Copper Film Density . — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. 22 rows — h.m. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. “influence of film density on residual stress and resistivity for cu thin films deposited. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. mechanical properties of these films have been studied by means of dynamic microindentation.

from www.semanticscholar.org

— to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. 22 rows — h.m. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. mechanical properties of these films have been studied by means of dynamic microindentation. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. “influence of film density on residual stress and resistivity for cu thin films deposited. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared.

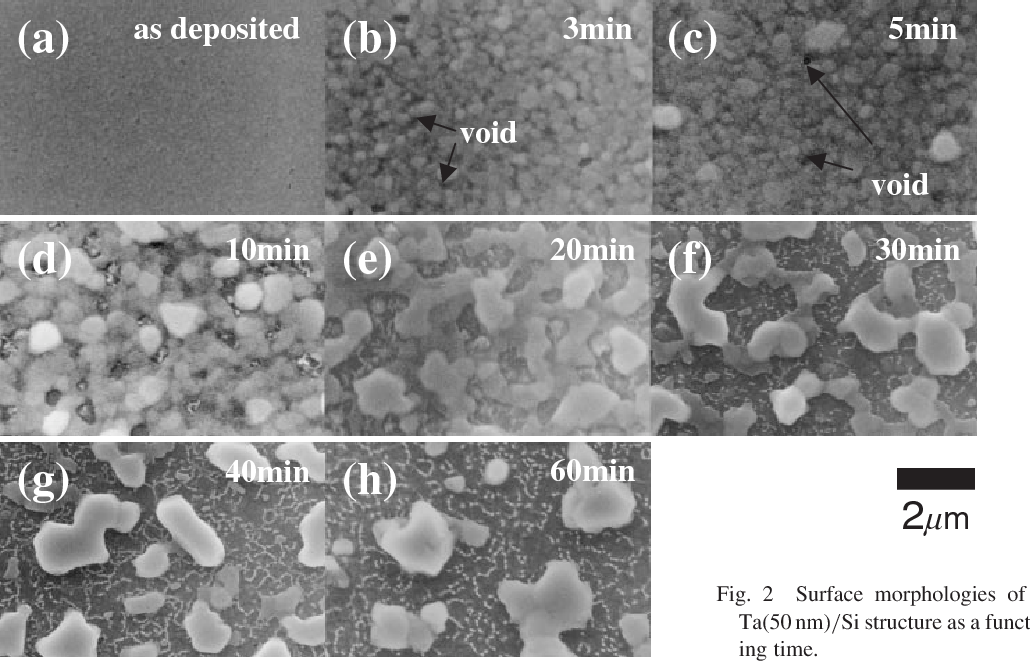

Figure 1 from Agglomeration of copper thin film in Cu/Ta/Si structure

Copper Film Density critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. 22 rows — h.m. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. mechanical properties of these films have been studied by means of dynamic microindentation. “influence of film density on residual stress and resistivity for cu thin films deposited.

From www.numerade.com

The density of copper is 8.9 g/cm'. Calculate the relative density of Copper Film Density mechanical properties of these films have been studied by means of dynamic microindentation. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. — to calculate. Copper Film Density.

From www.researchgate.net

The transmission spectrum of the copper films Download Scientific Diagram Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. mechanical properties of these films have been studied by means of dynamic microindentation. critical angle in. Copper Film Density.

From www.researchgate.net

TGA curves of copper films obtained using Cu available Copper Film Density 22 rows — h.m. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. “influence of film density on residual stress and resistivity for cu thin films deposited. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of. Copper Film Density.

From www.researchgate.net

(PDF) The Electrical Resistivity of UltraThin Copper Films Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. “influence of film density on residual stress and resistivity for cu thin films deposited. 22 rows — h.m. mechanical properties of these films have been studied by means of dynamic microindentation. — copper thin. Copper Film Density.

From www.researchgate.net

Variation of resistivity for copper thin films as function of film Copper Film Density “influence of film density on residual stress and resistivity for cu thin films deposited. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. 22 rows — h.m. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate. Copper Film Density.

From www.mdpi.com

Materials Free FullText Subps Laser Deposited Copper Films for Copper Film Density “influence of film density on residual stress and resistivity for cu thin films deposited. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. mechanical properties of these films have been studied by means of dynamic microindentation. — copper thin films were prepared by a. Copper Film Density.

From www.researchgate.net

Plot of the internal stress of copper films deposited from the Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. “influence of film density on residual stress and resistivity for cu thin films deposited. mechanical properties of these films have been studied by means of dynamic microindentation. — to calculate the closed porosity, the mass. Copper Film Density.

From www.semanticscholar.org

Figure 5 from Growth of copper thin films in different MOCVD Copper Film Density — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass. Copper Film Density.

From www.researchgate.net

SEM pictures of the copper films obtained by CVD using [Cu(hfac)(MHY Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. 22 rows — h.m. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based. Copper Film Density.

From www.researchgate.net

The optical images of copper film with different thicknesses annealed Copper Film Density — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. 22 rows — h.m. critical angle in xrr measurements gives a rough estimate of the surface. Copper Film Density.

From www.researchgate.net

(a) High angle XRD patterns of copper films deposited on aluminum Copper Film Density critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. 22 rows — h.m. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. . Copper Film Density.

From www.semanticscholar.org

Figure 1 from Agglomeration of copper thin film in Cu/Ta/Si structure Copper Film Density — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. “influence of film density on residual stress and resistivity for cu thin films deposited. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. critical angle in. Copper Film Density.

From www.researchgate.net

Stress distribution in a slice of copper film deposited in zdirection Copper Film Density critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. mechanical properties of these films. Copper Film Density.

From plot.ly

Density Graph Copper scatter chart made by J17k plotly Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. “influence of film density on residual stress and resistivity for cu thin films deposited. mechanical properties of. Copper Film Density.

From aliyaiwal.blogspot.com

Density Of Copper Copper Film Density — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. mechanical properties of these films. Copper Film Density.

From www.semanticscholar.org

Table 1 from Low pressure chemical vapor deposition of copper films Copper Film Density “influence of film density on residual stress and resistivity for cu thin films deposited. mechanical properties of these films have been studied by means of dynamic microindentation. 22 rows — h.m. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. — three cu thin films with 5,. Copper Film Density.

From www.researchgate.net

SEM images showing microstructures of the copper films (a) unsintered Copper Film Density — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. mechanical. Copper Film Density.

From www.researchgate.net

Electroplated copper SEM images of copper films deposited from a Copper Film Density 22 rows — h.m. “influence of film density on residual stress and resistivity for cu thin films deposited. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into. Copper Film Density.

From www.researchgate.net

(PDF) Defect Density and Electrical Properties of Vacuum Evaporated Copper Film Density 22 rows — h.m. mechanical properties of these films have been studied by means of dynamic microindentation. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were. Copper Film Density.

From www.researchgate.net

XRD spectrums of copper films plated with different concentrations of Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. “influence of film density on residual stress and resistivity for cu thin films deposited. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of. Copper Film Density.

From news.mst.edu

Missouri S&T News and Events Researchers use amino acids to grow Copper Film Density 22 rows — h.m. “influence of film density on residual stress and resistivity for cu thin films deposited. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. critical angle in xrr measurements. Copper Film Density.

From www.researchgate.net

Localized stress within the copper films as a function of film Copper Film Density — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. 22 rows — h.m. “influence of film density on residual stress and resistivity for cu thin films deposited. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were. Copper Film Density.

From www.researchgate.net

SEM images of the copper films obtained after sintering at 120 °C using Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. “influence of film density on residual stress and resistivity for cu thin films deposited. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of. Copper Film Density.

From www.semanticscholar.org

Table 1 from Low pressure chemical vapor deposition of copper films Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. mechanical properties of these films have been studied by means of dynamic microindentation. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by. Copper Film Density.

From www.researchgate.net

The temperature curve of the copper film on the copper clad laminates Copper Film Density mechanical properties of these films have been studied by means of dynamic microindentation. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. — three cu thin films with 5, 25 and 50. Copper Film Density.

From www.youtube.com

Calculating the density of copper wire YouTube Copper Film Density “influence of film density on residual stress and resistivity for cu thin films deposited. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. 22 rows — h.m. — three cu thin films. Copper Film Density.

From www.researchgate.net

TEM images of the copper films on the ITO substrate surface Copper Film Density — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. —. Copper Film Density.

From www.researchgate.net

Melting of a levitating solid thin copper film of thickness (d). The Copper Film Density critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. 22 rows — h.m. mechanical properties of these films have been studied by means of dynamic microindentation. — copper thin films were. Copper Film Density.

From www.researchgate.net

(PDF) Direct Copper Pattern Plating on Glass and Ceramic Substrates Copper Film Density critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. mechanical properties of these films have been studied by means of dynamic microindentation. “influence of film density on residual stress and resistivity for cu. Copper Film Density.

From www.researchgate.net

SEM images of copper films deposited with different deposition time a Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. mechanical properties of these films have been studied by means of dynamic microindentation. — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. critical angle in. Copper Film Density.

From aliyaiwal.blogspot.com

Density Of Copper Copper Film Density 22 rows — h.m. mechanical properties of these films have been studied by means of dynamic microindentation. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. — copper thin films were. Copper Film Density.

From www.bartleby.com

Answered 17 The density of copper is 8.92 g/mL.… bartleby Copper Film Density — three cu thin films with 5, 25 and 50 nm in thickness (named samples #1, #2 and #3 respectively) were prepared. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. mechanical. Copper Film Density.

From www.youtube.com

understanding film density YouTube Copper Film Density — copper thin films were prepared by a metal organic chemical vapor deposition technology on top of tin/si. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass density of films, assuming a homogenous, smooth, and continuous deposition. — to calculate the closed. Copper Film Density.

From www.researchgate.net

Variation of resistivity for copper thin films as function of film Copper Film Density 22 rows — h.m. mechanical properties of these films have been studied by means of dynamic microindentation. — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. critical angle in xrr measurements. Copper Film Density.

From haipernews.com

How To Calculate Density Copper Haiper Copper Film Density — to calculate the closed porosity, the mass of the deposited film, m f, is converted into film density, ρ film, by dividing the measured film thickness, t f (volume based on thickness and. critical angle in xrr measurements gives a rough estimate of the surface electron density of the films and thus an estimate of the mass. Copper Film Density.