What Is Grouping Of Dimensions In Measurements . A size dimension might be the overall width of the part or the diameter of a drilled hole. Separate one line of dimensions from another line. Affect how a part is manufactured. Tolerance is the amount a particular dimension is allowed to vary. Try to keep dimensions off the views themselves. Try to group related dimensions rather than scattering them. A location dimension might be length from the edge of the. Dimensioning is vital in the. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. State each dimension clearly, so it is understood in only one way. A numerical value expressed in appropriate units of measure and. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Show dimensions between points, lines or surfaces which have a necessary.

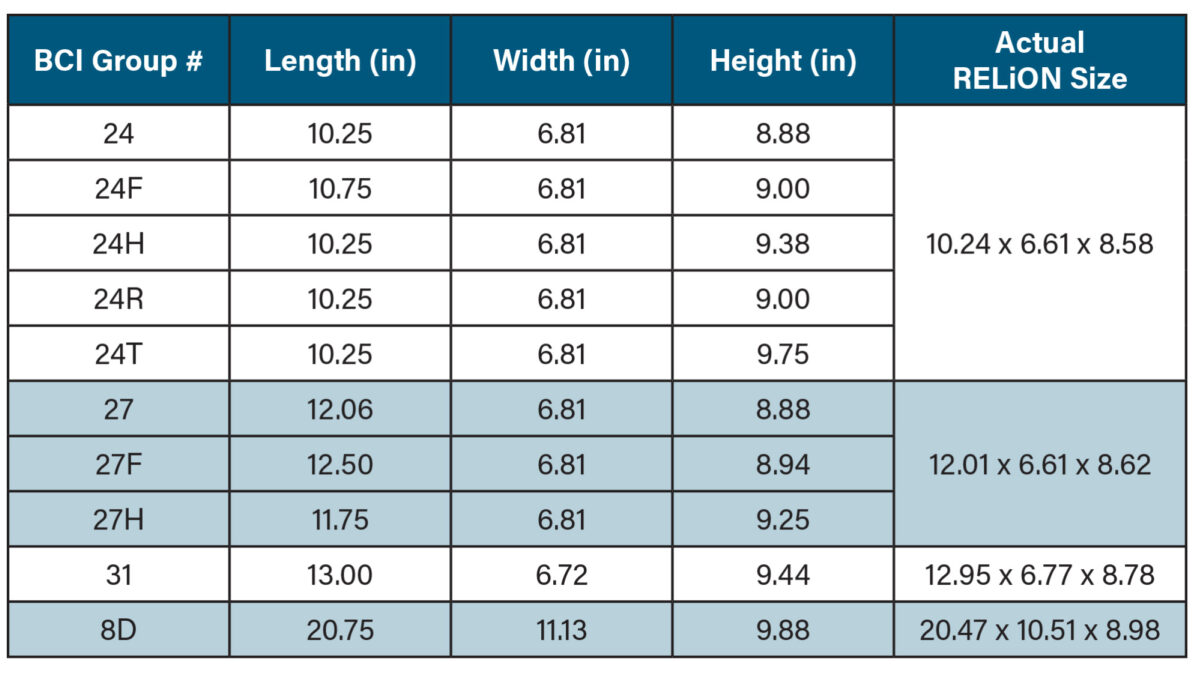

from www.relionbattery.com

State each dimension clearly, so it is understood in only one way. Show dimensions between points, lines or surfaces which have a necessary. A numerical value expressed in appropriate units of measure and. Try to group related dimensions rather than scattering them. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Tolerance is the amount a particular dimension is allowed to vary. Dimensioning is vital in the. A location dimension might be length from the edge of the. Try to keep dimensions off the views themselves. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified.

Group Size Guide For Deep Cycle Marine Batteries RELiON

What Is Grouping Of Dimensions In Measurements State each dimension clearly, so it is understood in only one way. Try to group related dimensions rather than scattering them. A location dimension might be length from the edge of the. A size dimension might be the overall width of the part or the diameter of a drilled hole. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Separate one line of dimensions from another line. Affect how a part is manufactured. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Show dimensions between points, lines or surfaces which have a necessary. Tolerance is the amount a particular dimension is allowed to vary. A numerical value expressed in appropriate units of measure and. Try to keep dimensions off the views themselves. State each dimension clearly, so it is understood in only one way. Dimensioning is vital in the.

From www.youtube.com

Dimensions & Measures Simplest explanation you have ever heard YouTube What Is Grouping Of Dimensions In Measurements Affect how a part is manufactured. Tolerance is the amount a particular dimension is allowed to vary. Show dimensions between points, lines or surfaces which have a necessary. A numerical value expressed in appropriate units of measure and. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering. What Is Grouping Of Dimensions In Measurements.

From www.youtube.com

Grouping Dimension by Measures in Matrix Visual Power BI An What Is Grouping Of Dimensions In Measurements A size dimension might be the overall width of the part or the diameter of a drilled hole. Try to group related dimensions rather than scattering them. Affect how a part is manufactured. Try to keep dimensions off the views themselves. A location dimension might be length from the edge of the. State each dimension clearly, so it is understood. What Is Grouping Of Dimensions In Measurements.

From www.whatconverts.com

Dimension Grouping What Is Grouping Of Dimensions In Measurements A numerical value expressed in appropriate units of measure and. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. A size dimension might be the overall width of the part or. What Is Grouping Of Dimensions In Measurements.

From www.dimensions.com

Elevator Lift Bank Layouts Dimensions & Drawings What Is Grouping Of Dimensions In Measurements Separate one line of dimensions from another line. A size dimension might be the overall width of the part or the diameter of a drilled hole. A location dimension might be length from the edge of the. A numerical value expressed in appropriate units of measure and. Try to group related dimensions rather than scattering them. Tolerance is the amount. What Is Grouping Of Dimensions In Measurements.

From www.slideserve.com

PPT Dimensioning PowerPoint Presentation, free download ID6739113 What Is Grouping Of Dimensions In Measurements Show dimensions between points, lines or surfaces which have a necessary. State each dimension clearly, so it is understood in only one way. A numerical value expressed in appropriate units of measure and. A location dimension might be length from the edge of the. Separate one line of dimensions from another line. Dimensioning is vital in the. Essentially, dimensioning refers. What Is Grouping Of Dimensions In Measurements.

From www.javelin-tech.com

Use Layers to Group SOLIDWORKS Dimensions for editing Standards What Is Grouping Of Dimensions In Measurements Separate one line of dimensions from another line. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. A numerical value expressed in appropriate units of measure and. A location dimension might be length from the edge of the. Show dimensions between points, lines or surfaces which. What Is Grouping Of Dimensions In Measurements.

From www.relionbattery.com

Group Size Guide For Deep Cycle Marine Batteries RELiON What Is Grouping Of Dimensions In Measurements Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Separate one line of dimensions from another line. State each dimension clearly, so it is understood in only one way. Dimensioning is vital in the. Affect how a part is manufactured. Show dimensions between points, lines or. What Is Grouping Of Dimensions In Measurements.

From thedataschool.com

Sets and Groups Grouping different dimensions of data The Data School What Is Grouping Of Dimensions In Measurements A location dimension might be length from the edge of the. Try to keep dimensions off the views themselves. State each dimension clearly, so it is understood in only one way. Affect how a part is manufactured. Dimensioning is vital in the. Try to group related dimensions rather than scattering them. Separate one line of dimensions from another line. Essentially,. What Is Grouping Of Dimensions In Measurements.

From www.whatconverts.com

Dimension Grouping What Is Grouping Of Dimensions In Measurements Try to group related dimensions rather than scattering them. Separate one line of dimensions from another line. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. A size dimension might be the overall width of the part or the diameter of a drilled hole. Show dimensions. What Is Grouping Of Dimensions In Measurements.

From www.pinterest.com

Living Room Dimensions (Sizes Guide) Living room size, Livingroom What Is Grouping Of Dimensions In Measurements Separate one line of dimensions from another line. Dimensioning is vital in the. Try to keep dimensions off the views themselves. Try to group related dimensions rather than scattering them. A location dimension might be length from the edge of the. A size dimension might be the overall width of the part or the diameter of a drilled hole. Affect. What Is Grouping Of Dimensions In Measurements.

From www.researchgate.net

Grouping of dimensions into product complexity Download Table What Is Grouping Of Dimensions In Measurements Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. A size dimension might be the overall width of the part or the diameter of a drilled hole. State each dimension clearly, so it is understood in only one way. Show dimensions between points, lines or surfaces. What Is Grouping Of Dimensions In Measurements.

From www.youtube.com

Grouping Dimensions in Grids YouTube What Is Grouping Of Dimensions In Measurements Dimensioning is vital in the. Separate one line of dimensions from another line. Try to group related dimensions rather than scattering them. A location dimension might be length from the edge of the. Show dimensions between points, lines or surfaces which have a necessary. State each dimension clearly, so it is understood in only one way. Try to keep dimensions. What Is Grouping Of Dimensions In Measurements.

From forums.sketchup.com

Issues with grouping dimensions SketchUp SketchUp Community What Is Grouping Of Dimensions In Measurements Dimensioning is vital in the. A location dimension might be length from the edge of the. Tolerance is the amount a particular dimension is allowed to vary. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Try to group related dimensions rather than scattering them. A size dimension might be the overall width of. What Is Grouping Of Dimensions In Measurements.

From www.slideserve.com

PPT Perceptual Organization & Scene A nalysis PowerPoint Presentation What Is Grouping Of Dimensions In Measurements Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. A size dimension might be the overall width of the part or the diameter of a drilled hole. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Tolerance is the amount. What Is Grouping Of Dimensions In Measurements.

From www.researchgate.net

Grouping by dimensions (Variant 2) Download Scientific Diagram What Is Grouping Of Dimensions In Measurements A location dimension might be length from the edge of the. Separate one line of dimensions from another line. Try to group related dimensions rather than scattering them. Show dimensions between points, lines or surfaces which have a necessary. State each dimension clearly, so it is understood in only one way. Dimensioning is vital in the. Tolerance is the amount. What Is Grouping Of Dimensions In Measurements.

From www.cad-notes.com

How to Use Different Units from the Drawing on Your AutoCAD Dimension What Is Grouping Of Dimensions In Measurements Dimensioning is vital in the. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. A numerical value expressed in appropriate units of measure and. A size dimension might be the overall. What Is Grouping Of Dimensions In Measurements.

From www.researchgate.net

Grouping of measured dimension of parts. Download Scientific Diagram What Is Grouping Of Dimensions In Measurements A numerical value expressed in appropriate units of measure and. Show dimensions between points, lines or surfaces which have a necessary. Affect how a part is manufactured. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and. What Is Grouping Of Dimensions In Measurements.

From www.researchgate.net

Grouping of variables for each parameter of the classroom... Download What Is Grouping Of Dimensions In Measurements Affect how a part is manufactured. Show dimensions between points, lines or surfaces which have a necessary. Try to keep dimensions off the views themselves. A location dimension might be length from the edge of the. Separate one line of dimensions from another line. Tolerance is the amount a particular dimension is allowed to vary. State each dimension clearly, so. What Is Grouping Of Dimensions In Measurements.

From docs.oracle.com

Introduction to Grouping What Is Grouping Of Dimensions In Measurements Tolerance is the amount a particular dimension is allowed to vary. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Affect how a part is manufactured. Separate one line of dimensions. What Is Grouping Of Dimensions In Measurements.

From www.chegg.com

Solved when grouping a large sample of measurements into What Is Grouping Of Dimensions In Measurements A location dimension might be length from the edge of the. A numerical value expressed in appropriate units of measure and. Try to group related dimensions rather than scattering them. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Dimensioning is vital in the. A size dimension might be the overall width of the. What Is Grouping Of Dimensions In Measurements.

From www.researchgate.net

Grouping measurements of all groups before (light blue) and after (dark What Is Grouping Of Dimensions In Measurements Try to keep dimensions off the views themselves. Dimensioning is vital in the. Tolerance is the amount a particular dimension is allowed to vary. A numerical value expressed in appropriate units of measure and. A size dimension might be the overall width of the part or the diameter of a drilled hole. Separate one line of dimensions from another line.. What Is Grouping Of Dimensions In Measurements.

From forums.autodesk.com

DIMENSION GROUP EQUAL DISTANCE Autodesk Community What Is Grouping Of Dimensions In Measurements Try to keep dimensions off the views themselves. A location dimension might be length from the edge of the. Dimensioning is vital in the. Try to group related dimensions rather than scattering them. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Tolerance is the amount a particular dimension is allowed to vary. Separate. What Is Grouping Of Dimensions In Measurements.

From www.core77.com

Reference Common Dimensions, Angles and Heights for Seating Designers What Is Grouping Of Dimensions In Measurements State each dimension clearly, so it is understood in only one way. Show dimensions between points, lines or surfaces which have a necessary. Tolerance is the amount a particular dimension is allowed to vary. A numerical value expressed in appropriate units of measure and. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. A. What Is Grouping Of Dimensions In Measurements.

From slideplayer.com

Repeated Measures Designs. In a Repeated Measures Design We have What Is Grouping Of Dimensions In Measurements Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Affect how a part is manufactured. A location dimension might be length from the edge of the. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Try to keep dimensions off. What Is Grouping Of Dimensions In Measurements.

From paintingvalley.com

Drawing Dimension Symbols at Explore collection of What Is Grouping Of Dimensions In Measurements A location dimension might be length from the edge of the. Try to group related dimensions rather than scattering them. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Show dimensions between points, lines or surfaces which have a necessary. State each dimension clearly, so it. What Is Grouping Of Dimensions In Measurements.

From www.rigordatasolutions.com

Dynamically grouping and ungrouping dimensions in Tableau What Is Grouping Of Dimensions In Measurements State each dimension clearly, so it is understood in only one way. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Tolerance is the amount a particular dimension is allowed to. What Is Grouping Of Dimensions In Measurements.

From hodeby.com

The Ultimate Guide to Room Sizes and Layouts Hodeby What Is Grouping Of Dimensions In Measurements State each dimension clearly, so it is understood in only one way. Tolerance is the amount a particular dimension is allowed to vary. Affect how a part is manufactured. Try to group related dimensions rather than scattering them. Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Try to keep dimensions off the views. What Is Grouping Of Dimensions In Measurements.

From www.researchgate.net

Fractal dimension measurements by group Download Scientific Diagram What Is Grouping Of Dimensions In Measurements Try to group related dimensions rather than scattering them. Separate one line of dimensions from another line. Affect how a part is manufactured. Tolerance is the amount a particular dimension is allowed to vary. Show dimensions between points, lines or surfaces which have a necessary. A size dimension might be the overall width of the part or the diameter of. What Is Grouping Of Dimensions In Measurements.

From docs.oracle.com

Introduction to Grouping What Is Grouping Of Dimensions In Measurements Try to group related dimensions rather than scattering them. Dimensioning is vital in the. A size dimension might be the overall width of the part or the diameter of a drilled hole. Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Tolerance is the amount a. What Is Grouping Of Dimensions In Measurements.

From www.oxfordlearnersdictionaries.com

dimension noun Definition, pictures, pronunciation and usage notes What Is Grouping Of Dimensions In Measurements Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Try to group related dimensions rather than scattering them. State each dimension clearly, so it is understood in only one way. A size dimension might be the overall width of the part or the diameter of a. What Is Grouping Of Dimensions In Measurements.

From thedataschool.com

Grouping Dimensions (Part 1) The Data School What Is Grouping Of Dimensions In Measurements Try to group related dimensions rather than scattering them. State each dimension clearly, so it is understood in only one way. A size dimension might be the overall width of the part or the diameter of a drilled hole. Affect how a part is manufactured. Try to keep dimensions off the views themselves. A numerical value expressed in appropriate units. What Is Grouping Of Dimensions In Measurements.

From www.youtube.com

What are Dimensions and Measures? YouTube What Is Grouping Of Dimensions In Measurements A numerical value expressed in appropriate units of measure and. A size dimension might be the overall width of the part or the diameter of a drilled hole. Separate one line of dimensions from another line. State each dimension clearly, so it is understood in only one way. Tolerance is the amount a particular dimension is allowed to vary. Plus. What Is Grouping Of Dimensions In Measurements.

From www.aiophotoz.com

Units And Dimensions Images and Photos finder What Is Grouping Of Dimensions In Measurements Essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. A numerical value expressed in appropriate units of measure and. State each dimension clearly, so it is understood in only one way. Dimensioning is vital in the. Separate one line of dimensions from another line. Show dimensions. What Is Grouping Of Dimensions In Measurements.

From www.whatconverts.com

Dimension Grouping What Is Grouping Of Dimensions In Measurements A numerical value expressed in appropriate units of measure and. State each dimension clearly, so it is understood in only one way. Dimensioning is vital in the. A location dimension might be length from the edge of the. A size dimension might be the overall width of the part or the diameter of a drilled hole. Tolerance is the amount. What Is Grouping Of Dimensions In Measurements.

From www.researchgate.net

Results of SubDimensional Grouping with IPA Based on Figure 3, it can What Is Grouping Of Dimensions In Measurements Tolerance is the amount a particular dimension is allowed to vary. State each dimension clearly, so it is understood in only one way. Show dimensions between points, lines or surfaces which have a necessary. A location dimension might be length from the edge of the. Separate one line of dimensions from another line. A numerical value expressed in appropriate units. What Is Grouping Of Dimensions In Measurements.