What Is Brazed . Allow it time to cool down before moving on anything else (or risk damaging it). Ensure good fit and proper clearances. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. As it stands, they can withstand demanding service conditions. The brazed joints can be destroyed under high service temperatures. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. So when you're brazing, maintain. The joint color is usually different from the base metal, creating an aesthetic disadvantage.

from shahab-co.com

Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. Ensure good fit and proper clearances. As it stands, they can withstand demanding service conditions. The brazed joints can be destroyed under high service temperatures. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. The joint color is usually different from the base metal, creating an aesthetic disadvantage. Allow it time to cool down before moving on anything else (or risk damaging it). So when you're brazing, maintain.

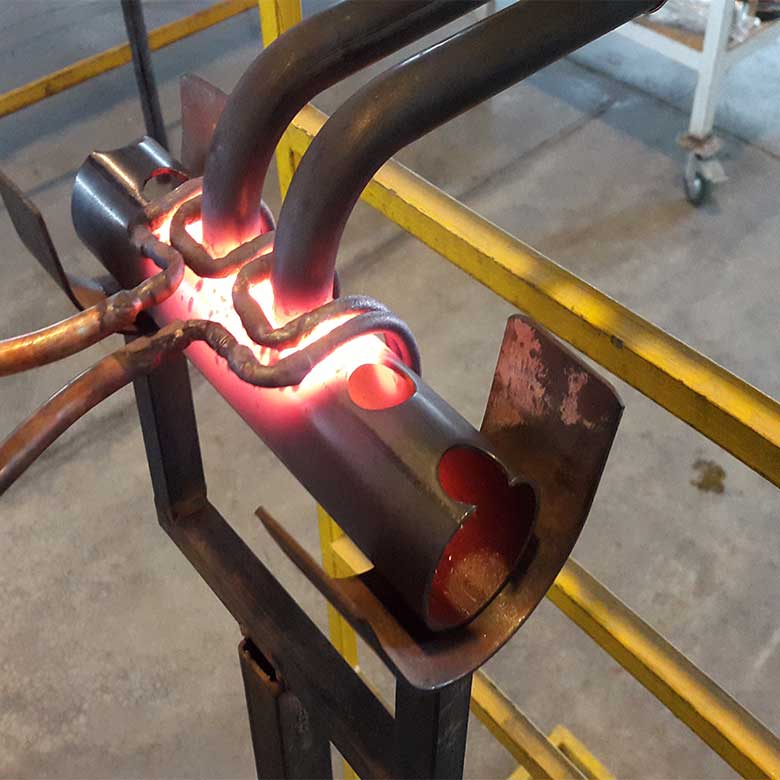

What is Induction brazing Brazing uses heat and a filler metal (alloy

What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. Ensure good fit and proper clearances. So when you're brazing, maintain. The brazed joints can be destroyed under high service temperatures. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. The joint color is usually different from the base metal, creating an aesthetic disadvantage. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. As it stands, they can withstand demanding service conditions. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. Allow it time to cool down before moving on anything else (or risk damaging it).

From www.cpvmfg.com

Joining Metals Your Frequently Asked Questions About Brazing, Answered What Is Brazed The brazed joints can be destroyed under high service temperatures. Ensure good fit and proper clearances. So when you're brazing, maintain. The joint color is usually different from the base metal, creating an aesthetic disadvantage. Allow it time to cool down before moving on anything else (or risk damaging it). To achieve a sound brazed joint, the filler and parent. What Is Brazed.

From www.welderscave.com

What is the Difference between Welding And Brazing Welders Cave What Is Brazed The brazed joints can be destroyed under high service temperatures. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. Allow it time to cool down before moving on anything else (or risk damaging it). As it stands, they can withstand demanding service conditions. To achieve a sound brazed joint, the filler and parent. What Is Brazed.

From exohjqeiv.blob.core.windows.net

What Is The Definition Of A Brazed Joint at James Zimmerman blog What Is Brazed To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. The joint color is usually different from the base metal, creating an aesthetic disadvantage. As it stands, they can withstand demanding service conditions. Brazing uses capillary action to distribute molten filler. What Is Brazed.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. Allow it time to cool down before moving on anything else (or risk damaging it). The brazed joints can be destroyed under high service temperatures. To achieve a sound brazed. What Is Brazed.

From hxebxeedi.blob.core.windows.net

What Is Brazing In Metal Work at Blair Glanz blog What Is Brazed So when you're brazing, maintain. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the. What Is Brazed.

From workshopinsider.com

Welding VS Brazing What Is The Difference? Insider What Is Brazed Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. So when you're brazing, maintain. As it stands, they can withstand demanding service conditions. The brazed joints can be destroyed under high service temperatures. The joint color is usually different from the base metal, creating an aesthetic disadvantage. Allow it time to cool down. What Is Brazed.

From fyorwcbmu.blob.core.windows.net

What Is A Brazed Heat Exchanger at Dwight Houghton blog What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. So when you're brazing, maintain. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. The brazed joints can be destroyed under high service temperatures. To achieve. What Is Brazed.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy What Is Brazed To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. As it stands, they can withstand demanding service conditions. So when you're brazing, maintain. The joint color is usually different from the base metal, creating an aesthetic disadvantage. Ensure good fit. What Is Brazed.

From www.youtube.com

Fundamentals of Brazing 5 Brazing the Assembly YouTube What Is Brazed The brazed joints can be destroyed under high service temperatures. So when you're brazing, maintain. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. Ensure good fit and proper clearances. Allow it time to cool down before moving on anything else (or risk damaging it). As it stands, they can withstand demanding service. What Is Brazed.

From www.twi-global.com

What are the different methods of brazing? TWI What Is Brazed So when you're brazing, maintain. Allow it time to cool down before moving on anything else (or risk damaging it). To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. To achieve a sound brazed joint, the filler, and parent materials. What Is Brazed.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages What Is Brazed Ensure good fit and proper clearances. So when you're brazing, maintain. The joint color is usually different from the base metal, creating an aesthetic disadvantage. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. The brazed joints can be destroyed under high service temperatures. To achieve a sound brazed joint, the filler and. What Is Brazed.

From blog.thepipingmart.com

What is Brazing Fluxes? Uses and Working What Is Brazed As it stands, they can withstand demanding service conditions. Ensure good fit and proper clearances. So when you're brazing, maintain. The joint color is usually different from the base metal, creating an aesthetic disadvantage. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. To achieve a sound brazed joint, the filler, and parent. What Is Brazed.

From www.youtube.com

Brazing Process Animation YouTube What Is Brazed To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Allow it. What Is Brazed.

From www.youtube.com

SWEP What is a Brazed Plate Heat Exchanger (BPHE) YouTube What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. As it stands, they can withstand demanding service conditions. So when you're brazing, maintain. The brazed joints can be destroyed under high service temperatures. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. Ensure good fit and proper clearances.. What Is Brazed.

From www.differencebetween.com

Difference Between Soldering and Brazing Soldering vs Brazing What Is Brazed To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible,. What Is Brazed.

From www.youtube.com

Difference between brazing and braze welding II Brazing & Braze Welding What Is Brazed The brazed joints can be destroyed under high service temperatures. Ensure good fit and proper clearances. So when you're brazing, maintain. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap. What Is Brazed.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding What Is Brazed The brazed joints can be destroyed under high service temperatures. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. The joint color is usually different from the base metal, creating an aesthetic disadvantage. Ensure good fit and proper clearances. Allow. What Is Brazed.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications What Is Brazed To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. As it. What Is Brazed.

From www.diydoctor.org.uk

How to Braze Metal in 6 Easy Steps DIY Doctor What Is Brazed The brazed joints can be destroyed under high service temperatures. So when you're brazing, maintain. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Allow it time to cool down before moving on anything else (or risk damaging it). The. What Is Brazed.

From blog.thepipingmart.com

Exothermic Welding vs Brazing What's the Difference What Is Brazed Allow it time to cool down before moving on anything else (or risk damaging it). Ensure good fit and proper clearances. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. As it stands, they can withstand demanding service conditions. The joint color is usually different from the base metal, creating an aesthetic disadvantage.. What Is Brazed.

From vacaero.com

Braze Joint Design Considerations What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Allow it time to cool down before moving on anything else (or risk damaging it). So when. What Is Brazed.

From exovxubli.blob.core.windows.net

Brazing For Beginners at Brandon Murillo blog What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. As it stands, they can withstand demanding service conditions. So when you're brazing, maintain. Ensure good fit and proper clearances. To achieve a sound brazed joint, the filler and parent. What Is Brazed.

From kaybrazing.com

Dimension BrazeFillets on Drawings? Kay & Associates Brazing Consultants What Is Brazed Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. As it stands, they can withstand demanding service conditions. Allow it time to cool down before moving on anything else (or risk damaging it). Ensure good fit and proper clearances. The brazed joints can be destroyed under high service temperatures. So when you're brazing,. What Is Brazed.

From blog.thepipingmart.com

Brazing Aluminium vs Welding What's the Difference What Is Brazed So when you're brazing, maintain. Ensure good fit and proper clearances. Allow it time to cool down before moving on anything else (or risk damaging it). To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. The brazed joints can be. What Is Brazed.

From www.pipsisland.com

10 Simple Steps to Braze Copper Pipe (Extended Tips) What Is Brazed So when you're brazing, maintain. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Allow it time to cool down before moving on anything else (or risk damaging it). Ensure good fit and proper clearances. Brazing uses capillary action to. What Is Brazed.

From blog.thepipingmart.com

How to Braze Mild Steel A Complete Guide What Is Brazed Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. The joint color is usually different from the base metal, creating an aesthetic disadvantage. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. As. What Is Brazed.

From exozgyfnw.blob.core.windows.net

What Is Brazing Welding Rod Used For at Alicia Porter blog What Is Brazed To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. As it stands, they can withstand demanding service conditions. Allow it time to cool down before moving on anything else (or risk damaging it). Ensure good fit and proper clearances. So. What Is Brazed.

From hxejftphm.blob.core.windows.net

What Is Brazing Metal Mean at Elizabeth Marks blog What Is Brazed As it stands, they can withstand demanding service conditions. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Allow it time to cool down before moving on anything else (or risk damaging it). So when you're brazing, maintain. Brazing uses. What Is Brazed.

From hxeqpigfx.blob.core.windows.net

What Tool Is Used For Brazing at Hoy blog What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. So when you're brazing, maintain. Allow it time to cool down before moving on anything else (or risk damaging it). To achieve a sound brazed joint, the filler and parent. What Is Brazed.

From www.wisegeek.com

What is Torch Brazing? (with pictures) What Is Brazed Allow it time to cool down before moving on anything else (or risk damaging it). Ensure good fit and proper clearances. The brazed joints can be destroyed under high service temperatures. So when you're brazing, maintain. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into. What Is Brazed.

From www.harrisproductsgroup.com.au

How Brazing Works Capillary Action Harris Products Group What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Ensure good fit and proper clearances. Brazing uses capillary action to distribute molten filler metal between the. What Is Brazed.

From blog.thepipingmart.com

Brazing Copper vs Soldering Copper What's the Difference What Is Brazed To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Allow it time to cool down before moving on anything else (or risk damaging it). To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and. What Is Brazed.

From www.scribd.com

Brazing Brazing is a metaljoining process in which two or more metal What Is Brazed So when you're brazing, maintain. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. As it stands, they can withstand demanding service conditions. To achieve a sound brazed joint, the filler, and parent materials should be metallurgically compatible, and the. What Is Brazed.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy What Is Brazed As it stands, they can withstand demanding service conditions. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. Brazing uses capillary action to distribute molten filler metal between the surfaces of the base metals. Allow it time to cool down. What Is Brazed.

From blog.thepipingmart.com

What Is Metal Brazing And How Does It Work? What Is Brazed The joint color is usually different from the base metal, creating an aesthetic disadvantage. So when you're brazing, maintain. To achieve a sound brazed joint, the filler and parent materials should be metallurgically compatible, and the joint design should incorporate a gap into which the molten braze filler. To achieve a sound brazed joint, the filler, and parent materials should. What Is Brazed.