Equipment Layout Diagram . The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. Learn what equipment layout is and how it affects the design and operation of plants and facilities. Learn what equipment layout is and how it is developed in piping design. Equipment layout is the detailing of conceptual layout. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. Find out the essential data, documents, and configurations for equipment layout design. It is the basic document of mechanical engineering design or in other words this document is the basis for development of. The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. Find out the factors to consider, such as plant layout. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks.

from optiwas.blogspot.com

Equipment layout is the detailing of conceptual layout. Learn what equipment layout is and how it is developed in piping design. Find out the factors to consider, such as plant layout. The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. It is the basic document of mechanical engineering design or in other words this document is the basis for development of. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. Find out the essential data, documents, and configurations for equipment layout design. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices.

Equipment Layout In Piping Design Considerations for Equipment and

Equipment Layout Diagram It is the basic document of mechanical engineering design or in other words this document is the basis for development of. Find out the essential data, documents, and configurations for equipment layout design. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Find out the factors to consider, such as plant layout. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. It is the basic document of mechanical engineering design or in other words this document is the basis for development of. Equipment layout is the detailing of conceptual layout. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. Learn what equipment layout is and how it affects the design and operation of plants and facilities. Learn what equipment layout is and how it is developed in piping design. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions.

From thepiping.com

What Is Equipment Layout Equipment Layout Diagram Learn what equipment layout is and how it is developed in piping design. The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Find out the. Equipment Layout Diagram.

From www.researchgate.net

Existing Generation Simplified Equipment Layout Diagram Download Equipment Layout Diagram The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. Find out the essential data, documents, and configurations for equipment layout design. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. The designer can do things like relocating, rotating, and. Equipment Layout Diagram.

From www.pooltech.com

CAD Design Pool Tech Your Cedar Rapids, IA Builder Equipment Layout Diagram Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. Equipment layout is the detailing of conceptual layout. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. It is the basic document of mechanical engineering design or in other words this document. Equipment Layout Diagram.

From www.slideshare.net

Equipment Layout Equipment Layout Diagram The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. Equipment layout is the detailing of conceptual layout. Find out the factors to consider, such as plant layout. Learn what equipment layout is and how it affects the design and operation of plants and facilities. P&id shows all. Equipment Layout Diagram.

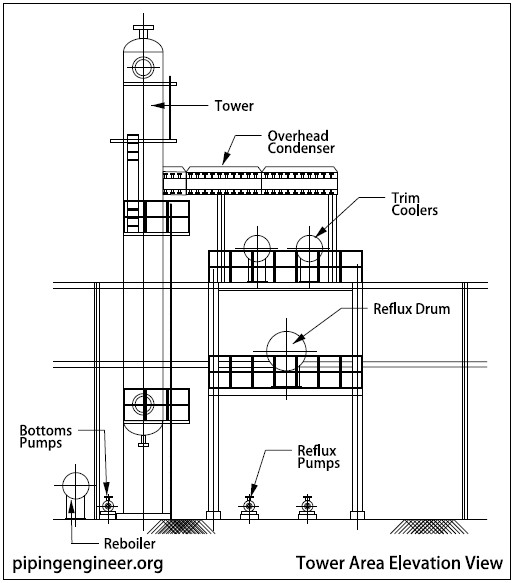

From www.pipingengineer.org

PFD and Equipment Layout of Distillation Tower Area The Piping Equipment Layout Diagram Find out the essential data, documents, and configurations for equipment layout design. Learn what equipment layout is and how it is developed in piping design. Equipment layout is the detailing of conceptual layout. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Learn what equipment layout is. Equipment Layout Diagram.

From cookprocesssolutions.com

Equipment Layout Cook Process Solutions, LLC Equipment Layout Diagram A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. With a manufacturing plant layout, you have the ability to move equipment around on paper in. Equipment Layout Diagram.

From www.pipingengineer.org

PFD and Equipment Layout of Distillation Tower Area The Piping Equipment Layout Diagram Learn what equipment layout is and how it is developed in piping design. Equipment layout is the detailing of conceptual layout. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. Find out the factors to consider, such as plant layout. Find out the essential data, documents, and. Equipment Layout Diagram.

From www.matrixpdm.com

equipment layout Matrix PDM Engineering Equipment Layout Diagram Learn what equipment layout is and how it is developed in piping design. It is the basic document of mechanical engineering design or in other words this document is the basis for development of. The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. 57 rows a comprehensive checklist for piping engineers to. Equipment Layout Diagram.

From www.researchgate.net

Schematic diagram of the layout of experimental equipment used for Equipment Layout Diagram A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. Learn what equipment layout is and how it is developed in piping design. The checklist covers various aspects of equipment. Equipment Layout Diagram.

From www.researchgate.net

Basic Equipment Layout Download Scientific Diagram Equipment Layout Diagram Learn what equipment layout is and how it affects the design and operation of plants and facilities. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. A piping & instrumentation diagram or p&id is. Equipment Layout Diagram.

From southwestmachinery.com

Equipmentlayout Equipment Layout Diagram 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Learn what equipment layout is and how it affects the design and operation of plants and facilities. The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. Learn what equipment layout. Equipment Layout Diagram.

From www.researchgate.net

Survey vessel equipment layout diagram. Download Scientific Diagram Equipment Layout Diagram 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Equipment layout is the detailing of conceptual layout. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. A piping & instrumentation diagram or p&id is a schematic illustration. Equipment Layout Diagram.

From www.ganghongmachine.com

Highspeed soy sauce, oyster sauce, cooking wine filling production Equipment Layout Diagram P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your. Equipment Layout Diagram.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Diagram 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Equipment layout is the detailing of conceptual layout. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. It is the basic document of mechanical engineering. Equipment Layout Diagram.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Diagram The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all. Equipment Layout Diagram.

From wermac.org

Piping Coordination System Plot Plans and Equipment Arrangements Equipment Layout Diagram It is the basic document of mechanical engineering design or in other words this document is the basis for development of. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the. Equipment Layout Diagram.

From optiwas.blogspot.com

Equipment Layout In Piping Design Considerations for Equipment and Equipment Layout Diagram Equipment layout is the detailing of conceptual layout. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. Find out the essential data, documents, and configurations for equipment layout design. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components.. Equipment Layout Diagram.

From www.conceptdraw.com

How to Create a Plant Layout Design Plant Layout Plans Factory Equipment Layout Diagram With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. Equipment layout is the detailing of conceptual layout. Learn what equipment layout is and how it is developed in piping. Equipment Layout Diagram.

From www.alamy.com

Photograph of a line drawing. '(PLAN LAYOUT OF) PART III, SECTION 1 Equipment Layout Diagram Find out the factors to consider, such as plant layout. Equipment layout is the detailing of conceptual layout. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. Learn what equipment layout is and how it is developed in piping design. P&id shows all of piping including the physical sequence of. Equipment Layout Diagram.

From www.amsc-usa.com

Warehouse Layout Guide Design & Tips for Efficient Warehousing Equipment Layout Diagram With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. Equipment layout is the detailing of conceptual layout. 57 rows a comprehensive checklist for piping engineers. Equipment Layout Diagram.

From www.researchgate.net

Simple equipment layout diagram provided by OpenCEL Download Equipment Layout Diagram Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. Learn what equipment layout is and how it affects the design and operation of plants and facilities. It is the basic document of mechanical engineering design or in other words this document is the basis for development of. The designer can. Equipment Layout Diagram.

From www.advancedconcessiontrailers.com

8.5 x 28 Equipment Layout Advanced Concession Trailers Equipment Layout Diagram It is the basic document of mechanical engineering design or in other words this document is the basis for development of. Learn what equipment layout is and how it affects the design and operation of plants and facilities. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. The designer can. Equipment Layout Diagram.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Diagram Find out the essential data, documents, and configurations for equipment layout design. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Learn about various aspects. Equipment Layout Diagram.

From www.equipmentmanufacturingandintegration.com

Equipment Layout Line Drawings Equipment Manufacturing & Integration Inc Equipment Layout Diagram Find out the essential data, documents, and configurations for equipment layout design. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. The designer can do things like relocating, rotating, and reorienting equipment. Equipment Layout Diagram.

From www.researchgate.net

15 Equipment layout on Tower and BTS Cabin of the proposed scheme Equipment Layout Diagram Find out the essential data, documents, and configurations for equipment layout design. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. Equipment layout is the detailing of conceptual. Equipment Layout Diagram.

From bavengineering.com

Equipment layouts BAV Engineering Equipment Layout Diagram With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment. Equipment Layout Diagram.

From www.scribd.com

Equipment Layout Diagram for PT VALE 2 Camera System with Component Equipment Layout Diagram The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. Find out the essential data, documents, and configurations for equipment layout design. Equipment layout is the detailing of conceptual layout. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to. Equipment Layout Diagram.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Equipment Layout Diagram Find out the factors to consider, such as plant layout. With a manufacturing plant layout, you have the ability to move equipment around on paper in order to maximize your square footage. Learn what equipment layout is and how it is developed in piping design. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation. Equipment Layout Diagram.

From automationforum.co

What is control room layout diagram and it purposes? Equipment Layout Diagram 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Find out the factors to consider, such as plant layout. Learn what equipment layout is and how it affects the design and operation of plants and facilities. The checklist covers various aspects of equipment location, placement, dimensions, elevations,. Equipment Layout Diagram.

From www.pinterest.com

Updated Machine layout with more (yes, more!) tools and power Equipment Layout Diagram The designer can do things like relocating, rotating, and reorienting equipment to see which option makes the most sense for your facility. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. Learn what equipment layout is and how it affects the design and operation of plants and. Equipment Layout Diagram.

From wermac.org

Piping Coordination System Plot Plans and Equipment Arrangements Equipment Layout Diagram The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. Find out the. Equipment Layout Diagram.

From ntg.missouristate.edu

NavOneColumn Template Master Equipment Layout Diagram The checklist covers various aspects of equipment location, placement, dimensions, elevations, access, maintenance, hse, and drawing conventions. 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Learn what equipment layout is and how it affects the design and operation of plants and facilities. Learn about various aspects. Equipment Layout Diagram.

From stlengineering.net

Equipment Layout, Selection, and Specification STL Engineering, LLC Equipment Layout Diagram P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. Learn what equipment layout is and how it is developed in piping design. The designer can do things like relocating, rotating, and reorienting. Equipment Layout Diagram.

From dir.indiamart.com

Equipment Layouts Preparation in India Equipment Layout Diagram 57 rows a comprehensive checklist for piping engineers to ensure that equipment layout drawings meet all required standards and good engineering practices. Learn about various aspects of equipment and piping layout in process plants, such as towers, heat exchangers, compressors, pumps,. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and. Equipment Layout Diagram.

From www.researchgate.net

Schematic diagram of the equipment layout of the steel apparatus taken Equipment Layout Diagram Learn what equipment layout is and how it affects the design and operation of plants and facilities. Find out the factors to consider, such as plant layout. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. 57 rows a comprehensive checklist for piping engineers to ensure that. Equipment Layout Diagram.