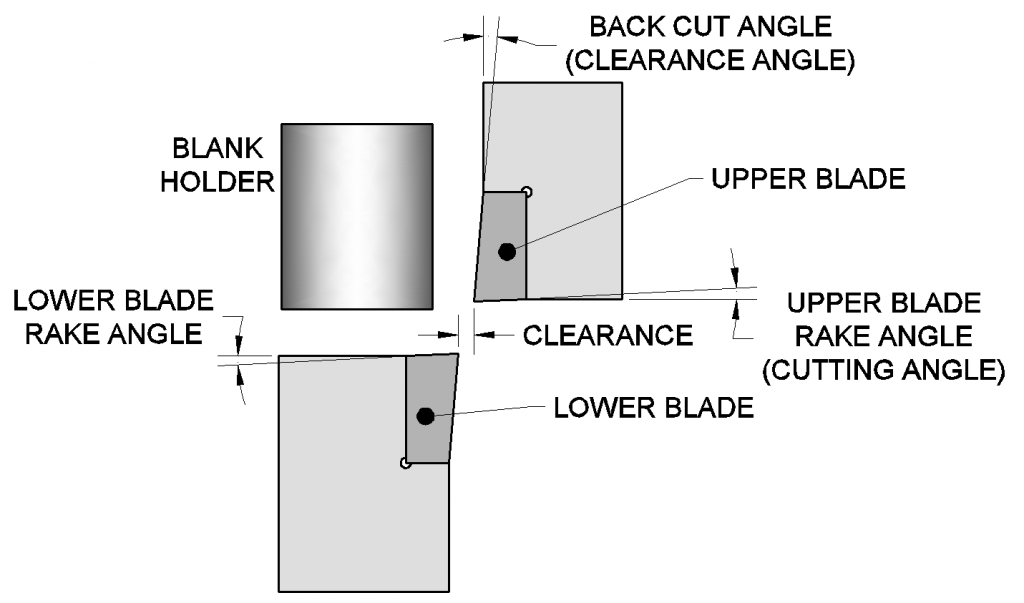

Shear Cut Edge . Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. shearing is a fabrication process that causes cold working right at the sheared edge. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. the cutting edge of the punch is dull or not hard enough. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. The shearing load is also higher for larger clearance. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. the edge has distortion and has burr. Sharpen or replace the punch.

from toolnotes.com

The shearing load is also higher for larger clearance. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. the edge has distortion and has burr. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. the cutting edge of the punch is dull or not hard enough. shearing is a fabrication process that causes cold working right at the sheared edge. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch.

Sheet Metal Shearing ToolNotes

Shear Cut Edge Sharpen or replace the punch. shearing is a fabrication process that causes cold working right at the sheared edge. The shearing load is also higher for larger clearance. Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. Sharpen or replace the punch. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. the cutting edge of the punch is dull or not hard enough. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. the edge has distortion and has burr.

From www.slideshare.net

Shearing metal Shear Cut Edge this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. Sharpen or replace the punch. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. shearing is a sheet metal cutting operation along a straight line between two. Shear Cut Edge.

From exotlklbh.blob.core.windows.net

The TransferredArc Cutting Process Is Used To Cut Materials That Are Shear Cut Edge shearing is a fabrication process that causes cold working right at the sheared edge. the cutting edge of the punch is dull or not hard enough. The shearing load is also higher for larger clearance. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet. Shear Cut Edge.

From www.converteraccessory.com

Slittng Assemblies by CAC Shear Cut Edge the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. Sharpen or replace the punch. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. Shearing parameters such as clearance, shear angle and rake angle also play a. Shear Cut Edge.

From www.waca.msf.org

Makasla Pinking Shears Scissors for Fabric, Craft Scissors Decorative Shear Cut Edge this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. The shearing load is also higher for larger clearance. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. the edge has distortion and has burr. optimizing the trim shear conditions. Shear Cut Edge.

From www.dienesusa.com

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality Shear Cut Edge the edge has distortion and has burr. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. this article delves into the shear cutting. Shear Cut Edge.

From www.researchgate.net

(PDF) Consideration of the reduced formability of a shear cut edge in Shear Cut Edge the edge has distortion and has burr. the cutting edge of the punch is dull or not hard enough. Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming. Shear Cut Edge.

From www.mdpi.com

JMMP Free FullText Determination of the Shear Angle in the Shear Cut Edge shearing is a fabrication process that causes cold working right at the sheared edge. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. Sharpen or replace the punch. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a. Shear Cut Edge.

From mellysews.com

How To Use Pinking Shears To Cut Fabric and Finish Seams Melly Sews Shear Cut Edge Sharpen or replace the punch. the edge has distortion and has burr. The shearing load is also higher for larger clearance. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. . Shear Cut Edge.

From ahssinsights.org

Cutting, Blanking, Shearing & Trimming AHSS Guidelines Shear Cut Edge shearing is a fabrication process that causes cold working right at the sheared edge. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. the cutting edge of the punch is dull or not hard enough. A variety of cutting processes that utilize shearing forces exist. Shear Cut Edge.

From www.youtube.com

VIPER Point Cutting Shears Hair Cutting Scissors by EXCELLENT EDGES Shear Cut Edge shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. the edge has distortion and has burr. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. the cutting edge of the punch is. Shear Cut Edge.

From fsmdirect.com

Shearing angles helps improve blanks from coil cutting Shear Cut Edge Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. Sharpen or replace the. Shear Cut Edge.

From www.automationdirect.com

Cable Shears heattreated shear cutting edges (PN CCP6D Shear Cut Edge the edge has distortion and has burr. Sharpen or replace the punch. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. The shearing load is also higher for larger clearance. the cutting edge of the punch is dull or not hard enough. shearing is a sheet metal cutting operation. Shear Cut Edge.

From www.tfico.com

Shear Blades TFICO Shear Cut Edge the edge has distortion and has burr. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. shearing is a fabrication process that causes cold working right at the sheared edge.. Shear Cut Edge.

From www.automationdirect.com

Cable Shears heattreated shear cutting edges (PN CCP6D Shear Cut Edge the cutting edge of the punch is dull or not hard enough. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. The shearing load is also higher for larger clearance. the edge has distortion and has burr. Sharpen or replace the punch. this article. Shear Cut Edge.

From www.researchgate.net

Measurement of microhardness distribution of shear cut edge. (Color Shear Cut Edge A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. the cutting edge of the punch is dull or not hard enough. shearing is a sheet. Shear Cut Edge.

From www.slideshare.net

Shearing Shear Cut Edge the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. shearing is a fabrication process that causes cold working right at the sheared. Shear Cut Edge.

From www.converteraccessory.com

Slitting Assemblies by CAC Shear Cut Edge the cutting edge of the punch is dull or not hard enough. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. the edge has distortion and has burr. the objective of this work is to provide an overview of the factors that influence the quality of. Shear Cut Edge.

From www.researchgate.net

Production process of a shear cut EFTT specimen for a closed (a)) and Shear Cut Edge this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. the edge has distortion and has burr. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. shearing is a fabrication process that causes cold working right. Shear Cut Edge.

From toolnotes.com

Sheet Metal Shearing ToolNotes Shear Cut Edge the cutting edge of the punch is dull or not hard enough. The shearing load is also higher for larger clearance. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power. Shear Cut Edge.

From www.youtube.com

Table top shear cut edge burr removal Machine. From valgro YouTube Shear Cut Edge Sharpen or replace the punch. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. the edge has distortion and has burr. shearing is a fabrication. Shear Cut Edge.

From toolnotes.com

Sheet Metal Shearing ToolNotes Shear Cut Edge shearing is a fabrication process that causes cold working right at the sheared edge. Sharpen or replace the punch. Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. the cutting edge of the punch is dull or not hard enough. optimizing the trim shear conditions or polishing. Shear Cut Edge.

From www.hairfinder.com

The difference between convex edge shears and beveled edge shears Shear Cut Edge Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. The shearing load is. Shear Cut Edge.

From www.thefabricator.com

Determining sharpness of sheet metal edges Shear Cut Edge Sharpen or replace the punch. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. shearing is a fabrication process that causes cold working right at the sheared edge. the cutting. Shear Cut Edge.

From dxoansrdi.blob.core.windows.net

Shear Edge Compression Molding at Betty Briggs blog Shear Cut Edge this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of. Shear Cut Edge.

From www.researchgate.net

Cutting edge geometry of solid wood in the shear cutting process Shear Cut Edge the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. Sharpen or replace the punch. this article delves into the shear cutting process, an essential technique in metalworking. Shear Cut Edge.

From washiscissor.com

Shear Knowledge Shear Quality, Steel Types, Blade Types and more.. Shear Cut Edge the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. The shearing load is also higher for larger clearance. optimizing the trim shear conditions or. Shear Cut Edge.

From www.scosarg.com

OMAS K419B Shear Cut Edge Planing Block D150 d50 Scott+Sargeant UK Shear Cut Edge Sharpen or replace the punch. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. the objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. the edge has distortion and has burr. optimizing the trim shear conditions or polishing. Shear Cut Edge.

From ahssinsights.org

Cutting, Blanking, Shearing & Trimming AHSS Guidelines Shear Cut Edge optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. shearing is a fabrication process that causes cold working right at the sheared edge. . Shear Cut Edge.

From www.wonkeedonkeetools.co.uk

How to sharpen edging shears? Wonkee Donkee Tools Shear Cut Edge this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. shearing is a fabrication process that causes cold working right at the sheared edge. Shearing parameters such as clearance, shear. Shear Cut Edge.

From www.youtube.com

SHEARING PROCESS SHEARING MECHANISM SHEAR FORCE SHEAR STRENGTH Shear Cut Edge The shearing load is also higher for larger clearance. Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. shearing is a fabrication process that causes cold working right at the sheared edge. the cutting edge of the punch is dull or not hard enough. Sharpen or replace the. Shear Cut Edge.

From www.automationdirect.com

Cable Shears heattreated shear cutting edges (PN CCP6D Shear Cut Edge this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. The shearing load is also higher for larger clearance. Sharpen or replace the punch. Shearing parameters such as clearance,. Shear Cut Edge.

From www.alibaba.com

Japanese Style Heavy Duty Heat Treatment Hardened Shear Cut Edge Hook Shear Cut Edge Shearing parameters such as clearance, shear angle and rake angle also play a large part in improving edge stretch. The shearing load is also higher for larger clearance. optimizing the trim shear conditions or polishing a flat trimmed edge approaches what can be achieved with laser trimming and water jet cutting. the objective of this work is to. Shear Cut Edge.

From www.cuttingedgeprdx.com

Cutting Edge Products Shear Cut Edge A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet. Sharpen or replace the punch. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. Shearing parameters such as clearance, shear angle and rake angle also play a. Shear Cut Edge.

From toolnotes.com

Sheet Metal Shearing ToolNotes Shear Cut Edge Sharpen or replace the punch. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. the cutting edge of the punch is dull or not hard enough. shearing is a fabrication process that causes cold working right at the sheared edge. The shearing load is also. Shear Cut Edge.

From www.dienesusa.com

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality Shear Cut Edge the edge has distortion and has burr. Sharpen or replace the punch. this article delves into the shear cutting process, an essential technique in metalworking that involves cutting. shearing is a sheet metal cutting operation along a straight line between two cutting edges by means of a power shear. Shearing parameters such as clearance, shear angle and. Shear Cut Edge.