Milling Tool Life . It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. Tool life refers to the useful life of a machine tool. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed.

from www.canadianmetalworking.com

Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. Tool life refers to the useful life of a machine tool. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu.

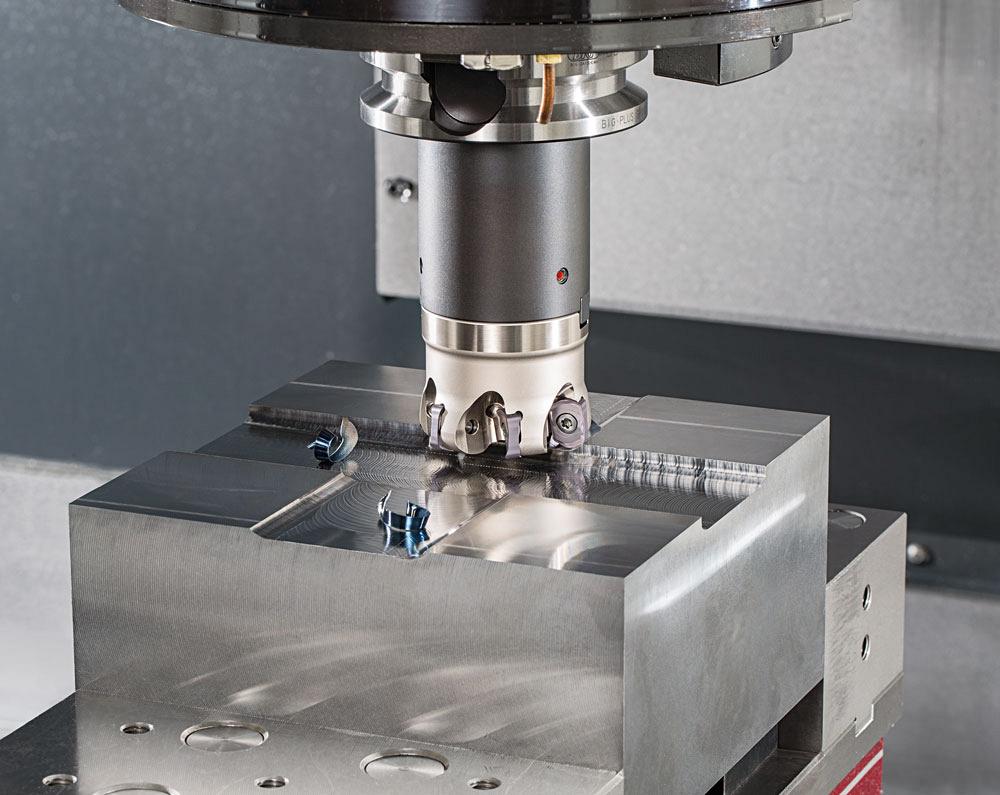

The versatility of multifunctional milling tools

Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. Tool life refers to the useful life of a machine tool. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and.

From www.kennametal.com

Milling Machine Basics Types, Classifications, and Cutting Tools Milling Tool Life Tool life refers to the useful life of a machine tool. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. Tool life is the duration of the actual cutting. Milling Tool Life.

From wallpapercrafter.com

milling, studio shot, turn, cable, machining, cnc, mechanics, still Milling Tool Life Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Tool. Milling Tool Life.

From senotools.en.made-in-china.com

CNC High Feedrate Face Milling Indexable Tool Holder for Milling Exn03r Milling Tool Life Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. Tool life. Milling Tool Life.

From www.aliexpress.com

long tool life 4 Flutes Milling tools Roughing End Mill cutter Rough Milling Tool Life Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing. Milling Tool Life.

From www.scribd.com

f.prd.11.Tool Life Monitoring 1 Milling Tool Life By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations.. Milling Tool Life.

From www.cutwel.co.uk

Milling Cutters Explained An Expert Guide Cutwel Ltd Milling Tool Life It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. Tool life refers to the useful life of a machine tool. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. Tool life is the duration of. Milling Tool Life.

From www.indiamart.com

Power Milling Tool at best price in New Delhi by R. S. Tools Milling Tool Life Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. Tool life refers to the useful life of a machine tool. By collecting data, manufacturers can optimize. Milling Tool Life.

From www.canadianmetalworking.com

Walter PVDcoated WHH15X milling grade provides long tool life during Milling Tool Life [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. Tool life refers to the useful life of a machine tool. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs. Milling Tool Life.

From www.chegg.com

Solved A Face Milling Operation on machine steel plate is Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. Tool life refers to the useful. Milling Tool Life.

From www.canadianmetalworking.com

The versatility of multifunctional milling tools Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Tool life refers to the useful life of a machine tool. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that. Milling Tool Life.

From ar.inspiredpencil.com

Face Milling Tool Milling Tool Life Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. Tool life refers to the useful life of a machine tool. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. The prediction of tool. Milling Tool Life.

From www.harveyperformance.com

End Mill and Milling Troubleshooting Guide In The Loupe Milling Tool Life Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool. Milling Tool Life.

From www.etmm-online.com

Through coolant holes in highperformance end mills for longer tool life Milling Tool Life By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. [11] found that the dominant factor influencing surface roughness. Milling Tool Life.

From www.lap-publishing.com

Improvement of Tool Life on Cnc Milling Machine / 9783659145735 Milling Tool Life Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. It was. Milling Tool Life.

From www.hit-tw.com

Titanium Alloy (Ti6Al4V) Machining Side Milling Hantop Milling Tool Life [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. Tool life refers to. Milling Tool Life.

From www.sumipol.com

11 Tips เพิ่ม Tool Life ลด Tool Wear ในงาน Machining Sumipol Milling Tool Life By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations.. Milling Tool Life.

From www.htcuttingtool.com

The difference between turning tool and milling tool Hitech Cutting Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. It was confirmed that the. Milling Tool Life.

From www.canadianmetalworking.com

Sandvik Coromant introduces a new highfeed milling cutter Milling Tool Life [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. Tool life is the duration of the. Milling Tool Life.

From tagteammfg.com

What is CNC Machining? Denver Manufacturing CNC Manufacturing Milling Tool Life Tool life refers to the useful life of a machine tool. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. Tool wear has a direct impact on the surface. Milling Tool Life.

From www.sumipol.com

11 Tips เพิ่ม Tool Life ลด Tool Wear ในงาน Machining Sumipol Milling Tool Life It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. Tool life is the duration of the actual cutting time after which a tool is no longer usable. Milling Tool Life.

From www.harveyperformance.com

3 Ways Tool Coatings Increase Tool Life In The Loupe Milling Tool Life Tool life refers to the useful life of a machine tool. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi. Milling Tool Life.

From www.youtube.com

Milling Tool and Work Holding Devices YouTube Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and. Milling Tool Life.

From www.machinemetrics.com

How to Identify and Reduce Tool Wear to Improve Quality Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. By. Milling Tool Life.

From wallpapercrafter.com

«milling» HD Wallpapers Milling Tool Life By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. Tool life refers to the useful life of a machine tool. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. [11] found that the dominant factor influencing surface roughness in end. Milling Tool Life.

From epictool.ca

Coolants Used in CNC Operations Epic Tool Milling Tool Life Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. Compared with. Milling Tool Life.

From wallpapercrafter.com

«milling tool» 1080P, 2k, 4k Full HD Wallpapers, Backgrounds Free Milling Tool Life [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. Tool. Milling Tool Life.

From www.toolskit.com

Milling Cutters Archives ToolsKit Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. Tool life is the duration of the actual cutting time after which a tool is no longer usable because. Milling Tool Life.

From pxhere.com

Free Images technology, tool, lathe, industry, drill, thread Milling Tool Life By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations.. Milling Tool Life.

From step.manufacturingtransformation.io

Solid Milling Barrel Tools Seco Online Academy Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations.. Milling Tool Life.

From atelier-yuwa.ciao.jp

Milling Cutter Tools Explained Types And Selection Guide WayKen Milling Tool Life It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Tool life refers to the useful life of a machine tool. Tool life is. Milling Tool Life.

From www.mdpi.com

Machines Free FullText Experimental Analysis of the Effect of Milling Tool Life The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. Tool life refers to the useful life of a machine tool. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. Tool life is. Milling Tool Life.

From wallpapercrafter.com

«milling» HD Wallpapers Milling Tool Life Tool wear has a direct impact on the surface quality of the workpiece, while tool breakage can cause machine downtime and. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. [11] found that the dominant factor influencing surface roughness in end milling of hardened steel in high speed. Tool life. Milling Tool Life.

From www.canadianmetalworking.com

The versatility of multifunctional milling tools Milling Tool Life It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations. By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. Tool wear has. Milling Tool Life.

From www.machinesused.com

Machines Used Heimatec DoubleEnd RightAngle Live Milling Tool Milling Tool Life By collecting data, manufacturers can optimize tool life, ensuring the greatest roi from tooling. The prediction of tool wear in milling using three popular machine learning algorithms, including anns, svr, and rfs was done by wu. It was confirmed that the tool can be used up to its tool life based on tool wear predictions and tool replacement timing determinations.. Milling Tool Life.

From www.youtube.com

Round Copy Milling Inserts For Longer Tool Life & Process Stability Milling Tool Life Tool life is the duration of the actual cutting time after which a tool is no longer usable because the tool deterioration reaches such a level that the cutting edge needs to be replaced to have a. Compared with the unoptimized milling tools, the optimized milling tools have significantly improved cutting performance and tool life, with. Tool life refers to. Milling Tool Life.