Lead Screw Linear Force Calculator . Force (n) = torque (nm) / lead (m). For example, if the goal is to produce 100 lb of. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. To calculate it, use the formula: The formula below is used to find the. Please contact us to discuss your screw application! Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. To calculate linear thrust of a screw assembly, use the following equation: The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. This relationship allows lead screws to convert. Torque = thrust required × screw lead/ (2 × efficiency).

from www.mdpi.com

Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. For example, if the goal is to produce 100 lb of. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. The formula below is used to find the. To calculate it, use the formula: Torque = thrust required × screw lead/ (2 × efficiency). Force (n) = torque (nm) / lead (m). To calculate linear thrust of a screw assembly, use the following equation: Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load.

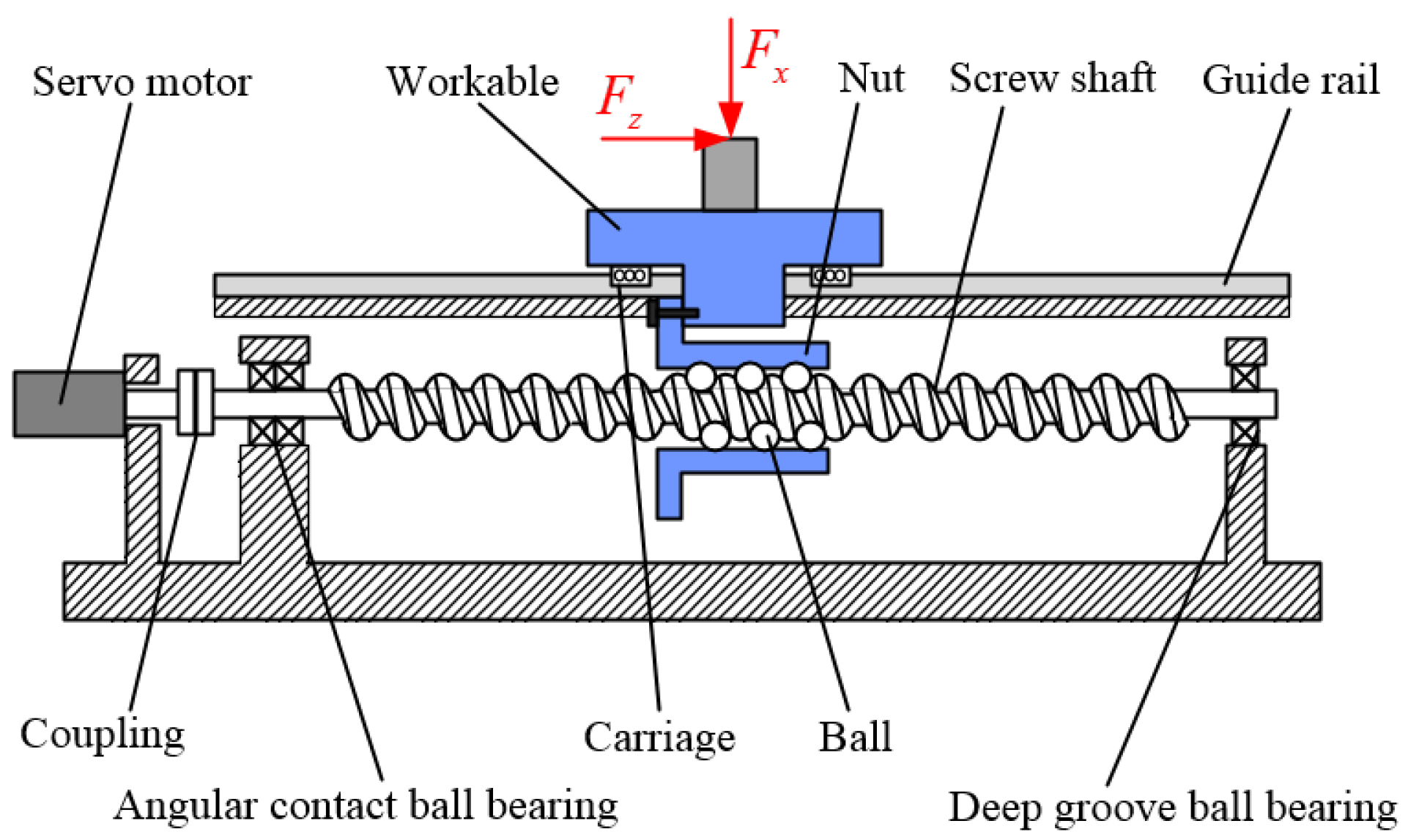

Applied Sciences Free FullText Dynamic Analysis of Ball Screw Feed

Lead Screw Linear Force Calculator Torque = thrust required × screw lead/ (2 × efficiency). Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Please contact us to discuss your screw application! The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. Force (n) = torque (nm) / lead (m). The formula below is used to find the. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. To calculate it, use the formula: To calculate linear thrust of a screw assembly, use the following equation: It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. For example, if the goal is to produce 100 lb of. This relationship allows lead screws to convert. Torque = thrust required × screw lead/ (2 × efficiency).

From eng-resources.charlotte.edu

Linear Motion System Product Calculations UNC Charlotte Engineering Lead Screw Linear Force Calculator The formula below is used to find the. To calculate it, use the formula: This relationship allows lead screws to convert. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. Lead screws are often used in linear. Lead Screw Linear Force Calculator.

From exofskdmm.blob.core.windows.net

Lead Screw Torque Calculator Metric at David High blog Lead Screw Linear Force Calculator It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. Quickly calculate the torque required to lift a load with. Lead Screw Linear Force Calculator.

From www.machinedesigning.com

Horizontal Linear Motion With Ball Screw 1 Machine Designing Lead Screw Linear Force Calculator Force (n) = torque (nm) / lead (m). It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. The lead screw torque calculator determine the torque required to move a load smoothly. Lead Screw Linear Force Calculator.

From www.eng-tips.com

Calculating tension in a twin left and right hand lead screw Lead Screw Linear Force Calculator Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. Please contact us to discuss your screw application!. Lead Screw Linear Force Calculator.

From www.physicsforums.com

Calculate the torque needed to move a lead screw Lead Screw Linear Force Calculator To calculate it, use the formula: Torque = thrust required × screw lead/ (2 × efficiency). Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the. Lead Screw Linear Force Calculator.

From blog.engineeringpaper.xyz

Lead Screw Torque and Efficiency Calculations The Official Lead Screw Linear Force Calculator Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Please contact us to discuss your screw application! Force (n) = torque (nm) / lead (m). For example, if the goal is to produce 100 lb of. To calculate it, use the formula: Lead screws are often used in linear actuators and positioning equipment to provide. Lead Screw Linear Force Calculator.

From blog.orientalmotor.com

Motor Sizing Basics Part 3 How to Calculate Speed, Acceleration Torque Lead Screw Linear Force Calculator It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. Force (n) = torque (nm) / lead (m). Torque = thrust required × screw lead/ (2 × efficiency). Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. The lead screw torque. Lead Screw Linear Force Calculator.

From www.youtube.com

Mechanical Design Free body Diagram of a Lead screw YouTube Lead Screw Linear Force Calculator To calculate it, use the formula: It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force. Lead Screw Linear Force Calculator.

From www.chegg.com

Solved Q2. A Ball Screw mechanism is driven by stepping Lead Screw Linear Force Calculator To calculate it, use the formula: Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Force (n) = torque (nm) / lead (m). Please contact us to discuss your screw application! The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the. Lead Screw Linear Force Calculator.

From saratov.myhistorypark.ru

Z Axis Stepper Motor And Lead Screw Torque Calculation 3D, 50 OFF Lead Screw Linear Force Calculator The formula below is used to find the. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw.. Lead Screw Linear Force Calculator.

From www.tolomatic.com

Selecting the Optimal Screw Technology Tolomatic Lead Screw Linear Force Calculator To calculate it, use the formula: To calculate linear thrust of a screw assembly, use the following equation: Torque = thrust required × screw lead/ (2 × efficiency). The formula below is used to find the. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. This relationship allows lead. Lead Screw Linear Force Calculator.

From www.mdpi.com

Applied Sciences Free FullText Dynamic Analysis of Ball Screw Feed Lead Screw Linear Force Calculator For example, if the goal is to produce 100 lb of. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. The amount of axial force that a lead screw assembly can withstand is determined by. Lead Screw Linear Force Calculator.

From www.thomsonlinear.com

Reduce Your Linear Motion Assemblies to a Single Component with Lead Screw Linear Force Calculator To calculate linear thrust of a screw assembly, use the following equation: The formula below is used to find the. Torque = thrust required × screw lead/ (2 × efficiency). It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. For example, if the goal is to produce 100 lb of. Please. Lead Screw Linear Force Calculator.

From www.iqsdirectory.com

Lead Screw What Is It? How Is It Used? Types, Threads Lead Screw Linear Force Calculator For example, if the goal is to produce 100 lb of. To calculate it, use the formula: Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. The formula below is used to find the. The. Lead Screw Linear Force Calculator.

From exofskdmm.blob.core.windows.net

Lead Screw Torque Calculator Metric at David High blog Lead Screw Linear Force Calculator Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. Force (n) = torque (nm) / lead (m). For example, if the goal is to produce 100 lb of. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the. Lead Screw Linear Force Calculator.

From www.youtube.com

Lead Screw Linear Motion YouTube Lead Screw Linear Force Calculator Please contact us to discuss your screw application! This relationship allows lead screws to convert. The formula below is used to find the. To calculate it, use the formula: The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Force (n) = torque (nm) / lead (m). For example, if. Lead Screw Linear Force Calculator.

From www.youtube.com

Power Screws Torque to Force Relationships in Just Over 10 Minutes Lead Screw Linear Force Calculator Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Torque = thrust required × screw lead/ (2 × efficiency). Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. For example, if the goal is to produce 100 lb of. It is useful to determine. Lead Screw Linear Force Calculator.

From www.circuitist.com

Steps per mm calculator lead screw & GT2 timing belt Lead Screw Linear Force Calculator To calculate it, use the formula: The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. To calculate linear thrust of a screw assembly, use the following equation: The amount. Lead Screw Linear Force Calculator.

From www.designworldonline.com

How to account for ball and lead screw inertia during system design Lead Screw Linear Force Calculator Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. The formula below is used to find the. This relationship allows lead screws to convert. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or. Lead Screw Linear Force Calculator.

From www.e-motionsupply.com

Ball Screw Lead Screw Linear Force Calculator Force (n) = torque (nm) / lead (m). Please contact us to discuss your screw application! The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. For example, if the goal is to produce 100 lb of. The. Lead Screw Linear Force Calculator.

From www.pinterest.com

Linear Force Calculator Force, Calculator, Linear Lead Screw Linear Force Calculator Please contact us to discuss your screw application! The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze.. Lead Screw Linear Force Calculator.

From www.youtube.com

Calculating Lead Screw Efficiency and Required Lifting Torque YouTube Lead Screw Linear Force Calculator For example, if the goal is to produce 100 lb of. Torque = thrust required × screw lead/ (2 × efficiency). To calculate linear thrust of a screw assembly, use the following equation: The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the. Lead Screw Linear Force Calculator.

From engineerexcel.com

Bolt Clamping Force Calculations EngineerExcel Lead Screw Linear Force Calculator For example, if the goal is to produce 100 lb of. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. It is useful to determine the output torque needed. Lead Screw Linear Force Calculator.

From www.scribd.com

Motor Torque Calculation Lead Screw Drive Loads PDF Gear Lead Screw Linear Force Calculator The formula below is used to find the. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. For example, if the goal is to produce 100 lb of. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Torque = thrust required × screw lead/. Lead Screw Linear Force Calculator.

From www.youtube.com

FRICTIONAL FORCES ON SCREWS // Equations Given and Explained YouTube Lead Screw Linear Force Calculator This relationship allows lead screws to convert. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Torque = thrust required × screw lead/ (2 × efficiency). It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. To calculate linear thrust of. Lead Screw Linear Force Calculator.

From calculatorshub.net

Lead Screw Torque Calculator Online Lead Screw Linear Force Calculator Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. The formula below is used to find the. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. Please contact us to discuss your. Lead Screw Linear Force Calculator.

From www.chegg.com

Solved Find the torque required to accelerate a 200 lb. Lead Screw Linear Force Calculator Torque = thrust required × screw lead/ (2 × efficiency). Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. Force (n) = torque. Lead Screw Linear Force Calculator.

From www.youtube.com

Overview of Ball Screw/Lead Screw Systems for Linear Movement YouTube Lead Screw Linear Force Calculator It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. Force (n) = torque (nm) / lead (m). For example,. Lead Screw Linear Force Calculator.

From calculatorshub.net

Screw Torque to Linear Force Calculator Online Lead Screw Linear Force Calculator To calculate it, use the formula: The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. The formula below is used to find the. Please contact us to discuss your screw application! For example, if the goal is to produce 100 lb of. This relationship allows lead screws to convert.. Lead Screw Linear Force Calculator.

From 3dprinting.stackexchange.com

Z axis Stepper motor and lead screw torque calculation 3D Printing Lead Screw Linear Force Calculator For example, if the goal is to produce 100 lb of. Torque = thrust required × screw lead/ (2 × efficiency). The formula below is used to find the. Force (n) = torque (nm) / lead (m). To calculate linear thrust of a screw assembly, use the following equation: This relationship allows lead screws to convert. It is useful to. Lead Screw Linear Force Calculator.

From calculatorshub.net

Stepper Motor Lead Screw Calculator Online Lead Screw Linear Force Calculator Please contact us to discuss your screw application! Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. For example, if the goal is to produce 100 lb of. The formula below is used to find. Lead Screw Linear Force Calculator.

From www.machinedesigning.com

Horizontal Linear Motion With Ball Screw 1 Machine Designing Lead Screw Linear Force Calculator Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. Quickly calculate. Lead Screw Linear Force Calculator.

From fyojqwyda.blob.core.windows.net

Lead Screw Calculation Formula at Jonathan Ertl blog Lead Screw Linear Force Calculator Torque = thrust required × screw lead/ (2 × efficiency). For example, if the goal is to produce 100 lb of. The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. Please contact us to discuss your screw. Lead Screw Linear Force Calculator.

From www.researchgate.net

Power losses in nutball screw connection Download Table Lead Screw Linear Force Calculator Please contact us to discuss your screw application! Lead screws are often used in linear actuators and positioning equipment to provide thrust (axial) force to drive a load. For example, if the goal is to produce 100 lb of. The lead screw torque calculator determine the torque required to move a load smoothly and precisely using a lead screw. The. Lead Screw Linear Force Calculator.

From www.physicsforums.com

Calculate the torque needed to move a lead screw Lead Screw Linear Force Calculator The amount of axial force that a lead screw assembly can withstand is determined by the diameter and lead of the screw and the material of the nut — plastic or bronze. It is useful to determine the output torque needed from a motor to produce the appropriate linear thrust. Please contact us to discuss your screw application! The formula. Lead Screw Linear Force Calculator.