Thermal Shock Ramp Rate . Projection to other temperature cycling ranges. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. What are element’s temperature ramp rate capabilities? In that sense, the fatigue life decreased when the frequency increased. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. In contrast, temperature cycle testing. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow.

from espec.com

A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. In contrast, temperature cycle testing. In that sense, the fatigue life decreased when the frequency increased. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Projection to other temperature cycling ranges. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. What are element’s temperature ramp rate capabilities?

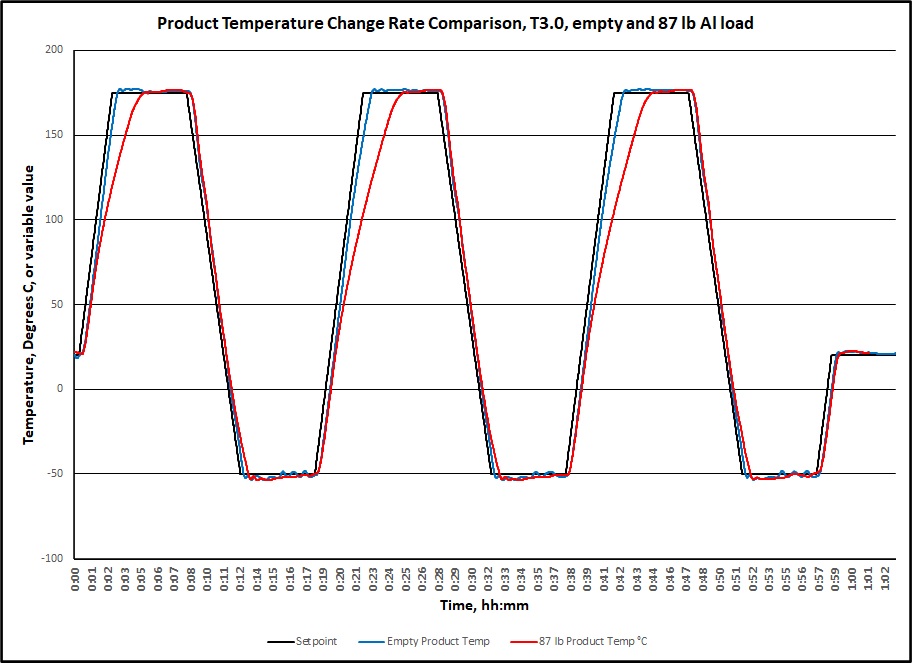

The effect of a thermal mass on the performance of a T3.0 system News

Thermal Shock Ramp Rate Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Projection to other temperature cycling ranges. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. In contrast, temperature cycle testing. In that sense, the fatigue life decreased when the frequency increased. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. What are element’s temperature ramp rate capabilities? Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute.

From studylib.es

ThermalCyclerRampRatesAppNote Thermal Shock Ramp Rate In contrast, temperature cycle testing. In that sense, the fatigue life decreased when the frequency increased. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. What are element’s temperature ramp rate capabilities? Ramping protects a process from. Thermal Shock Ramp Rate.

From www.slideserve.com

PPT Data Work Group Call Thermal Plants Ramp Rates PowerPoint Thermal Shock Ramp Rate Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. In contrast, temperature cycle testing. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. What are element’s temperature ramp rate capabilities? Ramping protects a process from rapid changes in the. Thermal Shock Ramp Rate.

From www.researchgate.net

Chronological heat ramp results (top to bottom) showing 3 He and 4 He Thermal Shock Ramp Rate In that sense, the fatigue life decreased when the frequency increased. What are element’s temperature ramp rate capabilities? Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Projection to other temperature cycling ranges. In contrast, temperature cycle. Thermal Shock Ramp Rate.

From www.researchgate.net

Hugoniot states in the ρ2v shock space, showing how values estimated Thermal Shock Ramp Rate Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Projection to other temperature cycling ranges. What are element’s temperature ramp rate capabilities? Thermal shock has a much faster ramp rate, thus. Thermal Shock Ramp Rate.

From www.semanticscholar.org

Figure 1 from Equivalent ramp rate function for thermal power systems Thermal Shock Ramp Rate In contrast, temperature cycle testing. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. What are element’s temperature ramp rate capabilities? Projection to other temperature cycling ranges. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. In that sense,. Thermal Shock Ramp Rate.

From www.researchgate.net

Measured rampup and rampdown rate of the COP film/sheet and PDMS Thermal Shock Ramp Rate A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. In that sense, the fatigue life decreased when the frequency increased. Projection to other temperature cycling ranges. In contrast, temperature cycle testing. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries. Thermal Shock Ramp Rate.

From www.researchgate.net

Heat currents 2Q(H ) absorbed by a sample of length 0.5 cm for a ramp Thermal Shock Ramp Rate Projection to other temperature cycling ranges. What are element’s temperature ramp rate capabilities? Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. In. Thermal Shock Ramp Rate.

From nvirosolutions.com

NvirosolutionsAll Products Thermal Shock Ramp Rate What are element’s temperature ramp rate capabilities? Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. In contrast, temperature cycle testing. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the. Thermal Shock Ramp Rate.

From www.researchgate.net

The effect of ramp rate on (a) maximum temperature difference across Thermal Shock Ramp Rate In contrast, temperature cycle testing. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Projection to other temperature cycling ranges. In that sense,. Thermal Shock Ramp Rate.

From www.researchgate.net

Different thermal ramps (left panels) and resulting KarlFisher curves Thermal Shock Ramp Rate Projection to other temperature cycling ranges. In contrast, temperature cycle testing. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. What are element’s temperature ramp rate capabilities? In that sense, the fatigue life decreased when the frequency increased. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per. Thermal Shock Ramp Rate.

From www.researchgate.net

Temperature ramp rate dependent thermal hysteresis of NNO film. Bottom Thermal Shock Ramp Rate Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Projection to other. Thermal Shock Ramp Rate.

From www.researchgate.net

3 H desorption profiles for different metals using standard thermal Thermal Shock Ramp Rate Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can. Thermal Shock Ramp Rate.

From www.thermofisher.com

PCR Thermal Cyclers Education Thermo Fisher Scientific US Thermal Shock Ramp Rate Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Projection to other temperature cycling ranges. What are element’s temperature ramp rate capabilities? Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. In. Thermal Shock Ramp Rate.

From www.unchainedlabs.com

Sizing with thermal ramp Unchained Labs Thermal Shock Ramp Rate In contrast, temperature cycle testing. What are element’s temperature ramp rate capabilities? Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Projection to. Thermal Shock Ramp Rate.

From www.gdmypt.com

Ramp Rate Temperature Chamber Climate Test ChamberThermal Shock Thermal Shock Ramp Rate Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. What are element’s temperature ramp rate capabilities? Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Projection to other temperature cycling ranges. In contrast, temperature cycle testing. In that sense, the fatigue life decreased when the frequency. Thermal Shock Ramp Rate.

From advancedta.com

KEY Thermal Testing Test Profiles — ATA Modular Flow Management Thermal Shock Ramp Rate In contrast, temperature cycle testing. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. In that sense, the fatigue life decreased when the. Thermal Shock Ramp Rate.

From www.researchgate.net

Thermal ramp model results. (a) The molar ratios (vs initial moles of Thermal Shock Ramp Rate Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Projection to other temperature cycling ranges. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. What are element’s temperature ramp rate capabilities? A maximum ramp rate of ≈ 50°c/minute to ≈. Thermal Shock Ramp Rate.

From www.researchgate.net

PV output power with the Power RampRate Control (PRRC) strategy under Thermal Shock Ramp Rate In that sense, the fatigue life decreased when the frequency increased. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Projection to other temperature cycling ranges. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. In contrast, temperature cycle testing. What are element’s temperature ramp rate capabilities?. Thermal Shock Ramp Rate.

From www.researchgate.net

Experimental values of the dynamic heat load versus current ramp rate Thermal Shock Ramp Rate In contrast, temperature cycle testing. In that sense, the fatigue life decreased when the frequency increased. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable. Thermal Shock Ramp Rate.

From www.researchgate.net

At a ramp rate va = 0.18 T/s (a) and (b) The distributions of radial Thermal Shock Ramp Rate In that sense, the fatigue life decreased when the frequency increased. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. What are element’s temperature ramp rate capabilities? Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Ramping protects a process from rapid changes in the setpoint. Thermal Shock Ramp Rate.

From www.gdmypt.com

Ramp Rate Temperature Chamber Climate Test ChamberThermal Shock Thermal Shock Ramp Rate A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Projection to other temperature cycling ranges. What are element’s temperature ramp rate capabilities? In contrast, temperature cycle testing. In that sense, the fatigue life decreased when the frequency increased.. Thermal Shock Ramp Rate.

From www.researchgate.net

8 Thermal Ramp Rate Profiles Sonic Resonance (Measured Ramp Rates Thermal Shock Ramp Rate Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. In that sense, the fatigue life decreased when the frequency increased. What are element’s temperature ramp rate capabilities? Projection to other temperature cycling ranges. In contrast, temperature cycle. Thermal Shock Ramp Rate.

From www.slideserve.com

PPT Pyrotechnic Shock Response PowerPoint Presentation, free download Thermal Shock Ramp Rate In contrast, temperature cycle testing. Projection to other temperature cycling ranges. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. In that sense, the fatigue life decreased when the frequency increased. Ramping protects a process from rapid. Thermal Shock Ramp Rate.

From www.researchgate.net

Ramps of temperature for every heat treatment (350 and 600 °C Thermal Shock Ramp Rate In contrast, temperature cycle testing. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. What are element’s temperature ramp rate capabilities? In that sense, the fatigue life decreased when the frequency increased. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in. Thermal Shock Ramp Rate.

From www.researchgate.net

Measured AC loss with the variation of the ramp rate of a single Thermal Shock Ramp Rate Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. What are element’s temperature ramp rate capabilities? Projection to other temperature cycling ranges. In contrast, temperature cycle testing. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. A maximum ramp rate. Thermal Shock Ramp Rate.

From www.scribd.com

Thermal Cyclers Key Thermal Cycling Concepts and Ramp Rates PDF Thermal Shock Ramp Rate In that sense, the fatigue life decreased when the frequency increased. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. What are element’s temperature ramp rate capabilities? A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Thermal shock tests. Thermal Shock Ramp Rate.

From espec.com

The effect of a thermal mass on the performance of a T3.0 system News Thermal Shock Ramp Rate Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. In contrast, temperature cycle testing. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Projection to other temperature cycling ranges. In that sense, the fatigue life decreased when the frequency. Thermal Shock Ramp Rate.

From www.researchgate.net

Ramp rate limits of thermal generating units Download Table Thermal Shock Ramp Rate Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. In that sense,. Thermal Shock Ramp Rate.

From www.researchgate.net

NOx adsorption at 100 °C for 10 min followed with TPD (10 °C/min linear Thermal Shock Ramp Rate What are element’s temperature ramp rate capabilities? Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. In contrast,. Thermal Shock Ramp Rate.

From www.slideserve.com

PPT HQ ramp rate effects PowerPoint Presentation, free download Thermal Shock Ramp Rate Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. In contrast, temperature cycle testing. A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. Thermal shock tests involve rapid temperature changes typically exceeding 15°c. Thermal Shock Ramp Rate.

From www.researchgate.net

TGA analysis thermal ramp, initiating at 50ºC and ending at 1000ºC Thermal Shock Ramp Rate What are element’s temperature ramp rate capabilities? In that sense, the fatigue life decreased when the frequency increased. Thermal shock tests involve rapid temperature changes typically exceeding 15°c per minute. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Projection to other temperature. Thermal Shock Ramp Rate.

From www.researchgate.net

Temperatures predicted by the multishock scheme compared to our ramp Thermal Shock Ramp Rate A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. What are element’s temperature ramp rate capabilities? Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. In contrast, temperature cycle testing. Ramping protects a process from rapid changes in the. Thermal Shock Ramp Rate.

From www.researchgate.net

Timetemperature profile with ramp rates for slowly heating both Thermal Shock Ramp Rate In contrast, temperature cycle testing. Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. In that sense, the fatigue life decreased when the frequency increased. Projection to other temperature cycling ranges. Thermal shock has a much faster ramp rate, thus imposing much more. Thermal Shock Ramp Rate.

From www.unchainedlabs.com

Sizing with thermal ramp Unchained Labs Thermal Shock Ramp Rate A maximum ramp rate of ≈ 50°c/minute to ≈ 100°c/minute (facility site dependent) can be achieved in element’s halt. In contrast, temperature cycle testing. What are element’s temperature ramp rate capabilities? Projection to other temperature cycling ranges. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Ramping protects a. Thermal Shock Ramp Rate.

From www.researchgate.net

Example of the ramprate measurement parameters selection (a) PV power Thermal Shock Ramp Rate Ramping protects a process from rapid changes in the setpoint and the resulting thermal shock as the controller tries to force the process variable to follow. Thermal shock has a much faster ramp rate, thus imposing much more damage to the solder joints than thermal cycling. Projection to other temperature cycling ranges. What are element’s temperature ramp rate capabilities? Thermal. Thermal Shock Ramp Rate.