Silicone Mold For Slip Casting . curious about the process of making plaster molds for ceramics & slip casting? First make a plaster sphere using your mold. Looking for an easy project to dip. Then use clay and the sphere to make a two part mold. you could make a mold from plaster. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. In this excerpt from the ceramics monthly. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you.

from www.aeromarineproducts.com

silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. curious about the process of making plaster molds for ceramics & slip casting? if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. First make a plaster sphere using your mold. Looking for an easy project to dip. We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. Then use clay and the sphere to make a two part mold. you could make a mold from plaster. In this example, we will create a mold to produce a keychain with an embedded apple airtag device.

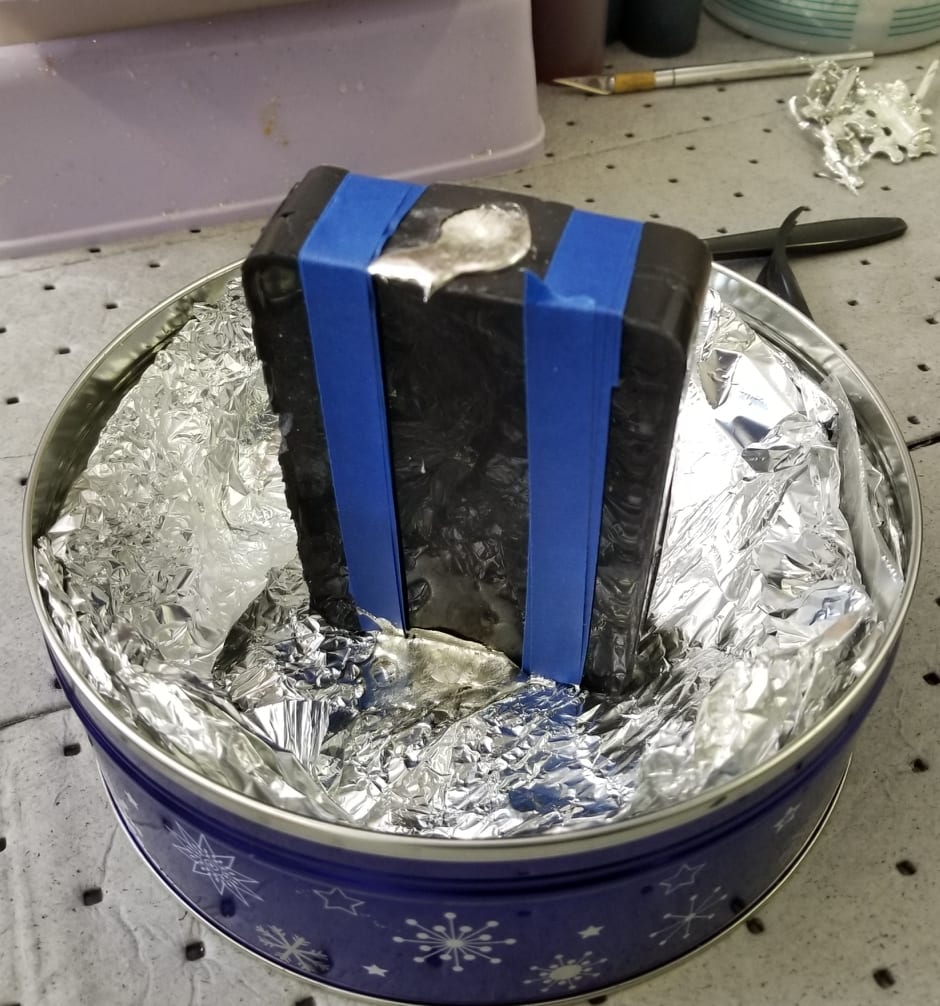

The MustTry Method for Pewter Casting with High Temp Silicone Mold

Silicone Mold For Slip Casting In this example, we will create a mold to produce a keychain with an embedded apple airtag device. you could make a mold from plaster. We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. Then use clay and the sphere to make a two part mold. First make a plaster sphere using your mold. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. Looking for an easy project to dip. curious about the process of making plaster molds for ceramics & slip casting? In this excerpt from the ceramics monthly.

From www.etsy.com

Slip Casting Mold Etsy Silicone Mold For Slip Casting We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. curious about the process of making plaster molds for ceramics & slip casting? In this. Silicone Mold For Slip Casting.

From www.youtube.com

Slip casting a cup from a one part plaster mold YouTube Silicone Mold For Slip Casting First make a plaster sphere using your mold. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. curious about the process of making plaster molds for ceramics & slip casting? In this excerpt from the ceramics monthly. you could make a mold from plaster. In this example, we. Silicone Mold For Slip Casting.

From www.amtcomposites.co.za

How To Make a Silicone Mold Using Mold Star 15 AMT Composites Silicone Mold For Slip Casting We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. curious about the process of making plaster molds for ceramics & slip casting? Looking for an easy project to dip. Then use clay and the sphere to make a two part mold. In this excerpt. Silicone Mold For Slip Casting.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Silicone Mold For Slip Casting We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. Then use clay and the sphere to make a two part mold. you could make a. Silicone Mold For Slip Casting.

From www.etsy.com

Slip Casting Mold Etsy Silicone Mold For Slip Casting you could make a mold from plaster. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. First make a plaster sphere using your mold. curious about the. Silicone Mold For Slip Casting.

From www.youtube.com

How To Make Silicone Molds & Cast Plaster YouTube Silicone Mold For Slip Casting silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. you could make a mold from plaster. curious about the process of making plaster molds for ceramics & slip casting? In this excerpt from the ceramics monthly. We also have to create an outer shell, which will. Silicone Mold For Slip Casting.

From nl.pinterest.com

SlipCasting 19 Steps (with Pictures) Pottery molds, Ceramic molds Silicone Mold For Slip Casting In this example, we will create a mold to produce a keychain with an embedded apple airtag device. Then use clay and the sphere to make a two part mold. In this excerpt from the ceramics monthly. Looking for an easy project to dip. curious about the process of making plaster molds for ceramics & slip casting? First make. Silicone Mold For Slip Casting.

From www.artnews.com

Best Moldmaking Latex and Rubber for Casting Silicone Mold For Slip Casting Then use clay and the sphere to make a two part mold. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. In this excerpt from the ceramics monthly. curious about the process of making plaster molds for ceramics & slip casting? First make a plaster sphere using your. Silicone Mold For Slip Casting.

From www.youtube.com

How to make silicone molds for casting concrete YouTube Silicone Mold For Slip Casting curious about the process of making plaster molds for ceramics & slip casting? In this example, we will create a mold to produce a keychain with an embedded apple airtag device. We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. Then use clay and. Silicone Mold For Slip Casting.

From www.turnerswarehouse.com

Silicone Casting Molds Square or Vertical Molds Turners Warehouse Silicone Mold For Slip Casting Looking for an easy project to dip. you could make a mold from plaster. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. curious about the process of making plaster molds for ceramics & slip casting? Then use clay and the sphere to make a two part mold.. Silicone Mold For Slip Casting.

From www.instructables.com

Advanced Silicone Mold Making Techniques for Epoxy Casting 4 Steps Silicone Mold For Slip Casting silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. if you’ve been wondering how to make a plaster mold for slip casting, today’s. Silicone Mold For Slip Casting.

From www.youtube.com

Perfect Castings From A Silicone Rubber Mold YouTube Silicone Mold For Slip Casting i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. Then use clay and the sphere to make a two part mold. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. silicone molds are pliable and lightweight compared to. Silicone Mold For Slip Casting.

From www.etsy.com

Handleless Cup Plaster Mold for Slip Casting, Casting Mold, Ceramic Silicone Mold For Slip Casting you could make a mold from plaster. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. In this excerpt from the ceramics monthly. Then use clay and the sphere to make a two part mold. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re. Silicone Mold For Slip Casting.

From www.youtube.com

How To Make a Two Part Mold Using Reusable imPRESSive Putty to make Silicone Mold For Slip Casting you could make a mold from plaster. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. curious about the process of making plaster molds for ceramics & slip casting? In this excerpt from the ceramics monthly. Looking for an easy project to dip. First make a. Silicone Mold For Slip Casting.

From dxoufcsgi.blob.core.windows.net

How To Make A Mold For Casting Plaster at James Leonard blog Silicone Mold For Slip Casting Then use clay and the sphere to make a two part mold. First make a plaster sphere using your mold. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over. Silicone Mold For Slip Casting.

From www.youtube.com

Silicone Rubber How To Mix Silicone Rubber Molding & Casting Silicone Mold For Slip Casting We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. Then use clay and the sphere to make a two part mold. In this excerpt from. Silicone Mold For Slip Casting.

From www.etsy.com

Slip Casting Mold Etsy Silicone Mold For Slip Casting In this excerpt from the ceramics monthly. you could make a mold from plaster. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. First make a plaster. Silicone Mold For Slip Casting.

From forgelabs.com

Mold Design with SLA 3D Printing Labs Silicone Mold For Slip Casting Looking for an easy project to dip. In this excerpt from the ceramics monthly. First make a plaster sphere using your mold. you could make a mold from plaster. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. if you’ve been wondering how to make a. Silicone Mold For Slip Casting.

From www.etsy.com

Epoxy Resin Mold Resin Casting Molds Rectangle Silicone Mold Etsy Silicone Mold For Slip Casting silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. First make a plaster sphere using your mold. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. you could make a mold from plaster. We also have to create. Silicone Mold For Slip Casting.

From formlabs.com

How to Make Silicone Molds A Practical Guide Silicone Mold For Slip Casting In this excerpt from the ceramics monthly. you could make a mold from plaster. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. Then use clay and the sphere to make a two part mold. First make a plaster sphere using your mold. i'm looking at either mold max. Silicone Mold For Slip Casting.

From www.youtube.com

Silicone is ! Is this too little?? Making a new silicone mold for Silicone Mold For Slip Casting silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. Then use clay and the sphere to make a two part mold. Looking for an easy project to dip. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. We also. Silicone Mold For Slip Casting.

From www.moldplasticinjection.com

How To Make Silicone Molds For Resin Casting & Candle Easy Ways On Silicone Mold For Slip Casting We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. In this excerpt from the ceramics monthly. First make a plaster sphere using your mold. you could make a mold from plaster. Then use clay and the sphere to make a two part mold. In. Silicone Mold For Slip Casting.

From www.ceramickingdomberlin.com

Moldmaking and Slipcasting — Ceramic Kingdom Silicone Mold For Slip Casting if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. Looking for an easy project to dip. you could make a mold from plaster. curious about the process of making plaster molds for ceramics & slip casting? i'm looking at either mold max 30/40 which is a tin. Silicone Mold For Slip Casting.

From www.etsy.com

Slip Casting Mold Etsy Silicone Mold For Slip Casting silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. you could make a mold from plaster. In this example, we will create a mold to produce a keychain. Silicone Mold For Slip Casting.

From www.etsy.com

Slip Casting Mold Etsy Silicone Mold For Slip Casting Then use clay and the sphere to make a two part mold. curious about the process of making plaster molds for ceramics & slip casting? Looking for an easy project to dip. In this excerpt from the ceramics monthly. First make a plaster sphere using your mold. We also have to create an outer shell, which will hold the. Silicone Mold For Slip Casting.

From www.aeromarineproducts.com

The MustTry Method for Pewter Casting with High Temp Silicone Mold Silicone Mold For Slip Casting In this excerpt from the ceramics monthly. you could make a mold from plaster. curious about the process of making plaster molds for ceramics & slip casting? i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. if you’ve been wondering how to make a plaster mold. Silicone Mold For Slip Casting.

From www.youtube.com

How to Silicone Mold & casting Flexible Foam YouTube Silicone Mold For Slip Casting silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. Then. Silicone Mold For Slip Casting.

From kimballartcenter.org

Kimball Art Center Silicone Mold For Slip Casting In this excerpt from the ceramics monthly. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. you could make a mold from plaster. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. We also have to. Silicone Mold For Slip Casting.

From www.youtube.com

Slip Casting with Plaster Molds In Six Steps YouTube Silicone Mold For Slip Casting you could make a mold from plaster. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. First make a plaster sphere using your mold. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. curious about the process. Silicone Mold For Slip Casting.

From making-a-mold.blogspot.com

Mold making and Casting products through EnvironMolds, LLC March 2018 Silicone Mold For Slip Casting First make a plaster sphere using your mold. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or a. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. you could make a mold from plaster. if you’ve been wondering how. Silicone Mold For Slip Casting.

From www.youtube.com

Silicone molds for epoxy resin / DIY / Resin art / Resin casting YouTube Silicone Mold For Slip Casting In this example, we will create a mold to produce a keychain with an embedded apple airtag device. We also have to create an outer shell, which will hold the liquid silicone inside and prevent it from pouring over the whole table. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing,. Silicone Mold For Slip Casting.

From www.walmart.com

249 Pieces Epoxy Resin Silicone Casting Molds Full Kits with 9 PCS Silicone Mold For Slip Casting you could make a mold from plaster. First make a plaster sphere using your mold. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. curious about the process of making. Silicone Mold For Slip Casting.

From www.instructables.com

3D Printing a Mold for a Slipcasting Mold 6 Steps (with Pictures Silicone Mold For Slip Casting First make a plaster sphere using your mold. In this example, we will create a mold to produce a keychain with an embedded apple airtag device. Looking for an easy project to dip. if you’ve been wondering how to make a plaster mold for slip casting, today’s post is for you. Then use clay and the sphere to make. Silicone Mold For Slip Casting.

From davidneat.wordpress.com

‘Beginner’s Basics’ mouldmaking and casting explained davidneat Silicone Mold For Slip Casting silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. Then use clay and the sphere to make a two part mold. curious about the process of making plaster molds for ceramics & slip casting? i'm looking at either mold max 30/40 which is a tin cure. Silicone Mold For Slip Casting.

From www.youtube.com

How I Make Molds for Resin Casting Silicone Rubber Mold YouTube Silicone Mold For Slip Casting First make a plaster sphere using your mold. silicone molds are pliable and lightweight compared to stiffer substances like plastic and they’re also easier to remove once a. Then use clay and the sphere to make a two part mold. i'm looking at either mold max 30/40 which is a tin cure silicone and recommends vacuum degassing, or. Silicone Mold For Slip Casting.