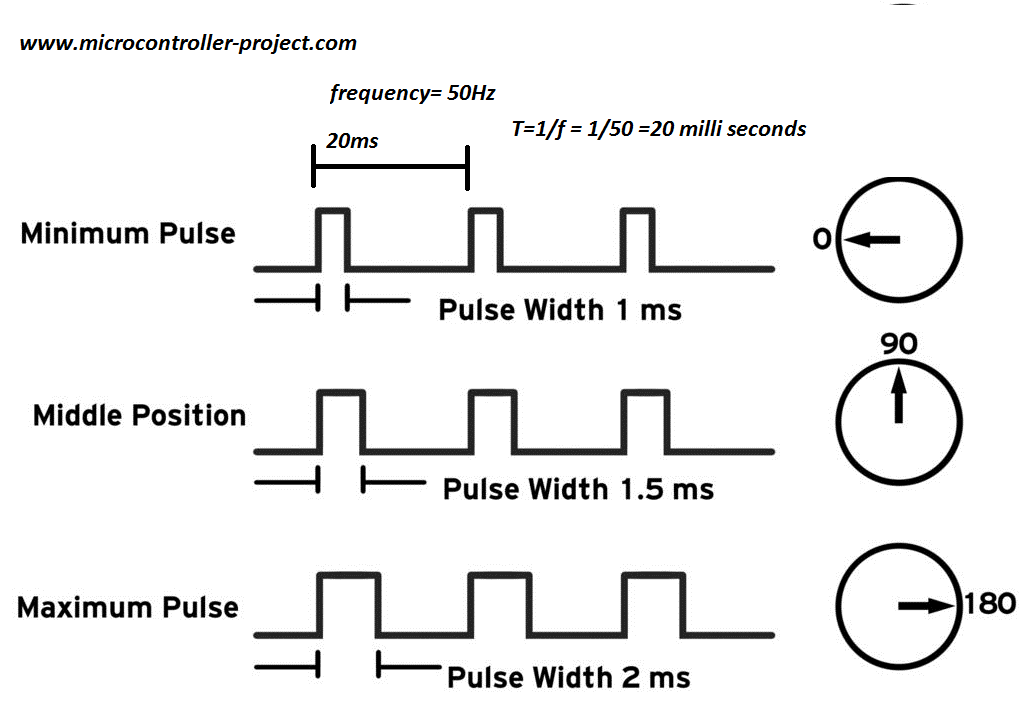

Servo Motor Duty Cycle . We typically express a duty cycle as a. i am unsure of the relationship between duty cycle and angle. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. I see lots of tutorials online with many different equations to calculate duty cycle for a. A duty cycle is the fraction of one period when a system or signal is active. Asked 3 years, 6 months ago. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz. Modified 3 years, 6 months. how to calculate duty cycle of a servo motor? “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. For example, if you have a.

from www.engineersgarage.com

since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. We typically express a duty cycle as a. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz. how to calculate duty cycle of a servo motor? A duty cycle is the fraction of one period when a system or signal is active. Modified 3 years, 6 months. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Asked 3 years, 6 months ago. I see lots of tutorials online with many different equations to calculate duty cycle for a. For example, if you have a.

Controlling Servo Motor with Stm32f103 microcontroller using

Servo Motor Duty Cycle “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. how to calculate duty cycle of a servo motor? Modified 3 years, 6 months. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. I see lots of tutorials online with many different equations to calculate duty cycle for a. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. i am unsure of the relationship between duty cycle and angle. For example, if you have a. A duty cycle is the fraction of one period when a system or signal is active. Asked 3 years, 6 months ago. We typically express a duty cycle as a.

From www.youtube.com

What is the relationship between angle and servo motor duty cycle? How Servo Motor Duty Cycle Modified 3 years, 6 months. how to calculate duty cycle of a servo motor? a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz. For example, if you have a. A duty cycle. Servo Motor Duty Cycle.

From www.kebamerica.com

4 Duty Cycles for Motors Engineers Need to Know Servo Motor Duty Cycle For example, if you have a. I see lots of tutorials online with many different equations to calculate duty cycle for a. Modified 3 years, 6 months. how to calculate duty cycle of a servo motor? i am unsure of the relationship between duty cycle and angle. Asked 3 years, 6 months ago. a typical servo motor. Servo Motor Duty Cycle.

From razzpisampler.oreilly.com

razzpisampler Servo Motor Duty Cycle Modified 3 years, 6 months. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. For example, if you have a. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. i am unsure of the. Servo Motor Duty Cycle.

From makersportal.com

Raspberry Pi Camera Panning with a Servo Motor — Maker Portal Servo Motor Duty Cycle Modified 3 years, 6 months. A duty cycle is the fraction of one period when a system or signal is active. For example, if you have a. Asked 3 years, 6 months ago. how to calculate duty cycle of a servo motor? We typically express a duty cycle as a. since the servo and motor require different clock. Servo Motor Duty Cycle.

From www.youtube.com

Electronics How to calculate duty cycle of a servo motor? YouTube Servo Motor Duty Cycle I see lots of tutorials online with many different equations to calculate duty cycle for a. i am unsure of the relationship between duty cycle and angle. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. A duty cycle is the fraction of one period when a system or signal. Servo Motor Duty Cycle.

From controllerstech.com

Interface Servo motor with STM32 Servo Motor Duty Cycle how to calculate duty cycle of a servo motor? I see lots of tutorials online with many different equations to calculate duty cycle for a. Asked 3 years, 6 months ago. We typically express a duty cycle as a. i am unsure of the relationship between duty cycle and angle. For example, if you have a. Modified 3. Servo Motor Duty Cycle.

From www.circuits-diy.com

Servo Motor Driver Circuit Servo Motor Duty Cycle i am unsure of the relationship between duty cycle and angle. A duty cycle is the fraction of one period when a system or signal is active. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. how to calculate duty cycle of. Servo Motor Duty Cycle.

From blog.wokwi.com

Learn to Control Servo motor using PWM Wokwi Style Servo Motor Duty Cycle how to calculate duty cycle of a servo motor? a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz. I see lots of tutorials online with many different equations to calculate duty cycle. Servo Motor Duty Cycle.

From www.electronicwings.com

Servo Motor Basics, Working principle & interfacing with Arduino Servo Motor Duty Cycle A duty cycle is the fraction of one period when a system or signal is active. Modified 3 years, 6 months. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. i am unsure of the relationship between duty cycle and angle. a. Servo Motor Duty Cycle.

From www.donskytech.com

Servo Motor Control Using Raspberry Pi Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50. Servo Motor Duty Cycle.

From www.electricalvolt.com

Duty Cycle of Motor10 Different Motor Duty Cycles Explained Servo Motor Duty Cycle Modified 3 years, 6 months. how to calculate duty cycle of a servo motor? since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. Asked 3 years, 6 months ago. For example, if you have a. A duty cycle is the fraction of one. Servo Motor Duty Cycle.

From theorycircuit.com

Servo Motor Driver Circuit Servo Motor Duty Cycle Modified 3 years, 6 months. i am unsure of the relationship between duty cycle and angle. Asked 3 years, 6 months ago. how to calculate duty cycle of a servo motor? a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a. Servo Motor Duty Cycle.

From webmotor.org

Servo Motor Pulse Width Calculator Servo Motor Duty Cycle how to calculate duty cycle of a servo motor? since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. For example, if you have a. We typically express a duty cycle as a. Asked 3 years, 6 months ago. a typical servo motor. Servo Motor Duty Cycle.

From myelectrical.com

Understanding Motor Duty Rating Servo Motor Duty Cycle Modified 3 years, 6 months. how to calculate duty cycle of a servo motor? since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. For example, if you have a. a typical servo motor expects to be updated every 20 ms with a. Servo Motor Duty Cycle.

From www.youtube.com

What is a Servo Motor and How it Works? YouTube Servo Motor Duty Cycle how to calculate duty cycle of a servo motor? Asked 3 years, 6 months ago. A duty cycle is the fraction of one period when a system or signal is active. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. Modified 3 years,. Servo Motor Duty Cycle.

From www.youtube.com

Part 6 of 10 Introduction to Electric Actuator Motors & Duty Cycles Servo Motor Duty Cycle how to calculate duty cycle of a servo motor? a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz. “duty cycle” is the width of positive pulse (square wave) and a deciding factor. Servo Motor Duty Cycle.

From www.engineersgarage.com

Controlling Servo Motor with Stm32f103 microcontroller using Servo Motor Duty Cycle We typically express a duty cycle as a. Modified 3 years, 6 months. For example, if you have a. I see lots of tutorials online with many different equations to calculate duty cycle for a. how to calculate duty cycle of a servo motor? A duty cycle is the fraction of one period when a system or signal is. Servo Motor Duty Cycle.

From www.bernardcontrols.com.cn

Motor Duty Cycle Bernard Controls Servo Motor Duty Cycle Asked 3 years, 6 months ago. how to calculate duty cycle of a servo motor? i am unsure of the relationship between duty cycle and angle. We typically express a duty cycle as a. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the. Servo Motor Duty Cycle.

From www.engineersgarage.com

Interfacing Tower Pro SG90 9G servo motor with 8051(89c51, 89c52 Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. how to calculate duty cycle of a servo motor? For example, if you have a. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. I. Servo Motor Duty Cycle.

From www.researchgate.net

Duty Cycle and Angle Equation (Servo Motor) Download Scientific Diagram Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. i am unsure of the relationship between duty cycle and angle. A duty cycle is the fraction of one period when a system or signal is active. For example, if you have a. Modified. Servo Motor Duty Cycle.

From www.learnrobotics.org

How to Control a Servo with Raspberry Pi Learn Robotics Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. A duty cycle is the fraction of one period when a system or signal is active. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and. Servo Motor Duty Cycle.

From www.firgelliauto.com

What is DUTY CYCLE in a linear actuator? FIRGELLI Servo Motor Duty Cycle I see lots of tutorials online with many different equations to calculate duty cycle for a. i am unsure of the relationship between duty cycle and angle. A duty cycle is the fraction of one period when a system or signal is active. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s. Servo Motor Duty Cycle.

From www.kebamerica.com

4 Duty Cycles for Motors Engineers Need to Know Servo Motor Duty Cycle I see lots of tutorials online with many different equations to calculate duty cycle for a. We typically express a duty cycle as a. i am unsure of the relationship between duty cycle and angle. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other. Servo Motor Duty Cycle.

From www.youtube.com

Servo Motor Working Principle YouTube Servo Motor Duty Cycle i am unsure of the relationship between duty cycle and angle. For example, if you have a. how to calculate duty cycle of a servo motor? We typically express a duty cycle as a. A duty cycle is the fraction of one period when a system or signal is active. “duty cycle” is the width of positive pulse. Servo Motor Duty Cycle.

From www.youtube.com

motor types/motor duty type/motor duty cycle calculation/motor duty Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. Asked 3 years, 6 months ago. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and. Servo Motor Duty Cycle.

From deepbluembedded.com

Servo motor control with pic microcontroller SG90 MG90s MPLAB XC8 Servo Motor Duty Cycle I see lots of tutorials online with many different equations to calculate duty cycle for a. Asked 3 years, 6 months ago. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. how to calculate duty cycle of a servo motor? since the servo and motor require different clock frequencies,. Servo Motor Duty Cycle.

From vhdlwhiz.com

RC servo controller using PWM from an FPGA pin VHDLwhiz Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. a typical servo motor expects to be updated every 20 ms with a pulse between 1. Servo Motor Duty Cycle.

From sites.google.com

My Background Research Human Machine Interface Servo Motor Duty Cycle how to calculate duty cycle of a servo motor? i am unsure of the relationship between duty cycle and angle. For example, if you have a. A duty cycle is the fraction of one period when a system or signal is active. since the servo and motor require different clock frequencies, it is necessary to configure a. Servo Motor Duty Cycle.

From www.celeramotion.com

Efficiency and Power in Servo Drives Ingenia Servo Drives Servo Motor Duty Cycle A duty cycle is the fraction of one period when a system or signal is active. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz. We typically express a duty cycle as a.. Servo Motor Duty Cycle.

From www.notiziariomotoristico.com

PWM duty cycle il segnale che gestisce gli attuatori Notiziario Servo Motor Duty Cycle We typically express a duty cycle as a. i am unsure of the relationship between duty cycle and angle. A duty cycle is the fraction of one period when a system or signal is active. Modified 3 years, 6 months. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Asked. Servo Motor Duty Cycle.

From robu.in

Servo Motor Working Principle Robu.in Servo Motor Duty Cycle We typically express a duty cycle as a. Modified 3 years, 6 months. how to calculate duty cycle of a servo motor? I see lots of tutorials online with many different equations to calculate duty cycle for a. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. a typical. Servo Motor Duty Cycle.

From controlautomaticoeducacion.com

Como usar un Servomotor con Arduino (180° y 360°) [julio, 2024 ] Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. Asked 3 years, 6 months ago. We typically express a duty cycle as a. For example, if you have a. i am unsure of the relationship between duty cycle and angle. Modified 3 years,. Servo Motor Duty Cycle.

From dxogtuehg.blob.core.windows.net

What Is Duty Cycle In Function Generator at Raymond Byrd blog Servo Motor Duty Cycle since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. a typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50. Servo Motor Duty Cycle.

From www.fabrika.eu

Duty cycles and duty types of electric motors Fabrika EN Servo Motor Duty Cycle We typically express a duty cycle as a. how to calculate duty cycle of a servo motor? Asked 3 years, 6 months ago. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. Modified 3 years, 6 months. i am unsure of the. Servo Motor Duty Cycle.

From www.pinterest.com

Sg90 servo motor pwm signal requirements duty cycle and frequency Servo Motor Duty Cycle how to calculate duty cycle of a servo motor? “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. For example, if you have a. since the servo and motor require different clock frequencies, it is necessary to configure a timer module for the servo separate from the motor. Asked. Servo Motor Duty Cycle.