecanicos.com

Sensor Knock Características Funcionamiento Tipos y mucho mas Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. The greater the vibration, the. Rotary Engine Knock Sensor.

From www.pelicanparts.com

Pelican Technical Article Volkswagen Golf GTI Mk IV Replacing Your Rotary Engine Knock Sensor a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. a knock sensor is an. Rotary Engine Knock Sensor.

From www.amazon.com

EWG LLC fit for 2PCS New 8961502020 Engine Knock Sensor Rotary Engine Knock Sensor the knock sensor is an important component of a modern engine that ensures optimal performance and. A faulty knock sensor can manifest through symptoms such as: a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine. Rotary Engine Knock Sensor.

From www.tickperformance.com

GM Knock Sensor Upgrade Kit for 199798 LS1 Engines Tick Performance Rotary Engine Knock Sensor the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. the knock sensor is an important component of a modern engine that ensures optimal performance and. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. a bad knock sensor can result. Rotary Engine Knock Sensor.

From www.youtube.com

Knock sensor YouTube Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. A faulty knock sensor can manifest through symptoms such as: the knock sensor is responsible for detecting any unusual engine noises, and if it fails,. Rotary Engine Knock Sensor.

From www.youtube.com

What Is Knock Sensor In Autos Function Of Knock Sensor YouTube Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. the knock sensor is an important component of a modern engine that ensures optimal performance and. in today’s video, zach covers the signs and. Rotary Engine Knock Sensor.

From www.amazon.com

BOSCH 0261231218 Original Equipment Engine Knock Sensor Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. The greater the vibration, the higher the ac voltage and frequency. in today’s video, zach covers the signs and symptoms of a bad knock sensor,.. Rotary Engine Knock Sensor.

From eeuroparts.com

Knock Sensors Explained Your Engine’s Stethoscope eEuroparts Rotary Engine Knock Sensor a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. in today’s video, zach covers the. Rotary Engine Knock Sensor.

From www.summitracing.com

Standard Motor Products KS249 Standard Motor Knock Sensors Summit Racing Rotary Engine Knock Sensor a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. A faulty knock sensor can manifest through symptoms such as: the knock sensor is an important component of a modern engine that ensures optimal performance and. The greater the vibration, the higher the ac voltage and frequency. in today’s video, zach covers the. Rotary Engine Knock Sensor.

From thephotographerdiaries.blogspot.com

Engine Knock Sensor How It Works Blog Of Sensor Rotary Engine Knock Sensor the knock sensor is an important component of a modern engine that ensures optimal performance and. in today’s video, zach covers the signs and symptoms of a bad knock sensor,. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. a knock sensor is built with. Rotary Engine Knock Sensor.

From ricksfreeautorepairadvice.com

How a knock sensor works — Ricks Free Auto Repair Advice Ricks Free Rotary Engine Knock Sensor a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. a knock sensor is. Rotary Engine Knock Sensor.

From www.summitracing.com

Standard Motor Products KS272 Standard Motor Knock Sensors Summit Racing Rotary Engine Knock Sensor the knock sensor is an important component of a modern engine that ensures optimal performance and. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. A faulty knock sensor can manifest through symptoms such as: a knock sensor is built with a piezoelectric crystal inside that. Rotary Engine Knock Sensor.

From www.summitracing.com

Standard Motor Products KS399 Standard Motor Knock Sensors Summit Racing Rotary Engine Knock Sensor a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. the knock sensor is responsible for detecting any unusual engine. Rotary Engine Knock Sensor.

From viatrack.ca

Engine knock detection and indication for all vehicles Rotary Engine Knock Sensor a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. A faulty knock sensor can manifest through symptoms such as: the knock sensor is an important component of a modern engine that ensures optimal performance and. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the. Rotary Engine Knock Sensor.

From eeuroparts.com

Knock Sensors Explained Your Engine’s Stethoscope eEuroparts Rotary Engine Knock Sensor a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. A faulty knock sensor can manifest through symptoms such as: the knock sensor is an important component of a modern engine that ensures optimal performance and. a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an. Rotary Engine Knock Sensor.

From www.mechanicaleducation.com

Engine Sensors And Types Of Engine Sensors And How They Work Rotary Engine Knock Sensor a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. The greater the vibration, the higher the ac voltage and frequency. in today’s video, zach covers the signs and symptoms of a bad knock sensor,. the three primary causes of engine knocking are improper combustion timing, connecting rod. Rotary Engine Knock Sensor.

From carfromjapan.com

How Does A Knock Sensor Work All You Need To Know CAR FROM JAPAN Rotary Engine Knock Sensor the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. in today’s video, zach. Rotary Engine Knock Sensor.

From www.saiautocare.com.au

What Is Engine Knocking? What Are Its Causes And How To Fix It? Rotary Engine Knock Sensor the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. a knock sensor is. Rotary Engine Knock Sensor.

From www.amazon.ca

NewYall Engine Knock Sensor with Electrical Connector, Detonation Rotary Engine Knock Sensor a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. The greater the vibration, the higher the ac voltage and frequency. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters.. Rotary Engine Knock Sensor.

From parts.ilmor.com

Engine Knock Sensor with Bolt Electrical & Sensors Ilmor Marine Parts Rotary Engine Knock Sensor in today’s video, zach covers the signs and symptoms of a bad knock sensor,. a bad knock sensor can result in the engine feeling sluggish or lacking in power, as the engine control unit (ecu) may overcompensate by retarding the ignition timing or altering other engine parameters. The greater the vibration, the higher the ac voltage and frequency.. Rotary Engine Knock Sensor.

From www.carid.com

Standard® KS264 Intermotor™ Ignition Knock Sensor Rotary Engine Knock Sensor a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. the knock sensor is an important component of a modern engine that ensures optimal performance and. in. Rotary Engine Knock Sensor.

From www.thevehiclelab.com

Knock Sensor Functions, Bad Symptoms, and Replacement Cost The Rotary Engine Knock Sensor a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. the knock sensor. Rotary Engine Knock Sensor.

From parts.ilmor.com

Engine Knock Sensor with Bolt Electrical & Sensors Ilmor Marine Parts Rotary Engine Knock Sensor the three primary causes of engine knocking are improper combustion timing, connecting rod or rod bearing. a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. The greater the vibration, the higher the ac voltage and frequency. the knock sensor is an important component of a modern engine that ensures optimal performance and.. Rotary Engine Knock Sensor.

From www.avaq.com

Ultimate Guide Knock Sensor Replacement & Service 2023 Avaq Rotary Engine Knock Sensor a knock sensor is built with a piezoelectric crystal inside that converts engine knock vibrations into an ac voltage. A faulty knock sensor can manifest through symptoms such as: the knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error. a knock sensor is an engine component designed. Rotary Engine Knock Sensor.

From www.bossautospares.co.za

Toyota RunX Knock Sensor Boss Auto Spares Rotary Engine Knock Sensor A faulty knock sensor can manifest through symptoms such as: a knock sensor is an engine component designed to detect engine detonations or ‘knocks.’. The greater the vibration, the higher the ac voltage and frequency. the knock sensor is an important component of a modern engine that ensures optimal performance and. a knock sensor is built with. Rotary Engine Knock Sensor.