Body Earthing Of Welding Machine . Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. It protects people and equipment, prevents damage, and improves the reliability of power systems. Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. The first step is to make sure the power source for the welding machine is turned off. In this article, you will find info on how to ground a welder. Grounding your welder is an essential safety practice that involves connecting the metal components of your welding machine to the earth to prevent the buildup of. Proper grounding ensures safety and weld quality. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. We'll explain various grounding methods, important factors to consider, and answer frequent questions. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. Grounding your welding machine ensures safety and minimizes the risk of electrical shock.

from ar.inspiredpencil.com

In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. In this article, you will find info on how to ground a welder. We'll explain various grounding methods, important factors to consider, and answer frequent questions. Proper grounding ensures safety and weld quality. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. Grounding your welding machine ensures safety and minimizes the risk of electrical shock.

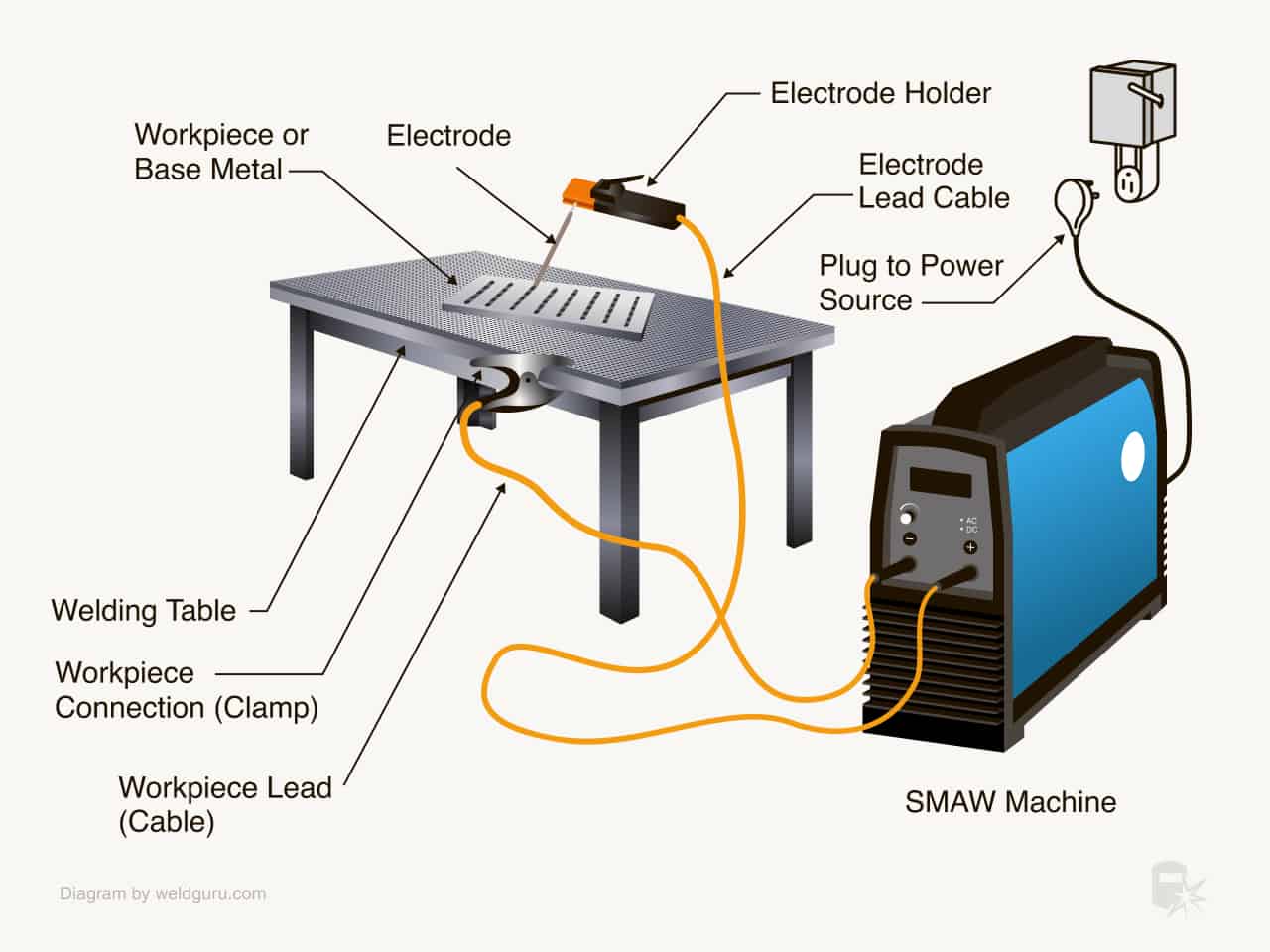

Arc Welding Machine Parts

Body Earthing Of Welding Machine Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. The first step is to make sure the power source for the welding machine is turned off. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. We'll explain various grounding methods, important factors to consider, and answer frequent questions. Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. In this article, you will find info on how to ground a welder. Proper grounding ensures safety and weld quality. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Grounding your welder is an essential safety practice that involves connecting the metal components of your welding machine to the earth to prevent the buildup of. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. It protects people and equipment, prevents damage, and improves the reliability of power systems. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk.

From weldingmachinesbestbuy.blogspot.com

Welding Machine Body Earthing Body Earthing Of Welding Machine We'll explain various grounding methods, important factors to consider, and answer frequent questions. In this article, you will find info on how to ground a welder. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. If you plan on welding with an electrical welding machine, it’s important. Body Earthing Of Welding Machine.

From www.electroniclinic.com

Introduction and components of Earthing System Electronic Clinic Body Earthing Of Welding Machine It protects people and equipment, prevents damage, and improves the reliability of power systems. In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. The first step is to make sure the power source for the welding machine is turned off. Proper grounding ensures safety and weld quality.. Body Earthing Of Welding Machine.

From www.indiamart.com

Single Phase Electric ARC 200i ESAB Welding Machine, Automation Grade Body Earthing Of Welding Machine Grounding your welding machine ensures safety and minimizes the risk of electrical shock. We'll explain various grounding methods, important factors to consider, and answer frequent questions. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. In this article, you will find info on how to ground a. Body Earthing Of Welding Machine.

From www.familyhandyman.com

Here's What You Need to Know About MIG Welding Pros, Cons, Cost and Body Earthing Of Welding Machine In this article, you will find info on how to ground a welder. The first step is to make sure the power source for the welding machine is turned off. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. We'll explain various grounding methods, important factors to consider, and answer frequent. Body Earthing Of Welding Machine.

From advanxis.com

Instrumentation Earthing Advanxis Technologies and Process Automation Body Earthing Of Welding Machine In this article, you will find info on how to ground a welder. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. The first step is to make sure the power source for the welding machine is turned off. We'll explain various. Body Earthing Of Welding Machine.

From blog.thepipingmart.com

What Are the Different Types of Welding Machines And Their Applications Body Earthing Of Welding Machine Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. It protects people and equipment, prevents damage, and improves the reliability of power systems. Proper grounding ensures safety and. Body Earthing Of Welding Machine.

From www.jeftechno.com

Exothermic Welding Service in India JEF Techno Body Earthing Of Welding Machine Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or. Body Earthing Of Welding Machine.

From www.desertcart.co.za

Buy Shakti Inverter Steel Welding Machine TIG400 Amps with 4 m Torch Body Earthing Of Welding Machine Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. To ground when welding, attach the welding machine’s ground clamp. Body Earthing Of Welding Machine.

From www.lectrotech.co.za

Exothermic Welding Basic Earthing LectroTech Body Earthing Of Welding Machine It protects people and equipment, prevents damage, and improves the reliability of power systems. In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. Proper grounding ensures safety and weld quality. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on. Body Earthing Of Welding Machine.

From www.youtube.com

Why Double Earthing is used in industries Benefits of Double Earthing Body Earthing Of Welding Machine Grounding your welder is an essential safety practice that involves connecting the metal components of your welding machine to the earth to prevent the buildup of. Proper grounding ensures safety and weld quality. Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. It protects people and. Body Earthing Of Welding Machine.

From weldingmachinesbestbuy.blogspot.com

Welding Machine Earthing Cable Body Earthing Of Welding Machine Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. We'll explain various grounding methods, important factors to consider, and answer frequent questions. Ensure a secure connection and avoid thin or sharp edges, which. Body Earthing Of Welding Machine.

From www.socomepower.com

How to Make an Exothermic Welded Earthing Connection? power Body Earthing Of Welding Machine To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate. Body Earthing Of Welding Machine.

From www.youtube.com

pakar cadweld dan earthing system part 1.AVI YouTube Body Earthing Of Welding Machine If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. In this article, you will find info on how to ground a welder. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. We'll explain various. Body Earthing Of Welding Machine.

From weldingmachinesbestbuy.blogspot.com

Earthing A Welding Machine Body Earthing Of Welding Machine In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. The first step is to make sure the power source for the welding machine is turned off. It protects people and. Body Earthing Of Welding Machine.

From www.shopclues.com

Welding machine Earthing Clamp Body Earthing Of Welding Machine In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. It protects people and equipment, prevents damage, and improves the reliability of power systems. In this article, you will find info on how to ground a welder. Equipment earthing is a connection between the electrical device body or. Body Earthing Of Welding Machine.

From www.dreamstime.com

Grounding Clamp Welding Machine Stock Photos Free & RoyaltyFree Body Earthing Of Welding Machine In this article, you will find info on how to ground a welder. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. Proper grounding ensures safety and weld quality. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. Grounding with your work lead will improve your performance and. Body Earthing Of Welding Machine.

From www.youtube.com

Welding Machine Me Body Earthing Q Lagaya Jata Hai tig welding Body Earthing Of Welding Machine Proper grounding ensures safety and weld quality. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. Grounding your welder is an essential safety practice that involves connecting the metal components. Body Earthing Of Welding Machine.

From www.electricaltechnology.org

Electrical Earthing and Grounding Methods, Types and Rules Body Earthing Of Welding Machine If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or. Body Earthing Of Welding Machine.

From weldingmachinesbestbuy.blogspot.com

Body Earthing Of Welding Machine Body Earthing Of Welding Machine Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. The first step is to make sure. Body Earthing Of Welding Machine.

From www.amazon.in

BCI Bansal ARC Welding machine Earthing clamp with holder 35/50 with Body Earthing Of Welding Machine Proper grounding ensures safety and weld quality. Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Ensure a secure connection and avoid thin or. Body Earthing Of Welding Machine.

From eziil.com

10 Types of Welding Machines & Their Uses Body Earthing Of Welding Machine Grounding your welder is an essential safety practice that involves connecting the metal components of your welding machine to the earth to prevent the buildup of. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. To ground when welding,. Body Earthing Of Welding Machine.

From www.weldingtribe.com

How to Hook up Stick Welding Leads Welding Tribe Body Earthing Of Welding Machine Grounding your welding machine ensures safety and minimizes the risk of electrical shock. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Proper grounding ensures safety and weld quality. Grounding with your work lead will improve your performance and complete your circuit but it will not ground. Body Earthing Of Welding Machine.

From www.youtube.com

welding machine 🔥🔥 proper earthing shorts patakhe Body Earthing Of Welding Machine We'll explain various grounding methods, important factors to consider, and answer frequent questions. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. In this article, you will find info on how to ground a welder. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. To ground when welding,. Body Earthing Of Welding Machine.

From ar.inspiredpencil.com

Arc Welding Machine Parts Body Earthing Of Welding Machine Grounding your welding machine ensures safety and minimizes the risk of electrical shock. The first step is to make sure the power source for the welding machine is turned off. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Equipment earthing is a connection between the electrical. Body Earthing Of Welding Machine.

From voolisaavery.blogspot.com

mesin welding impraboard Lisa Avery Body Earthing Of Welding Machine It protects people and equipment, prevents damage, and improves the reliability of power systems. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Equipment earthing is a connection between. Body Earthing Of Welding Machine.

From www.pinterest.co.kr

Exothermic welding system Permanent bonding for your earthing Body Earthing Of Welding Machine Grounding your welder is an essential safety practice that involves connecting the metal components of your welding machine to the earth to prevent the buildup of. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. Ensure a secure connection and avoid thin. Body Earthing Of Welding Machine.

From www.youtube.com

Earth Rod Welding YouTube Body Earthing Of Welding Machine If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. Grounding your welding machine ensures safety and minimizes the risk of electrical shock. We'll explain various grounding methods, important factors to. Body Earthing Of Welding Machine.

From arenill76schematic.z21.web.core.windows.net

Components Of Earthing System Body Earthing Of Welding Machine Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock risk. The first step is to make sure the power source for the welding machine is turned off. Grounding your welder is an essential safety practice that involves connecting the metal components of your. Body Earthing Of Welding Machine.

From www.electrical-knowhow.com

Identifying Correct Grounding Tools and Equipment Electrical Knowhow Body Earthing Of Welding Machine We'll explain various grounding methods, important factors to consider, and answer frequent questions. To ground when welding, attach the welding machine’s ground clamp to a clean, unpainted metal surface on the workpiece or the workbench. Proper grounding ensures safety and weld quality. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. Equipment. Body Earthing Of Welding Machine.

From www.youtube.com

Earthing Cable Joint How Cad Welding is done Grid Station Earthing Body Earthing Of Welding Machine In this article, you will find info on how to ground a welder. We'll explain various grounding methods, important factors to consider, and answer frequent questions. Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. Grounding your welding machine ensures safety and minimizes the risk of. Body Earthing Of Welding Machine.

From weldingmachinesbestbuy.blogspot.com

Earthing A Welding Machine Body Earthing Of Welding Machine In the following section, we’ll cover some of the more common ways that your welding machine works with a grounding clamp to. In this article, you will find info on how to ground a welder. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. Grounding your welding machine ensures safety and. Body Earthing Of Welding Machine.

From www.amazon.com

DEKO 135Amp MIG/MMA Welder,DC Inverter Digital Welding Machine,110V Body Earthing Of Welding Machine If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. The first step is to make sure the power source for the welding machine is turned off. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock. Body Earthing Of Welding Machine.

From www.arccaptain.com

Welding Machine Troubleshooting Common Problems and Solutions Body Earthing Of Welding Machine Equipment earthing is a connection between the electrical device body or neutral point and the ground through a metal link to ensure safety. Proper grounding ensures safety and weld quality. It protects people and equipment, prevents damage, and improves the reliability of power systems. Grounding with your work lead will improve your performance and complete your circuit but it will. Body Earthing Of Welding Machine.

From weldingtroop.com

How Many Types of Welding Machines are There and Their Uses? Body Earthing Of Welding Machine The first step is to make sure the power source for the welding machine is turned off. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. Grounding with your work lead will improve your performance and complete your circuit but it will not ground your welder to the earth and mitigate shock. Body Earthing Of Welding Machine.

From weldingmachinesbestbuy.blogspot.com

Double Earthing For Welding Machine Body Earthing Of Welding Machine Proper grounding ensures safety and weld quality. Ensure a secure connection and avoid thin or sharp edges, which can cause resistance, overheating, or arc instability. It protects people and equipment, prevents damage, and improves the reliability of power systems. If you plan on welding with an electrical welding machine, it’s important to ground the machine properly. The first step is. Body Earthing Of Welding Machine.