Measurement Of Surface Roughness In Metrology . the first is determining the method to perform the measurement. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. Many instruments can perform surface.

from www.slideshare.net

the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. the first is determining the method to perform the measurement. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. Many instruments can perform surface. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure.

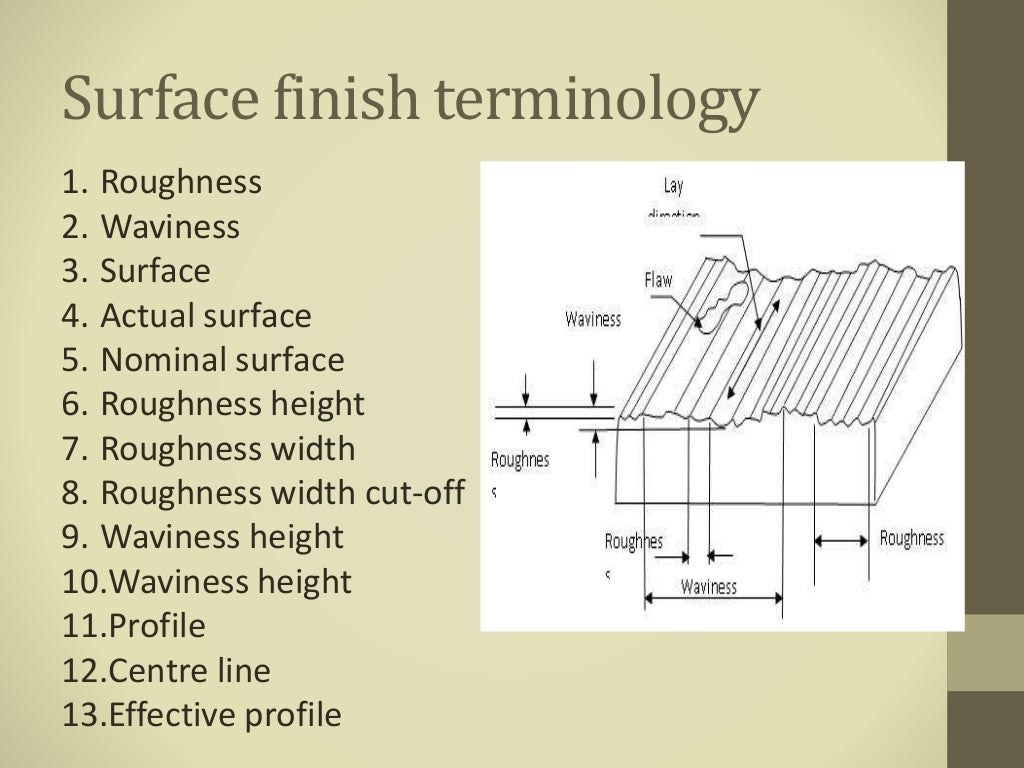

Surface finish measurement (mechanical measurement and metrology)

Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. Many instruments can perform surface. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the first is determining the method to perform the measurement. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product.

From get-it-made.co.uk

Surface Roughness Explained Ra Roughness Chart Measurement Of Surface Roughness In Metrology the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. Many instruments can perform surface. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the first is determining the method to perform the measurement.. Measurement Of Surface Roughness In Metrology.

From www.edmdept.com

3D Metrology & Surface Roughness Measurement EDMIS Measurement Of Surface Roughness In Metrology Many instruments can perform surface. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear,. Measurement Of Surface Roughness In Metrology.

From www.mdpi.com

Metrology Free FullText Application Scenarios of a Tactile Surface Measurement Of Surface Roughness In Metrology surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. Many instruments can perform surface. the first is determining the method to perform the measurement. . Measurement Of Surface Roughness In Metrology.

From www.mdpi.com

Metrology Free FullText Application Scenarios of a Tactile Surface Measurement Of Surface Roughness In Metrology surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. the first is determining the method to perform the measurement. surface roughness describes. Measurement Of Surface Roughness In Metrology.

From www.youtube.com

Metrology Lec08 Measurement of Surface Roughness YouTube Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the first is determining the method to perform the measurement. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. surface metrology methods are used to examine and measure the topography. Measurement Of Surface Roughness In Metrology.

From www.novacam.com

Measuring circumferential roughness in hardtoreach spaces Novacam Measurement Of Surface Roughness In Metrology Many instruments can perform surface. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the measurement of surface roughness is a key quality control process. Measurement Of Surface Roughness In Metrology.

From www.slideshare.net

Surface finish measurement (mechanical measurement and metrology) Measurement Of Surface Roughness In Metrology For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. Many instruments can perform surface. surface metrology methods are used to examine and measure the. Measurement Of Surface Roughness In Metrology.

From www.mdpi.com

Metrology Free FullText Application Scenarios of a Tactile Surface Measurement Of Surface Roughness In Metrology the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. the first is determining the method to perform the measurement. For instance, in mechanical components,. Measurement Of Surface Roughness In Metrology.

From www.youtube.com

Introduction to Surface Roughness / Metrology chap 3 measurement of Measurement Of Surface Roughness In Metrology Many instruments can perform surface. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the first is determining the method to perform the measurement. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product.. Measurement Of Surface Roughness In Metrology.

From www.scribd.com

(Metrology and Measurement Systems) Experimental Analysis by Measurement Of Surface Roughness In Metrology For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. Many instruments can perform surface. the first is determining the method to perform the measurement. . Measurement Of Surface Roughness In Metrology.

From www.engineeringchoice.com

What Is Surface Roughness? Unit, Chart, Measurement Measurement Of Surface Roughness In Metrology the first is determining the method to perform the measurement. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. surface metrology methods are used to examine and measure the topography. Measurement Of Surface Roughness In Metrology.

From www.slideshare.net

Surface finish measurement (mechanical measurement and metrology) Measurement Of Surface Roughness In Metrology the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. the first is determining the method to perform the measurement. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. Many instruments can perform surface.. Measurement Of Surface Roughness In Metrology.

From www.azom.com

How White Light Interferometry Can Measure Surface Roughness Measurement Of Surface Roughness In Metrology For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product.. Measurement Of Surface Roughness In Metrology.

From www.tribonet.org

Surface Roughness Measurement About Tribology Measurement Of Surface Roughness In Metrology For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the. Measurement Of Surface Roughness In Metrology.

From www.confovis.com

Roughness measurement optical 3D surface metrology Measurement Of Surface Roughness In Metrology Many instruments can perform surface. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. surface metrology methods are used to examine and measure the topography at. Measurement Of Surface Roughness In Metrology.

From www.researchgate.net

Surface roughness measurement procedures Download Scientific Diagram Measurement Of Surface Roughness In Metrology Many instruments can perform surface. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and. Measurement Of Surface Roughness In Metrology.

From www.alamy.com

Optical 3D surface measurement system dimensional metrology and Measurement Of Surface Roughness In Metrology the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. Many instruments can perform surface. the measurement of surface roughness is a key quality control process that. Measurement Of Surface Roughness In Metrology.

From www.edmdept.com

3D Metrology Surface Roughness Measurement & Tester Measurement Of Surface Roughness In Metrology the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. the first is determining the method to perform the measurement. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the measurement of surface roughness is a key quality control process. Measurement Of Surface Roughness In Metrology.

From www.researchgate.net

Types of surface roughness measurement Download Scientific Diagram Measurement Of Surface Roughness In Metrology surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. Many instruments can perform surface. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the first is determining the method to perform the measurement. . Measurement Of Surface Roughness In Metrology.

From michmet.com

Average Roughness basics Michigan Metrology Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in.. Measurement Of Surface Roughness In Metrology.

From www.mdpi.com

Metrology Free FullText Application Scenarios of a Tactile Surface Measurement Of Surface Roughness In Metrology Many instruments can perform surface. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. the measurement of surface roughness is a key quality control process that. Measurement Of Surface Roughness In Metrology.

From mavink.com

Surface Roughness Units Measurement Of Surface Roughness In Metrology Many instruments can perform surface. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. surface metrology methods are used to examine and measure the topography at. Measurement Of Surface Roughness In Metrology.

From www.metrology-services.com

Surface Roughness & Surface Finish Analysis Metrology Services from Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product.. Measurement Of Surface Roughness In Metrology.

From metrologicallyspeaking.com

Surface Roughness Measurement and Applications Everything About Metrology Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a. Measurement Of Surface Roughness In Metrology.

From www.youtube.com

METROLOGY 2 MEASUREMENT OF SURFACE ROUGHNESS PROPERTIES OF Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. Many instruments can perform surface. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and. Measurement Of Surface Roughness In Metrology.

From digitalmetrology.com

GE Roughness Specimen K2 Digital Metrology Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the first is determining the method to perform the measurement. the measurement of surface roughness is a key quality control process. Measurement Of Surface Roughness In Metrology.

From michmet.com

Nanometerscale roughness Michigan Metrology Measurement Of Surface Roughness In Metrology For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. surface metrology methods are used to examine and measure the topography at different length scales and spatial. Measurement Of Surface Roughness In Metrology.

From www.alamy.com

Optical 3D surface measurement system dimensional metrology and Measurement Of Surface Roughness In Metrology For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the first is determining the method to perform the measurement. surface metrology methods are used to examine and measure the topography. Measurement Of Surface Roughness In Metrology.

From www.researchgate.net

Setup for surface roughness measurement (Ra) Surface roughness was Measurement Of Surface Roughness In Metrology For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. the first is determining the method to perform the measurement. surface roughness describes the. Measurement Of Surface Roughness In Metrology.

From michmet.com

Traversing length, evaluation length and sampling length Michigan Measurement Of Surface Roughness In Metrology the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. the first is determining the method to perform the measurement. surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. For instance, in mechanical. Measurement Of Surface Roughness In Metrology.

From www.slideserve.com

PPT A look at different surface roughness measurement methods with Measurement Of Surface Roughness In Metrology Many instruments can perform surface. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. surface roughness describes the microstructures and irregularities found on a. Measurement Of Surface Roughness In Metrology.

From www.spiedigitallibrary.org

Line edge roughness measurement on vertical sidewall for reference Measurement Of Surface Roughness In Metrology surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. Many instruments can perform surface. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. surface roughness describes the microstructures and irregularities found on. Measurement Of Surface Roughness In Metrology.

From metrologicallyspeaking.com

Verisurf Software® CMM Surface Finish Measurement Everything About Measurement Of Surface Roughness In Metrology surface metrology methods are used to examine and measure the topography at different length scales and spatial frequencies of a surface. the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. the measurement of surface roughness is a key quality control process that can significantly impact the. Measurement Of Surface Roughness In Metrology.

From digitalmetrology.com

GE Roughness Specimen G1 Digital Metrology Measurement Of Surface Roughness In Metrology surface roughness describes the microstructures and irregularities found on a surface, which can include grooves,. the measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. Many instruments can perform surface. For instance, in mechanical components, a high level of surface roughness can lead to increased friction,. Measurement Of Surface Roughness In Metrology.

From www.youtube.com

Mitutoyo Metrology Class How to Measure Surface Roughness with the Measurement Of Surface Roughness In Metrology the surtronic ® duo ii surface roughness measurement tester is designed to measure surface roughness, and can be utilised in. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. Many instruments can perform surface. surface roughness describes the microstructures and irregularities found on a surface, which. Measurement Of Surface Roughness In Metrology.