Insert Coating Type . There are different types of coatings, such as tin (titanium nitride), ticn. When the edge becomes worn, swapping it out. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. They can also help maintain surface finish at much higher feed rates. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. An insert may have multiple coatings, of different materials. The coating of a cutting insert can improve its performance and durability. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick.

from mavink.com

That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. An insert may have multiple coatings, of different materials. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. There are different types of coatings, such as tin (titanium nitride), ticn. The coating of a cutting insert can improve its performance and durability. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. They can also help maintain surface finish at much higher feed rates.

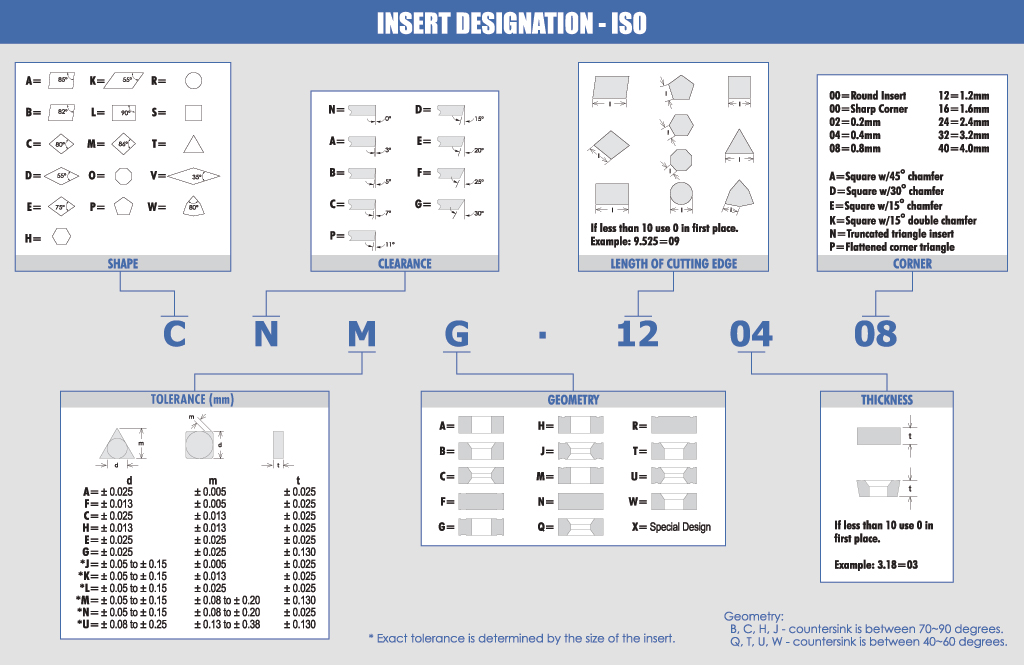

Insert Designation Chart

Insert Coating Type V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. When the edge becomes worn, swapping it out. They can also help maintain surface finish at much higher feed rates. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. The coating of a cutting insert can improve its performance and durability. There are different types of coatings, such as tin (titanium nitride), ticn. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. An insert may have multiple coatings, of different materials. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating.

From www.mscdirect.com

Turning Inserts MSC Industrial Supply Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. When the edge becomes worn, swapping it out. The coating of a cutting insert can improve its performance and durability. An insert may have multiple coatings, of different materials. That said, however, productivity and tool life can be dramatically improved with the. Insert Coating Type.

From georgeandmatilda.com.au

ZEISS SmartLife Eyewear Lenses & Matilda Eyecare Insert Coating Type The coating of a cutting insert can improve its performance and durability. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. When the edge becomes worn, swapping it out. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and. Insert Coating Type.

From wendeschneidplatten.cemecon.de

Premium coatings for cutting inserts CemeCon Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. That said, however, productivity and. Insert Coating Type.

From www.best-carbide.com

tungsten CNC carbide turning insert Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. There are. Insert Coating Type.

From www.mdpi.com

Coatings Free FullText Optimization of Crystalline Diamond Coating Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. There are different types of coatings, such as tin (titanium nitride), ticn. V type inserts, with their 35° cutting edge, provide smooth cutting action,. Insert Coating Type.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. When the edge becomes worn, swapping it out. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. That said, however, productivity and tool life can be dramatically improved with. Insert Coating Type.

From www.canadianmetalworking.com

Manufacturers drive coatings forward Insert Coating Type The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. They can also help maintain. Insert Coating Type.

From solutions.travers.com

Drill Coating Selection Chart Choose The Right Coating For Your Drill Insert Coating Type Advanced coatings like altin pvd provide additional wear resistance and longer tool life. There are different types of coatings, such as tin (titanium nitride), ticn. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. They can also help maintain surface finish at much higher feed rates. When the edge becomes worn,. Insert Coating Type.

From www.gwstoolgroup.com

Tool Coatings GWS Tool Group Insert Coating Type The coating of a cutting insert can improve its performance and durability. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of. Insert Coating Type.

From huanatools.com

Complete application of carbide Inserts Huana Tools Insert Coating Type When the edge becomes worn, swapping it out. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. Advanced coatings like altin pvd provide additional wear resistance and. Insert Coating Type.

From mavink.com

Insert Designation Chart Insert Coating Type There are different types of coatings, such as tin (titanium nitride), ticn. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. The coating of a cutting insert can improve its performance and durability. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. An insert may have. Insert Coating Type.

From www.mdpi.com

Coatings Free FullText Analyses of Tool Wear and Chip Type for Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. They can. Insert Coating Type.

From www.carbideend-mills.com

HRC9193.5 Hardness Custom Carbide Inserts , TiCN Coating Milling Insert Coating Type Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. There are different types of coatings, such. Insert Coating Type.

From www.mmsonline.com

Insert Coating Makes the Grade in Progress Initiative Modern Machine Shop Insert Coating Type Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. They can also help maintain surface finish. Insert Coating Type.

From www.indiamart.com

Carbide Insert Rapicut SPKN and TPKN, Xcut Brand All Type Inserts at Insert Coating Type The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. There are different types of coatings, such as tin (titanium nitride), ticn. When the edge becomes worn, swapping it out. They can also help maintain surface finish at much higher feed rates. That said, however, productivity and tool life can be dramatically. Insert Coating Type.

From www.nextgentooling.com

The Difference Between a Swiss Type CNC and a CNC Lathe & the Cutting Insert Coating Type Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. There are different types of coatings,. Insert Coating Type.

From www.cnccarbideinserts.com

PVD Coating Cemented Carbide Inserts CNC For All Types Milling Requirements Insert Coating Type Advanced coatings like altin pvd provide additional wear resistance and longer tool life. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. An insert may have multiple coatings,. Insert Coating Type.

From www.mscdirect.com

Heavy Roughing (Single Sided) Insert Coating Type V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. They can also help maintain surface finish at much higher feed rates. When the edge becomes worn, swapping. Insert Coating Type.

From katherinewall.z13.web.core.windows.net

Carbide Insert Chart Pdf Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. They can. Insert Coating Type.

From www.icarbide.com

High Performance Carbide Inserts icarbide Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. Rather than a permanent braze,. Insert Coating Type.

From ticoating.com

PVD (Physical Vapor Deposition) Coating multilayered and composite Insert Coating Type That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns. Insert Coating Type.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Insert Coating Type An insert may have multiple coatings, of different materials. The coating of a cutting insert can improve its performance and durability. When the edge becomes worn, swapping it out. There are different types of coatings, such as tin (titanium nitride), ticn. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved. Insert Coating Type.

From www.cnccarbideinserts.com

PVD Coating Cemented Carbide Inserts CNC For All Types Milling Requirements Insert Coating Type They can also help maintain surface finish at much higher feed rates. The coating of a cutting insert can improve its performance and durability. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. That said, however, productivity and. Insert Coating Type.

From www.vrogue.co

Types Of Threaded Fasteners Screws And Bolts Equipmen vrogue.co Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. They can also help maintain surface finish at much higher feed rates. An insert may have multiple coatings, of different materials. Advanced coatings. Insert Coating Type.

From www.harveyperformance.com

3 Ways Tool Coatings Increase Tool Life In The Loupe Insert Coating Type V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. An insert may have multiple coatings, of different materials. The coating of a cutting. Insert Coating Type.

From www.burraycarbide.com

SOMT Carbide Indexable Square Milling Insert from China manufacturer Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. There are different types of coatings, such as tin (titanium nitride), ticn. That said, however, productivity and tool. Insert Coating Type.

From ponasa.condesan-ecoandes.org

Carbide Insert Identification Chart Ponasa Insert Coating Type The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. The coating of a cutting insert can improve its performance and durability. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. Rather than a permanent braze, indexable tooling relies on a screw. Insert Coating Type.

From aurorascicorp.com

PVD Coating System Buying Guide Aurora Scientific Corp Insert Coating Type The coating of a cutting insert can improve its performance and durability. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. When the edge becomes worn, swapping it out. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. They can also help maintain surface finish at much. Insert Coating Type.

From www.indiamart.com

Carbide CVD coating and PVD coating Metal Milling Insert, for Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. The coating of a cutting insert can improve its performance and durability. When the edge becomes worn, swapping it out. Rather than a permanent braze, indexable tooling relies on. Insert Coating Type.

From www.youtube.com

Why is there a coating of different colors on the insert Why is the Insert Coating Type Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. An insert may have multiple coatings, of different materials. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. There are different types of coatings, such as tin (titanium nitride), ticn. That said, however, productivity and tool life can. Insert Coating Type.

From www.silcotek.com

So Many Coatings, So Little Time. Why Are There So Many CVD Coatings? Insert Coating Type There are different types of coatings, such as tin (titanium nitride), ticn. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. Since inserts are typically multiple materials sandwiched together, tool manufacturers use the word ‘grade’ to instead of ‘material’. Advanced coatings like altin pvd provide additional wear resistance and longer. Insert Coating Type.

From www.cdcnctools.com

Cemented Carbide inserts SNMG type Insert CNC Indexable Cutter PVD Coating Insert Coating Type That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. An insert may have multiple coatings, of different materials. The cross section in this picture shows 3 different coatings, each between 2 microns and 10 microns thick. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. When. Insert Coating Type.

From materean.com

Names of coating/surface defects Paul Wu's Blog Insert Coating Type Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. That said, however, productivity and tool life can be dramatically improved with the use of an appropriate diamond coating. There are different types of coatings,. Insert Coating Type.

From www.swisscuttools.com

Turning Inserts Designation SystemISO SwissCut Insert Coating Type V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy. When the edge becomes worn, swapping it out. They can also help maintain surface finish at much higher feed rates. There are different types of coatings, such as tin (titanium nitride), ticn. Rather than a permanent. Insert Coating Type.

From www.alibaba.com

Brazed Cbn Insert Coating Cbn Insert Cnga1204084n Process Hardened Insert Coating Type The coating of a cutting insert can improve its performance and durability. Rather than a permanent braze, indexable tooling relies on a screw or clamp to secure the carbide insert to the tool body. An insert may have multiple coatings, of different materials. Advanced coatings like altin pvd provide additional wear resistance and longer tool life. They can also help. Insert Coating Type.