Aluminum 6061 T6 Vs T4 . The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. Generally suitable for medium to high strength requirements,. In the t4 condition, fairly severe forming can be done; Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. Four basic temper designations are used for aluminum alloys. In the o temper or annealed condition, alloy 6061 has good formability. They share alloy composition and.

from mungfali.com

They share alloy composition and. Four basic temper designations are used for aluminum alloys. In the t4 condition, fairly severe forming can be done; In the o temper or annealed condition, alloy 6061 has good formability. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. Generally suitable for medium to high strength requirements,. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought.

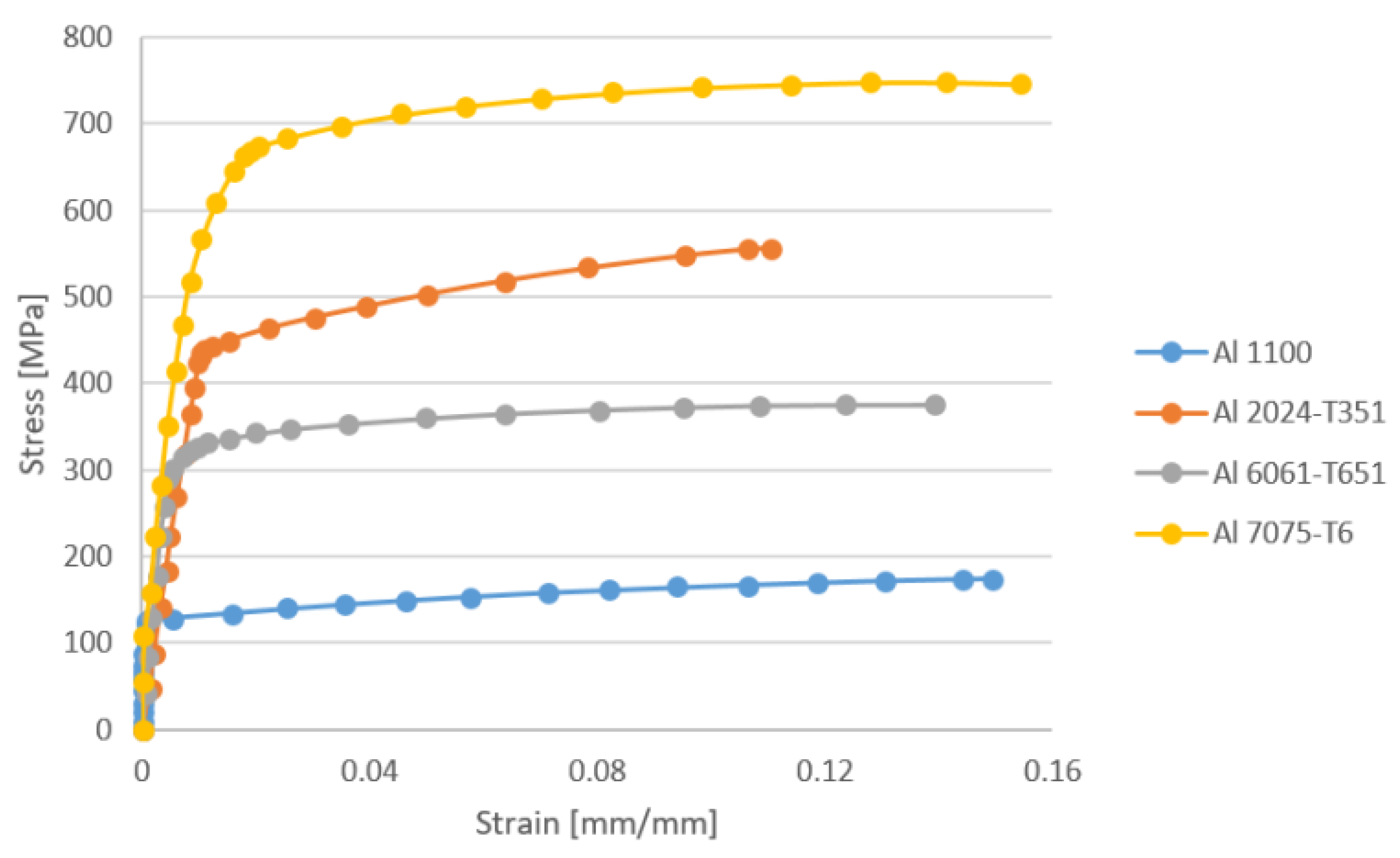

Stress Strain Curve For Aluminum 6061 T6

Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; Generally suitable for medium to high strength requirements,. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. They share alloy composition and. Four basic temper designations are used for aluminum alloys. In the t4 condition, fairly severe forming can be done; The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the o temper or annealed condition, alloy 6061 has good formability. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability.

From www.indiamart.com

Aluminium 6061 T6, Thickness 4 mm at Rs 295/kg in Mumbai ID Aluminum 6061 T6 Vs T4 Generally suitable for medium to high strength requirements,. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the t4 condition, fairly severe forming can be done; This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. The primary distinction between aluminum 6061 t6 vs t4. Aluminum 6061 T6 Vs T4.

From www.mt-aluminum.com

6061 Series Aluminum 6061T6 6061T4 Alloy Mingtai Aluminum Aluminum 6061 T6 Vs T4 They share alloy composition and. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the t4 condition, fairly severe forming can be done; Four basic temper designations are used for aluminum alloys. Generally suitable for medium to high strength requirements,. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum. Aluminum 6061 T6 Vs T4.

From www.semanticscholar.org

Table 1 from Effect of Hardness Test on Precipitation Hardening Aluminum 6061 T6 Vs T4 Four basic temper designations are used for aluminum alloys. They share alloy composition and. In the o temper or annealed condition, alloy 6061 has good formability. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and. Aluminum 6061 T6 Vs T4.

From www.approvedsheetmetal.com

5052H32 vs 6061T6 Aluminum (Updated for 2024) ASM Aluminum 6061 T6 Vs T4 In the o temper or annealed condition, alloy 6061 has good formability. In the t4 condition, fairly severe forming can be done; Four basic temper designations are used for aluminum alloys. They share alloy composition and. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. Generally suitable for medium to high strength requirements,. The primary distinction between. Aluminum 6061 T6 Vs T4.

From www.thefabricator.com

Bending aluminum 101 How to bend 6061T6 aluminum Aluminum 6061 T6 Vs T4 Four basic temper designations are used for aluminum alloys. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the t4 condition, fairly severe forming can be done; Generally suitable for medium to high. Aluminum 6061 T6 Vs T4.

From www.aedmetals.com

6061 Aluminum Sheet A.E.D. METAL PRODUCTS Aluminum 6061 T6 Vs T4 The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the o temper or annealed condition, alloy 6061 has good formability. They share alloy composition and. Generally suitable for medium to high strength requirements,. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability.. Aluminum 6061 T6 Vs T4.

From www.engineeringclicks.com

6061T6 Aluminium The Ultimate Guide EngineeringClicks Aluminum 6061 T6 Vs T4 The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the o temper or annealed condition, alloy 6061 has good formability. This chapter provides additional detail and illustrations for the use of temper designations. Aluminum 6061 T6 Vs T4.

From blog.thepipingmart.com

Aluminium 6061 T6 vs 6082 T6 What's the Difference Aluminum 6061 T6 Vs T4 Generally suitable for medium to high strength requirements,. They share alloy composition and. Four basic temper designations are used for aluminum alloys. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent. Aluminum 6061 T6 Vs T4.

From www.researchgate.net

SN diagrams for 7075 and 6061 aluminum alloys with T6 temper. The solid Aluminum 6061 T6 Vs T4 The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the o temper or annealed condition, alloy 6061 has good formability. Four basic temper designations are used for aluminum alloys. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum. Aluminum 6061 T6 Vs T4.

From www.foismetal.com

Choosing the Right Aluminum Alloy Between 6061T6 and 6061T4 Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; In the o temper or annealed condition, alloy 6061 has good formability. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. They share alloy composition and.. Aluminum 6061 T6 Vs T4.

From www.researchgate.net

Physical properties of 6061T4 aluminum. Download Table Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. This chapter provides additional detail and illustrations for the use of temper designations in the. Aluminum 6061 T6 Vs T4.

From www.steelplatepipe.com

Coated Anodized Surface Aluminum Alloy Sheet 6061 Customized Color T4 T6 Aluminum 6061 T6 Vs T4 Generally suitable for medium to high strength requirements,. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. In the t4 condition, fairly severe forming can be done; In the o temper or annealed condition, alloy 6061. Aluminum 6061 T6 Vs T4.

From wordpress-331561-1541677.cloudwaysapps.com

What Is The Different Aluminum 6061 T6 VS 7075 T6 JC Metal Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. Four basic temper designations are used for aluminum alloys. Generally suitable for medium to high strength requirements,.. Aluminum 6061 T6 Vs T4.

From steelmax.co.kr

SB209 6061T6 Aluminum Sheet ASME Standard 스틸맥스 Aluminum 6061 T6 Vs T4 The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Generally suitable for medium to high strength requirements,. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. Aluminum 6061 has good corrosion resistance, mechanical properties,. Aluminum 6061 T6 Vs T4.

From blog.thepipingmart.com

Aluminium 6060T5 vs 6061T6 What's the Difference Aluminum 6061 T6 Vs T4 They share alloy composition and. Generally suitable for medium to high strength requirements,. In the t4 condition, fairly severe forming can be done; Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the o temper or annealed condition, alloy 6061 has good formability. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective. Aluminum 6061 T6 Vs T4.

From www.marketsmartb2b.com

Grade 2 Titanium vs 6061T6 Aluminium What's the Difference? Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Generally suitable for medium to high strength requirements,. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. Four basic temper designations are used for. Aluminum 6061 T6 Vs T4.

From www.thefabricator.com

Formable aluminum Press brake bending 6061 with the 20 rule Aluminum 6061 T6 Vs T4 In the o temper or annealed condition, alloy 6061 has good formability. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions,. Aluminum 6061 T6 Vs T4.

From www.researchgate.net

Comparison on 6061T6 and 6061T4 curve Download Scientific Diagram Aluminum 6061 T6 Vs T4 Generally suitable for medium to high strength requirements,. In the o temper or annealed condition, alloy 6061 has good formability. In the t4 condition, fairly severe forming can be done; Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. Four basic temper designations are used for aluminum alloys. The primary distinction between aluminum 6061 t6 vs t4. Aluminum 6061 T6 Vs T4.

From mungfali.com

Stress Strain Curve For Aluminum 6061 T6 Aluminum 6061 T6 Vs T4 They share alloy composition and. Generally suitable for medium to high strength requirements,. In the t4 condition, fairly severe forming can be done; Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the o temper or annealed condition, alloy 6061 has good formability. This chapter provides additional detail and illustrations for the use of temper designations. Aluminum 6061 T6 Vs T4.

From mungfali.com

Stress Strain Curve For Aluminum 6061 T6 Aluminum 6061 T6 Vs T4 In the o temper or annealed condition, alloy 6061 has good formability. Four basic temper designations are used for aluminum alloys. In the t4 condition, fairly severe forming can be done; They share alloy composition and. Generally suitable for medium to high strength requirements,. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which. Aluminum 6061 T6 Vs T4.

From aluminumsheetplate.com

6061t4 aluminum plate sheet Aluminum 6061 T6 Vs T4 This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. In the o temper or annealed condition, alloy 6061 has good formability. They share alloy composition and. Four basic temper designations are used for aluminum alloys. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In. Aluminum 6061 T6 Vs T4.

From www.sampmax.com

6061T6 Aluminum IBeam with AMSQQA 200 standard for construction Aluminum 6061 T6 Vs T4 Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. They share alloy composition and. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both. Aluminum 6061 T6 Vs T4.

From www.chalcoaluminum.com

6061 O T4 T6 3C Digital Shell Aluminum Sheet Supplier Chalco Aluminum Aluminum 6061 T6 Vs T4 The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the t4 condition, fairly severe forming can be done; They share alloy composition and. In the o temper or annealed condition, alloy 6061 has good formability. Four basic temper designations are used for aluminum alloys. Generally. Aluminum 6061 T6 Vs T4.

From blog.thepipingmart.com

Aluminium 6060 T6 vs 6061 What's the Difference Aluminum 6061 T6 Vs T4 The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the o temper or annealed condition, alloy 6061 has good formability. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. In the t4 condition,. Aluminum 6061 T6 Vs T4.

From www.researchgate.net

Resulting tensile test for FSW (6061T4) aluminum alloy. Download Table Aluminum 6061 T6 Vs T4 Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. They share alloy composition. Aluminum 6061 T6 Vs T4.

From www.pipingmaterial.ae

6061 t6 aluminum sheet, t6 aluminum plate, a96061 strip suppliers UAE Aluminum 6061 T6 Vs T4 They share alloy composition and. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the o temper or annealed condition, alloy 6061 has good formability. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. Four basic temper designations are used for aluminum. Aluminum 6061 T6 Vs T4.

From www.alu-plate.com

6063 T4 Aluminum Plate Sheet Haomei Aluminum Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; Generally suitable for medium to high strength requirements,. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the o temper or annealed condition, alloy 6061 has good formability. This chapter provides additional detail and illustrations. Aluminum 6061 T6 Vs T4.

From www.semanticscholar.org

Table 1 from Fatigue crack growth in friction stir welds of 6082T6 and Aluminum 6061 T6 Vs T4 In the o temper or annealed condition, alloy 6061 has good formability. Four basic temper designations are used for aluminum alloys. The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. In the t4 condition, fairly severe forming can be done; Generally suitable for medium to high. Aluminum 6061 T6 Vs T4.

From mungfali.com

Stress Strain Curve For Aluminum 6061 T6 Aluminum 6061 T6 Vs T4 This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the t4 condition, fairly severe forming can be done; The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent. Aluminum 6061 T6 Vs T4.

From www.semanticscholar.org

Table 4 from Fatigue crack growth in friction stir welds of 6082T6 and Aluminum 6061 T6 Vs T4 This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. In the t4 condition, fairly severe forming can be done; The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Four basic temper designations are used. Aluminum 6061 T6 Vs T4.

From www.amardeepsteel.com

Aluminium 6061T6 vs Aluminium 6063T5 Aluminum 6061 T6 Vs T4 The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. In the t4 condition, fairly severe forming can be done; In the o temper or annealed condition, alloy 6061 has good formability. Four basic temper. Aluminum 6061 T6 Vs T4.

From www.scribd.com

6005T6 Aluminum Vs 6061T6 Aluminum Ultimate Tensile Strength Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; The primary distinction between aluminum 6061 t6 vs t4 lies in their respective temper conditions, which represent the heat treatment processes they undergo. They share alloy composition and. In the o temper or annealed condition, alloy 6061 has good formability. Four basic temper designations are used for aluminum alloys. Generally. Aluminum 6061 T6 Vs T4.

From www.aluminium-flat-bar.com

EN AW6061 T4/T6/T651 aluminum flat bus bar_Aluminium busbar Manufacturers Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. In the o temper or annealed condition, alloy 6061 has good formability. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. The primary distinction between aluminum. Aluminum 6061 T6 Vs T4.

From basicstagemakeuptutorial.blogspot.com

fatigue design curves for 6061 t6 aluminum basicstagemakeuptutorial Aluminum 6061 T6 Vs T4 In the t4 condition, fairly severe forming can be done; Generally suitable for medium to high strength requirements,. Four basic temper designations are used for aluminum alloys. This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. In the o temper or annealed condition, alloy 6061 has good formability.. Aluminum 6061 T6 Vs T4.

From www.dhanlaxmisteel.com

What is 6061t6 Aluminum? Aluminum 6061 T6 Vs T4 This chapter provides additional detail and illustrations for the use of temper designations in the aluminum industry today for both wrought. In the t4 condition, fairly severe forming can be done; Four basic temper designations are used for aluminum alloys. Aluminum 6061 has good corrosion resistance, mechanical properties, formability, weldability, and machinability. They share alloy composition and. Generally suitable for. Aluminum 6061 T6 Vs T4.